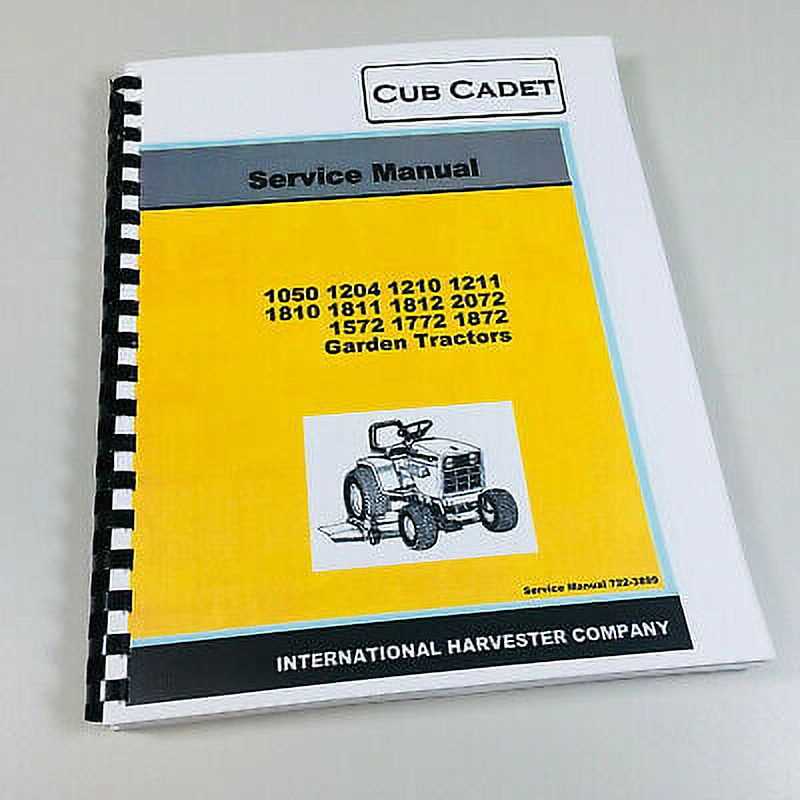

Proper upkeep of garden machinery is essential for ensuring optimal performance and longevity. Understanding the intricacies of these powerful machines can greatly enhance their efficiency and reliability. This section delves into the vital aspects of maintaining and troubleshooting a specific model of lawn tractor, offering insights that can empower users to address common issues effectively.

Throughout this guide, you will discover practical tips and step-by-step instructions designed to simplify the maintenance process. Whether you are facing minor challenges or preparing for routine servicing, having a comprehensive understanding of your equipment will enable you to make informed decisions. With the right knowledge at your fingertips, you can confidently tackle various tasks, ensuring that your outdoor equipment remains in top-notch condition.

From basic preventative measures to more involved solutions, this resource serves as a valuable companion for both novice users and seasoned enthusiasts. By familiarizing yourself with the inner workings of your lawn tractor, you will not only enhance its performance but also enjoy a more rewarding gardening experience.

Overview of the Lawn Tractor

This section provides an insightful look into a popular model of lawn care equipment known for its efficiency and ease of use. Designed for homeowners, this machine combines power with user-friendly features, making it an excellent choice for maintaining lawns and gardens.

Key Features

- Powerful engine for effective cutting

- Ergonomic controls for comfort

- Durable construction for longevity

- Efficient grass collection system

Benefits of Using This Tractor

- Enhanced maneuverability in tight spaces

- Time-saving capabilities for larger areas

- Cost-effective maintenance solutions

- Increased productivity with advanced technology

Common Issues with Cub Cadet LT1042

When it comes to maintaining a riding mower, various problems can arise that may hinder its performance and efficiency. Understanding these typical challenges can help users troubleshoot and ensure their machine operates smoothly. From mechanical failures to electrical concerns, recognizing the signs early can prevent further complications.

One frequent issue is difficulty starting the engine, which may stem from a weak battery or faulty ignition system. Additionally, owners might encounter problems with the cutting deck, such as uneven grass height or clippings not being discharged properly. This can be attributed to dull blades or a clogged discharge chute.

Another common concern involves the transmission, where users may notice a lack of response when shifting gears. This could indicate low fluid levels or worn-out components. Furthermore, unusual noises during operation often signal underlying mechanical issues that require immediate attention.

Lastly, electrical problems, including malfunctioning lights or battery drainage, are also prevalent. These can result from faulty wiring or a depleted battery. By being aware of these typical challenges, owners can take proactive steps to maintain their mower effectively.

Essential Tools for Repairs

When tackling maintenance tasks on your outdoor equipment, having the right instruments is crucial for achieving effective and efficient results. A well-equipped toolkit not only simplifies the process but also enhances safety and accuracy during each job. Understanding which items are necessary can make a significant difference in your repair experience.

Start with basic hand tools such as wrenches and screwdrivers, which are fundamental for loosening and tightening various components. Pliers are also indispensable, as they provide grip and leverage when handling stubborn parts. Additionally, a reliable socket set will allow for quicker and easier access to bolts and nuts that are otherwise hard to reach.

For more advanced tasks, consider including diagnostic tools like multimeters to troubleshoot electrical issues. A torque wrench is essential for ensuring that fasteners are secured to the proper specifications, preventing damage from over-tightening. Lastly, don’t forget about safety gear, such as gloves and goggles, which protect you while you work.

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. This section outlines a comprehensive approach to maintaining your machinery, focusing on key tasks that should be performed periodically. By following these guidelines, you can help prevent breakdowns and ensure efficient operation.

Essential Tasks

Here are the main maintenance activities that should be conducted regularly:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil with fresh lubricant to ensure proper engine function. |

| Air Filter Inspection | Every 25 hours | Check and clean the air filter to maintain airflow and engine efficiency. |

| Blade Sharpening | Every season | Sharpen or replace blades to achieve a clean cut and reduce engine strain. |

| Battery Check | Monthly | Inspect battery connections and charge level to ensure reliable starting. |

Procedure Guidelines

Follow these procedures for each task to ensure effective maintenance:

- Gather all necessary tools and materials before starting.

- Always refer to the user guide for specific instructions related to your equipment.

- Wear appropriate safety gear, including gloves and goggles.

- Dispose of any waste materials according to local regulations.

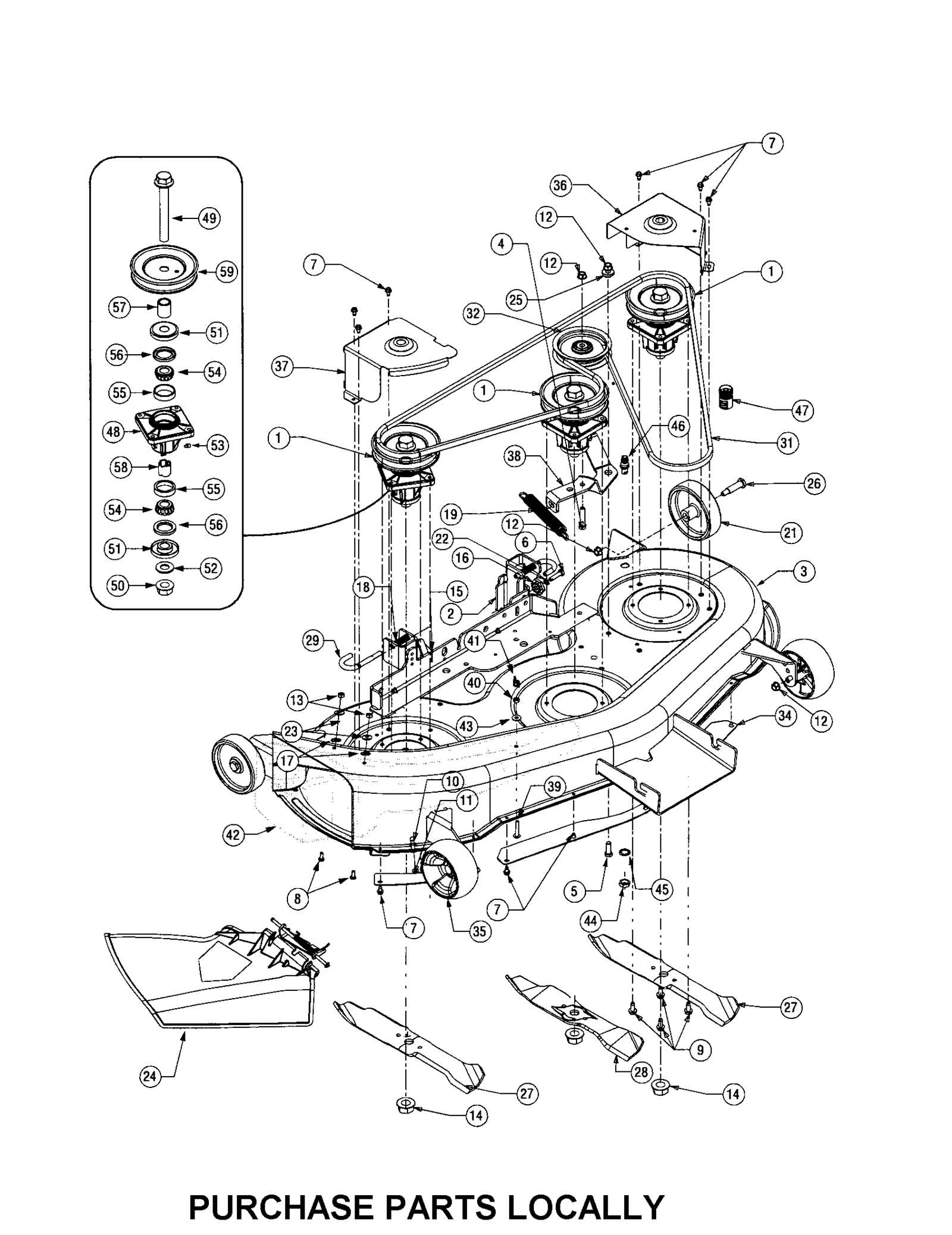

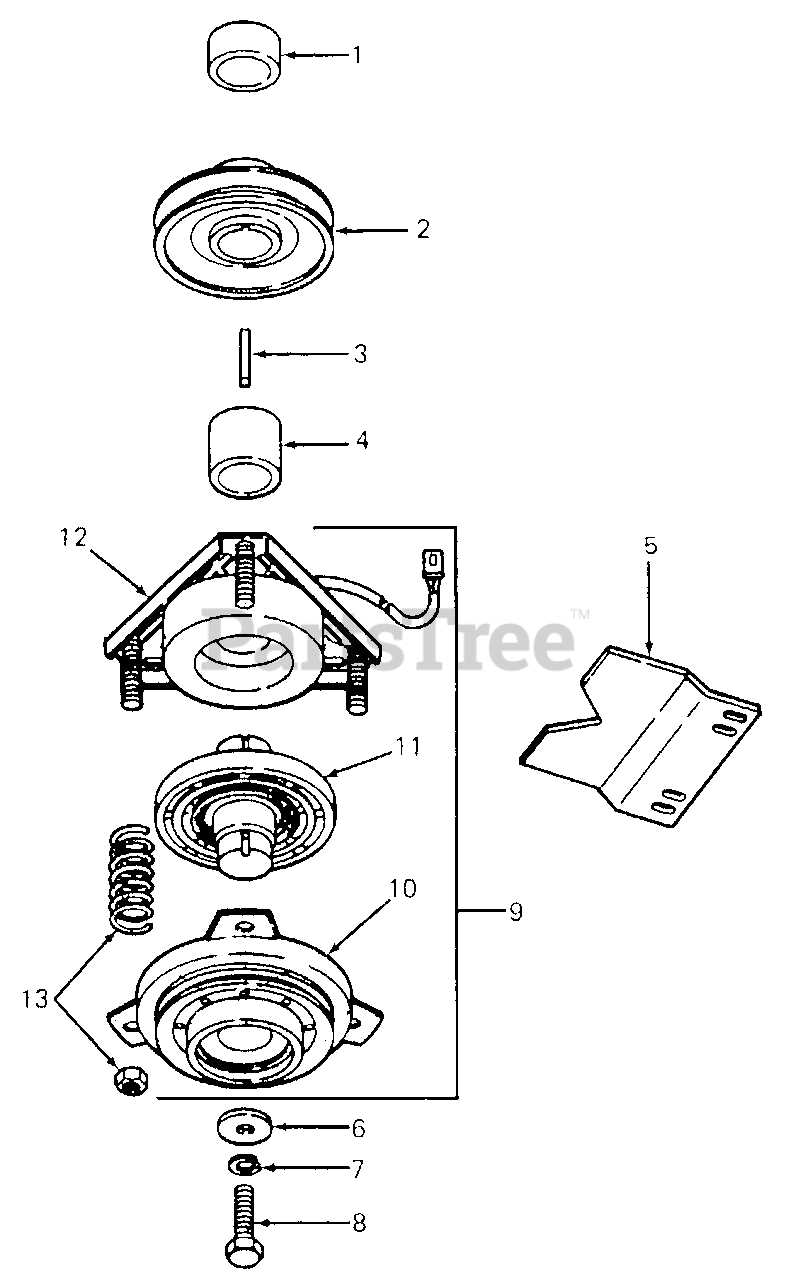

How to Replace the Blades

Maintaining the sharpness and integrity of the cutting implements is crucial for optimal performance. This section will guide you through the process of removing and installing new blades, ensuring a clean and efficient cut every time. Proper blade replacement not only enhances the efficiency of your machine but also contributes to a healthier lawn.

Tools and Materials Needed

Before starting, gather the following tools and materials:

| Tool/Material | Purpose |

|---|---|

| Socket wrench | To remove blade bolts |

| New blades | To replace old, worn blades |

| Safety gloves | To protect your hands |

| Grease | To lubricate the mounting area |

Step-by-Step Instructions

Follow these steps to successfully replace the blades:

- Ensure the machine is turned off and disconnected from any power source.

- Use the socket wrench to remove the bolts securing the blades.

- Carefully detach the old blades and dispose of them properly.

- Install the new blades, ensuring they are positioned correctly.

- Secure the blades by tightening the bolts securely.

- Apply grease to the mounting area to facilitate smooth operation.

By following these steps, you will ensure that your cutting implements remain in top condition, contributing to the overall efficiency of your equipment.

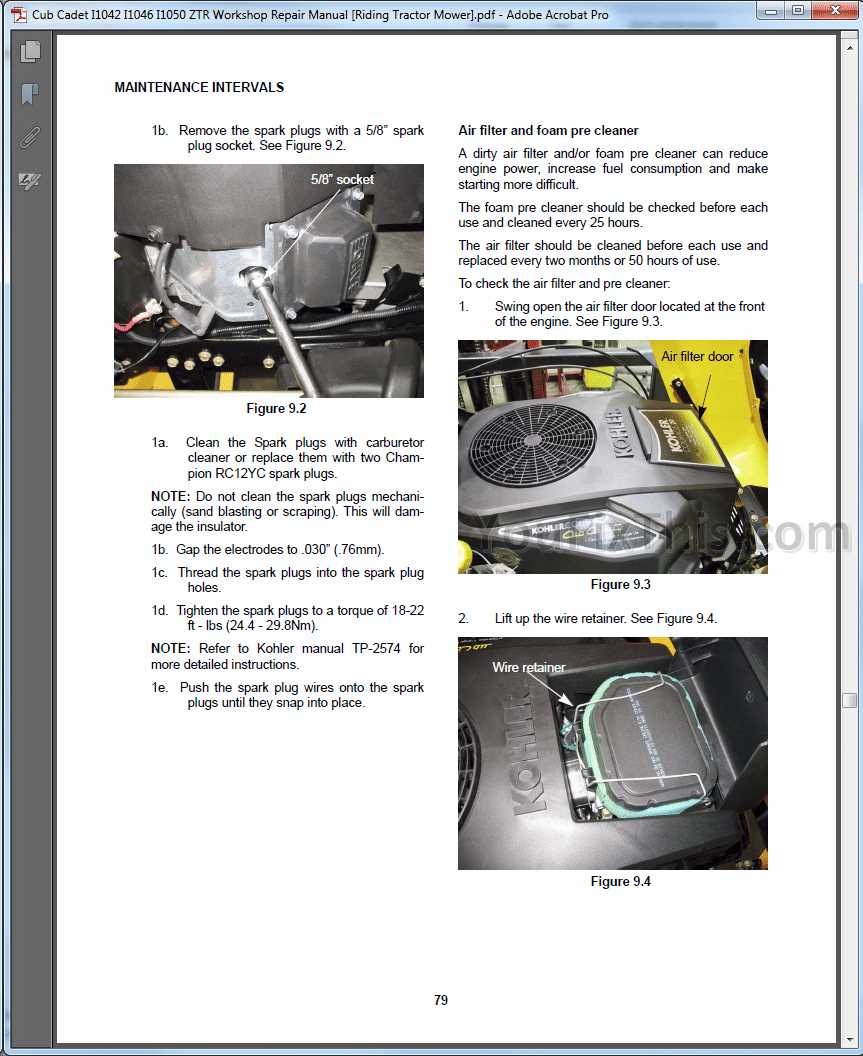

Troubleshooting Electrical Problems

Addressing electrical issues in outdoor equipment can be challenging yet rewarding. Proper diagnosis is essential to ensure that the machinery operates efficiently and reliably. Common symptoms include failure to start, erratic behavior of electrical components, and blown fuses. By systematically checking each part of the system, you can identify the root cause and implement effective solutions.

Start with the Battery: The battery is often the first component to inspect. Ensure that it is fully charged and free from corrosion. A multimeter can help check voltage levels; a reading below the recommended level indicates a need for charging or replacement.

Inspect Wiring and Connections: Frayed or damaged wires can lead to intermittent issues. Examine all visible wiring for signs of wear or disconnection. Secure all connections, as loose terminals may cause poor conductivity and operational failures.

Check Fuses and Relays: Blown fuses are a common cause of electrical failure. Replace any faulty fuses and test relays for proper function. A malfunctioning relay may prevent power from reaching critical components.

Test the Ignition System: If starting issues persist, evaluate the ignition system. Inspect the spark plug and ignition coil for signs of wear. Replacing worn parts can often resolve starting problems and improve overall performance.

Examine Safety Switches: Safety switches are designed to prevent operation under unsafe conditions. Ensure that all switches are functioning correctly, as a faulty switch can inhibit starting or operation even when other systems are intact.

By following these steps, you can effectively troubleshoot and resolve electrical issues, ensuring your outdoor equipment runs smoothly and efficiently.

Engine Overhaul Instructions

Overhauling the power unit is a critical procedure that ensures optimal performance and longevity. This guide provides step-by-step instructions for disassembling, inspecting, and reassembling the engine components, allowing for effective maintenance and restoration of functionality.

Preparation and Tools

Before starting the overhaul, gather the necessary tools and materials:

- Socket and wrench set

- Screwdrivers (flat and Phillips)

- Torque wrench

- Replacement gaskets and seals

- Oil and fuel filters

- Cleaning solvents

- Rags and containers for parts

Step-by-Step Process

- Disassembly:

- Disconnect the battery and remove any electrical connections.

- Drain the oil and fuel from the system.

- Carefully detach the external components, including the air cleaner and muffler.

- Unbolt the engine from its mounting, lifting it free from the chassis.

- Inspection:

- Examine the cylinder for wear or scoring.

- Check the piston rings for damage and proper fit.

- Inspect valves for seating and potential leaks.

- Review all gaskets and seals for signs of deterioration.

- Reassembly:

- Replace worn or damaged components as necessary.

- Use new gaskets and seals during reassembly to prevent leaks.

- Tighten bolts to manufacturer specifications using a torque wrench.

- Reinstall external components and ensure all connections are secure.

- Final Checks:

- Refill the engine with oil and fuel.

- Reconnect the battery and check all electrical connections.

- Perform a final inspection for any loose bolts or potential issues.

Following these detailed steps will ensure that the engine is overhauled effectively, restoring its performance and reliability. Regular maintenance checks post-overhaul will also help prolong the lifespan of the unit.

Adjusting the Deck Height

Maintaining the optimal cutting height of your mowing equipment is crucial for achieving a healthy lawn and efficient performance. Proper adjustment allows for a consistent cut, which can enhance the appearance of your yard while promoting grass growth. This section will guide you through the steps to effectively modify the deck height of your machine.

Understanding Deck Height Settings

The deck height is adjustable to accommodate different grass types and conditions. Familiarizing yourself with the various settings will help you choose the best height for your specific needs. Consider the following:

- Shorter heights are suitable for established lawns.

- Higher settings work better for taller grasses or uneven terrain.

- Regular adjustments may be necessary based on seasonal growth patterns.

Steps to Adjust the Deck Height

- Ensure the mower is on a flat surface for accurate measurement.

- Locate the height adjustment lever or mechanism, usually found near the deck or on the chassis.

- Loosen the adjustment lever, if applicable, to allow for movement.

- Raise or lower the deck to the desired height, referencing the height indicator if available.

- Secure the lever in place to maintain the chosen height.

- Test the mower on a small patch of grass to ensure satisfactory results.

Regularly checking and adjusting the cutting height can greatly improve the health of your lawn and the efficiency of your machine. Remember to consider the grass type and season when making these adjustments for the best outcomes.

Fuel System Care and Repair

The efficiency of a small engine greatly depends on the proper functioning of its fuel system. Regular maintenance and timely troubleshooting are essential to ensure optimal performance and longevity. This section provides insights into maintaining the components responsible for fuel delivery, as well as addressing common issues that may arise.

Regular Inspection: Frequent checks of the fuel lines, filters, and tank are crucial. Look for signs of wear, leaks, or blockages. Replacing damaged parts promptly can prevent larger issues from developing.

Fuel Quality: Using clean, high-quality fuel is vital for smooth operation. Stale or contaminated fuel can lead to poor performance. Always store fuel properly and avoid using old fuel that has been sitting for an extended period.

Filter Maintenance: The fuel filter plays a critical role in keeping debris from entering the engine. Clean or replace the filter as recommended in the guidelines. A clogged filter can restrict fuel flow, causing the engine to sputter or stall.

Fuel Line Care: Inspect the fuel lines for cracks or brittleness. These can lead to leaks or interruptions in fuel delivery. Ensure all connections are secure, and consider replacing lines that show signs of deterioration.

Carburetor Attention: The carburetor mixes air and fuel for combustion. Regular cleaning and adjustment can improve performance. Pay attention to any signs of rough idling or difficulty starting, as these may indicate a need for service.

Winterization: Preparing the fuel system for colder months is essential. Consider adding a fuel stabilizer and running the engine to ensure it reaches all components. Draining the system may also be necessary to prevent damage from freezing temperatures.

By adhering to these maintenance practices, you can enhance the reliability and efficiency of the fuel system, ensuring that your engine operates smoothly for years to come.

Transmission Issues and Fixes

The transmission system is a crucial component of any riding mower, directly influencing its performance and functionality. Problems in this area can lead to significant operational difficulties, impacting both speed and control. Understanding common issues and their solutions can help maintain optimal performance and extend the lifespan of the equipment.

Common Transmission Problems

- Slipping Gears: This occurs when the mower fails to maintain speed, often due to worn or damaged components.

- Stalling: A sudden stop while in motion can indicate a malfunctioning transmission, possibly caused by insufficient fluid levels.

- No Movement: If the mower does not move at all, the issue could stem from a broken belt or a faulty drive system.

- Unusual Noises: Grinding or clunking sounds may signal internal damage or the need for lubrication.

Troubleshooting and Solutions

- Check Fluid Levels: Ensure the transmission fluid is at the proper level. Low fluid can lead to overheating and damage.

- Inspect Belts: Look for signs of wear or breakage in drive belts. Replace them if necessary.

- Examine Components: Inspect gears and other parts for wear and tear. Replacing damaged components can restore functionality.

- Adjust Settings: Make necessary adjustments to the transmission settings, which may help resolve shifting issues.

- Consult a Professional: If problems persist, seeking assistance from a qualified technician can provide expert diagnosis and repairs.

Safety Precautions During Repairs

When undertaking maintenance on outdoor machinery, ensuring personal safety is paramount. Proper precautions can significantly reduce the risk of accidents and injuries, allowing for a smoother and more effective troubleshooting process.

First and foremost, always disconnect the power source before beginning any work. This simple step can prevent accidental starts and protect the user from electric shocks. Additionally, it is essential to wear appropriate protective gear, including gloves, goggles, and sturdy footwear, to shield against potential hazards.

Furthermore, working in a well-ventilated area can help avoid inhalation of harmful fumes or dust generated during the service. Keeping the workspace organized and free of clutter minimizes tripping hazards and allows for easy access to tools and parts. Regularly checking that tools are in good condition also contributes to a safer working environment.

Finally, staying informed about the specific machinery and following manufacturer guidelines can help identify potential risks. Maintaining a cautious mindset throughout the process ensures that safety remains the top priority.

Where to Find Replacement Parts

When it comes to maintaining your lawn care equipment, sourcing the right components is essential for ensuring optimal performance. Whether you’re dealing with a worn-out blade or a malfunctioning engine part, finding quality replacements can make all the difference in keeping your machine running smoothly.

Authorized Dealers

One of the most reliable options for obtaining parts is through authorized dealers. These outlets often carry a comprehensive selection of original components that meet the manufacturer’s specifications. Visiting a local dealer not only provides access to genuine items but also allows you to seek expert advice regarding installation and compatibility.

Online Retailers

For convenience, many turn to online retailers that specialize in outdoor equipment. Websites dedicated to parts supply can offer a vast inventory, often at competitive prices. Be sure to check user reviews and ratings to ensure you’re purchasing from a reputable source, and verify that the parts are compatible with your specific model.