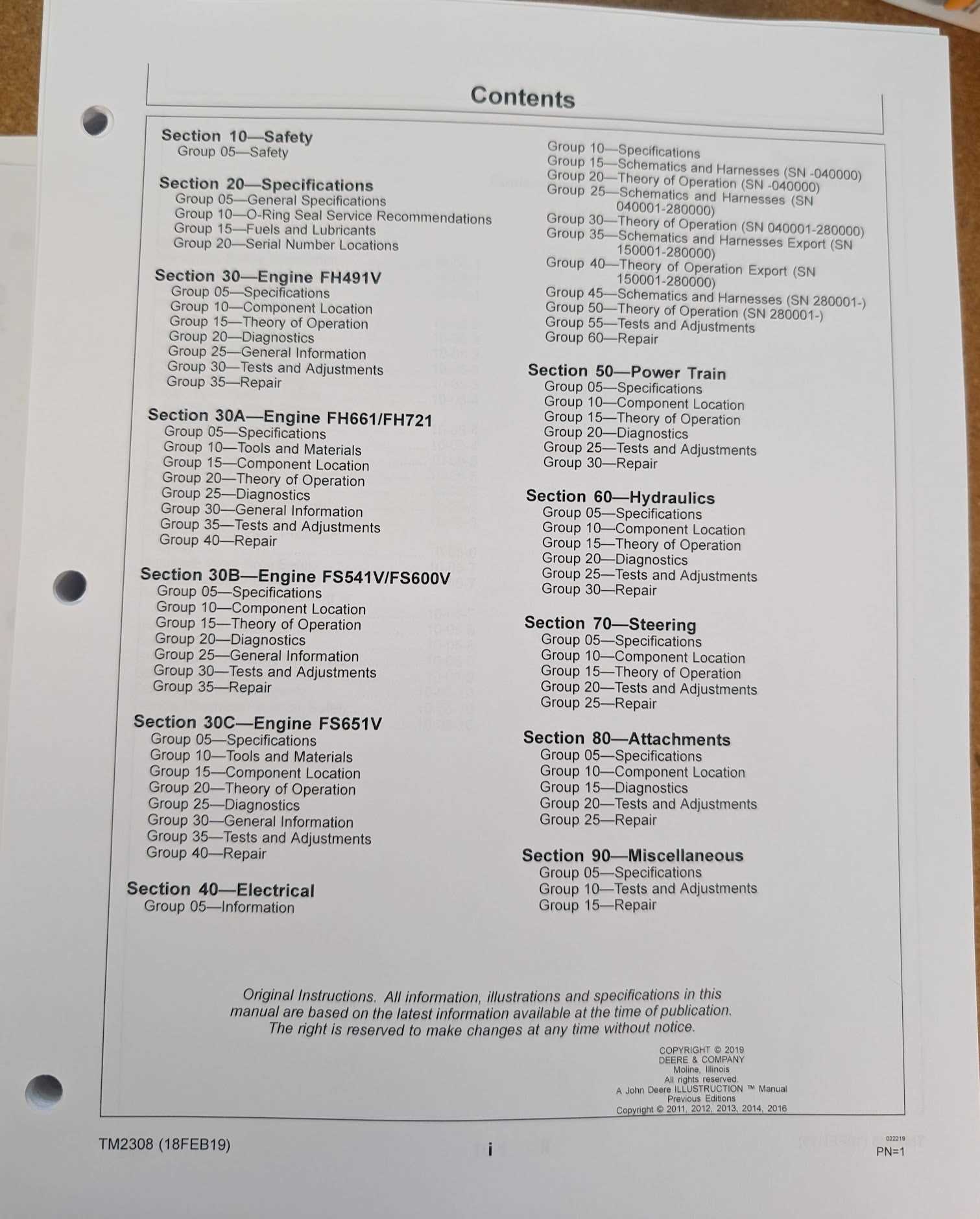

When it comes to maintaining outdoor machinery, understanding the intricacies of each component is essential for optimal performance. A well-structured resource can provide invaluable insights into common issues and solutions, ensuring that your equipment remains in peak condition for years to come.

This guide aims to equip users with the necessary knowledge to navigate the challenges of upkeep and repair. By delving into detailed procedures and offering troubleshooting tips, it empowers operators to address potential problems effectively, thereby enhancing longevity and efficiency.

Whether you’re a seasoned professional or a novice, having access to a thorough reference can streamline the maintenance process. From routine checks to more complex adjustments, mastering these skills can lead to significant savings and improved functionality of your beloved machinery.

Overview of John Deere X304

This section provides an insightful look into a popular model within the landscaping equipment category. Designed for efficiency and ease of use, this machine is well-regarded among enthusiasts and professionals alike. Its robust build and versatile features make it a reliable choice for various outdoor tasks.

Equipped with a powerful engine, the unit delivers exceptional performance, allowing users to tackle both small and large areas with ease. The cutting system is engineered to provide a clean and precise finish, ensuring that lawns are well-maintained. Moreover, the comfortable seating and user-friendly controls enhance the overall experience, making it suitable for extended periods of operation.

In addition to its operational capabilities, this model is compatible with a range of attachments, enabling users to expand its functionality. Whether for mowing, snow removal, or other tasks, the adaptability of this machine adds significant value, making it a smart investment for homeowners and professionals seeking reliability and performance.

Common Issues with X304 Models

Various challenges can arise when operating these popular riding machines. Understanding the most frequent problems can help owners maintain optimal performance and extend the lifespan of their equipment. Below are some of the typical concerns reported by users.

Engine Problems

- Starting Issues: Difficulty in starting the engine may be due to battery problems, faulty spark plugs, or issues with the ignition system.

- Overheating: Overheating can occur from inadequate coolant levels, blocked air intakes, or issues with the cooling system.

- Loss of Power: A decline in power may be caused by fuel delivery issues, clogged air filters, or worn-out components.

Transmission and Steering Concerns

- Shifting Difficulties: Problems with gear shifting can result from low fluid levels, damaged linkage, or worn clutches.

- Steering Issues: Poor steering response may be linked to worn tie rods, low hydraulic fluid, or damaged steering components.

- Noisy Operation: Unusual sounds during operation can indicate worn belts, loose parts, or misalignment within the drivetrain.

Essential Tools for Repairs

When it comes to maintaining and fixing equipment, having the right instruments at hand can significantly enhance the process. A well-equipped workspace not only streamlines tasks but also ensures that issues are addressed efficiently and effectively. Below is a selection of fundamental tools that every technician should consider for optimal performance and longevity of machinery.

Basic Hand Tools

Hand tools are the backbone of any maintenance routine. They provide versatility and ease of use for a variety of tasks. Here are some key hand tools to keep in your collection:

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening or tightening nuts and bolts. |

| Screwdrivers | Essential for driving screws and performing intricate adjustments. |

| Pliers | Great for gripping, twisting, and cutting wires. |

| Socket Set | Ideal for accessing hard-to-reach fasteners. |

Power Tools

In addition to hand tools, power tools can greatly expedite larger tasks. These instruments offer enhanced capabilities, making them invaluable for serious maintenance work. Consider including the following in your toolkit:

| Tool | Purpose |

|---|---|

| Drill | Used for making holes and driving screws quickly. |

| Angle Grinder | Effective for cutting and grinding metal components. |

| Impact Wrench | Provides high torque for loosening stubborn fasteners. |

| Rotary Tool | Versatile tool for sanding, polishing, and engraving. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. This guide provides a comprehensive approach to maintaining your machine, focusing on key areas that require attention to keep it running smoothly.

Follow these steps for effective maintenance:

- Inspect Fluid Levels:

- Check engine oil and replace if necessary.

- Verify the coolant level and top off if needed.

- Examine the hydraulic fluid and ensure it is within the recommended range.

- Clean Air Filters:

- Remove the air filter and inspect for dirt and debris.

- Clean or replace the filter according to the manufacturer’s guidelines.

- Examine the Battery:

- Check the battery terminals for corrosion and clean them if necessary.

- Test the battery charge and replace it if it is weak or old.

- Inspect Belts and Hoses:

- Look for signs of wear, cracks, or fraying on belts.

- Check hoses for leaks or damage and replace as needed.

- Sharpen Blades:

- Remove the blades and sharpen them to ensure a clean cut.

- Balance the blades after sharpening to prevent vibration.

- Clean the Exterior:

- Wash the exterior of the machine to remove dirt and debris.

- Inspect for any rust or paint damage and address it promptly.

Following this maintenance guide will help prolong the life of your machinery and enhance its performance. Regular checks and timely interventions are key to efficient operation.

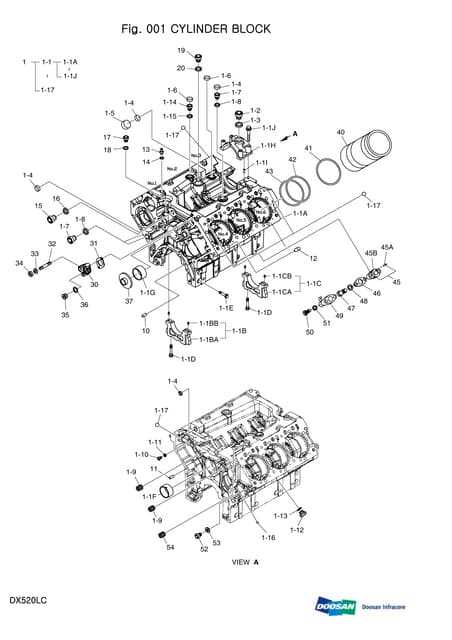

Understanding the Engine Components

Grasping the intricate elements of a power unit is essential for maintaining optimal performance and longevity. Each part plays a critical role, contributing to the overall functionality and efficiency of the machinery. A clear understanding of these components not only aids in troubleshooting but also enhances the ability to execute proper maintenance.

Key Parts of the Engine

The core of any power unit is the engine block, which houses various internal mechanisms. Within this structure, you will find cylinders where fuel combustion occurs, generating the energy needed for operation. Additionally, components such as pistons, connecting rods, and crankshafts work in concert to convert this energy into mechanical motion.

Fuel and Air Delivery Systems

Another vital aspect involves the systems responsible for delivering fuel and air to the engine. The carburetor or fuel injectors regulate the mixture, ensuring optimal combustion. Proper airflow is facilitated by the intake manifold, while exhaust systems remove combustion byproducts, maintaining efficiency and performance.

Understanding these elements provides a solid foundation for effective upkeep and problem resolution, ensuring the machinery operates smoothly over time.

Electrical System Troubleshooting Tips

Diagnosing issues within the electrical system of your equipment can often be a complex task, yet it is crucial for ensuring optimal performance. Understanding the common symptoms and following a systematic approach can simplify the troubleshooting process, helping you identify and resolve problems efficiently.

1. Check the Battery: A weak or dead battery is a frequent culprit for electrical failures. Start by inspecting the battery connections for corrosion and ensuring they are tight. Use a multimeter to measure the voltage; it should ideally read around 12.6 volts or more when fully charged.

2. Inspect Fuses: Blown fuses can interrupt the power supply to various components. Locate the fuse box and visually inspect each fuse. Replace any that are damaged or burnt out, and make sure to use the correct amperage rating.

3. Examine Wiring and Connectors: Damaged or frayed wiring can lead to short circuits or intermittent faults. Carefully inspect the wiring harness for any signs of wear or damage. Ensure that all connectors are securely attached and free of dirt or corrosion.

4. Test Electrical Components: If specific components, such as lights or starters, are malfunctioning, use a multimeter to check their functionality. This will help determine whether the issue lies within the component itself or elsewhere in the electrical circuit.

5. Review Ground Connections: Poor grounding can lead to a host of electrical issues. Ensure all ground connections are clean and secure. A solid ground is essential for the proper operation of electrical components.

6. Consult the Owner’s Guide: When in doubt, refer to the equipment’s owner’s guide for detailed information about the electrical system. This resource often includes wiring diagrams and troubleshooting steps specific to your model.

By following these troubleshooting tips, you can effectively identify and rectify electrical issues, ensuring your equipment operates smoothly and reliably.

Changing the Oil: A Simple Process

Regular maintenance of your equipment is essential for optimal performance and longevity. One crucial aspect of this upkeep is the oil change, which ensures that the engine runs smoothly and efficiently. This process can be straightforward and does not require extensive technical knowledge, making it accessible for anyone willing to invest a little time and effort.

To successfully complete an oil change, follow these simple steps:

| Step | Description |

|---|---|

| 1. Gather Supplies | Collect the necessary tools and materials, including new oil, an oil filter, a wrench, and a drain pan. |

| 2. Warm Up the Engine | Run the engine for a few minutes to warm up the oil, which helps it drain more easily. |

| 3. Drain the Old Oil | Position the drain pan under the oil pan and remove the drain plug to let the used oil flow out completely. |

| 4. Replace the Oil Filter | Remove the old filter using a wrench and install the new one, ensuring a proper seal. |

| 5. Add New Oil | Replace the drain plug and add fresh oil through the fill cap, checking the level with a dipstick. |

| 6. Dispose of Old Oil | Properly dispose of the used oil and filter at a recycling center or designated location. |

By following these steps, you can ensure that your equipment remains in excellent condition, enhancing its performance and extending its life. Regular oil changes will keep your engine running smoothly for years to come.

Deck and Blade Maintenance Strategies

Proper care of the cutting deck and blades is essential for achieving optimal performance and longevity of your mowing equipment. Regular maintenance ensures efficient grass cutting, reduces wear, and promotes a healthy lawn. Implementing effective strategies can help you maintain a well-functioning system.

Here are some key strategies to consider:

- Regular Cleaning: After each use, clean the underside of the deck to remove grass clippings, dirt, and debris. This prevents rust and ensures better airflow.

- Blade Inspection: Frequently check the blades for signs of wear or damage. Look for nicks, dull edges, or bends that can affect cutting performance.

- Sharpening Blades: Keep blades sharp for a clean cut. Sharpen them at least once per season or more often if cutting dense grass.

- Blade Replacement: If blades are excessively worn or damaged, replace them promptly. New blades improve efficiency and promote healthy grass growth.

- Deck Leveling: Ensure the deck is properly leveled for an even cut. An uneven deck can lead to scalping or uncut patches.

- Greasing Moving Parts: Regularly lubricate all moving parts of the deck to reduce friction and prevent wear.

By following these maintenance strategies, you can enhance the performance and durability of your mowing equipment, ensuring a pristine lawn and efficient operation.

Battery Care for Longevity

Proper maintenance of a power source is essential for ensuring its long lifespan and optimal performance. By following a few simple practices, you can extend the life of your battery, enhance its efficiency, and avoid unexpected failures.

Regular Inspection

Conduct frequent checks of your power source to identify any signs of wear or damage. Look for corrosion on terminals and ensure that connections are secure. Cleaning the terminals with a mixture of baking soda and water can prevent buildup that impedes performance.

Optimal Charging Practices

Always use the recommended charger to avoid overcharging or undercharging, which can shorten the lifespan. Avoid leaving the battery in a fully discharged state for prolonged periods, as this can lead to permanent damage. Additionally, try to maintain the charge level between 20% and 80% for best results.

Recognizing Signs of Wear

Understanding the indicators of deterioration is crucial for maintaining the longevity and efficiency of your equipment. Regular observation can help in identifying issues before they escalate, ensuring optimal performance and reducing the risk of unexpected breakdowns.

Visual Inspection: Start by examining the exterior for any visible signs of damage. Cracks, rust, or unusual wear patterns can signal that components may need attention. Pay special attention to areas that experience high friction or stress.

Unusual Noises: Listen carefully for any abnormal sounds while the machinery is in operation. Grinding, squeaking, or rattling noises may indicate that parts are not functioning properly and could require servicing or replacement.

Performance Changes: Notice any changes in performance, such as decreased power or efficiency. If the equipment struggles to perform tasks it once handled easily, it may be a sign that certain components are worn out and need to be addressed.

Vibration Levels: Increased vibrations during operation can point to imbalances or failing parts. Regularly monitor these levels, as excessive vibration can lead to further damage if left unchecked.

By being vigilant and recognizing these signs of wear early on, you can take proactive steps to maintain your equipment, ensuring it remains reliable and effective for years to come.

Seasonal Storage Recommendations

Proper preparation for seasonal storage is essential to ensure the longevity and optimal performance of your outdoor equipment. Taking the time to follow specific guidelines can help protect your machinery from the elements and prevent potential issues during the next use. This section outlines important practices to consider before putting your equipment away for an extended period.

Cleaning and Maintenance

Before storing, thoroughly clean the machinery to remove dirt, grass, and debris. This step prevents rust and damage over time. Inspect all components for wear or damage and perform necessary maintenance, such as changing the oil and replacing filters. A well-maintained unit is less likely to suffer from complications during the next season.

Proper Storage Conditions

Choose a dry, sheltered location to store your equipment. Exposure to moisture and extreme temperatures can lead to deterioration. If possible, elevate the machinery off the ground to avoid contact with damp surfaces. Additionally, consider using a protective cover to shield it from dust and other environmental factors. Regularly check the stored equipment to ensure it remains in good condition throughout the off-season.

Upgrades and Performance Enhancements

Improving the efficiency and capabilities of your outdoor machinery can lead to a more productive experience and longer lifespan. By focusing on various enhancements, users can achieve better functionality, increased power, and a more comfortable operation. Below are some suggested upgrades that can significantly elevate the performance of your equipment.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Tuning | Adjusting the engine settings to optimize fuel usage and power output. | Improved efficiency and acceleration. |

| Enhanced Air Filter | Installing a high-performance air filter to improve airflow. | Better engine performance and reduced wear. |

| Upgraded Tires | Choosing tires designed for specific terrains to enhance grip and stability. | Increased traction and handling. |

| LED Lighting | Replacing standard lights with LED options for brighter and more efficient lighting. | Enhanced visibility and lower energy consumption. |

| Comfort Seat | Installing an ergonomic seat to improve operator comfort during long tasks. | Reduced fatigue and improved productivity. |

By implementing these upgrades, users can unlock the full potential of their equipment, making tasks easier and more efficient. Each enhancement contributes to a more enjoyable and effective working experience.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often seem daunting, but with the right strategies, the process can become significantly smoother. Whether you are seeking a specific item or looking to upgrade, understanding where to look and how to navigate options is crucial.

Online Resources

The internet is a treasure trove of information and options for sourcing parts. Here are some effective methods to explore:

- Official Websites: Manufacturers typically provide a list of authorized dealers and part catalogs.

- E-commerce Platforms: Websites like Amazon and eBay often have a wide range of options, including both new and used components.

- Specialty Stores: Many online retailers specialize in specific types of equipment, offering tailored selections and expertise.

Local Options

While online shopping is convenient, don’t overlook local resources. They can provide immediate solutions and personalized service:

- Local Dealers: Authorized dealers often have a stock of genuine parts and can assist with compatibility questions.

- Auto Parts Stores: Many general auto parts retailers carry components suitable for a range of equipment.

- Salvage Yards: These can be a cost-effective source for used parts that are still in good condition.

By utilizing a combination of online and local resources, you can streamline the process of finding the right components for your equipment, ensuring you keep it running smoothly and efficiently.