For enthusiasts of air-powered rifles, maintaining the longevity and performance of their equipment can be both a rewarding and challenging endeavor. This section delves into practical methods for enhancing the efficiency and restoring the functionality of a classic model known for its simplicity and versatility. Here, users will find clear steps and tips to ensure their equipment is in prime condition, ready to deliver consistent accuracy and reliability.

Detailed insights provided cover essential maintenance practices, addressing common issues that can emerge with prolonged use. From understanding key components to adjusting specific mechanisms, this guide equips users with the knowledge necessary to sustain their air rifle’s performance over time. With an emphasis on preserving the original design’s precision, users can approach each task with confidence.

Whether aiming to refresh older mechanisms or replace worn-out parts, the information here is crafted to support all levels of experience. By following these guidelines, owners can restore their equipment’s dependable performance, ensuring a seamless shooting experience that reflects the model’s enduring reputation.

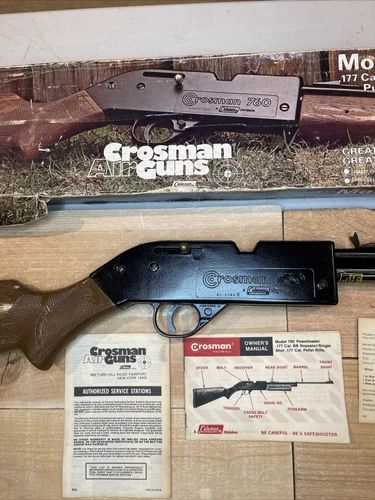

Guide to Maintaining Your Crosman 760

Regular upkeep of your air-powered rifle ensures it operates smoothly and safely. Proper maintenance not only extends the longevity of the mechanism but also optimizes each shot for accuracy and reliability. This guide covers essential care practices to keep your equipment in peak condition, focusing on cleaning, inspection, and preventive measures.

Essential Cleaning Practices

Maintaining the inner workings of the rifle requires attention to detail and consistency. Begin with the barrel, as it accumulates residue over time, impacting performance. Use a high-quality cleaning rod or a recommended alternative to remove dirt and build-up. Remember to avoid excess moisture, as it can cause internal parts to corrode. Always use a light oil designed for airguns, applying sparingly to prevent over-lubrication.

Inspecting Key Components

Routine checks are crucial for the safety and effectiveness of your equipment. Focus on seals, screws, and the pump mechanism, looking for signs of wear or looseness. Seals are particularly vital, as any air leakage can hinder performance. Tighten any loose screws and ensure they are secure without over-tightening, as this can strip threads. If the pump shows stiffness, it may need lubrication or adjustment to ensure consistent operation.

By following these steps, your equipment will remain

Understanding the Crosman 760 Mechanism

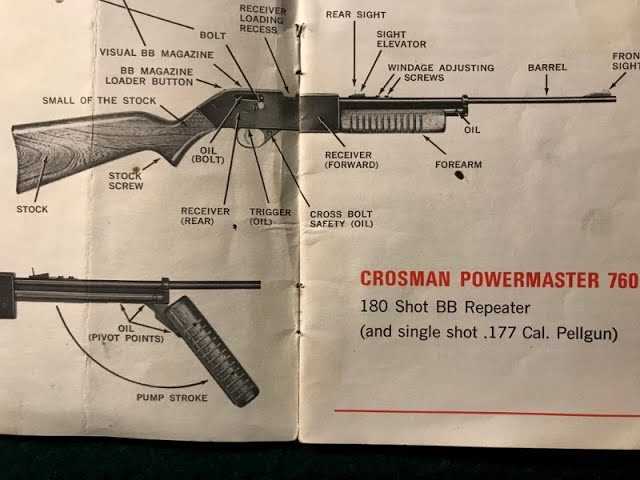

The internal mechanism of this classic air-powered device relies on a carefully coordinated system that ensures smooth operation and reliable performance. To fully appreciate its structure and functionality, it’s essential to explore the key components and how they work together to deliver power and precision.

- Pneumatic Chamber: This section generates compressed air, vital for propelling the pellet with significant velocity. The pressure buildup is controlled by a series of internal seals and valves, which play a crucial role in maintaining consistent performance.

- Trigger System: Connected to the firing sequence, the trigger assembly manages the release of compressed air. A combination of springs and levers ensure smooth operation, allowing for controlled and accurate discharge each time.

- Barrel and Bore: The elongated tube directs the pellet toward the target with precision. Its internal smoothness and alignment are crucial for accuracy, guiding the projectile in a controlled path once fired.

- Loading Mechanism: The loading port is designed to efficiently position the pellet in the barrel.

Disassembly Steps for Crosman 760

This guide provides a detailed breakdown of the step-by-step process to take apart your air-powered tool for maintenance or upgrades. Careful and systematic disassembly is crucial to ensure all components are kept intact and easily reassembled later. Follow these steps to safely and efficiently access the internal mechanisms.

Gather Necessary Tools

Before beginning, gather all necessary tools, such as small screwdrivers, pliers, and a soft cloth to prevent scratches. Having the right tools prepared helps make the process smoother and avoids unnecessary damage.

Step-by-Step Disassembly Process

- Remove the fasteners: Begin by carefully unscrewing all visible screws on the body. Place each screw on a tray or cloth to keep them organized.

- Detach external parts: Slowly detach the outer casing parts. Gently pull apart the pieces, avoiding excessive force that might damage clips or pins.

- Access the inner ass

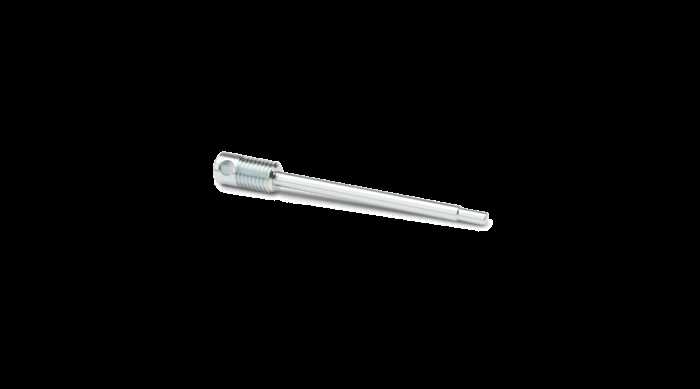

Essential Tools for Repairing the 760

Maintaining this model involves a range of reliable tools, carefully selected to support precision and ease in each stage of the process. Proper preparation with the right instruments ensures effective results, from minor adjustments to significant maintenance needs.

Basic Hand Tools

The essential collection begins with quality hand tools. A set of screwdrivers in varying sizes is necessary for accessing and assembling the model’s internal components, particularly those parts held in place by smaller fasteners. Equally important is a dependable set of pliers, useful for holding, bending, or aligning small elements that require fine handling.

Precision Instruments

For enhanced accuracy, precision tools like a small torque wrench are crucial, helping prevent overtightening that could damage internal threads. A fine-tipped needle file is beneficial when smoothing or resizing surfaces, while a micrometer enables precise measurements,

How to Fix Air Leaks

Addressing air leaks is essential to maintain optimal performance and ensure longevity. Small leaks can reduce pressure, affecting accuracy and efficiency. Here, we’ll explore methods to identify and resolve common leak issues, enhancing reliability and functionality.

Identifying the Source of the Leak

Begin by carefully examining the system’s main areas where leaks frequently occur. Check seals, connections, and any points where parts join. Applying a small amount of soapy water around these areas can help; bubbles indicate air escaping, pinpointing the exact leak location.

Tools and Materials Needed

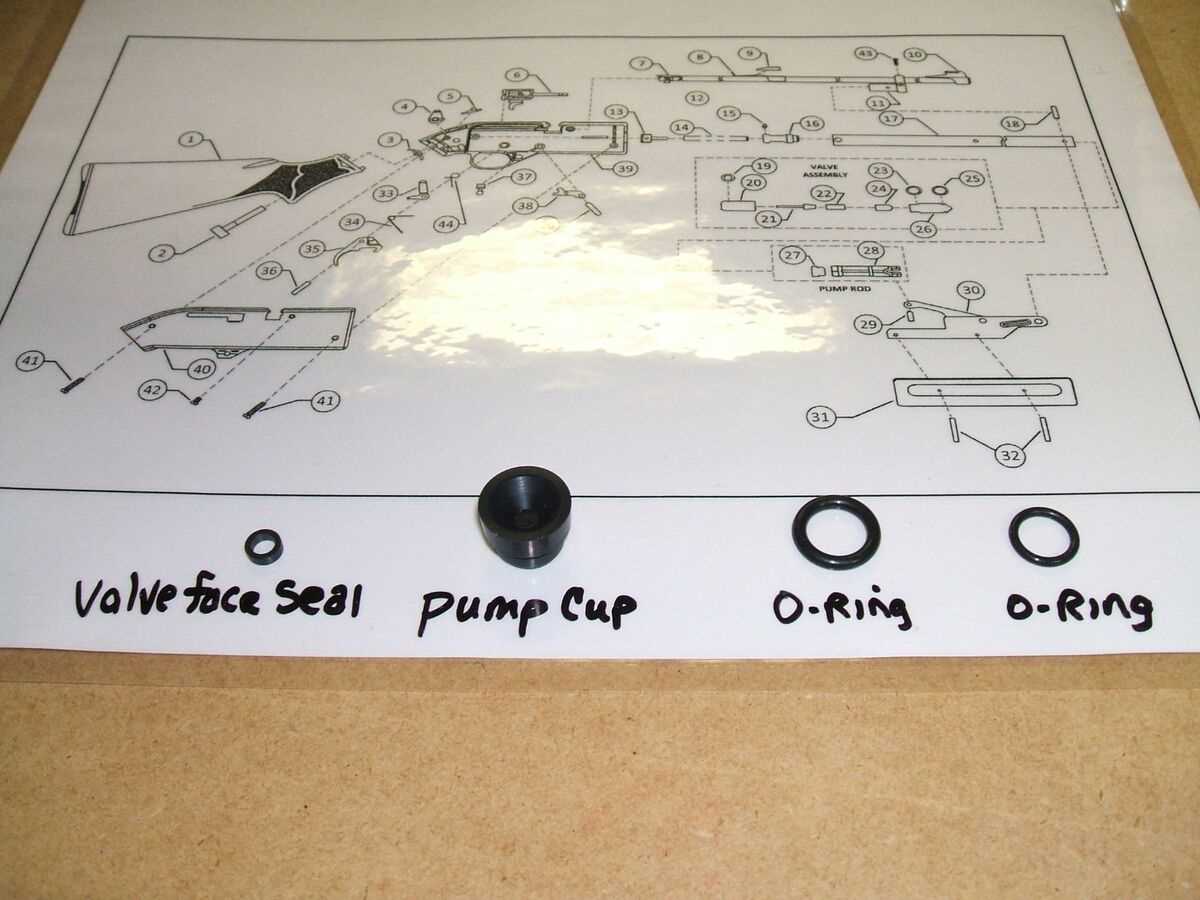

Tool/Material Purpose Soapy Water Solution Used to detect leaks by forming bubbles at escape points. O-Ring Kit Replacing Worn or Damaged Parts

Ensuring the optimal performance of your air rifle often involves addressing components that have deteriorated over time. Regular inspection and timely replacement of these parts can significantly enhance functionality and prolong the lifespan of the device. Understanding the signs of wear and knowing which elements to replace is crucial for maintaining accuracy and reliability.

Identifying Worn Components

Several indicators can help you determine when a part has reached the end of its usefulness. Common signs include inconsistent shooting performance, unusual noises during operation, or visible damage to specific components. Familiarity with the main elements of the air rifle will aid in recognizing these issues early on.

Replacement Parts Overview

When it comes to replacing worn components, selecting the right parts is essential. Below is a table summarizing common parts that may require attention and their corresponding functions:

Part Function Seals Maintain air pressure and prevent leaks. Piston Controls the air compression within the chamber. Trigger Assembly Facilitates firing mechanism engagement. Cylinder Holds air and regulates power delivery. Replacing these components as needed will ensure that your air rifle continues to perform at its best. Regular maintenance and part replacement can save you time and enhance your shooting experience.

Troubleshooting Pumping Issues

Pumping problems can significantly affect the performance of your air-powered device, leading to inefficiencies and dissatisfaction. Identifying the root causes of these issues is essential for restoring optimal functionality. This section will guide you through common symptoms and possible solutions to enhance your experience.

Identifying Common Symptoms

Many users encounter difficulties when trying to achieve the required pressure. If the pump feels unusually stiff or fails to compress air effectively, it may indicate a mechanical problem. Additionally, if you notice air leaks during the pumping process, this could suggest worn-out seals or valves. Observing these signs early can prevent further damage and ensure smooth operation.

Potential Solutions

To address pumping difficulties, first check the integrity of the seals and gaskets. Replacing worn components can often resolve air leakage issues. Furthermore, ensure that the pumping mechanism is properly lubricated to facilitate smoother movement. Regular maintenance and inspection will help prevent problems and prolong the lifespan of your device.

Improving Pellet Accuracy

Achieving precision with projectiles requires a combination of techniques and adjustments that enhance performance and consistency. This section focuses on several effective strategies to enhance the accuracy of your shots, ensuring that each release is as effective as possible. Understanding the factors that influence accuracy will enable you to make informed choices and improvements.

Factors Affecting Accuracy

Several elements can impact the precision of projectile shooting. These include the quality of the ammunition, the condition of the barrel, environmental conditions, and the shooter’s technique. By addressing each of these factors, you can significantly enhance your shooting results.

Factor Description Improvement Tips Ammunition Quality The consistency and design of pellets greatly affect performance. Choose high-quality pellets with uniform weight and shape. Barrel Condition A clean and well-maintained barrel promotes better accuracy. Regularly clean the barrel to remove debris and fouling. Environmental Conditions Wind, humidity, and temperature can all influence accuracy. Consider shooting indoors or during calm weather conditions. Shooter Technique Proper stance, grip, and breathing control are crucial. Practice consistent shooting posture and breathing techniques. Conclusion

By focusing on the factors that affect shooting precision, you can implement effective strategies to enhance your skills. A systematic approach to ammunition selection, maintenance, environmental awareness, and technique can lead to noticeable improvements in accuracy, ultimately resulting in a more enjoyable and successful shooting experience.

Cleaning and Lubricating Techniques

Maintaining the optimal performance of air-powered devices requires regular cleaning and proper lubrication. These essential tasks not only enhance functionality but also extend the lifespan of the equipment. By adopting effective methods for cleaning and lubrication, users can ensure that their device remains in top condition.

Cleaning should begin with a thorough inspection to identify any accumulated dirt or debris. Utilizing a soft cloth or brush can effectively remove particles from both external surfaces and internal components. For hard-to-reach areas, a small, soft-bristled brush is recommended. It is crucial to avoid the use of abrasive materials, which can damage the surface or components.

Next, lubrication plays a vital role in maintaining smooth operation. Selecting the appropriate lubricant is key; a silicone-based or oil lubricant is often ideal for this type of device. Applying a small amount of lubricant to moving parts, such as pivots and seals, ensures that everything operates seamlessly. It is important to avoid over-lubricating, as excess can attract dirt and cause malfunctions.

In conclusion, incorporating regular cleaning and lubrication into your maintenance routine will significantly improve the performance and longevity of your air-powered device. By following these guidelines, you can enjoy reliable operation for years to come.

Common Problems and Quick Fixes

When using pneumatic air rifles, enthusiasts often encounter various issues that can affect performance. Understanding these common challenges and their solutions can significantly enhance the shooting experience and prolong the life of the equipment. Below are some frequent complications and their straightforward remedies.

1. Air Leakage: If air is escaping from the valve area, check for damaged seals or o-rings. Replacing these components can quickly resolve the issue, restoring proper functionality.

2. Inconsistent Shooting Power: Fluctuations in shooting velocity may stem from inadequate air pressure. Ensure the air reservoir is filled correctly, and examine the valve mechanism for any obstructions.

3. Jamming: A jammed projectile can cause interruptions in shooting. Clear any blockages by gently removing the projectile and inspecting the chamber for foreign objects. Regular cleaning can help prevent this issue.

4. Scope Misalignment: If the aiming device is not aligned properly, adjust it according to the manufacturer’s instructions. This adjustment ensures accurate targeting and improves overall shooting performance.

5. Foul Barrel: A dirty barrel can lead to decreased accuracy. Use a cleaning rod and appropriate solvent to remove residue and maintain optimal performance.

Addressing these common issues promptly can enhance reliability and ensure enjoyable shooting sessions. Regular maintenance is key to preventing many of these problems from arising in the first place.

Preventing Long-Term Wear and Tear

Maintaining the longevity of your equipment requires a proactive approach to care and usage. Regular attention to minor details can significantly reduce the risk of degradation over time. By implementing simple maintenance practices, you can ensure that your device remains functional and efficient for years to come.

One of the most effective strategies is to establish a routine cleaning schedule. Accumulation of dust and debris can lead to blockages and malfunction. Using appropriate cleaning solutions and tools will help preserve essential components and enhance overall performance. Additionally, storing the equipment in a dry, temperature-controlled environment can prevent moisture-related damage.

Monitoring wear indicators, such as performance fluctuations or unusual sounds, is crucial for early detection of potential issues. Addressing these signs promptly can prevent further complications and costly repairs. Furthermore, using the equipment as intended and avoiding excessive force or misuse will contribute to its durability.

Lastly, consider periodic professional inspections. Experts can identify areas of concern that may not be immediately apparent to the user. Investing in regular evaluations can be a worthwhile measure to extend the lifespan of your device and ensure optimal operation.

Reassembling the Crosman 760 Properly

Reassembly of a pneumatic air rifle requires precision and attention to detail. Properly putting together the components ensures optimal performance and longevity of the device. Each part plays a crucial role in the functionality, and a meticulous approach can prevent future issues.

Steps for Successful Reassembly

Follow these key steps to ensure all parts fit correctly and function as intended:

Step Description 1 Start by aligning the main body and ensuring the seals are in good condition. 2 Carefully insert the barrel, ensuring it is locked into place without forcing it. 3 Reconnect the trigger assembly, making sure each component fits securely. 4 Attach the stock, ensuring all screws are tightened to prevent any movement. 5 Conduct a thorough inspection of the assembly before testing for functionality. Common Issues to Avoid

While reassembling, watch for these frequent pitfalls that can hinder performance:

- Over-tightening screws, which may strip threads.

- Misaligning parts, leading to operational failures.

- Neglecting to replace worn seals, causing air leaks.

Testing After Repairs

After completing any maintenance on your air rifle, it is crucial to ensure that everything functions correctly. Testing not only confirms that the repairs were successful but also guarantees safety and performance. This section outlines essential procedures to verify the integrity and functionality of your equipment post-maintenance.

Initial Functionality Check

Begin by conducting a basic functionality test. Check all moving parts to ensure they operate smoothly without any unusual resistance or noise. It is important to examine the mechanism thoroughly, as any irregularities can indicate underlying issues. Take your time during this step to observe any signs of malfunction.

Accuracy and Performance Evaluation

Once the initial checks are completed, proceed to evaluate the accuracy and overall performance. Use a safe and designated area for testing, ensuring that you adhere to all safety protocols. Fire a few test shots at a target to assess precision and consistency. If the results are not satisfactory, further adjustments may be necessary to achieve optimal performance.