Understanding the intricacies of fluid handling machinery is essential for ensuring their longevity and efficiency. When issues arise, having a comprehensive resource at your disposal can make a significant difference in the restoration process. This section aims to provide clear guidance on addressing common challenges associated with these vital devices.

Effective troubleshooting and servicing require not only knowledge of the equipment’s components but also an awareness of best practices in maintenance. Whether you are dealing with performance inconsistencies or unexpected breakdowns, following a structured approach can lead to successful outcomes. This guide will explore practical techniques and insights that empower users to tackle issues confidently.

Equipping yourself with the right information is crucial for anyone involved in the operation or upkeep of these machines. By fostering a proactive mindset towards maintenance, you can minimize downtime and enhance productivity. In the following sections, we will delve into essential procedures, tools, and tips that will aid you in restoring functionality and efficiency to your equipment.

Understanding Graco T1 Transfer Pump

This section delves into the intricacies of a specific fluid handling device that is widely utilized in various industries. Its design facilitates the efficient movement of liquids from one location to another, making it an essential tool for many applications. Understanding its components and functionality can enhance user experience and operational efficiency.

Key Features: The device is engineered for durability and reliability, featuring robust materials that withstand harsh conditions. Its intuitive design simplifies usage, allowing operators to easily manage liquid flow and pressure settings.

Applications: This equipment is commonly employed in sectors such as construction, automotive, and manufacturing, where effective liquid transfer is crucial. Knowledge of its versatility can help users identify optimal scenarios for its implementation, maximizing productivity.

Maintenance Considerations: Regular upkeep is vital for sustaining performance. Users should be aware of common issues and maintenance practices that can prolong the lifespan of the device, ensuring that it remains in optimal working condition.

Common Issues with Graco Pumps

When working with fluid handling equipment, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and preventing costly downtime. Issues can range from minor adjustments to significant malfunctions that require immediate attention.

One frequent concern is inconsistent flow rates, which can lead to uneven application and waste of materials. This may be caused by clogged filters or improper settings, necessitating regular maintenance to ensure smooth operation. Another issue is air leaks, which can disrupt the system’s pressure and result in erratic performance. Identifying and sealing these leaks is crucial for maintaining efficiency.

Additionally, wear and tear on components over time can lead to diminished effectiveness. Regular inspections and timely replacements of worn parts are vital to prolonging the lifespan of the equipment. Users may also face problems related to power supply, where fluctuations or interruptions can affect performance stability. Ensuring a reliable power source can mitigate this risk.

Lastly, user error can sometimes lead to operational issues, emphasizing the importance of proper training and adherence to guidelines. Addressing these common challenges proactively can significantly enhance the reliability and effectiveness of fluid management systems.

Tools Required for Repair

When undertaking maintenance on equipment, having the right tools is essential for a successful outcome. Proper instruments not only streamline the process but also ensure safety and efficiency. Below is a comprehensive list of items you will need to effectively conduct the necessary tasks.

| Tool | Description |

|---|---|

| Wrench Set | Variety of sizes to fit different fasteners securely. |

| Screwdriver Set | Includes both flathead and Phillips for versatility. |

| Pliers | Useful for gripping, twisting, and cutting wire or small components. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Safety Goggles | Protects eyes from debris and harmful substances during work. |

| Gloves | Provides hand protection while handling tools and materials. |

| Utility Knife | For cutting through packaging or seals with precision. |

| Multimeter | Used to measure electrical parameters to diagnose issues. |

| Cleaning Supplies | Includes rags and solvents for maintaining cleanliness during the process. |

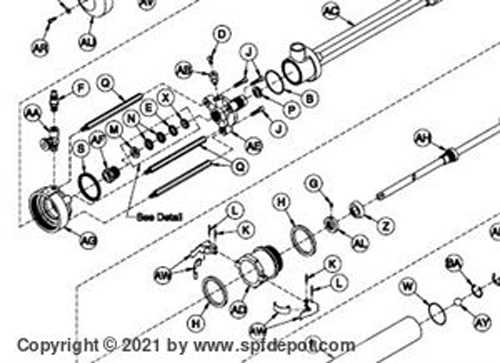

Step-by-Step Disassembly Process

This section outlines the essential steps required to safely and effectively take apart the equipment for thorough inspection and maintenance. Following these instructions will help ensure that all components are handled correctly, minimizing the risk of damage and facilitating easier reassembly.

Preparation Before Disassembly

Before starting the disassembly, it’s important to gather the necessary tools and materials:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Pliers

- Container for small parts

- Lubricant for reassembly

Additionally, ensure the working area is clean and well-lit, which will aid in identifying parts and prevent misplacement.

Disassembly Steps

- Begin by disconnecting the power source to prevent any accidental activation during the process.

- Remove any external covers or shields, taking care to keep track of screws and small components.

- Next, detach the main housing by unscrewing the fasteners and gently lifting it off.

- Proceed to take apart internal components, starting with the most accessible parts, and documenting each step.

- Place all removed pieces into the container to avoid losing them and label components as necessary for easier identification during reassembly.

- Inspect each part for wear or damage, making notes on what needs to be replaced or serviced.

Following this systematic approach will help ensure a smooth disassembly process, paving the way for effective maintenance and upkeep of the equipment.

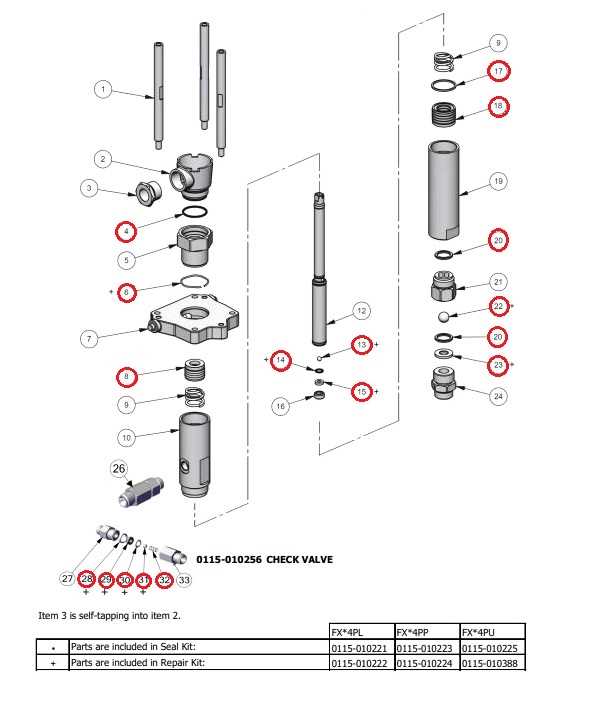

Inspecting Pump Components

Proper examination of the individual elements within a liquid transfer system is crucial for maintaining optimal functionality. Regular checks can help identify wear and tear, ensuring longevity and efficient performance. This section outlines the steps and considerations for a thorough assessment of these essential parts.

Visual Examination

Begin with a careful visual inspection of all accessible components. Look for signs of damage such as cracks, corrosion, or wear. Pay special attention to seals and gaskets, as they are critical for preventing leaks. Any visible deterioration may indicate a need for replacement or further investigation.

Functional Testing

After the visual check, proceed to functional testing. This involves running the system under normal operating conditions to observe its performance. Listen for unusual noises, which may suggest mechanical issues, and monitor for vibrations that could signal misalignment. Ensure that all connections are secure, and assess the overall responsiveness of the mechanism. Any irregularities should be documented for further action.

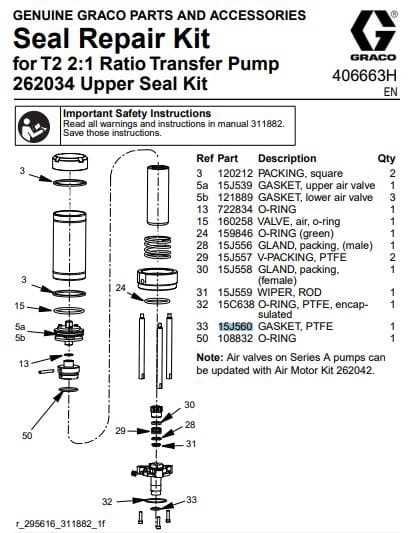

How to Replace Worn Parts

Maintaining the efficiency of your equipment is crucial for optimal performance. Over time, certain components may wear out due to regular usage, affecting the overall functionality. Replacing these deteriorated parts is essential to ensure longevity and reliability. This section will guide you through the process of identifying and substituting worn components effectively.

Identifying Worn Components

Before proceeding with any replacements, it is vital to recognize the signs of wear. Common indicators include unusual noises, leaks, or decreased efficiency. Visual inspections can reveal cracks, discoloration, or any irregularities that signal the need for a replacement. Regular monitoring will help in catching issues early, minimizing potential damage.

Steps for Replacement

Once you have identified the faulty parts, follow these steps for a successful replacement:

- Gather Necessary Tools: Ensure you have all required tools and new components ready before starting the process.

- Disconnect Power: Always disconnect the power source to prevent accidents during the replacement.

- Remove the Worn Part: Carefully detach the worn component, noting its position for accurate installation of the new part.

- Install the New Component: Align the new part properly and secure it in place, following any manufacturer specifications.

- Reconnect Power: Once everything is reassembled, restore the power and test the equipment to ensure proper operation.

Following these steps will help you maintain the efficiency of your machinery and extend its lifespan. Regular maintenance and timely replacements are key to achieving optimal performance.

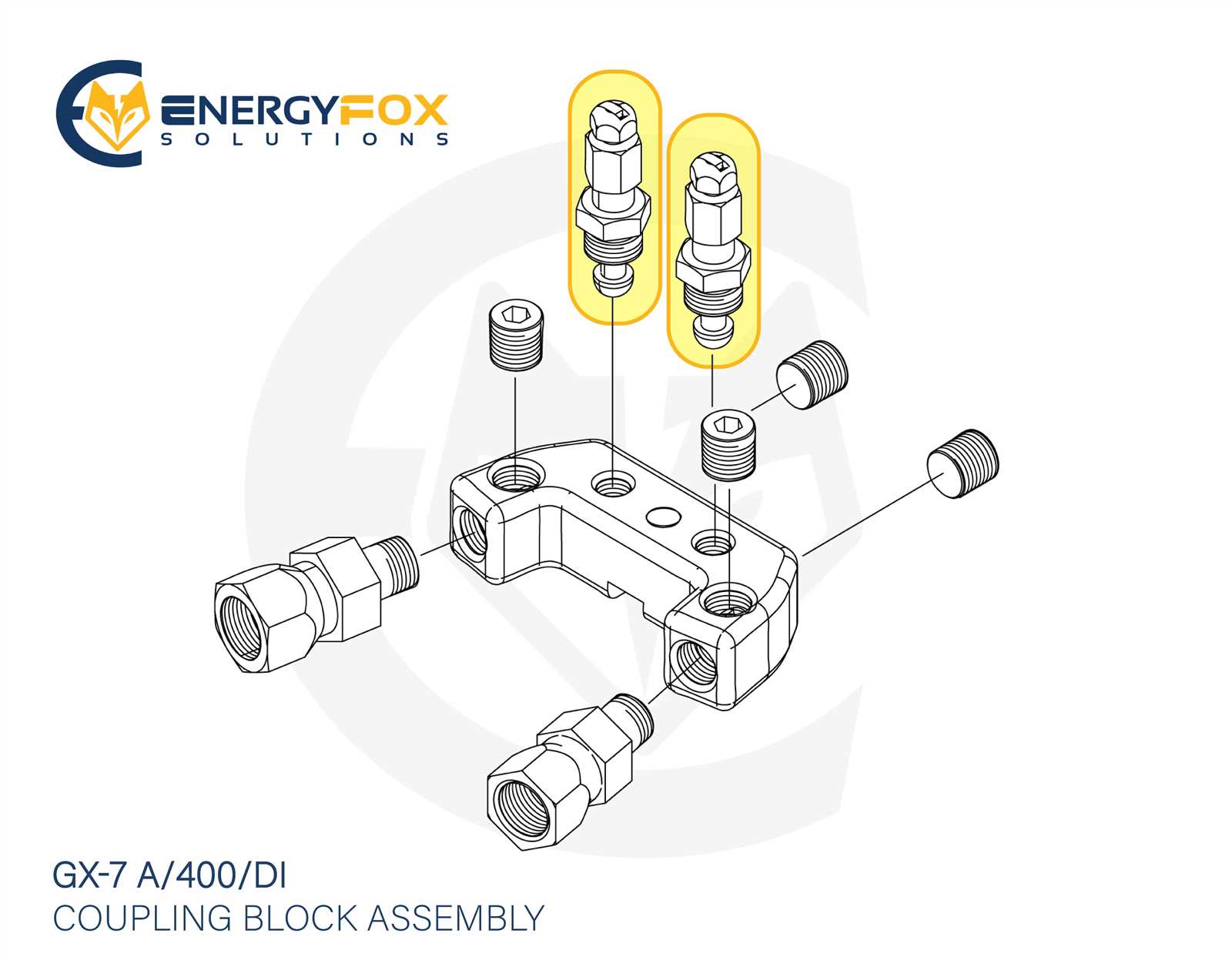

Reassembling the Pump Correctly

Ensuring the proper reassembly of your device is crucial for its optimal functionality and longevity. This stage requires careful attention to detail, as each component must fit together precisely to avoid future malfunctions. Follow the outlined steps meticulously to restore the equipment to its full operating potential.

Step-by-Step Guide

Begin by organizing all parts and tools to streamline the reassembly process. Refer to your previous notes or documentation to confirm the order of assembly. Here’s a basic outline of the procedure:

| Step | Description |

|---|---|

| 1 | Clean all components thoroughly to remove any debris or residue. |

| 2 | Inspect each part for wear and damage, replacing any faulty components. |

| 3 | Start assembling from the base up, ensuring that seals and gaskets are correctly positioned. |

| 4 | Secure all fasteners to the manufacturer’s specifications to ensure proper tightness. |

| 5 | Conduct a thorough check of all connections and fittings before finalizing the assembly. |

Final Checks

After reassembly, it’s essential to perform a test run to verify that everything operates smoothly. Monitor for unusual noises or leaks, and be prepared to disassemble and adjust if necessary. Proper attention during reassembly significantly contributes to the efficiency and lifespan of your device.

Testing the Pump Functionality

Evaluating the operational performance of your equipment is crucial to ensure it operates efficiently. This process involves a systematic approach to identify any potential issues that may affect its performance. Regular assessments help maintain optimal functioning and extend the lifespan of the device.

Preparation for Testing

Before initiating the evaluation, ensure that the unit is clean and free from any obstructions. Check all connections and verify that the power source is stable. It’s advisable to consult the specifications to understand the expected output levels. Proper preparation will facilitate a smoother testing process.

Conducting the Functionality Test

Begin the assessment by activating the device and observing its operation. Pay close attention to any unusual sounds or vibrations, which could indicate underlying problems. Monitor the output to confirm it aligns with the expected performance metrics. If discrepancies arise, further investigation may be necessary to pinpoint the source of the issue.

Documentation of Findings: Keep detailed records of your observations during the test. This information will be invaluable for troubleshooting and future reference. Regular testing and maintenance will ensure continued efficiency and reliability.

Maintenance Tips for Longevity

Ensuring the longevity of your equipment requires regular attention and care. By following a few simple maintenance practices, you can significantly extend the lifespan and performance of your machinery. This section outlines essential tips that will help keep your device in optimal condition, preventing unnecessary breakdowns and costly repairs.

Regular Inspections

Conducting frequent checks is vital. Look for signs of wear and tear, such as leaks or unusual noises. Addressing minor issues early can prevent major failures down the line. Ensure that all components are securely fastened and that there are no obstructions that could hinder operation.

Proper Cleaning and Lubrication

Cleaning your equipment regularly is crucial for maintaining its efficiency. Remove dust, debris, and any residue that may accumulate during use. Additionally, apply the appropriate lubricant to moving parts as recommended, ensuring smooth operation and reducing friction.

Troubleshooting Common Problems

Addressing issues that arise during operation is crucial for maintaining optimal functionality. Recognizing symptoms and understanding potential causes can significantly reduce downtime and enhance efficiency. This section outlines typical complications and provides insights into effective solutions.

One frequent challenge is inconsistent flow. This may stem from blockages or leaks within the system. Inspecting hoses and connections for any signs of wear or obstructions can often resolve this issue. Ensuring all components are securely fastened can also mitigate flow problems.

Noisy operation is another concern. Excessive sound may indicate an internal malfunction or misalignment. Checking for loose parts and ensuring that all components are properly aligned can help alleviate unwanted noise. Regular maintenance is key to preventing such disturbances.

In some instances, the equipment may fail to start. This can result from electrical issues or a drained power source. Verifying connections and ensuring that the unit is receiving adequate power are essential first steps. If the issue persists, consulting an expert may be necessary.

Lastly, overheating can occur, especially during prolonged use. Monitoring temperature levels and allowing for appropriate cooldown periods can prevent damage. Regularly cleaning filters and ensuring proper ventilation will also contribute to maintaining safe operating temperatures.

Safety Precautions During Repairs

When undertaking maintenance tasks on equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure a secure working environment and minimize risks associated with handling machinery and tools. Adhering to established guidelines can significantly enhance the overall safety of the procedure.

Personal Protective Equipment (PPE)

Always wear appropriate personal protective equipment to safeguard against potential hazards. This includes gloves to protect hands from chemicals or sharp edges, safety goggles to shield the eyes from debris, and ear protection to guard against excessive noise. Respirators may also be necessary if fumes or dust are present in the workspace.

Work Area Organization

Maintain a clean and organized work area to reduce the likelihood of accidents. Ensure that tools are neatly arranged and easily accessible, and remove any unnecessary items that may pose tripping hazards. Proper lighting is essential to enhance visibility and facilitate safe handling of components. Additionally, be aware of any potential electrical hazards and ensure that all equipment is disconnected from power sources before beginning any tasks.

When to Seek Professional Help

Understanding the limits of your expertise is crucial when dealing with mechanical systems. While many issues can be resolved independently, some situations require the intervention of a qualified technician. Recognizing the signs that indicate the need for professional assistance can save you time, money, and potential hazards.

Signs That Indicate Professional Assistance is Needed

| Indicator | Description |

|---|---|

| Unusual Noises | If you hear grinding, rattling, or other strange sounds, it may signal a serious problem. |

| Leaking Fluids | Fluid leaks can indicate component failure and should be addressed immediately to prevent further damage. |

| Persistent Malfunctions | Repeated issues that don’t resolve with basic troubleshooting suggest a deeper underlying problem. |

| Warning Lights | Dashboard alerts or indicators are a clear signal that professional assessment is necessary. |

Benefits of Professional Evaluation

Seeking expert assistance not only ensures safety but also enhances the longevity of your equipment. Professionals have the training and tools necessary to diagnose and address complex issues effectively. Additionally, they can provide valuable insights that may prevent future complications.

Resources for Further Assistance

When facing challenges with your equipment, having access to the right resources can make all the difference. This section aims to guide you towards valuable support options that can enhance your understanding and troubleshooting capabilities.

Online Forums: Engaging with communities dedicated to similar equipment can provide insights and practical solutions. These platforms often host discussions where users share their experiences and advice, making them a treasure trove of information.

Manufacturer’s Website: The official site often contains a wealth of resources, including FAQs, troubleshooting tips, and detailed guides that can help you address common issues effectively.

Video Tutorials: Visual aids can be particularly beneficial. Platforms like YouTube feature countless instructional videos that walk you through various processes step by step, helping you visualize the necessary actions.

Customer Support: Don’t hesitate to reach out directly to the manufacturer’s support team. They can provide tailored assistance, ensuring you receive guidance specific to your needs.

Local Technicians: If DIY approaches aren’t yielding results, consulting with a local expert can be invaluable. They bring hands-on experience and can often resolve issues more efficiently.

By utilizing these resources, you can enhance your troubleshooting skills and ensure your equipment operates smoothly for years to come.