In the world of outdoor adventures, the importance of keeping your all-terrain vehicle in top condition cannot be overstated. This section serves as a comprehensive resource for enthusiasts looking to enhance their understanding of vehicle upkeep, ensuring optimal performance and longevity. Whether you’re a seasoned rider or a newcomer, grasping the fundamentals of maintenance will significantly enrich your experience.

Here, you will discover essential tips and techniques tailored to various aspects of vehicle care. From routine inspections to troubleshooting common issues, this guide aims to empower you with the knowledge needed to tackle any situation with confidence. Understanding the mechanics and functions of your machine will not only improve your riding experience but also save you time and resources in the long run.

Equipped with the right information, you’ll be better prepared to handle maintenance tasks efficiently. Dive into the following sections to learn about crucial procedures and insights that will keep your all-terrain vehicle running smoothly for years to come.

Essential Maintenance for Your ATV

Regular upkeep is crucial for ensuring the longevity and optimal performance of your all-terrain vehicle. By following a consistent maintenance routine, you can enhance both safety and reliability, allowing you to enjoy your rides without worry.

Routine Inspections

Conducting periodic checks on various components is fundamental. Inspect the tires for wear and proper inflation, examine the brakes for responsiveness, and ensure all lights are functioning correctly. Regular assessments help identify potential issues before they escalate, saving time and money in the long run.

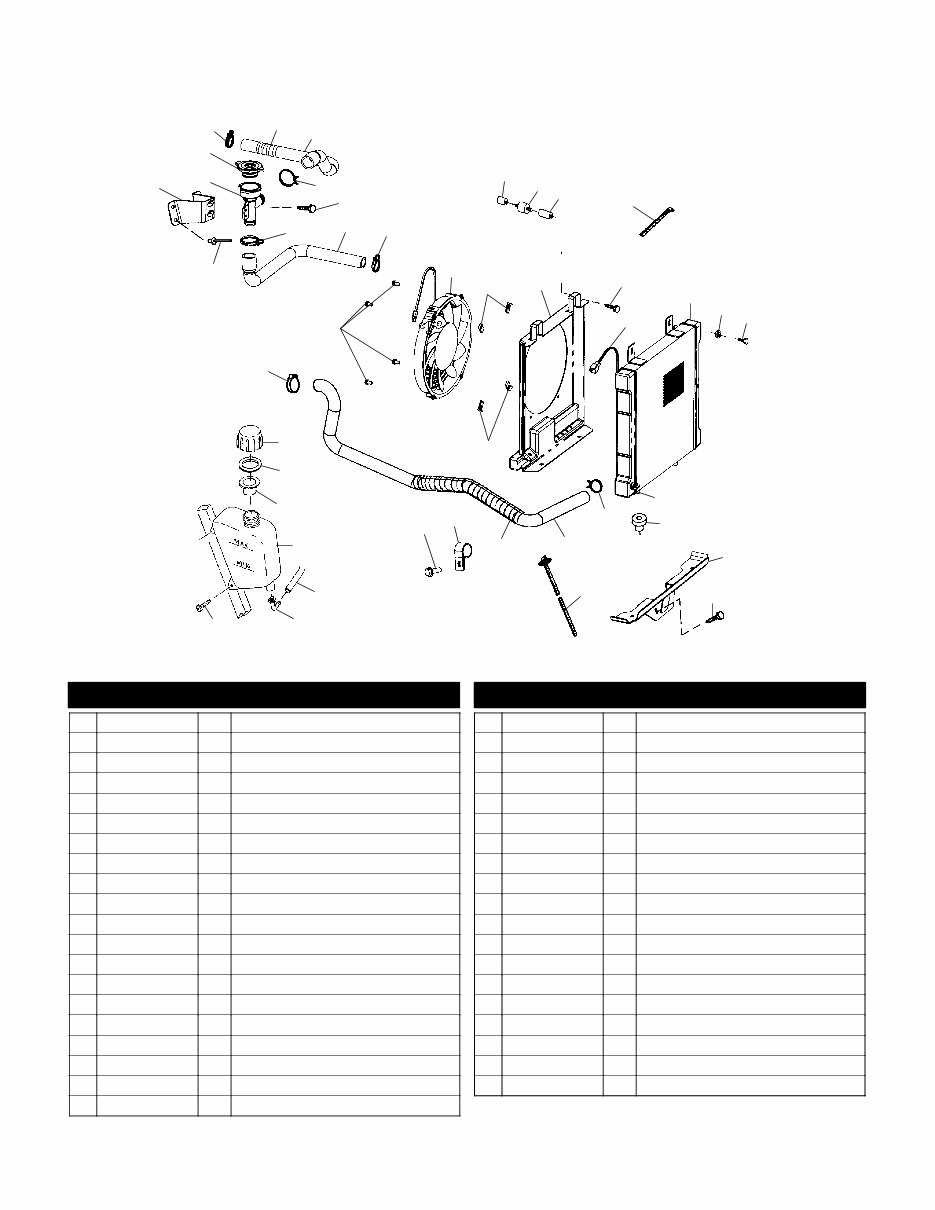

Fluid Management

Maintaining the correct fluid levels is vital for your vehicle’s operation. Regularly check and replace engine oil, coolant, and brake fluid as needed. Proper lubrication of moving parts not only prevents overheating but also promotes smooth functionality. Make it a habit to monitor these fluids, ensuring your machine runs at peak efficiency.

Common Issues and Their Solutions

In the world of all-terrain vehicles, various challenges can arise that may affect performance and functionality. Identifying these problems early and applying the correct solutions is essential for maintaining optimal operation. Below are some frequently encountered issues and their corresponding remedies.

| Issue | Solution |

|---|---|

| Engine won’t start | Check the battery for charge; replace if necessary. Ensure the ignition system is functioning properly. |

| Overheating | Inspect the cooling system for leaks and ensure the radiator is clean. Replace any damaged hoses. |

| Poor acceleration | Examine the fuel filter for clogs; replace if dirty. Check the throttle cable for proper adjustment. |

| Unusual noises from the engine | Inspect for loose components; tighten any bolts or screws. Listen for any abnormal sounds indicating wear. |

| Electrical issues | Test the wiring harness for damage. Replace any frayed or broken wires. |

Understanding the Engine Components

Gaining insight into the elements that comprise a motor is essential for effective maintenance and troubleshooting. Each part plays a vital role in ensuring the smooth operation of the machine, contributing to overall performance and longevity.

Key components of an engine include:

- Crankshaft: This rotating shaft converts linear motion into rotational energy, powering various systems.

- Pistons: These cylindrical pieces move up and down within the cylinders, facilitating combustion.

- Cylinders: Housing the pistons, these chambers are where fuel and air mix for combustion.

- Camshaft: This component controls the timing of the valve openings and closings, ensuring efficient airflow.

- Valves: Responsible for regulating the intake of air and the expulsion of exhaust gases.

- Ignition System: This setup generates the spark necessary to ignite the fuel-air mixture.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and damage.

Understanding these components enhances the ability to diagnose issues and perform necessary adjustments, leading to improved functionality and reliability.

Step-by-Step Repair Processes

This section outlines the detailed procedures for addressing common issues with your vehicle, ensuring that maintenance tasks are completed effectively and safely. By following these sequential steps, you can enhance your understanding of the components and improve the overall performance of your machine.

1. Initial Assessment: Begin by examining the vehicle for visible signs of wear or damage. Look for leaks, cracks, or any abnormal sounds. A thorough inspection helps identify the specific areas that require attention.

2. Gather Tools and Materials: Collect all necessary tools and replacement parts before starting any task. This preparation minimizes downtime and allows for a smoother workflow throughout the process.

3. Disassembly: Carefully remove any components that obstruct access to the affected area. Use appropriate tools to avoid damaging surrounding parts. Document each step to ensure proper reassembly later.

4. Repair or Replacement: Once access is gained, execute the required repairs or replace damaged components. Ensure that all parts are compatible and securely fitted to maintain functionality.

5. Reassembly: Reverse the disassembly steps, carefully reattaching all components. Follow the documentation created during disassembly to ensure accuracy.

6. Final Inspection: After reassembly, conduct a comprehensive check to confirm that everything is in its proper place and functioning correctly. Test the vehicle in a controlled environment to ensure reliability.

By adhering to these systematic procedures, you can effectively address issues and maintain your vehicle’s optimal performance, enhancing its longevity and reliability.

Tools Needed for Effective Repairs

Having the right instruments is essential for performing maintenance and restoration tasks efficiently. The right equipment not only enhances productivity but also ensures that the job is done correctly, minimizing the risk of damage and improving the longevity of the vehicle.

Basic hand tools are indispensable for any maintenance work. These typically include wrenches, sockets, screwdrivers, and pliers, which are crucial for loosening and tightening various components. Additionally, specialized tools may be necessary for specific tasks, such as torque wrenches for precise adjustments and diagnostic tools for troubleshooting issues.

Safety gear is equally important to protect yourself during the repair process. This includes gloves, goggles, and a sturdy pair of work boots. Ensuring a safe working environment is vital for both efficiency and personal safety.

Lastly, having a well-organized workspace can significantly enhance the repair process. Toolboxes or storage systems for keeping your instruments sorted and easily accessible will save time and reduce frustration while working on any project.

Safety Precautions During Maintenance

When conducting maintenance on any vehicle, prioritizing safety is essential to ensure a secure working environment. Understanding and implementing the necessary precautions can help prevent accidents and injuries, making the process more efficient and effective.

First and foremost, always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear. This gear protects against potential hazards such as sharp objects, chemicals, and falling debris.

Before starting any work, ensure that the vehicle is on a flat surface and securely positioned. Utilize jack stands or wheel chocks to stabilize the vehicle, preventing unintended movement. Additionally, disconnect the battery to eliminate the risk of electrical shock or short circuits while working on the system.

Keep your workspace organized and free of clutter. A clean environment reduces the chance of accidents caused by tripping or misplaced tools. Moreover, always use the correct tools for the job, as this not only enhances efficiency but also minimizes the risk of injury from improper handling.

Lastly, be aware of your surroundings and the potential risks associated with the maintenance tasks at hand. Familiarize yourself with the vehicle’s components and consult relevant documentation to ensure a thorough understanding of the work being performed. Adhering to these safety guidelines will contribute to a smoother and safer maintenance experience.

Electrical System Troubleshooting Guide

This section aims to assist users in diagnosing issues related to the electrical components of their vehicle. Understanding the common problems that may arise within the electrical system is essential for effective maintenance and repair. The following guidelines outline the necessary steps to identify and resolve these issues.

Common Electrical Issues

- Dead Battery: A frequent occurrence that can prevent the vehicle from starting.

- Faulty Wiring: Damaged or frayed wires may disrupt electrical flow.

- Defective Fuses: Blown fuses can interrupt power to various systems.

- Inoperative Lights: Failure of headlights or indicators often points to underlying problems.

Troubleshooting Steps

- Inspect the Battery: Check for corrosion on terminals and ensure proper connections.

- Test the Fuses: Replace any blown fuses and monitor the system for recurring issues.

- Examine Wiring: Look for visible damage or wear; repair or replace as necessary.

- Check Components: Assess switches, lights, and other electrical parts for functionality.

By following these steps, users can efficiently pinpoint and address electrical issues, ensuring optimal performance of their vehicle’s system.

Maintaining the Suspension System

The suspension system is crucial for ensuring a smooth and safe ride. Regular upkeep can enhance performance, extend the lifespan of components, and improve overall handling. Here are some essential practices for maintaining this vital system.

Regular Inspections

- Check for wear and tear on shock absorbers and struts.

- Inspect bushings and mounts for signs of deterioration.

- Examine springs for any signs of sagging or damage.

Lubrication

Proper lubrication is key to reducing friction and preventing premature wear. Focus on:

- Applying grease to all moving parts, including joints and bearings.

- Using the recommended lubricant to avoid compatibility issues.

By following these maintenance tips, you can ensure optimal performance and longevity of the suspension system, contributing to a safer riding experience.

Replacing Fluids and Filters

Maintaining optimal performance in your vehicle involves regular fluid and filter changes. This process ensures that all systems operate efficiently, preventing potential damage and enhancing longevity. Adhering to recommended intervals for these tasks is crucial for peak functionality.

Below is a guide for the essential fluids and filters that require attention:

| Fluid/Filter | Recommended Change Interval |

|---|---|

| Engine Oil | Every 1,000 miles |

| Transmission Fluid | Every 1,500 miles |

| Air Filter | Every 2,000 miles |

| Fuel Filter | Every 3,000 miles |

| Brake Fluid | Every 2 years |

Following these guidelines helps ensure a smooth and safe riding experience, ultimately prolonging the lifespan of your vehicle.

Enhancing Performance Through Upgrades

Improving the capabilities of your all-terrain vehicle can lead to a more enjoyable and efficient experience. By focusing on various enhancements, riders can significantly boost speed, handling, and overall responsiveness. This section will explore key modifications that can help elevate performance and maximize your vehicle’s potential.

Key Areas for Improvement

To achieve optimal performance, consider upgrading specific components that directly influence power and agility. Below are some essential areas to focus on:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Exhaust System | High-performance exhaust | Increased horsepower and torque |

| Air Intake | Cold air intake system | Improved airflow for better combustion |

| Suspension | Adjustable shocks | Enhanced stability and comfort |

| Gearing | Aftermarket sprockets | Faster acceleration and improved speed |

Conclusion

Implementing these upgrades can transform your vehicle’s performance, making it more powerful and responsive. With careful selection and installation of high-quality parts, enthusiasts can enjoy a significant enhancement in their riding experience.