In the realm of machinery, ensuring optimal performance is paramount. This segment delves into the essential techniques and strategies for keeping your valuable equipment in peak condition. Understanding the intricacies of functionality and upkeep can significantly enhance longevity and reliability.

The following sections provide detailed insights into troubleshooting common issues, conducting routine checks, and implementing effective solutions. With a focus on practical advice and step-by-step processes, users will gain a clearer understanding of how to address various challenges that may arise over time.

Moreover, this guide emphasizes the importance of safety and precautionary measures during maintenance tasks. Proper handling and knowledge are crucial for both efficiency and user well-being. By adhering to best practices outlined herein, operators can ensure that their machinery remains a dependable asset for years to come.

Overview of Case 446 Models

This section provides a comprehensive look at the various models in a well-known line of garden tractors. These machines are celebrated for their durability and versatility, making them a favorite among enthusiasts and professionals alike. Each model has distinct features and specifications that cater to different needs, ensuring optimal performance across a range of tasks.

Key Features and Specifications

The tractors in this series are equipped with powerful engines and robust build quality, which enhance their reliability. With options for different attachments, users can customize their machines for mowing, tilling, or snow removal. The ergonomic design and user-friendly controls also contribute to a smooth operating experience.

Comparative Insights

Common Issues with Case 446

This section addresses frequent challenges encountered with this particular equipment model. Understanding these common problems can aid in maintaining optimal performance and prolonging the lifespan of the machine. Below are several typical issues along with their possible causes and solutions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Starting difficulties | Weak battery, faulty starter, fuel supply issues | Check battery charge, inspect starter connections, ensure fuel is reaching the engine |

| Overheating | Low coolant levels, blocked radiator, faulty thermostat | Check and refill coolant, clean radiator, test and replace thermostat |

| Poor performance | Clogged air filter, worn spark plugs, incorrect fuel mixture | Replace air filter, inspect and replace spark plugs, adjust fuel settings |

| Hydraulic issues | Low fluid levels, leaks in hoses, faulty pump | Check fluid levels, inspect hoses for leaks, test and replace pump if necessary |

Tools Required for Repairs

Undertaking maintenance tasks necessitates a selection of essential instruments to ensure efficient and effective work. Having the right equipment at hand not only facilitates the process but also enhances safety and accuracy during each task.

Fundamental tools typically include a variety of wrenches and sockets for fastening and loosening components, as well as screwdrivers of different sizes and types for handling screws. Additionally, pliers and wire cutters are invaluable for gripping and cutting materials when needed.

Measuring devices, such as calipers and tape measures, play a crucial role in achieving precise dimensions, while a level ensures that everything is aligned correctly. A sturdy workbench and proper lighting are also vital to create an organized and well-lit workspace, enhancing overall efficiency.

For more specialized tasks, consider adding tools like torque wrenches and diagnostic equipment. These can help in achieving specific torque settings and troubleshooting issues, respectively. By assembling a comprehensive toolkit, you set the stage for successful maintenance endeavors.

Step-by-Step Repair Procedures

This section provides a comprehensive approach to tackling mechanical issues effectively. By following these organized steps, you can ensure that the process is systematic and efficient, minimizing the risk of errors and enhancing the likelihood of a successful outcome.

Preparation and Safety Measures

Before initiating any work, it is crucial to gather all necessary tools and parts. Ensure that your workspace is clean and well-lit. Familiarize yourself with safety protocols, including the use of personal protective equipment. Always disconnect power sources and follow proper procedures to avoid accidents.

Detailed Breakdown of Each Step

Start by diagnosing the issue thoroughly. Document any symptoms observed. Proceed with disassembly by carefully removing components in a logical order, labeling each part as needed. Once access is gained, inspect each element for damage or wear. After completing repairs or replacements, reassemble in reverse order, ensuring all connections are secure. Finally, conduct a test run to verify that everything functions as intended.

Maintenance Tips for Longevity

Ensuring the prolonged functionality and efficiency of your machinery requires a proactive approach to upkeep. Regular attention to key components not only enhances performance but also minimizes the risk of unexpected failures. Below are essential practices that can significantly extend the lifespan of your equipment.

Routine Inspections

Conducting systematic evaluations of your equipment allows you to identify wear and tear early. Look for signs of damage, unusual noises, or leaks. Keeping a checklist for these inspections can help maintain consistency.

Lubrication and Cleaning

Regularly lubricating moving parts reduces friction and prevents overheating. Additionally, maintaining a clean environment around the machinery helps avoid debris accumulation, which can lead to operational issues.

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Inspection of components | Monthly | Early detection of issues |

| Lubrication | Every 500 hours | Reduces wear and tear |

| Cleaning | Weekly | Prevents buildup and damage |

| Fluid level checks | Bi-weekly | Ensures optimal operation |

Parts Replacement and Compatibility

Ensuring the proper functionality of machinery often requires timely substitution of components. Understanding the nuances of compatibility between parts is crucial for optimal performance and longevity.

When considering the exchange of elements, several factors come into play:

- Specifications: Always refer to the original specifications to identify suitable alternatives.

- Manufacturer Guidelines: Following recommendations from the manufacturer can prevent compatibility issues.

- Quality Standards: Selecting high-quality replacements can enhance durability and efficiency.

To aid in the selection process, consider the following steps:

- Review the existing parts for any identifying numbers or codes.

- Consult compatibility charts or databases provided by manufacturers.

- Seek feedback from professionals or experienced users regarding recommended substitutes.

Maintaining a comprehensive inventory of compatible components can streamline future repairs and replacements. Being proactive in sourcing quality parts not only ensures immediate functionality but also contributes to the overall health of the machinery.

Safety Precautions During Repairs

Ensuring a safe environment while performing maintenance tasks is crucial to prevent accidents and injuries. By adhering to established safety guidelines, individuals can work more effectively and with greater confidence. This section outlines essential practices to follow during servicing operations.

- Personal Protective Equipment (PPE): Always wear appropriate gear such as gloves, goggles, and helmets to protect against hazards.

- Work Area Organization: Keep your workspace tidy. Remove unnecessary tools and materials to minimize trip hazards.

- Electrical Safety: Disconnect power sources before starting any electrical work to avoid shocks or short circuits.

- Proper Tool Use: Use tools that are suited for the task at hand and ensure they are in good condition to prevent malfunctions.

Following these guidelines not only safeguards your well-being but also enhances the efficiency of the task at hand. Regularly review safety protocols to stay updated on best practices.

- Always inform others in the vicinity about your activities.

- Stay focused and avoid distractions while working.

- In case of an emergency, know the location of first aid kits and emergency exits.

By prioritizing safety, you contribute to a secure environment, making the maintenance process smoother and more productive.

Testing and Diagnostics Methods

This section explores various approaches to evaluating and troubleshooting machinery. By systematically examining components, operators can identify issues that may hinder performance. Accurate diagnostics are crucial for maintaining efficiency and prolonging the lifespan of equipment.

Visual Inspection Techniques

One of the simplest yet most effective methods involves a thorough visual examination of the equipment. Look for signs of wear, leaks, or physical damage. Regular inspections can reveal underlying problems before they escalate, allowing for timely intervention.

Operational Testing Procedures

Conducting operational tests is essential for assessing functionality. Running the equipment under various conditions helps to pinpoint discrepancies in performance. Monitoring parameters such as noise levels, vibration, and temperature can provide valuable insights into potential malfunctions.

Upgrading Components for Better Performance

Enhancing the functionality of machinery can significantly impact its efficiency and longevity. By focusing on key elements, operators can achieve improved power output, reduced downtime, and better overall performance. Strategic upgrades not only optimize existing capabilities but also contribute to more sustainable operation in the long run.

Key Components to Consider

- Engine Enhancements: Upgrading to a more efficient engine can lead to better fuel economy and increased power. Consider options like turbocharging or tuning for higher performance.

- Hydraulic Systems: Improved hydraulic components can enhance responsiveness and lifting capacity, allowing for smoother operation.

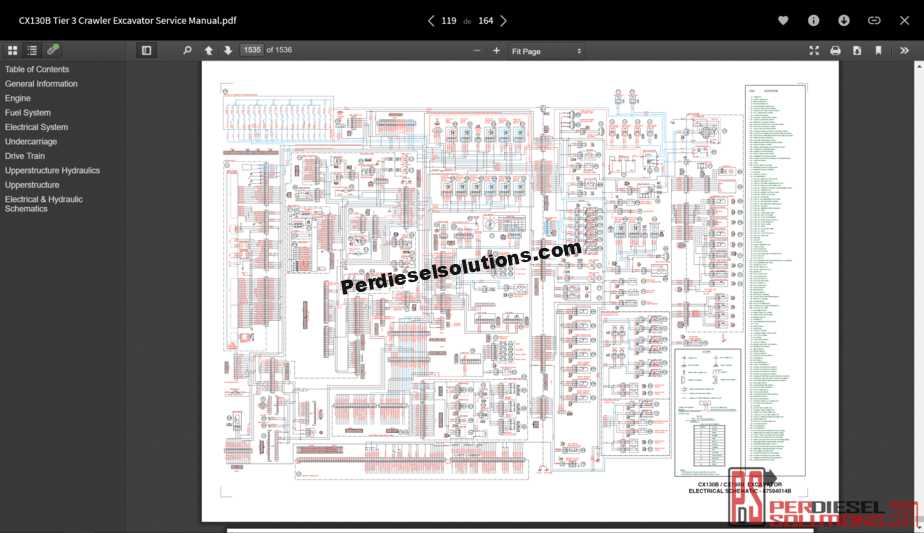

- Electrical Systems: Modernizing electrical components, such as the battery and alternator, can improve reliability and reduce maintenance costs.

- Tracks and Tires: Opting for higher-quality tracks or tires can enhance traction and stability, particularly in challenging terrains.

Benefits of Upgrading

- Increased Efficiency: Upgraded components typically function better, leading to less energy waste.

- Improved Safety: Modern components often come with advanced safety features, reducing the risk of accidents.

- Lower Operating Costs: Enhanced parts often lead to reduced wear and tear, minimizing long-term expenses.

- Enhanced Resale Value: Machinery with upgraded components can command higher prices in the market.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting of heavy machinery. Here, users can find valuable insights and solutions to frequently encountered challenges, enhancing their understanding and operational efficiency.

| Question | Answer |

|---|---|

| What should I do if the engine won’t start? | Check the battery connections, fuel levels, and ignition system. Ensure that all components are functioning properly before attempting to start the engine again. |

| How often should I perform maintenance? | Regular upkeep is recommended every 100 hours of operation or at least once a month, whichever comes first, to ensure optimal performance. |

| What are the signs of a hydraulic leak? | Look for fluid puddles beneath the machinery, decreased performance, or unusual noises. Prompt attention to these signs can prevent further damage. |

| Where can I find replacement parts? | Replacement components can be obtained from authorized dealers, online marketplaces, or specialized suppliers for heavy equipment. |

| How do I troubleshoot electrical issues? | Begin by checking the fuses, wiring connections, and battery health. Use a multimeter to diagnose specific electrical problems more accurately. |

Resources for Further Learning

To enhance your knowledge and skills in maintenance and troubleshooting, it is beneficial to explore a variety of educational materials and platforms. These resources can provide valuable insights and practical information to support your journey.

- Online Courses: Websites like Coursera and Udemy offer specialized courses on machinery upkeep and diagnostics.

- Books: Consider reading comprehensive guides and textbooks focused on mechanical systems and engineering principles.

- Forums and Communities: Engaging with online forums such as Reddit and dedicated machinery groups can help you connect with experienced individuals who share their expertise.

- YouTube Channels: Many content creators provide step-by-step videos that illustrate techniques and best practices in maintenance.

- Manufacturer Resources: Official websites often feature helpful documentation, FAQs, and customer support that can aid in resolving specific issues.

By utilizing these resources, you can deepen your understanding and improve your capabilities in the field of equipment maintenance and repair.