The proper upkeep of outdoor machinery is essential for ensuring efficient performance and longevity. Understanding the intricacies of these devices allows users to tackle common issues and implement effective solutions, enhancing reliability during harsh weather conditions.

In this section, we will explore various aspects of maintaining your equipment. From diagnosing frequent complications to conducting routine assessments, this resource aims to empower users with the knowledge needed for successful management. Mastering these skills will not only improve functionality but also save time and resources in the long run.

Equipping yourself with the right techniques and insights can transform your experience, making it more enjoyable and less daunting. With a focus on practical advice and troubleshooting strategies, you will be well-prepared to handle challenges as they arise, ensuring that your machinery remains in top condition.

Essential Tools for Snow Thrower Maintenance

Proper upkeep of your equipment is crucial for optimal performance and longevity. Having the right implements on hand can make a significant difference in ensuring that all components function smoothly and efficiently. This section outlines the key tools needed to keep your machine in peak condition throughout the winter season.

Firstly, a set of basic hand tools, including wrenches and screwdrivers, is essential for performing routine adjustments and minor fixes. Additionally, oil and grease for lubrication are necessary to prevent wear and tear on moving parts. A sturdy brush is also useful for clearing debris that can hinder operation.

For more in-depth maintenance, consider investing in a torque wrench to ensure that all fasteners are tightened to the manufacturer’s specifications. A diagnostic tool can help identify any issues with performance, providing valuable insights into necessary repairs. Finally, safety gear such as gloves and goggles should always be used to protect yourself while working on your equipment.

Common Issues and Troubleshooting Steps

This section addresses frequent problems encountered during operation and provides effective solutions. Understanding these challenges can enhance the user experience and prolong equipment longevity.

-

Insufficient Clearing:

If the unit fails to clear effectively, consider the following:

- Check for blockages in the chute or auger.

- Inspect the blade for damage or wear.

- Ensure the correct speed settings are applied.

-

Starting Issues:

Difficulty starting the machine can stem from various factors:

- Examine the fuel level and quality.

- Inspect the spark plug for fouling or wear.

- Ensure all safety features are engaged properly.

-

Strange Noises:

Unusual sounds may indicate underlying problems:

- Listen for grinding or rattling, which could suggest loose parts.

- Check for foreign objects caught in the mechanism.

- Assess the belt tension and condition for wear.

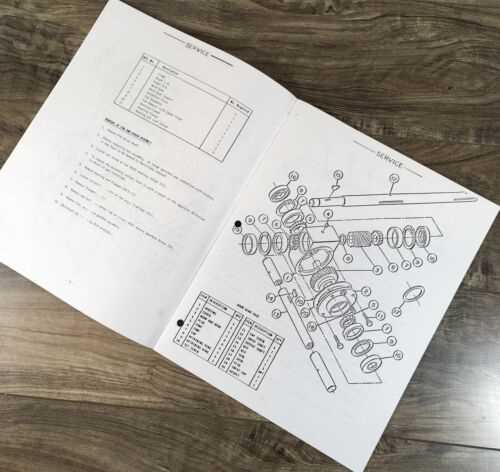

How to Replace the Auger Belt

Changing the belt that drives the rotating mechanism is an essential task for maintaining optimal performance. This process ensures that the unit operates smoothly and effectively, allowing for better handling of the material being processed. Understanding the steps involved will make this maintenance easier and more efficient.

Begin by disconnecting the power source to ensure safety. Once secured, tilt the unit back to access the underside. Locate the belt cover, which is typically held in place by screws or clips. Remove these fasteners and take off the cover to expose the belt system.

Next, examine the condition of the existing belt. If it shows signs of wear, stretching, or damage, it will need to be replaced. To remove the old belt, carefully detach it from the pulleys, taking note of its routing. This will help you install the new one correctly.

Afterward, take the new belt and position it over the pulleys following the routing you observed earlier. Ensure it fits snugly and is properly aligned with the grooves. Once in place, reattach the belt cover, securing it with the screws or clips you previously removed.

Finally, lower the unit back to its original position and reconnect the power. Test the operation to ensure everything functions correctly. Regular maintenance of this component will prolong the life of your equipment and enhance its efficiency.

Understanding Engine Components and Functions

The core of any mechanical device relies on various parts working in harmony to achieve efficient performance. Each component plays a vital role in the overall operation, contributing to the smooth functioning of the system. A thorough understanding of these elements is essential for effective troubleshooting and maintenance.

Power Unit: This is the primary source of energy, converting fuel into mechanical motion. Its efficiency directly affects the performance of the entire apparatus.

Ignition System: Responsible for starting the process, this system ignites the fuel-air mixture, enabling combustion. Proper functioning is crucial for reliable operation.

Fuel Delivery Mechanism: This system ensures a steady flow of fuel to the combustion chamber. Any disruption can lead to performance issues, emphasizing the need for regular checks.

Exhaust System: After combustion, the byproducts must be expelled efficiently. A well-designed exhaust system minimizes harmful emissions and maximizes performance.

Cooling System: Maintaining optimal temperature is vital. This system prevents overheating, ensuring the engine runs smoothly and prolonging its lifespan.

By grasping the roles and interactions of these components, users can better maintain and optimize the machinery, ensuring longevity and peak performance.

Winter Preparation and Storage Tips

Preparing your outdoor equipment for the cold months is essential to ensure its longevity and performance. Proper care and storage can prevent damage and facilitate easy operation when needed. Here are some important considerations to keep in mind.

- Clean the machine thoroughly to remove any debris or residue that could cause corrosion.

- Check all moving parts for wear and tear, replacing any damaged components as necessary.

- Ensure the fuel system is properly maintained, including using fuel stabilizers to prevent degradation.

- Store the equipment in a dry, sheltered location to protect it from harsh weather conditions.

Additionally, consider the following tips:

- Run the engine for a few minutes before storing to circulate fluids and prevent moisture buildup.

- Disconnect the battery if applicable, and store it in a cool, dry place to prolong its life.

- Inspect and replace any worn-out cables or belts to avoid future issues.

- Label all components and tools for easy access when you’re ready to use them again.

By taking these steps, you can ensure that your equipment remains in excellent condition and is ready for action when the season calls for it.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring a secure environment is paramount. Adhering to specific guidelines minimizes risks and promotes efficiency, ultimately safeguarding both the individual and the equipment. Awareness of potential hazards is crucial in preventing accidents and ensuring a successful outcome.

Personal Protective Equipment

Utilizing appropriate personal protective gear is essential. This includes gloves, goggles, and sturdy footwear to shield against sharp edges and flying debris. Ensuring that the workspace is clear of obstacles also helps in maintaining focus and avoiding slips or falls.

Proper Tool Handling

Using tools correctly and keeping them in good condition is vital. Familiarity with each tool’s function enhances safety and effectiveness. Regular inspections and maintenance of tools can prevent malfunctions, further reducing the likelihood of injury during operations.

Regular Maintenance Schedule for Longevity

Establishing a consistent upkeep routine is essential for ensuring optimal performance and extending the lifespan of your equipment. By adhering to a well-defined schedule, users can prevent unexpected failures and maintain efficiency throughout the operating season.

Daily Checks

Before each use, perform a brief assessment of the machinery. Inspect for any visible damage, ensuring that all components are secure and functioning correctly. Pay attention to the condition of belts and cables, as well as fluid levels. Addressing minor issues promptly can avert more significant problems later.

Seasonal Maintenance

At the start and end of the operational period, conduct a comprehensive inspection. This includes changing lubricants, replacing filters, and cleaning any accumulated debris. Following these seasonal protocols not only enhances performance but also prepares the equipment for optimal operation in varying conditions.

Adjusting Skid Shoes for Optimal Performance

Achieving peak efficiency in your outdoor clearing equipment involves fine-tuning various components, particularly those that make contact with the ground. Properly setting the distance and angle of these components can greatly enhance functionality and prolong the lifespan of your machinery.

To ensure optimal operation, follow these guidelines for adjusting the aforementioned components:

| Adjustment Step | Description |

|---|---|

| 1. Inspect Condition | Check for wear and tear. Replace if damaged to maintain effectiveness. |

| 2. Set Height | Adjust the height to achieve the desired clearance based on surface conditions. |

| 3. Level Alignment | Ensure that the components are level to provide uniform operation across different terrains. |

| 4. Tighten Fasteners | Secure all fasteners to prevent movement during use, which can affect performance. |

By following these steps, you can enhance the functionality of your equipment and ensure it operates smoothly, making your outdoor tasks more manageable.

How to Change Spark Plugs

Maintaining optimal performance in outdoor machinery often involves periodic component replacements. One critical element that requires attention is the ignition element, which ensures efficient operation. Replacing this part can lead to enhanced functionality and fuel efficiency.

Follow these steps to successfully complete the replacement:

| Step | Description |

|---|---|

| 1 | Ensure the engine is off and cool before beginning work to avoid burns or other injuries. |

| 2 | Remove the engine cover if applicable, allowing access to the ignition element. |

| 3 | Carefully disconnect the ignition wire from the existing component, taking care not to damage any connections. |

| 4 | Utilize the appropriate tool to unscrew the old element from its socket. |

| 5 | Install the new part by screwing it into place, ensuring a snug fit without overtightening. |

| 6 | Reconnect the ignition wire, ensuring a secure connection to facilitate proper operation. |

| 7 | Replace the engine cover if removed, and perform a test to verify the new component is functioning correctly. |

Regularly checking and replacing this vital part will contribute to the longevity and effectiveness of your equipment.

Recognizing Electrical System Problems

Identifying issues within the electrical framework of your equipment is essential for maintaining its functionality. Various symptoms can indicate underlying faults, ranging from minor glitches to significant malfunctions. By understanding these signs, you can take appropriate measures to ensure optimal performance and longevity.

Common Symptoms of Electrical Issues

Look for these prevalent indicators that may suggest electrical complications:

| Indicator | Description |

|---|---|

| Inconsistent Operation | Frequent interruptions or unexpected behavior during use can signify electrical anomalies. |

| Unusual Sounds | Humming or buzzing noises may indicate a problem within the electrical components. |

| Burning Smell | A noticeable odor could suggest overheating or damaged wiring. |

| Dim or Flickering Lights | Inconsistent lighting may point to voltage irregularities. |

Steps to Diagnose Issues

To effectively address potential faults, follow these diagnostic steps:

- Inspect all connections for signs of corrosion or loose wiring.

- Test the voltage levels with a multimeter to ensure they are within acceptable ranges.

- Examine fuses and circuit breakers for any signs of tripping or damage.

Benefits of Using Quality Replacement Parts

Utilizing high-grade components during maintenance enhances the overall performance and longevity of equipment. Opting for premium alternatives not only ensures reliability but also minimizes the risk of future issues.

One of the most significant advantages is the assurance of compatibility and fit. Quality parts are designed to meet or exceed the original specifications, promoting optimal functionality.

| Advantage | Description |

|---|---|

| Durability | High-quality components typically last longer, reducing the frequency of replacements. |

| Performance | Premium parts contribute to smoother operation and enhanced efficiency. |

| Safety | Reliable components help prevent accidents and malfunctions. |

| Warranty | Many quality parts come with warranties, providing added peace of mind. |

Cleaning and Inspecting the Chassis

Maintaining the structural integrity of your equipment is crucial for optimal performance and longevity. Regular examination and cleanliness of the outer frame can prevent issues and enhance functionality.

Begin with a thorough cleaning process to eliminate debris and contaminants. This ensures that all components function smoothly and reduces wear over time.

- Gather necessary tools: brushes, cloths, and appropriate cleaning agents.

- Disconnect any power sources for safety.

- Remove loose dirt and grime with a soft brush.

After cleaning, it’s essential to inspect the chassis for any signs of damage or wear. Look for:

- Cracks or bends in the frame that may affect stability.

- Rust or corrosion that could compromise material strength.

- Loose bolts or screws that may need tightening.

Addressing these issues promptly will help ensure reliable operation during use. Regular upkeep of the structure not only extends its lifespan but also enhances overall performance.