Maintaining a heavy-duty vehicle is crucial for ensuring optimal performance and longevity. This guide offers essential insights into the upkeep and troubleshooting of a robust pickup, focusing on critical systems and components. From engine care to electrical systems, every aspect plays a vital role in the overall functionality of your vehicle.

In the world of automotive craftsmanship, understanding the intricacies of your truck can save both time and money. Detailed knowledge empowers owners to diagnose issues early, perform routine checks, and carry out necessary enhancements. By following a systematic approach, one can ensure that the vehicle remains reliable and efficient throughout its service life.

With a plethora of information available, it can be overwhelming to navigate through various sources. This resource simplifies the process, providing a structured overview and practical advice. Whether you are a seasoned mechanic or a first-time owner, this compilation aims to assist you in maintaining your vehicle with confidence and ease.

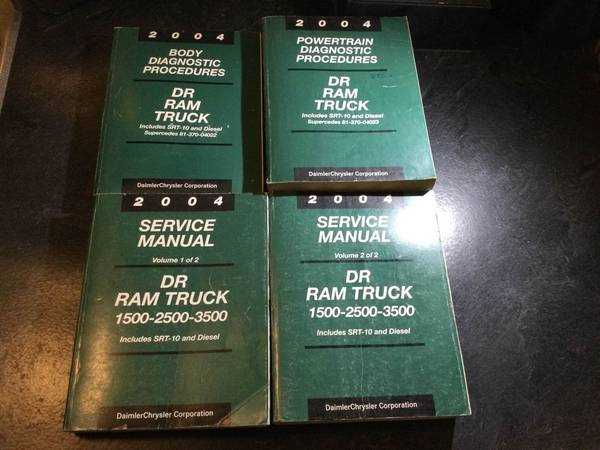

Overview of the 2004 Dodge Ram 3500

This section provides a comprehensive look at a robust vehicle known for its durability and performance. Designed to handle demanding tasks, it combines powerful engineering with a comfortable driving experience. Ideal for both work and leisure, it stands out in its class for versatility and reliability.

The combination of functionality and style makes it a favored choice among those who require a dependable transport solution. Whether navigating rugged terrain or cruising on highways, it delivers an exceptional performance that meets various needs.

Common Issues and Solutions

This section addresses frequent challenges encountered with heavy-duty trucks, along with practical solutions to enhance performance and reliability. Identifying and resolving these issues can significantly improve the lifespan and functionality of the vehicle.

-

Electrical Problems:

Issues with wiring and connections can lead to various malfunctions. Regularly inspect the battery, fuses, and connectors for corrosion or damage.

- Clean corrosion from battery terminals.

- Replace any blown fuses.

- Ensure all connections are tight and free from rust.

-

Transmission Difficulties:

Shifting problems may arise due to low fluid levels or worn components. Regular maintenance is key to preventing these issues.

- Check fluid levels and top up as necessary.

- Inspect the transmission filter and replace if clogged.

- Consult a professional if slipping persists.

-

Engine Performance:

Declines in engine efficiency can be linked to fuel system issues or air intake blockages. Routine checks are essential.

- Replace the air filter regularly.

- Ensure fuel injectors are clean and functioning.

- Monitor for any unusual sounds or vibrations.

-

Brake Concerns:

Brake performance is crucial for safety. Worn pads or discs can lead to decreased stopping power.

- Inspect brake pads for wear and replace as needed.

- Check brake fluid levels and top up if low.

- Test brakes periodically for responsiveness.

lessCopy code

By proactively addressing these common challenges, owners can ensure their heavy-duty vehicles remain in optimal condition, thus avoiding more significant repairs and ensuring safer driving experiences.

Essential Tools for Repairs

When tackling automotive maintenance, having the right instruments is crucial for achieving efficient and effective outcomes. Proper tools not only facilitate the work process but also ensure safety and precision. This section highlights the fundamental instruments necessary for successful vehicle servicing.

Basic Hand Tools

- Wrenches: A variety of sizes is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips head screwdrivers are needed for various tasks.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Sets: These allow for quick changes and adjustments, especially in tight spaces.

Specialized Instruments

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Diagnostic Scanner: Helps identify issues by reading error codes from the vehicle’s computer.

- Jack and Jack Stands: Vital for safely lifting and supporting the vehicle during maintenance.

- Oil Filter Wrench: Facilitates the easy removal of the oil filter during oil changes.

Equipping yourself with these essential tools will empower you to perform a wide range of automotive tasks with confidence and ease.

Maintenance Tips for Longevity

Ensuring the enduring performance of your vehicle requires a proactive approach to upkeep. By implementing routine care and attention, you can significantly enhance the lifespan and reliability of your machinery.

Regular Inspections: Conducting frequent checks on essential components, such as the engine, brakes, and suspension, helps identify potential issues before they escalate. Look for signs of wear and tear, and address any abnormalities promptly.

Fluid Maintenance: Keeping all fluids at optimal levels is crucial. Regularly inspect and replace engine oil, transmission fluid, coolant, and brake fluid as recommended. This not only ensures smooth operation but also prevents serious damage.

Tire Care: Maintain proper tire pressure and tread depth to enhance safety and fuel efficiency. Rotate tires regularly to promote even wear, and replace them when necessary to ensure optimal handling.

Battery Health: Regularly check battery terminals for corrosion and ensure connections are secure. Clean or replace the battery as needed to avoid starting issues and electrical malfunctions.

Cleaning and Protection: Regular washing and waxing protect your vehicle’s exterior from rust and corrosion. Interior care is equally important; vacuuming and using protective sprays can prolong the life of upholstery and surfaces.

Driving Habits: Adopt smooth driving practices, such as gradual acceleration and braking, to reduce stress on components. Avoid overloading the vehicle and adhere to weight limits to enhance performance and safety.

By following these guidelines, you can significantly extend the life of your vehicle, ensuring it remains reliable and efficient for years to come.

Understanding the Engine Specifications

When exploring the intricacies of a heavy-duty vehicle’s powertrain, it is essential to grasp the fundamental characteristics that define its performance and efficiency. These specifications serve as a blueprint for understanding how the engine operates, its capabilities, and how it meets the demands of various tasks. A clear comprehension of these aspects enables enthusiasts and owners alike to optimize maintenance and troubleshooting efforts.

Key Engine Attributes

Each engine comprises several critical components, including displacement, horsepower, and torque. Displacement refers to the total volume of all the cylinders, directly influencing the power output. Horsepower is a measure of the engine’s ability to perform work, while torque reflects the rotational force available, which is crucial for towing and heavy lifting. Understanding these parameters helps users determine the suitability of the engine for specific applications.

Performance Metrics

In addition to basic specifications, performance metrics such as fuel efficiency, emissions ratings, and acceleration figures are vital. Fuel efficiency indicates how effectively the engine converts fuel into power, impacting operational costs. Emissions ratings reveal the environmental impact of the vehicle, while acceleration figures provide insight into its responsiveness. Together, these metrics paint a comprehensive picture of the engine’s overall performance and efficiency.

Transmission Troubleshooting Guide

This section aims to provide essential insights for diagnosing and resolving common issues related to the transmission system. Understanding the symptoms and potential causes can lead to effective solutions, ensuring optimal performance and longevity of the vehicle’s transmission.

When encountering transmission problems, consider the following steps:

- Identify Symptoms:

- Unusual noises (grinding, whining)

- Delayed or harsh shifting

- Fluid leaks under the vehicle

- Warning lights on the dashboard

- Check Fluid Levels:

Ensure that the transmission fluid is at the appropriate level and in good condition. Low or dirty fluid can lead to various performance issues.

- Inspect Connections:

Examine electrical connections and harnesses for signs of damage or corrosion. Faulty connections can disrupt the transmission’s operation.

- Test the Torque Converter:

A malfunctioning torque converter can cause problems such as slipping or overheating. Testing its functionality is crucial.

- Scan for Error Codes:

Utilize an OBD-II scanner to retrieve any diagnostic trouble codes. These codes provide valuable information for pinpointing issues.

By following these guidelines, vehicle owners can systematically troubleshoot transmission issues, leading to informed decisions regarding repairs or maintenance. Remember, timely intervention can prevent further damage and costly repairs.

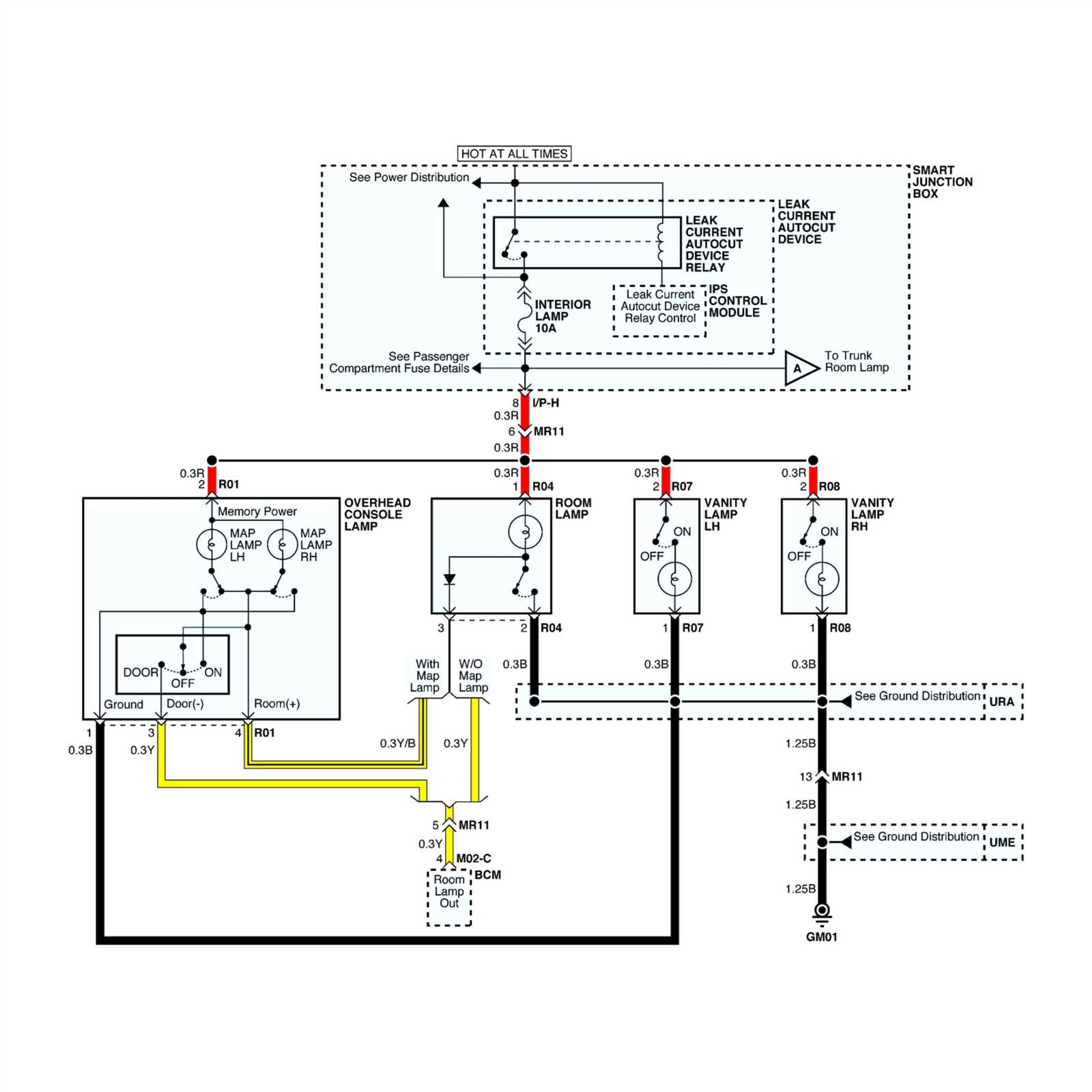

Electrical System Insights

The electrical framework of heavy-duty vehicles plays a crucial role in ensuring optimal performance and reliability. Understanding the intricacies of this system is essential for maintaining functionality and addressing potential issues before they escalate. From power distribution to component interactions, each element is designed to work harmoniously to support various operations.

Key Components

At the heart of the electrical system lies the battery, which provides the necessary power to start the engine and energize various electrical parts. Additionally, the alternator is vital for recharging the battery while the engine runs, ensuring a continuous power supply. Wiring harnesses facilitate communication between different systems, while fuses protect components from electrical surges.

Troubleshooting Tips

When diagnosing issues within the electrical system, it is important to check connections for corrosion or looseness, as these can disrupt power flow. Using a multimeter can help measure voltage and continuity, aiding in pinpointing malfunctions. Regular inspections can preemptively identify wear and tear on critical components, ultimately prolonging their lifespan.

Maintenance Practices

To ensure the longevity and efficiency of the electrical system, routine maintenance is essential. This includes checking battery terminals for cleanliness, inspecting wiring for frays or damage, and testing the alternator’s output. Adopting these practices can lead to enhanced performance and reduced likelihood of unexpected breakdowns.

Suspension and Steering Basics

The suspension and steering systems are crucial components of any vehicle, playing a vital role in maintaining control, comfort, and safety. These systems work together to ensure that the wheels remain in contact with the road while absorbing shocks and vibrations, thereby enhancing overall driving experience.

Suspension systems consist of various elements, including springs, shock absorbers, and control arms. Their primary function is to support the vehicle’s weight, isolate it from road irregularities, and ensure a smooth ride. Well-functioning suspension contributes to better handling and stability, particularly during turns or when navigating uneven surfaces.

Steering mechanisms, on the other hand, provide the driver with the ability to direct the vehicle effectively. This system includes components such as the steering wheel, column, rack, and pinion, which translate the driver’s input into precise movements of the front wheels. A responsive steering system is essential for maneuverability and safety, allowing for accurate navigation in various driving conditions.

Regular maintenance and timely inspections of both suspension and steering components are essential to prevent wear and tear, ensuring optimal performance and safety on the road. Identifying signs of issues, such as uneven tire wear or unusual noises, can help in addressing problems before they escalate.

Braking System Maintenance

Ensuring the optimal performance of the stopping mechanism is crucial for safety and reliability. Regular upkeep not only prolongs the lifespan of components but also enhances the overall driving experience. This section outlines essential practices for maintaining the braking system effectively.

Key Maintenance Practices

To keep the braking system in peak condition, several vital procedures should be followed:

| Task | Frequency | Description |

|---|---|---|

| Inspect Brake Pads | Every 6,000 miles | Check for wear and replace if thickness is below recommended level. |

| Check Brake Fluid | Monthly | Ensure fluid is at proper level and replace if contaminated. |

| Examine Rotors | Every 12,000 miles | Look for scoring or warping and replace as necessary. |

| Test Brake Lines | Every 12,000 miles | Inspect for leaks, cracks, or corrosion. |

Signs of Potential Issues

Recognizing early signs of malfunction can prevent costly repairs. Look out for unusual noises, decreased responsiveness, or vibrations while braking. Prompt attention to these symptoms will ensure safety and performance remain uncompromised.

Finding OEM Parts for Repairs

Locating original equipment manufacturer components for maintenance tasks is crucial for ensuring longevity and optimal performance. Utilizing authentic parts can significantly enhance the reliability of your vehicle, preserving its functionality and value.

To start, it is essential to identify reputable suppliers that specialize in genuine components. Online platforms and local dealerships often offer a wide selection, making it easier to source the necessary items. Additionally, visiting dedicated automotive parts stores can provide the advantage of in-person assistance, helping you find the exact specifications needed.

Research is a vital step in this process. Check for part numbers and compatibility to avoid any discrepancies. Many manufacturers provide detailed catalogs and databases that can aid in this search. Don’t hesitate to consult community forums or automotive groups; these resources can offer valuable insights and recommendations from fellow enthusiasts.

Another effective approach is to consider certified pre-owned parts. These can be an excellent alternative, often offering the same quality at a lower cost. Just ensure that they meet the necessary standards and specifications to maintain your vehicle’s integrity.

Finally, when making a purchase, always verify the return policy and warranty options. This provides peace of mind, ensuring that if the component doesn’t meet your expectations, you have the ability to exchange it without hassle.