Maintaining a powerful cutting tool is essential for ensuring its longevity and optimal performance. Understanding the intricacies of these machines allows users to tackle common issues, enhance efficiency, and prolong their lifespan. This section provides a thorough overview of necessary procedures and troubleshooting techniques to keep your equipment running smoothly.

Key components of any cutting device require regular attention to prevent wear and tear. From the engine to the cutting chain, every part plays a crucial role in overall functionality. Familiarity with these elements empowers users to identify problems early and take corrective measures effectively.

In this guide, we will delve into practical tips and step-by-step instructions that facilitate the upkeep of your tool. Whether you’re a seasoned professional or a casual user, having access to this information will help you maintain your device in peak condition, ensuring that it meets your cutting needs whenever called upon.

Overview of Stihl MS 211

This section provides a comprehensive understanding of a popular model in the power tool lineup designed for cutting and trimming tasks. It combines user-friendly features with robust performance, making it an ideal choice for both professionals and enthusiasts alike.

Key Features

- Lightweight design for easy handling

- Powerful engine that balances efficiency and performance

- Advanced anti-vibration system for improved comfort

- Tool-less chain tensioning for quick adjustments

- Durable construction to withstand various working conditions

Applications

- Tree trimming and pruning

- Firewood cutting

- General landscaping tasks

- Maintenance of wooded areas

- DIY projects requiring precise cuts

This model stands out due to its combination of efficiency and ease of use, making it a favored option among those who need reliable cutting tools for various applications.

Common Issues with Stihl Chainsaws

Chainsaws are essential tools for many outdoor tasks, but they can encounter a range of problems that affect their performance. Understanding these common challenges can help users maintain their equipment and ensure efficient operation.

One frequent issue is starting difficulty, often caused by fuel-related problems or ignition system failures. Users may find that their equipment won’t start or runs inconsistently, which can be frustrating during critical jobs.

Another common concern is chain tension. An improperly adjusted chain can lead to decreased cutting efficiency and potential safety hazards. Regular checks and adjustments are vital to maintain optimal performance.

Additionally, overheating can occur due to prolonged use without adequate breaks or insufficient lubrication. This can lead to severe damage if not addressed promptly. Proper maintenance routines are essential to prevent such occurrences.

Lastly, users may experience chain dullness, which reduces cutting speed and increases effort. Keeping a sharp chain is crucial for effective operation and safety during use.

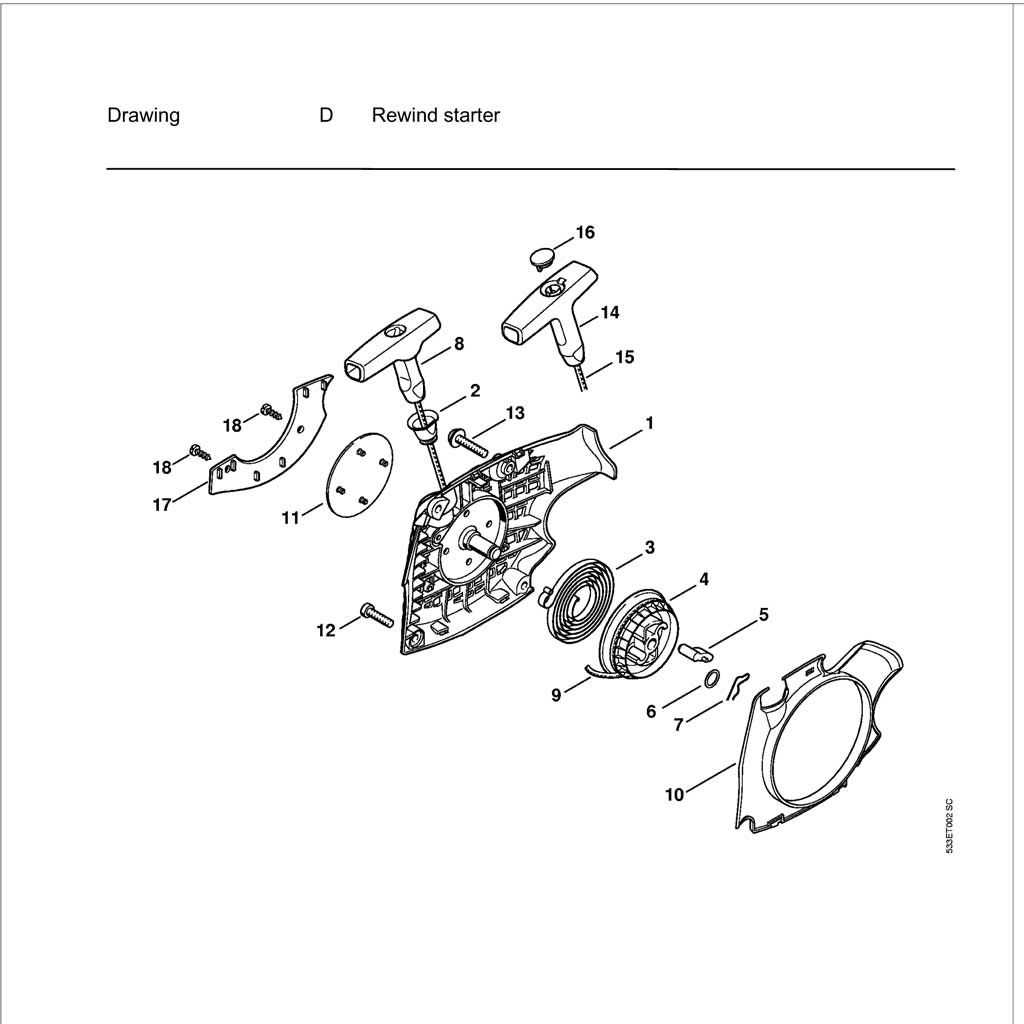

Essential Tools for Repair

When it comes to maintaining and fixing equipment, having the right instruments on hand is crucial. These essential implements not only streamline the process but also ensure that each task is completed with precision. Understanding which tools are necessary can make a significant difference in the effectiveness of your work.

Basic Hand Tools

Every toolkit should start with basic hand instruments. A good set typically includes screwdrivers, wrenches, and pliers. These items are fundamental for loosening, tightening, and manipulating various components. Additionally, having a torque wrench can ensure that fasteners are tightened to the correct specifications, preventing damage during reassembly.

Specialized Equipment

For more complex tasks, specialized tools may be required. Items like compression testers and spark plug wrenches are invaluable for diagnosing engine performance issues. A chain tool is also essential for maintaining cutting systems, allowing for safe and efficient adjustments. Investing in these specialized tools will enhance your ability to troubleshoot and maintain equipment effectively.

Step-by-Step Maintenance Guide

Regular upkeep is essential for optimal performance and longevity of your chainsaw. This guide provides a comprehensive approach to maintaining your equipment, ensuring it runs efficiently and safely. By following these straightforward steps, you can keep your tool in top condition, minimizing the risk of issues and enhancing its functionality.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean Air Filter | After every 5 hours of use | Remove and clean the filter to ensure proper airflow and prevent engine strain. |

| Inspect Spark Plug | Every 10 hours | Check for wear and replace if necessary to ensure reliable ignition. |

| Sharpen Chainsaw Chain | As needed | Regularly check the chain for sharpness; sharpen when cuts become less efficient. |

| Check Fuel Mixture | Every use | Ensure the correct fuel mixture is used to prevent engine damage. |

| Examine Bar and Chain | After every use | Inspect for wear, damage, or debris; clean and lubricate as needed. |

By adhering to this maintenance schedule, you can enhance the reliability and performance of your equipment, ensuring it serves you well for years to come. Regular checks and prompt actions can save time and money in the long run.

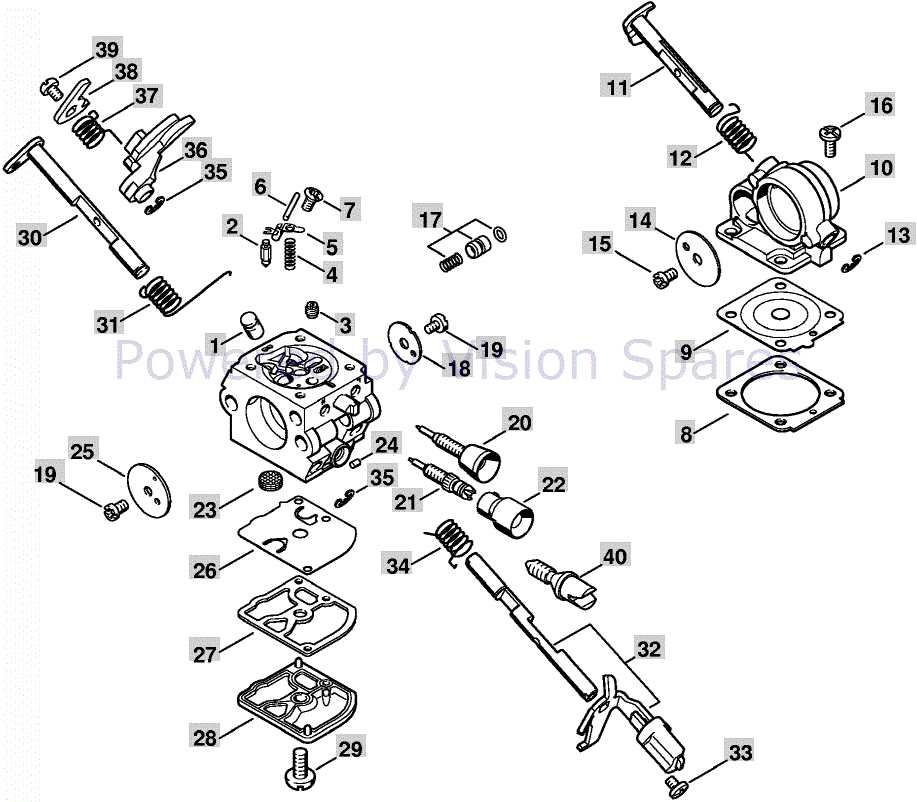

Understanding the Engine Components

The internal workings of a small engine are essential for its operation and performance. Comprehending each part and its role can enhance troubleshooting and maintenance, ensuring longevity and efficiency. This section delves into the primary elements that constitute the engine, shedding light on their functions and significance.

Key Components Overview

Every engine is made up of several critical parts that work in unison. Each component plays a unique role in the combustion process and overall functionality. The following table outlines these essential elements along with their primary functions:

| Component | Function |

|---|---|

| Cylinder | Houses the piston and is where combustion occurs. |

| Piston | Moves up and down within the cylinder, compressing the fuel-air mixture. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Fuel System | Delivers the appropriate mixture of fuel and air to the combustion chamber. |

| Ignition System | Initiates the combustion process by creating a spark. |

Importance of Each Component

Understanding the significance of each engine part can facilitate better maintenance practices. For example, ensuring the piston operates smoothly can prevent wear and improve efficiency. Similarly, a well-functioning ignition system is vital for reliable starting and performance. Regular checks and servicing of these components can lead to enhanced operation and reduced chances of malfunction.

Replacing the Chainsaw Chain

Changing the cutting chain on your power saw is essential for maintaining optimal performance and safety. A dull or damaged chain can lead to inefficient cutting and increase the risk of accidents. This section provides a straightforward guide to ensure a smooth replacement process.

Tools Needed

- New cutting chain

- Wrench or screwdriver

- Chain oil

- Protective gloves

- Safety goggles

Steps to Replace the Chain

- Ensure the power tool is turned off and unplugged, or the battery is removed.

- Use the wrench or screwdriver to loosen the nuts on the guide bar.

- Carefully remove the guide bar and the old chain from the tool.

- Place the new chain around the guide bar, ensuring it fits correctly with the cutting direction aligned.

- Reattach the guide bar, tightening the nuts securely without over-torquing.

- Lubricate the chain with oil to ensure smooth operation.

- Check the tension of the chain by pulling it away from the guide bar; it should snap back into place without excessive slack.

Regularly inspecting and replacing the chain will enhance the efficiency of your cutting tasks and extend the life of your equipment. Always consult your tool’s specifications for compatibility and maintenance recommendations.

Fuel System Troubleshooting

The fuel system is a critical component in ensuring optimal performance of outdoor power equipment. Issues within this system can lead to poor operation, reduced efficiency, or complete failure to start. Identifying and resolving fuel-related problems can significantly enhance the longevity and functionality of the machine.

Common Fuel System Issues

- Clogged Fuel Filter: A dirty filter can restrict fuel flow.

- Fuel Line Leaks: Cracks or breaks in the fuel line can cause leaks and air intake.

- Old Fuel: Stale or contaminated fuel can lead to starting difficulties.

- Carburetor Problems: Misadjustments or buildup can prevent proper fuel mixing.

Troubleshooting Steps

- Check the fuel level and ensure that it is fresh and clean.

- Inspect the fuel filter for clogs and replace if necessary.

- Examine fuel lines for cracks or leaks, and replace any damaged sections.

- Remove and clean the carburetor to eliminate any deposits or blockages.

- Test the ignition system to ensure it is functioning properly, as fuel delivery may be adequate but ignition faulty.

Ignition System Diagnostics

The ignition system is crucial for optimal engine performance, acting as the catalyst that ignites the fuel-air mixture. Diagnosing issues within this system can significantly enhance efficiency and reliability. By understanding the components involved, one can identify potential malfunctions and restore proper functionality.

Key Components: The primary elements include the spark plug, ignition coil, and wiring. Each plays a vital role in creating a spark and ensuring it reaches the combustion chamber effectively.

Diagnostic Steps: Begin by inspecting the spark plug for wear or deposits. A damaged or dirty plug can lead to misfires. Next, check the ignition coil for continuity and proper voltage output. Additionally, examine the wiring for any signs of fraying or disconnection, as these can impede the electrical flow.

Conclusion: Regular diagnostics of the ignition system can prevent larger issues down the line, ensuring your engine runs smoothly and efficiently.

Proper Cleaning Techniques

Maintaining equipment in optimal condition is crucial for performance and longevity. Regular cleaning not only enhances functionality but also prevents potential damage. Following effective cleaning practices ensures that your tools remain reliable and efficient.

Begin with Safety Precautions: Before starting the cleaning process, always disconnect the power source or remove the fuel. Wearing appropriate safety gear, such as gloves and goggles, is essential to protect yourself from debris and chemicals.

Use the Right Tools: Gather necessary cleaning supplies such as soft brushes, cloths, and non-corrosive cleaners. Avoid abrasive materials that could scratch or damage surfaces. A gentle approach goes a long way in preserving the integrity of your equipment.

Cleaning Process: Start by removing any large debris and dirt. Use a brush to dislodge stubborn particles from crevices. For oily or greasy areas, apply a suitable cleaner and wipe down with a soft cloth. Ensure that all components are thoroughly dried to prevent rust and corrosion.

Regular Maintenance: Establish a routine cleaning schedule based on usage frequency. Regular upkeep not only maintains performance but also identifies wear and tear early on, allowing for timely repairs.

By following these cleaning techniques, you can ensure that your equipment remains in top shape, ready to tackle any task efficiently.

Safety Tips for Repairs

Ensuring personal safety during maintenance tasks is crucial for anyone working with power equipment. Proper precautions can help prevent accidents and injuries while allowing for efficient work. Understanding the necessary steps before beginning any task can significantly enhance overall safety.

Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear. This equipment serves as a barrier against potential hazards, such as flying debris or sharp components. Make sure the workspace is clean and organized to minimize risks of trips or falls.

Before starting any maintenance, disconnect the power source to eliminate the chance of accidental activation. Familiarize yourself with the equipment’s specific features and functions, as this knowledge will aid in identifying safe handling practices. Utilize the right tools for each job to avoid unnecessary strain and reduce the risk of injury.

In addition, maintain a clear understanding of the manufacturer’s guidelines and recommendations. These instructions provide valuable insights into safe operation and care, ensuring that you adhere to established safety protocols. Should any doubts arise during the process, seeking assistance or consulting a professional can prevent mishaps.

When to Seek Professional Help

Understanding the right moments to consult an expert can significantly enhance the longevity and efficiency of your equipment. While many tasks can be tackled independently, certain situations call for professional intervention to ensure safety and optimal performance.

Here are some indicators that it’s time to reach out to a qualified technician:

- Persistent Issues: If problems continue after multiple attempts to fix them, it’s wise to consult a specialist.

- Unusual Sounds: Hearing strange noises that weren’t present before may indicate a deeper issue that requires expert evaluation.

- Loss of Power: A noticeable decline in performance can suggest underlying mechanical failures.

- Fuel or Oil Leaks: Any leakage should be addressed immediately by a professional to prevent further damage or safety hazards.

- Unfamiliar Components: If you’re unsure about specific parts or how to proceed with repairs, seeking assistance is the best approach.

Taking these factors into account can help prevent costly mistakes and ensure that your equipment remains in peak condition.

Parts Replacement Options

When it comes to maintaining your equipment, exploring various alternatives for component replacement is essential. Ensuring that you have access to high-quality parts can significantly enhance the performance and longevity of your machine. This section discusses several options available for sourcing replacements, allowing you to make informed decisions.

OEM Parts: Original Equipment Manufacturer parts are specifically designed for your model. They guarantee compatibility and often come with a warranty, providing peace of mind in terms of quality and fit.

Aftermarket Components: These parts are produced by third-party manufacturers and can often be found at a lower cost. While they may not always match the exact specifications of OEM parts, many reputable brands offer reliable alternatives that perform adequately.

Used Parts: For those looking to save on costs, second-hand components can be a viable option. Ensure that you inspect these items thoroughly to confirm their condition and functionality before purchase.

Custom Solutions: In some cases, specialized repairs may require custom-made parts. Engaging with skilled technicians who can fabricate specific components can be beneficial, especially for unique situations or older models.

By considering these options, you can effectively address any issues with your equipment and maintain its optimal performance over time.