Understanding the intricacies of a specific machine can significantly enhance its longevity and performance. This section offers valuable insights into various aspects of upkeep and problem-solving techniques, aimed at assisting users in navigating common challenges.

From routine care practices to identifying potential issues, this guide serves as an essential resource for ensuring optimal functionality. Users will find a wealth of information tailored to empower them with the knowledge needed for effective management.

Whether you are facing minor glitches or seeking to enhance overall efficiency, our comprehensive approach will help you delve into essential strategies. Equip yourself with the ultimate tools to maintain and improve your equipment’s operation.

Craftsman T1200 Overview

This section provides a comprehensive examination of a versatile lawn maintenance machine designed for optimal performance and user convenience. It combines durability with advanced features, making it suitable for both residential and light commercial use. Users can expect a reliable tool that enhances productivity while maintaining a user-friendly experience.

The model is equipped with a robust engine, ensuring efficient power delivery for various landscaping tasks. Its ergonomic design allows for easy maneuverability, while the cutting mechanism is engineered to provide clean and precise results. Additionally, the unit is designed with maintenance in mind, featuring accessible components that simplify upkeep and ensure longevity.

Incorporating innovative technology, this equipment offers adjustable settings, allowing users to customize their experience based on specific needs. The design emphasizes safety, with features that protect the operator during use. Overall, this model represents a practical investment for anyone looking to maintain their outdoor spaces effectively.

Common Issues with Craftsman T1200

Many users encounter specific challenges while using their lawn care equipment. Recognizing and addressing these problems early can lead to a smoother experience and prolong the life of the machine. Below are some frequently reported issues that may arise and potential solutions to consider.

Performance Problems

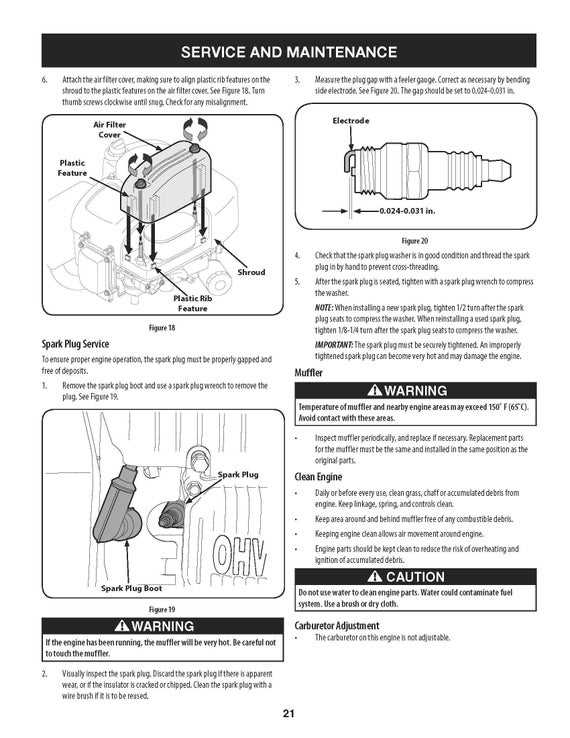

Reduced performance can be attributed to various factors, including fuel quality, air filter clogs, or spark plug issues. Regular maintenance checks are essential to ensure optimal operation.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine Stalling | Poor fuel, clogged air filter, faulty spark plug | Check fuel quality, clean or replace air filter, replace spark plug |

| Difficulty Starting | Dead battery, fuel system issues, starter problems | Charge or replace battery, inspect fuel lines, check starter motor |

Mechanical Failures

Mechanical components may wear out over time, leading to failures. Identifying signs of wear and taking preventive measures can help mitigate these issues.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Worn Blades | Frequent use, hitting hard objects | Sharpen or replace blades regularly |

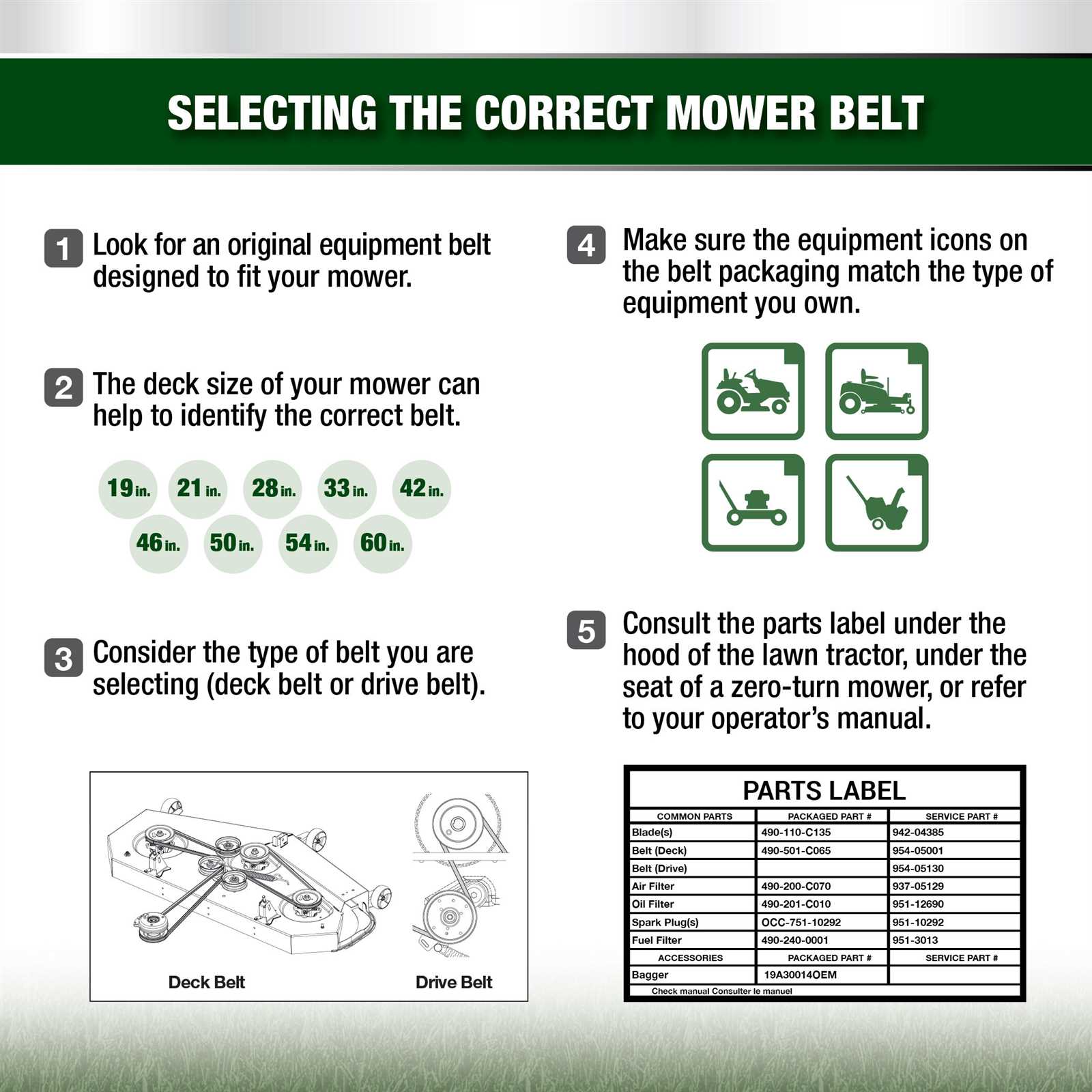

| Transmission Problems | Lack of lubrication, damaged belts | Lubricate moving parts, inspect and replace belts as needed |

Tools Needed for Repairs

Having the right equipment is crucial for ensuring that any maintenance task is performed efficiently and effectively. A well-equipped workspace not only enhances productivity but also minimizes the risk of damage during the process. This section outlines essential instruments required for successful upkeep tasks, providing a foundation for those who wish to tackle issues with confidence.

Firstly, a comprehensive set of hand tools, including wrenches, screwdrivers, and pliers, is necessary for addressing various components. These tools enable precise adjustments and secure fittings. Additionally, power tools, such as drills and saws, can significantly expedite tasks, making them indispensable for larger jobs.

Safety gear should never be overlooked. Protective eyewear, gloves, and masks are vital for safeguarding oneself against debris and hazardous materials. Moreover, having a sturdy workbench and adequate lighting will facilitate a safe and organized environment.

Lastly, measuring tools, such as calipers and tape measures, play an important role in achieving accurate dimensions, ensuring that all components fit properly. By assembling this toolkit, individuals will be well-prepared to address any challenges that may arise during their maintenance endeavors.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for addressing common issues that may arise with your equipment. By following the outlined procedures meticulously, you can ensure effective troubleshooting and restoration, enhancing the longevity of your device. Whether you’re dealing with mechanical malfunctions or performance inconsistencies, these instructions will help you navigate the repair process with confidence.

Identifying the Issue

Before commencing any fixes, it’s crucial to accurately identify the problem. Start by observing any unusual sounds, movements, or performance drops. Make a note of specific symptoms, as this information will guide your subsequent steps. Documentation of your findings can be invaluable for reference during the repair process.

Gathering Necessary Tools

Once the issue is pinpointed, assemble the required tools and materials. Commonly needed items may include screwdrivers, pliers, and replacement parts. Ensure that everything is within reach to facilitate a smooth workflow. Taking the time to prepare your workspace will significantly impact the efficiency of your repair efforts. Safety gear should also be on hand to protect against any potential hazards.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular attention to detail not only enhances performance but also minimizes the likelihood of unexpected failures. Adopting a consistent maintenance routine will keep your machinery running smoothly and efficiently, allowing you to achieve optimal results for years to come.

Regular Cleaning

Cleaning your tools and equipment after each use is crucial. Remove any debris, dust, or residue that may accumulate during operation. This practice prevents wear and tear and ensures that all components function correctly. Pay special attention to air filters and moving parts, as they are often prone to clogging and friction.

Scheduled Inspections

Implement a schedule for routine inspections to identify potential issues before they escalate. Check for signs of wear, loose connections, or fluid leaks. By addressing minor problems early on, you can avoid costly repairs and extend the life of your machinery. Keeping a log of these inspections will help track performance and highlight any recurring issues.

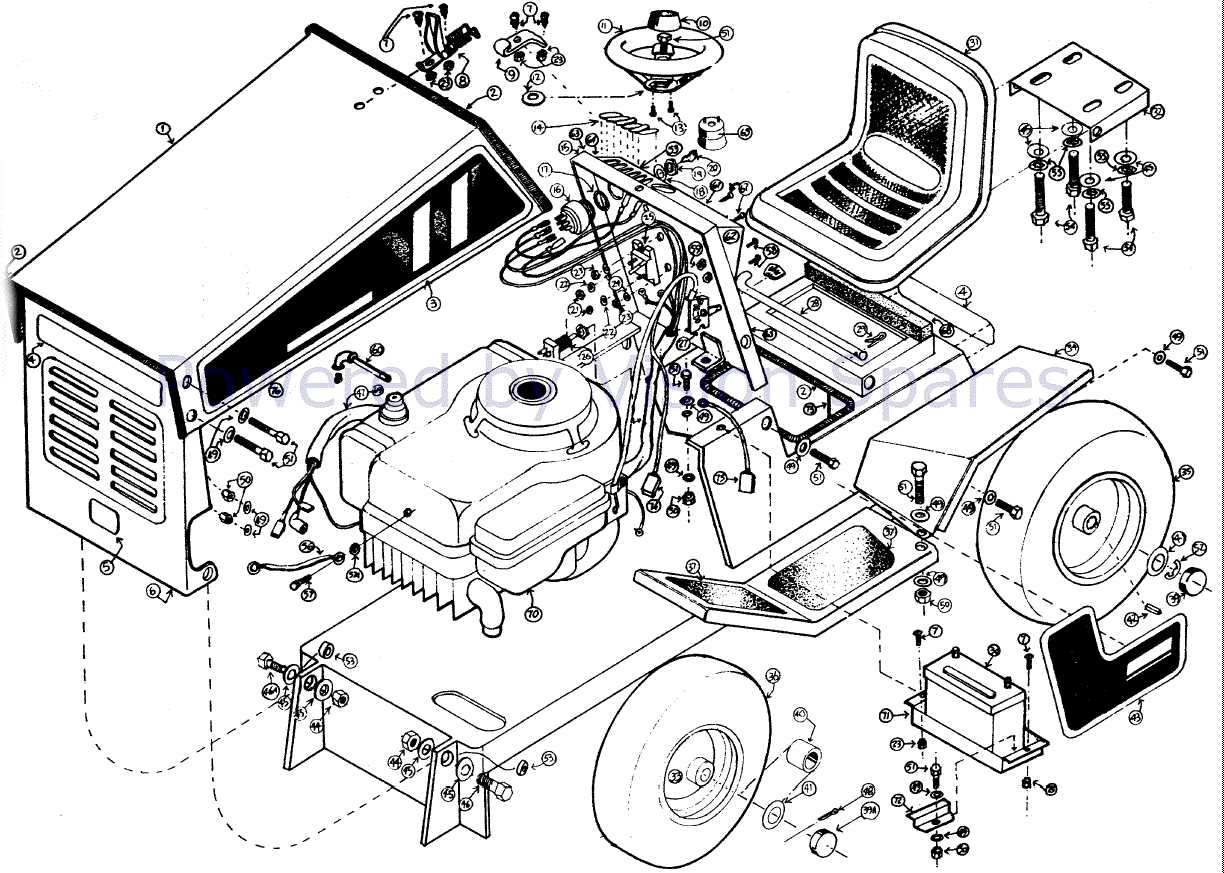

Replacing Key Components Explained

Understanding the process of swapping out vital elements in machinery is crucial for maintaining optimal performance. This section delves into the steps and considerations necessary for effectively replacing important parts, ensuring the equipment operates smoothly and efficiently.

Identifying Components for Replacement

Before initiating the replacement process, it’s essential to recognize which components require attention. Look for signs of wear, damage, or malfunction, such as unusual noises, decreased performance, or visible deterioration. Regular inspection can help pinpoint issues before they escalate, allowing for timely intervention.

Step-by-Step Replacement Process

Once the components have been identified, the next step involves a systematic approach to their removal and installation. Begin by disengaging power to ensure safety. Carefully detach the faulty part, taking note of its connections and positioning. When installing the new component, align it properly and secure it according to the manufacturer’s specifications. Lastly, conduct a thorough check to confirm that everything is in place and functioning as intended.

By following these guidelines, you can effectively manage the replacement of key parts, enhancing the longevity and reliability of your machinery.

Troubleshooting Electrical Problems

Addressing electrical issues can often seem daunting, yet systematic troubleshooting can lead to effective solutions. By understanding the common symptoms and following a methodical approach, you can identify and resolve various electrical complications with confidence.

Here are some common signs of electrical malfunctions:

- Inconsistent power supply

- Burning smells or scorched areas

- Frequent blown fuses or tripped breakers

- Unresponsive components

To effectively troubleshoot these problems, consider the following steps:

- Safety First: Always disconnect the power source before conducting any inspections.

- Visual Inspection: Examine wires and connections for any signs of damage or wear.

- Check Fuses and Breakers: Ensure that fuses are intact and circuit breakers are functioning properly.

- Use a Multimeter: Test voltage and continuity in circuits to identify any faults.

- Inspect Components: Verify that all parts are operational and not obstructed or damaged.

If these steps do not resolve the issue, it may be necessary to consult with a professional for further evaluation. Regular maintenance can also help prevent future electrical problems.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, prioritizing safety is essential. Ensuring a secure environment minimizes the risk of accidents and injuries, allowing for a more efficient and effective process. Adhering to specific guidelines not only protects the individual performing the work but also safeguards the equipment being handled.

Before starting any task, it is vital to wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and sturdy footwear to prevent injuries from sharp objects or heavy components. Additionally, a well-lit workspace is crucial to clearly see all parts and tools, reducing the chances of errors.

Disconnecting the power source is one of the most important steps to prevent accidental activation. Always ensure that machinery is properly isolated and secured before beginning any disassembly or inspection. Familiarize yourself with the equipment’s components and operation, which can help identify potential hazards.

Keeping the workspace organized and free of clutter is also essential. A tidy environment reduces the likelihood of tripping hazards and makes tools easier to locate. Furthermore, it is wise to have a first aid kit readily accessible in case of minor injuries, ensuring a quick response if needed.

Lastly, never hesitate to seek assistance or clarification if uncertain about any aspect of the task. Collaborating with knowledgeable individuals can enhance safety and lead to better outcomes. By following these precautions, you can ensure a safer and more productive experience during your maintenance endeavors.

Where to Find Replacement Parts

Finding the right components for your equipment can be essential for maintaining its functionality and longevity. Whether you are looking to replace a worn-out piece or upgrade an existing part, there are several avenues to explore to secure the necessary items. This guide outlines various resources and strategies to help you locate the parts you need effectively.

Online Retailers

Many online platforms specialize in offering a wide array of components for various brands and models. These retailers often provide detailed specifications and compatibility information to ensure you select the correct part.

| Website | Description |

|---|---|

| Amazon | A vast marketplace with numerous sellers offering a variety of components. |

| eBay | A platform for both new and used parts, often at competitive prices. |

| Specialty Stores | Dedicated websites that focus on specific equipment types, often with expert support. |

Local Dealers and Stores

Visiting local dealers can provide hands-on assistance and immediate access to parts. These establishments may also offer valuable insights and recommendations based on your specific needs.

| Type of Store | Benefits |

|---|---|

| Authorized Dealers | Access to original components and expert advice. |

| Hardware Stores | Convenient for basic replacement parts and tools. |

| Salvage Yards | Potentially lower-cost options for used parts. |

DIY vs. Professional Repairs

When it comes to fixing equipment, individuals often face the choice between tackling the job themselves or hiring an expert. Each approach has its own merits and drawbacks, and understanding these can help determine the best path forward based on the situation, skills, and resources available.

Advantages of DIY

Opting for a do-it-yourself approach can be both rewarding and cost-effective. Here are some benefits of this method:

| Benefit | Description |

|---|---|

| Cost Savings | Eliminating labor fees can lead to significant savings. |

| Learning Experience | Gaining hands-on experience can enhance skills and knowledge. |

| Flexibility | Work can be done at your convenience without scheduling conflicts. |

Advantages of Professional Services

Engaging a specialist can also provide distinct benefits, particularly in complex scenarios. Consider the following advantages:

| Benefit | Description |

|---|---|

| Expertise | Professionals possess specialized knowledge and experience. |

| Time Efficiency | Experts can often complete tasks more quickly than amateurs. |

| Warranty | Many services offer guarantees, providing peace of mind. |