Ensuring optimal performance and longevity of your automobile requires thorough understanding and careful attention to its mechanics. This section offers an in-depth look into the vital aspects of maintaining a compact vehicle, focusing on essential procedures and troubleshooting tips that every owner should know. With detailed insights, readers can confidently navigate the intricacies of their vehicle’s systems.

From routine inspections to advanced repairs, this guide encompasses a wide range of topics aimed at enhancing the driving experience. By following the outlined practices, car enthusiasts and everyday drivers alike will find themselves better equipped to handle various challenges that may arise. Empower yourself with the knowledge necessary to keep your vehicle in top condition, ensuring a smooth journey ahead.

Whether you’re addressing minor issues or tackling more significant concerns, the information presented here will serve as a valuable resource. Emphasizing practicality and clarity, this guide encourages proactive measures to prevent future complications, ultimately fostering a deeper appreciation for the mechanics behind your automobile.

Overview of the 1996 Toyota Tercel

This section provides an insightful exploration of a compact vehicle known for its reliability and efficiency. It serves as a practical choice for urban commuting and offers an enjoyable driving experience.

The model features a variety of characteristics that cater to diverse driving needs:

- Engine Performance: Equipped with a robust powertrain, it ensures a balanced blend of power and fuel efficiency.

- Interior Comfort: The cabin is designed for user comfort, offering ample space for passengers and cargo.

- Safety Features: Includes essential safety elements aimed at providing peace of mind during travels.

- Fuel Economy: Known for its economical fuel consumption, making it a budget-friendly option for daily use.

Additionally, this vehicle is often praised for its longevity and low maintenance costs, making it a favored choice among drivers seeking dependable transportation.

Overall, this compact car stands out for its practicality and efficiency, making it a noteworthy option in its class.

Essential Tools for DIY Repairs

When tackling automotive projects at home, having the right equipment is crucial for success. A well-stocked toolkit can make all the difference in efficiently addressing various issues. From basic maintenance to more complex tasks, specific implements can help ensure a smooth and effective process.

Below is a list of fundamental tools that every enthusiast should consider adding to their collection:

| Tool | Description |

|---|---|

| Socket Set | A versatile collection of sockets allows for easy access to various fasteners and makes loosening or tightening bolts much simpler. |

| Wrenches | Adjustable and fixed wrenches are essential for gripping and turning nuts and bolts of different sizes. |

| Screwdriver Set | A variety of flathead and Phillips screwdrivers is necessary for working with different types of screws. |

| Pliers | These are useful for gripping, twisting, and cutting wires and small components. |

| Jack and Jack Stands | To safely lift the vehicle for undercarriage access, a reliable jack and sturdy jack stands are indispensable. |

| Multimeter | This tool is essential for diagnosing electrical issues, measuring voltage, current, and resistance in circuits. |

Equipping yourself with these key tools can empower you to handle a range of tasks with confidence, enhancing your ability to perform maintenance and troubleshooting efficiently.

Common Issues and Troubleshooting Tips

Every vehicle may experience certain complications over time, and being aware of these common problems can significantly assist in maintaining optimal performance. Understanding potential difficulties enables owners to act promptly and avoid more serious issues down the line.

Frequent Engine Performance Problems

One prevalent concern involves engine performance. Symptoms such as sluggish acceleration or irregular idling may indicate underlying issues. It’s advisable to check the air filter, fuel system, and ignition components. Regular maintenance can enhance engine efficiency and prevent more severe complications.

Electrical System Challenges

Electrical system malfunctions are another typical issue that can arise. Common signs include dimming lights or unresponsive power accessories. Checking the battery and connections is essential, as corrosion or loose terminals may disrupt functionality. Additionally, ensuring proper fuse integrity can prevent electrical failures.

By staying vigilant about these issues and performing regular inspections, vehicle owners can ensure a smoother driving experience and prolong the lifespan of their automobiles.

Engine Maintenance and Specifications

Proper upkeep of the engine is crucial for ensuring longevity and optimal performance of any vehicle. This section outlines essential guidelines and specifications that are fundamental to maintaining the power unit in top condition. Regular checks and timely interventions can significantly enhance efficiency and prevent potential issues.

Key aspects of engine care include:

- Routine oil changes to keep the engine lubricated.

- Monitoring coolant levels to prevent overheating.

- Regular inspection of air and fuel filters for optimal air intake and fuel delivery.

- Checking and replacing spark plugs to ensure smooth ignition.

- Evaluating belts and hoses for wear and tear to avoid failures.

In addition to routine maintenance, understanding the engine specifications is vital for any modifications or repairs:

- Displacement: The total volume of all cylinders.

- Compression Ratio: The ratio of the maximum to minimum volume in the combustion chamber.

- Power Output: The engine’s capability to produce horsepower.

- Torque: The rotational force produced by the engine.

- Fuel Type: Specifications regarding the appropriate fuel grade.

Adhering to these guidelines ensures the engine remains efficient, responsive, and reliable, contributing to a smoother driving experience.

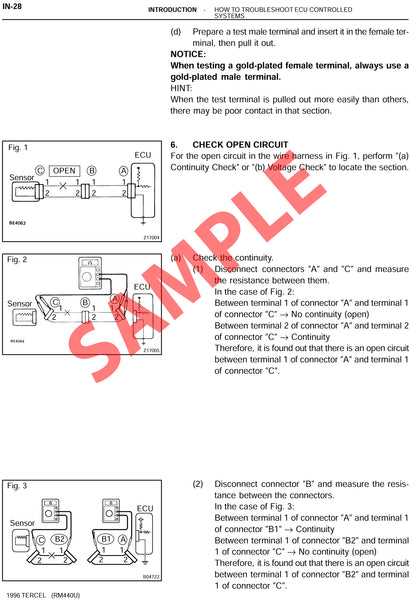

Electrical System Diagnostics Explained

Effective evaluation of the electrical framework in a vehicle is crucial for ensuring optimal performance and reliability. This process involves a series of systematic procedures designed to identify issues, verify functionality, and enhance the overall efficiency of the electrical components. Understanding the intricacies of these assessments can aid in troubleshooting and resolving potential malfunctions.

Identifying Common Issues

Regular inspections can reveal typical problems such as wiring faults, short circuits, or component failures. Utilizing diagnostic tools allows for precise detection of these issues, enabling quick remediation. Knowledge of common symptoms, like dimming lights or irregular instrument readings, can also assist in pinpointing the source of electrical disturbances.

Utilizing Diagnostic Tools

The implementation of specialized diagnostic devices is essential in accurately assessing the condition of the electrical system. Multimeters, oscilloscopes, and scan tools provide valuable data regarding voltage levels, continuity, and error codes. Proper use of these instruments enhances the ability to diagnose and repair faults efficiently, leading to improved vehicle reliability.

Transmission Repair and Adjustments

This section provides essential insights into the maintenance and fine-tuning of the transmission system. Understanding the intricacies of this vital component ensures optimal performance and longevity of the vehicle.

Proper service of the transmission involves several key steps:

- Fluid Inspection: Regularly check the transmission fluid level and condition. Low or contaminated fluid can lead to performance issues.

- Leak Detection: Look for any signs of leaks around seals and gaskets. Addressing leaks promptly can prevent further damage.

- Filter Replacement: Change the transmission filter as recommended. A clean filter helps maintain fluid quality and efficiency.

- Adjustment of Cables: Ensure that the shift cables are properly adjusted. Misalignment can affect shifting performance.

- Torque Converter Check: Inspect the torque converter for any signs of malfunction, as it plays a crucial role in transmission efficiency.

Following these procedures can enhance the functionality of the transmission, contributing to a smoother driving experience and improved overall vehicle reliability.

Brake System Inspection and Maintenance

Regular evaluation and upkeep of the braking system are crucial for ensuring vehicle safety and optimal performance. This process involves assessing various components, identifying potential issues, and executing necessary adjustments or replacements. A well-maintained braking mechanism enhances responsiveness and prolongs the lifespan of related parts.

Inspection Procedures

Begin by examining the brake pads and discs for signs of wear or damage. Look for uneven surfaces, excessive thinning, or any cracks that may compromise functionality. It is essential to check the brake fluid level and its condition, as contaminated or low fluid can lead to decreased performance. Additionally, inspect the brake lines for leaks or corrosion.

Maintenance Practices

Routine maintenance includes replacing worn brake pads and resurfacing or replacing discs as needed. Regularly flushing and refilling the brake fluid ensures optimal hydraulic performance. Furthermore, lubricating the calipers and sliding pins will help maintain smooth operation. Always follow manufacturer recommendations for intervals and specific practices to ensure safety and effectiveness.

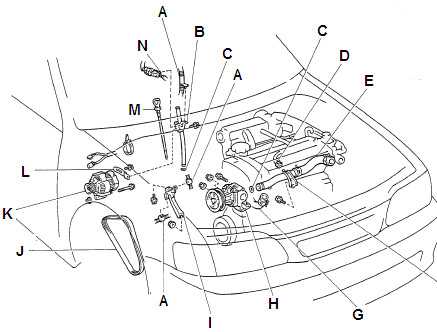

Suspension and Steering Components Guide

This section provides a comprehensive overview of the elements that contribute to vehicle handling and ride quality. Understanding the various components involved in the suspension and steering systems is essential for maintaining optimal performance and ensuring safety on the road.

Key Suspension Parts

The suspension system plays a crucial role in supporting the vehicle’s weight, absorbing shocks, and maintaining contact between the tires and the road surface. Key components include:

| Component | Function |

|---|---|

| Shock Absorbers | Dampen the impact of road irregularities to enhance ride comfort. |

| Struts | Provide structural support and help maintain wheel alignment. |

| Coil Springs | Support the vehicle’s weight and absorb energy from bumps. |

| Control Arms | Connect the suspension to the vehicle’s frame while allowing for movement. |

Steering System Overview

The steering mechanism is vital for directing the vehicle’s movement and ensuring driver control. Familiarity with the components involved aids in recognizing potential issues and maintaining steering efficiency:

| Component | Function |

|---|---|

| Steering Wheel | Allows the driver to control the direction of the vehicle. |

| Steering Column | Connects the steering wheel to the steering mechanism. |

| Rack and Pinion | Converts the rotational motion of the steering wheel into linear motion for the wheels. |

| Tie Rods | Transmit the motion from the steering gear to the wheels. |

Exhaust System Care and Repairs

The proper maintenance of the exhaust mechanism is crucial for ensuring optimal engine performance and reducing harmful emissions. Regular inspections can help identify potential issues before they escalate, ultimately prolonging the lifespan of the vehicle’s components.

Common Issues and Symptoms

Various signs may indicate problems within the exhaust assembly. Unusual noises, such as hissing or rattling, often suggest leaks or loose components. Additionally, a noticeable decrease in fuel efficiency or a check engine light may signal underlying issues that require attention.

Maintenance Tips

To maintain the exhaust system effectively, consider conducting periodic visual inspections for rust or damage. Keeping the area clear of debris can prevent blockages and promote proper airflow. Regular professional assessments are also recommended to ensure all connections and mounts are secure, thereby enhancing performance and safety.

Safety Precautions for Repair Work

Engaging in maintenance tasks requires a thorough understanding of safety measures to ensure a secure working environment. Proper precautions can significantly reduce the risk of accidents and injuries during the process. Adhering to guidelines not only protects the individual but also enhances the overall efficiency of the task at hand.

Essential Gear

Wearing appropriate protective equipment is crucial. This includes items such as gloves, safety glasses, and sturdy footwear. Such gear acts as a barrier against potential hazards, minimizing the risk of injury from sharp objects, chemicals, or heavy components.

Workspace Organization

Maintaining a tidy workspace contributes to safety. An organized area reduces the likelihood of tripping hazards and facilitates easier access to tools and materials. Ensuring that all tools are in good condition and stored properly can also prevent accidents.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from cuts and chemicals |

| Safety Glasses | Shield eyes from debris and harmful substances |

| Steel-Toed Boots | Guard feet against heavy objects |

| Ear Protection | Minimize noise-related hearing damage |