In the realm of photographic equipment, accurate light measurement is crucial for capturing the perfect shot. When these sophisticated instruments encounter issues, understanding their intricacies can make all the difference in bringing them back to optimal functionality. This section provides insights into the common problems faced by users and offers a pathway to effective solutions.

Whether you’re an avid enthusiast or a professional, having the ability to troubleshoot and restore your light evaluation tool is invaluable. This guide delves into the essential steps and techniques that will empower you to diagnose faults and implement necessary adjustments. With a little patience and the right approach, you can breathe new life into your cherished device.

Emphasizing clarity and accessibility, the following content will equip you with the knowledge needed to tackle repairs confidently. From understanding the basic components to executing repairs, each section aims to simplify the process and enhance your understanding of the device’s operation.

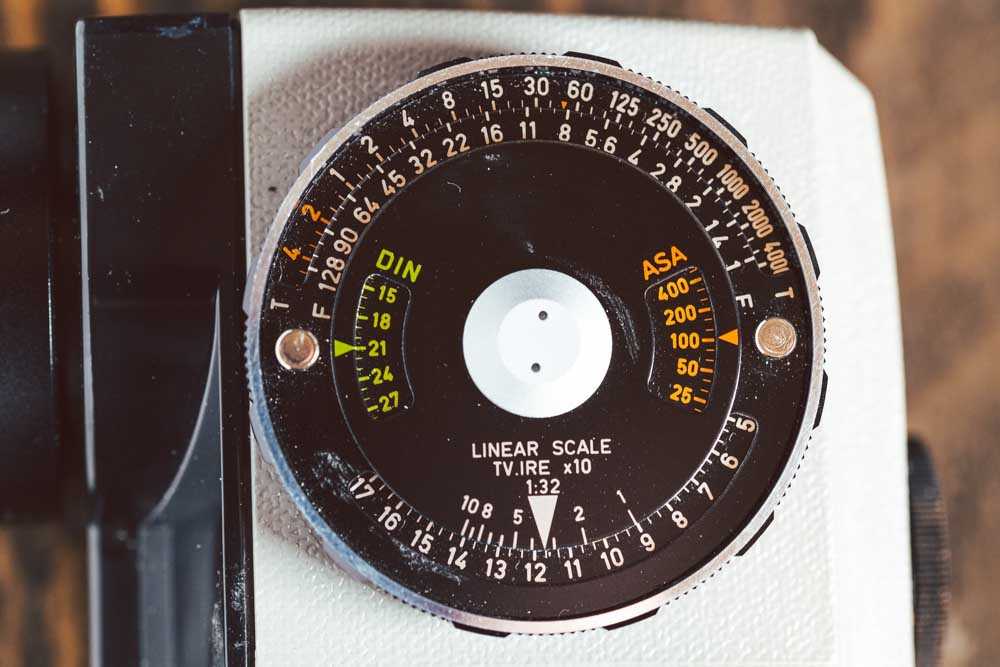

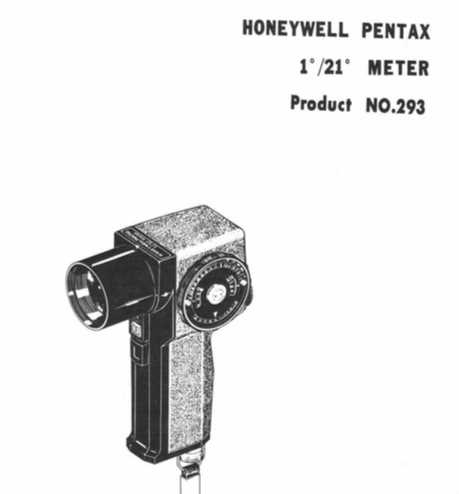

Overview of the Light Measurement Device

This section provides a comprehensive look at a compact and efficient tool designed for precise light measurement. Renowned for its accuracy and ease of use, this device is favored by photographers and professionals alike. Understanding its features and functionality is essential for maximizing its potential in various settings.

Key Features

- High precision in measuring ambient light.

- Compact design, ideal for portability.

- Easy-to-read display for quick assessments.

- Multiple measurement modes for versatility.

- Durable construction suitable for field use.

Applications

- Photography: Ensures optimal exposure settings.

- Film Production: Aids in achieving desired lighting conditions.

- Architectural Projects: Evaluates lighting for interior spaces.

- Art Installations: Measures light to enhance visual effects.

Common Issues with the Spotmeter

Measuring light accurately is crucial for photographers, but various challenges can arise with light metering devices. Understanding these common complications can help users diagnose problems and maintain optimal functionality.

Calibration Problems

One prevalent issue is the device becoming uncalibrated over time. This can lead to inaccurate readings, affecting exposure settings. Regular checks and adjustments are essential to ensure that the measurements reflect true light levels. Users should consult the specifications for calibration techniques specific to their model.

Battery and Power Issues

Another frequent concern involves the power source. Weak or depleted batteries can cause the unit to malfunction, leading to inconsistent readings. It is advisable to use high-quality batteries and replace them regularly. Additionally, checking for corrosion in battery compartments can prevent further complications.

Tools Needed for Repair

When undertaking the restoration of precision instruments, having the right equipment is essential for ensuring success. The following list highlights the necessary implements that facilitate the troubleshooting and maintenance of these delicate devices.

Essential Equipment

To effectively address issues, the following tools are indispensable:

- Multimeter – Used for measuring voltage, current, and resistance to diagnose electrical faults.

- Screwdrivers – A set of precision screwdrivers is crucial for accessing internal components.

- Tweezers – Fine tweezers help in handling small parts without causing damage.

- Cleaning Kit – Includes brushes and cloths for maintaining lens clarity and component cleanliness.

Additional Supplies

In addition to the basic tools, consider the following supplies:

- Soldering Iron – Necessary for repairing electrical connections.

- Adhesives – A variety of glues for securing components when needed.

- Protective Gear – Safety glasses and gloves to ensure personal protection during the process.

Equipping yourself with these tools will enhance your ability to effectively maintain and restore functionality to precision instruments.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a specific measurement device. Following these steps carefully will ensure that you can access the internal components without causing damage, allowing for effective troubleshooting or modification. Ensure that you have the necessary tools at hand before beginning the process.

Tools Required

Before starting the disassembly, gather the following items:

- Screwdriver Set – A precision set with various sizes.

- Plastic Pry Tools – To avoid damaging the casing.

- Tweezers – For handling small components.

- Magnetic Tray – To keep screws organized.

Disassembly Steps

1. Power Off: Ensure the device is completely powered down and disconnected from any power sources.

2. Remove External Components: Begin by detaching any removable parts, such as the battery compartment and external covers. Use the appropriate screwdriver for screws.

3. Open the Housing: Carefully insert a plastic pry tool into the seams of the housing. Gently work your way around to release clips without damaging the surface.

4. Unscrew Internal Fasteners: Locate and remove any screws securing the internal assembly. Keep them in a magnetic tray to avoid loss.

5. Detach Internal Components: Gently lift out components, ensuring you note the placement of each part for reassembly.

By following these instructions, you will be able to access the internal elements safely and efficiently, paving the way for any further adjustments or examinations you wish to perform.

Replacing the Battery

Maintaining optimal performance of your light-measuring device requires occasional battery replacement. Ensuring a fresh power source will enhance accuracy and prolong the life of the instrument. This section outlines the steps necessary to safely and effectively replace the power unit.

Step-by-Step Guide

Begin by locating the battery compartment, usually found on the base or side of the device. Use a small screwdriver to gently remove the cover, taking care not to damage any surrounding components. Once the cover is off, carefully extract the old battery, noting its orientation for proper installation of the new one.

Installing the New Power Source

Insert the new battery in the same orientation as the previous one, ensuring a snug fit. After securing the battery, replace the compartment cover and tighten the screws lightly to avoid stripping. Finally, test the device to confirm that it powers on and functions correctly, ensuring your equipment is ready for use.

Calibrating the Meter After Repair

Ensuring precise functionality after servicing is crucial for optimal performance. Calibration involves adjusting the device to guarantee accurate readings, allowing for reliable exposure settings. This process is essential to maintain the integrity of measurements taken in various lighting conditions.

Steps for Accurate Calibration

Begin by using a known reference light source to test the accuracy of the readings. Set the meter to a standard exposure value and compare the results with those obtained from the reference. Adjust the settings accordingly to align the meter’s output with the known values.

Final Checks and Adjustments

Once the initial calibration is complete, perform a series of tests across different lighting environments. Take readings in both bright and dim conditions to ensure consistency. If discrepancies arise, further adjustments may be necessary. Regular checks and recalibrations are recommended to maintain accuracy over time.

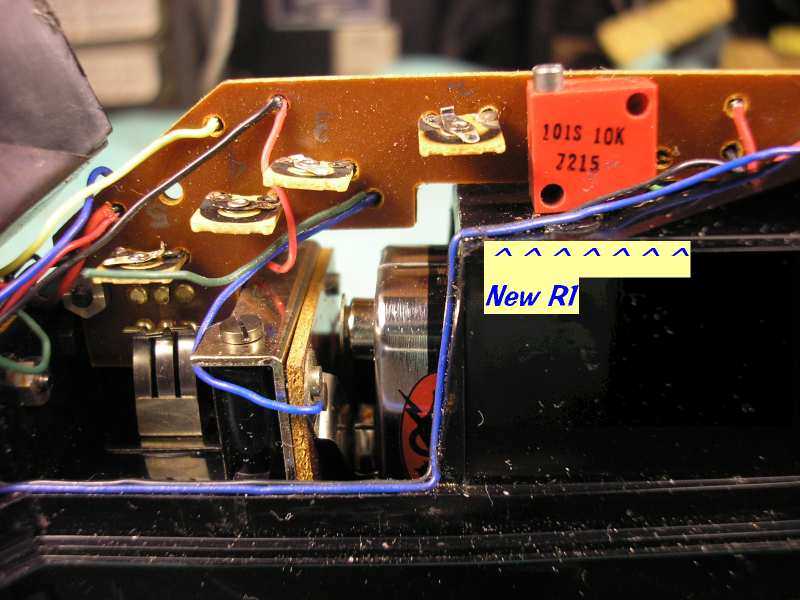

Fixing Electrical Malfunctions

Electrical issues can significantly hinder the performance of precision instruments. Understanding the common problems and their solutions is essential for restoring functionality. This section will provide insights into diagnosing and resolving these challenges effectively.

Identifying Symptoms is the first step in addressing any electrical malfunction. Users should look for signs such as erratic readings, unresponsive buttons, or unusual noises. These indicators often suggest underlying issues that need attention.

Once symptoms are noted, troubleshooting becomes critical. Start by checking power sources and connections. Ensure that batteries are correctly installed and functional. Loose or corroded contacts can also lead to inconsistent performance. Cleaning these connections may resolve the issue.

If basic checks do not yield results, component examination is necessary. Look for damaged circuits or burnt components. Utilizing a multimeter can help test continuity and voltage levels, identifying faulty parts that require replacement.

In cases of persistent problems, consulting documentation or technical resources can provide valuable guidance. Schematics and diagrams can clarify complex systems, aiding in pinpointing specific failures.

Finally, preventive measures are essential to maintain optimal performance. Regular maintenance, such as cleaning and checking components, can minimize the risk of future electrical malfunctions. Being proactive ensures longevity and reliability of the device.

Maintaining Your Spotmeter

Regular upkeep of your light measurement device is essential for ensuring its longevity and accuracy. By following a few simple practices, you can keep your equipment in top condition, allowing for consistent performance during your photographic endeavors.

Cleaning is a fundamental aspect of maintenance. Gently wipe the exterior with a soft, lint-free cloth to remove dust and fingerprints. For the lens, use a dedicated lens cleaner and a microfiber cloth to avoid scratches. Regularly inspecting the lens for any debris can prevent issues with light readings.

Another crucial element is battery care. Always check battery levels before use, and replace them promptly when they begin to weaken. Storing your device with fresh batteries can prevent corrosion and potential damage. Additionally, consider removing batteries during long periods of inactivity.

Calibration should be performed periodically to ensure precise measurements. If you notice inconsistencies in readings, consult a professional for calibration services. Keeping a record of calibration dates can help track when adjustments are needed.

Finally, storage plays a significant role in maintaining your equipment. Store it in a cool, dry place, away from direct sunlight and extreme temperatures. Utilizing a protective case can also shield it from physical damage during transport.

Understanding the Circuit Board

The circuit board serves as the heart of any electronic device, playing a crucial role in connecting various components to ensure optimal functionality. This intricate layer of pathways and connections facilitates the flow of electricity, allowing signals to travel seamlessly throughout the system.

Components such as resistors, capacitors, and transistors are arranged meticulously on the board, each serving a specific purpose. The arrangement and quality of these elements significantly impact the overall performance and reliability of the device.

Maintenance of the circuit board is essential for longevity. Regular checks can prevent issues such as corrosion or broken connections, which might lead to malfunction. Understanding the layout and function of each component is vital for anyone looking to troubleshoot or enhance the performance of their device.

Troubleshooting Exposure Problems

When working with exposure measurement devices, it’s essential to identify and resolve issues that may lead to inaccurate readings. Understanding common problems and their solutions can significantly improve your photography experience. This section provides guidance on how to troubleshoot typical exposure-related challenges effectively.

Common exposure issues can stem from various sources, including device malfunctions, incorrect settings, or environmental factors. The following table outlines potential problems, their causes, and recommended solutions:

| Problem | Possible Causes | Suggested Solutions |

|---|---|---|

| Inconsistent Readings | Device calibration issues, battery depletion | Recalibrate the device, replace the battery |

| Overexposure | Improper incident angle, too much ambient light | Adjust the angle of measurement, use a diffuser |

| Underexposure | Incorrect ISO settings, low light conditions | Verify ISO settings, consider using a longer exposure time |

| Fluctuating Readings | Wind interference, unstable surfaces | Stabilize the device, shield from wind |

By systematically addressing these issues, you can ensure more reliable exposure assessments and enhance the quality of your photographic work.

Finding Replacement Parts Online

Locating components for your equipment can be a daunting task, especially when it comes to vintage or specialized devices. However, the internet provides a wealth of resources that can help you find the necessary items to restore functionality. This section outlines effective strategies to source these essential parts online.

Begin by utilizing dedicated marketplaces and auction sites that specialize in photography gear and accessories. These platforms often feature listings from both individual sellers and retailers, giving you a broad selection to choose from.

| Website | Description |

|---|---|

| eBay | A global auction site where you can find a variety of used and new components. |

| Amazon | An extensive marketplace with numerous sellers offering replacement parts for various devices. |

| KEH | A retailer specializing in second-hand photography equipment, known for their quality and reliability. |

| Fred Miranda | A community forum and marketplace where enthusiasts buy and sell gear, including parts. |

| Craigslist | A classified ads website where local sellers may list parts or equipment for sale. |

In addition to these platforms, consider joining online communities and forums focused on photography. Members often share leads on where to find rare components and may even sell items directly. Engaging with enthusiasts can enhance your search and provide valuable insights.

Lastly, don’t overlook specialized retailers and manufacturers who may still carry the components you need. Checking their official websites or contacting them directly can yield fruitful results. By exploring these avenues, you can successfully track down the parts essential for your project.