In the world of outdoor equipment, understanding the nuances of upkeep can significantly enhance performance and longevity. Every device, regardless of its complexity, requires a certain level of attention to ensure it operates smoothly and efficiently. This section delves into essential strategies for maintaining your tools, focusing on the intricacies of regular checks and preventative measures.

Effective care involves recognizing common issues and knowing the steps to address them swiftly. By familiarizing yourself with the operational intricacies, you can preemptively tackle challenges that may arise during use. A solid grasp of these principles not only improves functionality but also fosters a deeper connection with the machinery you depend on.

Moreover, understanding the assembly and disassembly processes can provide invaluable insights into how components interact. This knowledge empowers users to make informed decisions when facing performance hiccups. Emphasizing hands-on experience, this section will guide you through the necessary procedures, ensuring you are well-equipped to handle various scenarios with confidence.

Understanding Echo GT 200R Components

Grasping the intricacies of each part in a gardening tool can significantly enhance its performance and longevity. This section delves into the essential elements that contribute to the overall functionality, enabling users to maintain and operate their equipment effectively. By familiarizing oneself with these components, operators can ensure that their device runs smoothly and efficiently.

Powerhead: The powerhead serves as the core of the unit, housing the engine and providing the necessary energy for operation. Understanding its mechanics is crucial for troubleshooting any performance issues.

Cutter Head: The cutter head is the part that performs the actual cutting. It is vital to know the types of blades or strings compatible with the head to achieve optimal results for different tasks.

Throttle Control: This component regulates the speed of the engine, allowing for precise control during operation. Familiarity with its functionality can enhance user experience and efficiency.

Fuel System: Comprising the tank, lines, and filter, this system is essential for delivering the necessary fuel to the engine. Regular inspection of these parts can prevent fuel-related issues and ensure smooth operation.

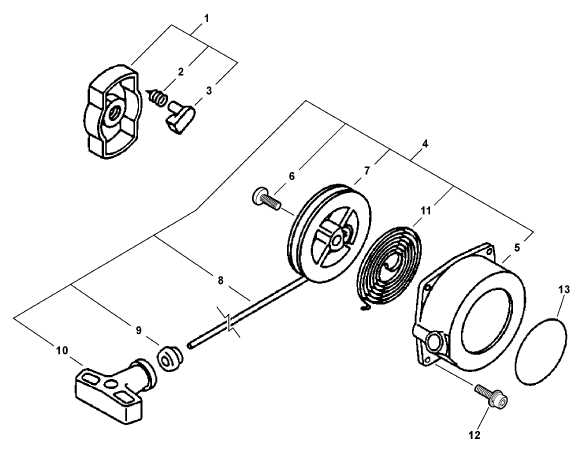

Start Mechanism: The starting system, which includes the recoil starter, is fundamental for igniting the engine. Understanding its design can aid in diagnosing starting difficulties.

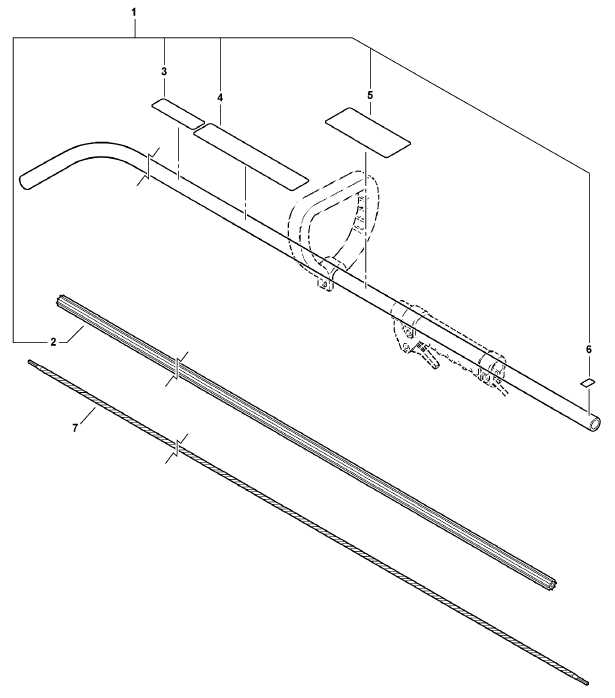

Handle and Shaft: These components provide stability and control while using the tool. Their design influences maneuverability and comfort during extended use.

By gaining insights into these key parts, users can better appreciate the technology behind their gardening tools and take informed steps towards maintenance and enhancement of performance.

Common Issues with Echo GT 200R

When dealing with outdoor equipment, certain problems tend to arise frequently, affecting performance and efficiency. Understanding these common challenges can help users maintain their devices and ensure longevity.

Fuel System Problems

One prevalent issue is related to the fuel system. Clogged filters or stale fuel can lead to poor engine performance. Regularly checking and replacing the fuel filter is essential to avoid these complications. Additionally, using fresh fuel can prevent buildup that may impede operation.

Starting Difficulties

Another common challenge is starting difficulties. Worn spark plugs or incorrect choke settings can hinder ignition. Ensuring the spark plug is in good condition and correctly adjusting the choke can significantly improve starting reliability.

Step-by-Step Repair Guide

This section provides a detailed approach to troubleshooting and restoring your equipment. Each step is designed to help you systematically address common issues, ensuring a thorough understanding of the components involved and the procedures necessary for effective resolution.

Step 1: Preparation

Before diving into the process, gather all necessary tools and materials. A clean workspace is essential for effective work. Ensure you have safety gear, such as gloves and goggles, to protect yourself during the process.

Step 2: Diagnosis

Begin by identifying the symptoms of the problem. Listen for unusual sounds and observe any performance issues. Take notes on what you find, as this information will guide you in determining the necessary actions.

Step 3: Disassembly

Carefully take apart the unit, noting the location of each component. Use a digital camera or smartphone to document the assembly, which can be helpful during reassembly. Keep screws and small parts organized to prevent loss.

Step 4: Inspection

Examine each part for wear and damage. Look for cracks, frayed wires, or any signs of deterioration. This step is crucial in pinpointing the root cause of the issue.

Step 5: Replacement

If you find damaged components, procure the appropriate replacements. Ensure they are compatible with your model. Install new parts carefully, following the specifications provided by the manufacturer.

Step 6: Reassembly

Once all necessary parts have been replaced, begin reassembling the unit. Refer to the documentation or photographs taken during disassembly. Ensure that everything is securely fitted and aligned correctly.

Step 7: Testing

After reassembly, conduct a thorough test to ensure functionality. Observe the equipment in operation and listen for any irregularities. If everything functions correctly, your efforts have been successful!

Step 8: Maintenance

To prolong the lifespan of your equipment, implement a regular maintenance schedule. This includes cleaning, inspecting, and addressing minor issues before they escalate.

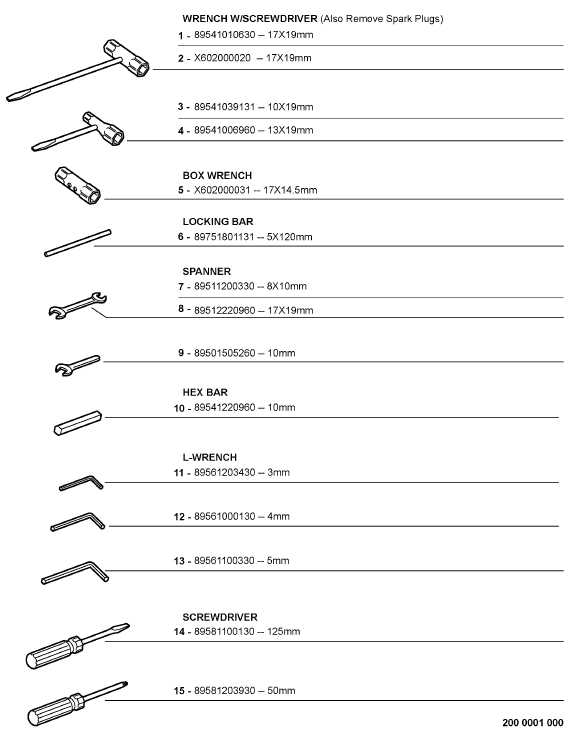

Tools Needed for Repairs

To effectively address maintenance and service tasks on your equipment, having the right tools is essential. Proper instruments not only facilitate the process but also ensure safety and precision during work. Below is a guide to the necessary tools that will assist in performing various functions efficiently.

Essential Tools

Here’s a list of indispensable instruments for effective servicing:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws of various sizes. |

| Wrench Set | To adjust and secure nuts and bolts securely. |

| Plier | For gripping and bending wires or components. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Fuel Container | To safely store and handle fuel for the equipment. |

Additional Recommendations

Beyond the essential tools, having a few additional items can enhance your maintenance experience. Consider adding safety goggles for eye protection, gloves for hand safety, and a multimeter for electrical diagnostics. These accessories can help you work more effectively while minimizing risks associated with equipment servicing.

Safety Precautions During Maintenance

Ensuring safety during servicing and upkeep tasks is essential for both the technician and the equipment. Following proper guidelines can prevent accidents and enhance the longevity of tools. Adopting a proactive approach to safety not only safeguards physical well-being but also ensures effective operation.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the workspace is clean and well-lit to minimize hazards.

- Disconnect the power source before beginning any maintenance tasks to avoid accidental activation.

- Utilize the correct tools for the job to prevent damage and ensure efficiency.

- Keep a fire extinguisher nearby, especially when working with flammable materials.

It is also vital to be aware of specific safety instructions provided by the manufacturer. Adhering to these guidelines can significantly reduce risks associated with maintenance work.

- Review the equipment’s operational manual for safety warnings and precautions.

- Do not attempt repairs if you are unsure or untrained; consult a professional instead.

- Work in pairs when handling large or heavy components to prevent injuries.

- Regularly inspect tools and equipment for wear and tear before use.

By integrating these safety measures into routine maintenance practices, one can create a secure and efficient environment, promoting successful outcomes in all servicing endeavors.

Regular Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor power equipment requires consistent upkeep. Regular attention to key components not only enhances performance but also extends the lifespan of the machine, saving you time and money in the long run.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean the air filter | Every 10 hours of use | Remove debris and wash with soap and water; ensure it’s completely dry before reinserting. |

| Check spark plug | Every 25 hours of use | Inspect for wear and replace if necessary; ensure proper gap is set. |

| Change oil | Every 50 hours of use | Use the recommended type; dispose of old oil responsibly. |

| Sharpen blades | At least once per season | Keep blades sharp for efficient cutting; dull blades can damage the equipment. |

| Inspect fuel system | Before each use | Check for leaks and use fresh fuel; old fuel can cause starting issues. |

Replacing Spark Plug on Echo GT 200R

Maintaining optimal engine performance requires regular attention to various components, one of which is the spark plug. This small yet crucial part ignites the air-fuel mixture in the combustion chamber, ensuring your equipment runs smoothly. Over time, wear and carbon buildup can hinder performance, making it essential to replace the spark plug periodically.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. You will need a socket wrench with the appropriate spark plug socket, a new spark plug, and optionally, a gap gauge to ensure the correct distance between the electrodes.

Steps to Replace the Spark Plug

Begin by disconnecting the ignition source to prevent any accidental starts. Locate the spark plug, which is typically found on the side of the engine. Use the socket wrench to carefully remove the old plug, turning it counterclockwise. Once removed, inspect the old plug for signs of wear or damage.

Next, take the new spark plug and check the gap using the gap gauge. Adjust if necessary, then screw the new plug into place by hand to avoid cross-threading. Once snug, use the socket wrench to tighten it firmly but be cautious not to overtighten, as this can cause damage to the engine.

Reconnect the ignition source, and your equipment should be ready for operation. Regularly checking and replacing the spark plug can significantly enhance performance and longevity.

Adjusting Carburetor Settings Explained

Tuning the fuel delivery system is crucial for optimal engine performance. This process involves fine-tuning the mixture of air and fuel, ensuring the engine runs smoothly and efficiently. Proper adjustments can lead to improved power output, reduced emissions, and better fuel economy.

Understanding Mixture Adjustment

The air-fuel mixture directly impacts the combustion process. If the mixture is too rich or too lean, it can lead to various engine issues. Balancing this mixture is essential for achieving peak performance.

Step-by-Step Adjustment Process

| Step | Description |

|---|---|

| 1 | Start the engine and allow it to reach operating temperature. |

| 2 | Locate the adjustment screws on the carburetor. |

| 3 | Turn the screws clockwise to enrich the mixture or counterclockwise to lean it. |

| 4 | Monitor engine performance and make incremental adjustments as needed. |

| 5 | Once optimal settings are achieved, secure all adjustments. |

Troubleshooting Starting Problems

Experiencing difficulties when trying to start your equipment can be frustrating. Various factors may contribute to these issues, ranging from fuel delivery to ignition system malfunctions. Understanding the common causes can help in diagnosing the problem effectively.

Firstly, check the fuel system. Ensure that the fuel tank is filled with fresh, clean fuel. Stale or contaminated fuel can hinder the starting process. Additionally, examine the fuel lines and filter for blockages or leaks that may impede fuel flow.

Next, inspect the spark plug. A worn or fouled spark plug can prevent proper ignition. Remove the plug and look for signs of damage or excessive carbon buildup. Cleaning or replacing the spark plug may resolve starting issues.

It’s also essential to evaluate the air filter. A clogged air filter restricts airflow to the engine, affecting performance. Ensure that the filter is clean and free of debris to facilitate optimal operation.

If the equipment still fails to start, consider the battery and electrical components. A weak or dead battery can impede ignition. Check connections for corrosion and ensure that the battery is charged adequately.

By systematically addressing these areas, you can identify the underlying cause of starting issues and restore functionality to your equipment.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process if you know where to look. The internet offers a plethora of resources that cater specifically to those in need of spare parts. By utilizing various platforms, you can save both time and money while ensuring you obtain the necessary items for your machine’s upkeep.

Popular Online Resources

Several websites specialize in providing parts for a wide range of tools and machinery. These platforms often feature comprehensive catalogs, customer reviews, and detailed specifications to help you make informed decisions. Here are some recommended options:

| Website | Features | Notes |

|---|---|---|

| PartShop.com | Extensive inventory, user-friendly interface | Fast shipping available |

| ToolPartsDirect.net | Detailed diagrams, competitive pricing | Good for hard-to-find parts |

| eBay | Wide range of options, auction and buy-it-now | Be cautious of seller ratings |

Tips for Successful Purchases

When shopping for parts online, ensure you have the correct model number and specifications. Cross-reference the part numbers with official listings to avoid errors. Additionally, consider purchasing from reputable sellers who offer return policies, as this adds an extra layer of security to your transaction.