When it comes to owning a high-performance two-wheeler, understanding its intricate mechanisms is crucial for optimal functionality and longevity. This section aims to provide essential insights and comprehensive instructions for ensuring your motorcycle remains in peak condition. From routine upkeep to troubleshooting common issues, having a reliable resource can make all the difference.

By familiarizing yourself with various components and their interactions, you empower yourself to tackle maintenance tasks with confidence. Whether you are a seasoned enthusiast or a newcomer to the world of motorcycling, this guide will serve as a valuable reference, helping you navigate the complexities of your machine. The goal is to equip you with the knowledge needed to enhance your riding experience while ensuring safety and reliability.

With step-by-step explanations and practical tips, you’ll find the information presented here to be straightforward and accessible. Emphasizing the importance of regular inspections and timely interventions, this guide encourages a proactive approach to maintenance. Embrace the journey of keeping your motorcycle in top shape, and enjoy every ride to the fullest.

Essential Tools for KTM Duke 200

Having the right set of equipment is crucial for maintaining and enhancing your two-wheeled vehicle. The following tools will help ensure that you can perform essential tasks effectively, ensuring optimal performance and longevity.

- Wrenches: A variety of wrenches, including adjustable and socket types, will allow you to tackle different bolt sizes and shapes.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will cover most fasteners on the machine.

- Torque Wrench: This tool ensures that you apply the correct amount of force when tightening bolts, preventing damage.

- Chain Tool: Essential for maintaining and adjusting the drive system, making sure it runs smoothly.

- Oil Filter Wrench: Useful for changing oil filters easily, ensuring a clean and efficient engine operation.

In addition to the primary tools listed above, consider including the following items in your toolkit:

- Multi-tool: A compact option that combines several functions in one, ideal for quick fixes.

- Pliers: Useful for gripping and manipulating various components.

- Jack or Stand: Essential for safely lifting the vehicle during maintenance tasks.

- Gloves: Protect your hands from grease and sharp edges while working.

Investing in these essential tools will greatly enhance your ability to maintain your vehicle efficiently and safely.

Maintenance Schedule Overview

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. A well-structured maintenance schedule helps in identifying potential issues before they escalate, allowing for timely interventions. This section outlines the key intervals and tasks necessary to maintain peak operational efficiency.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Engine Oil Change | Every 3,000 miles or 6 months | Replace engine oil and filter for optimal lubrication. |

| Air Filter Inspection | Every 6,000 miles | Check and clean or replace the air filter as needed. |

| Tire Condition Check | Monthly | Inspect tire pressure and tread depth for safety. |

| Brake System Inspection | Every 6,000 miles | Examine brake pads, fluid levels, and overall system functionality. |

| Chain Lubrication | Every 500 miles | Lubricate the chain to ensure smooth operation and prevent wear. |

| Coolant Level Check | Every 12,000 miles | Monitor coolant levels and refill or replace as necessary. |

Common Issues and Troubleshooting

Understanding frequent challenges and their solutions is essential for maintaining optimal performance in any two-wheeled vehicle. Owners may encounter various complications that can hinder their riding experience. This section aims to address typical problems and provide practical solutions to enhance reliability.

Electrical Problems: One of the most prevalent issues involves electrical components. Malfunctions in the battery or wiring can lead to starting difficulties or flickering lights. Regularly inspecting connections and ensuring the battery is charged can help mitigate these problems.

Fuel System Issues: Fuel delivery complications can also arise, often manifesting as stalling or poor acceleration. Clogged filters or fuel injectors may be the culprits. Routine cleaning and inspection of these components will help ensure smooth operation.

Cooling System Failures: Overheating is a serious concern that can stem from coolant leaks or radiator blockages. Monitoring coolant levels and inspecting hoses regularly can prevent overheating and subsequent engine damage.

Brake Concerns: Brake performance is crucial for safety. Squeaking or grinding noises may indicate worn pads or insufficient fluid levels. Regular maintenance checks will ensure the braking system functions effectively.

Suspension Troubles: A bumpy ride can often signal issues with the suspension system. Inspecting shock absorbers and adjusting settings can significantly enhance comfort and control.

By being aware of these common issues and following the recommended troubleshooting steps, riders can maintain their vehicle’s performance and enjoy a safer, more reliable riding experience.

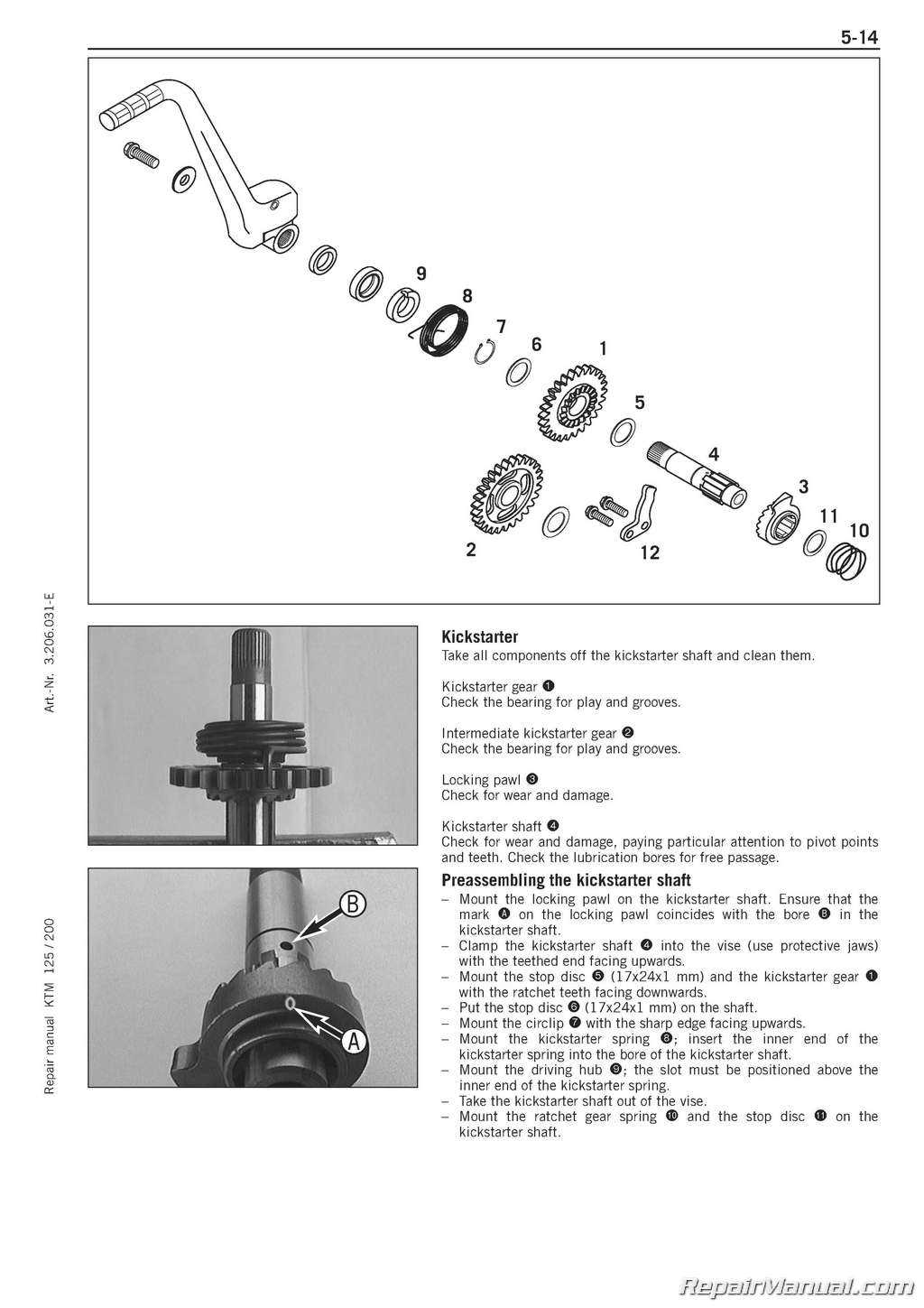

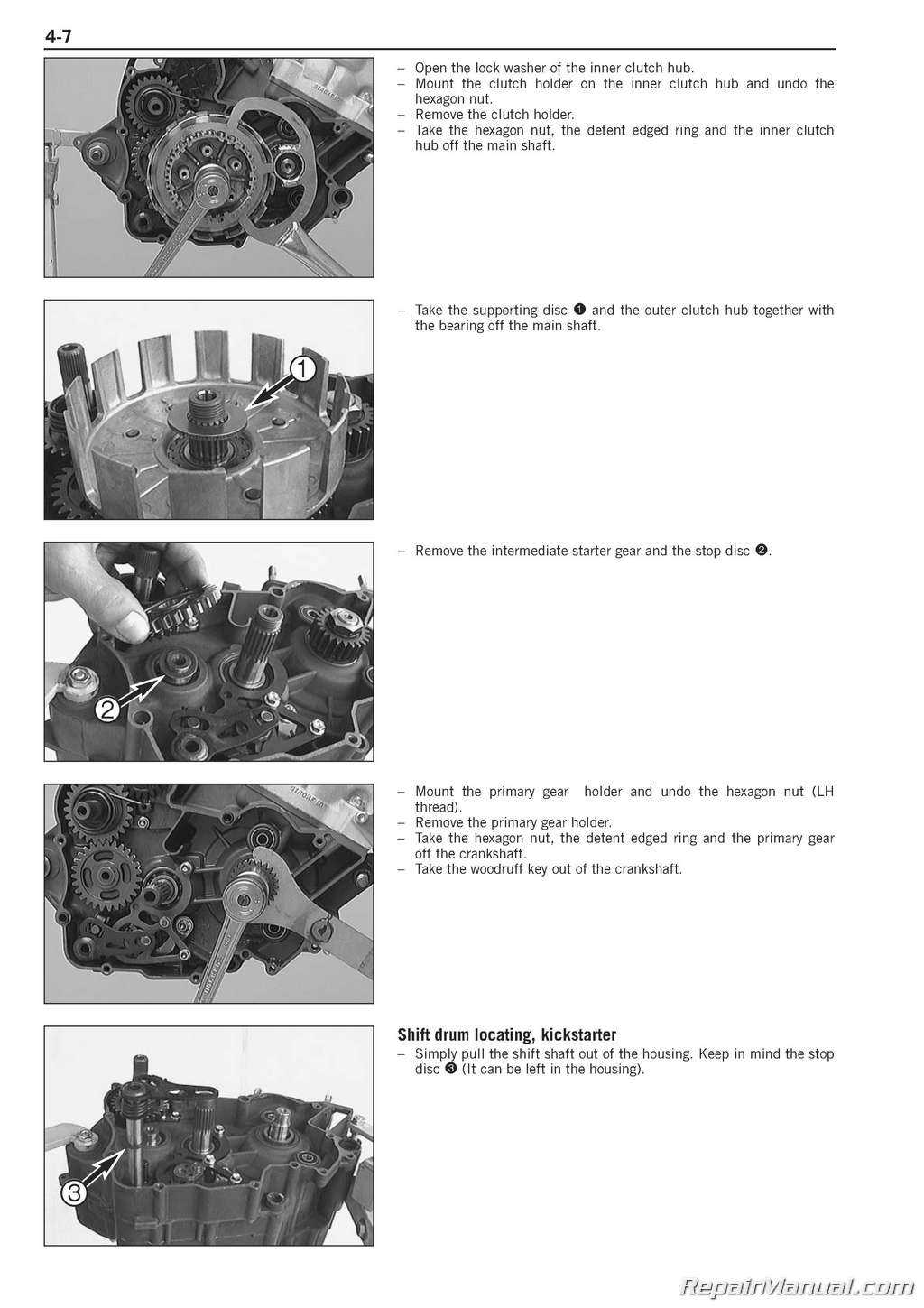

Step-by-Step Repair Procedures

This section provides a detailed approach to addressing common maintenance and restoration tasks for your motorcycle. Following these procedures can enhance performance and prolong the lifespan of your vehicle, ensuring it operates at its best.

Begin by gathering the necessary tools and materials. Familiarize yourself with the specific components you will be working on, as understanding their functions is crucial for effective servicing. Ensure that you have a clean workspace to facilitate the process.

Next, proceed with the disassembly of parts as needed. Take care to label and organize components to simplify reassembly later. Documenting your steps with notes or photos can also be helpful.

Once disassembled, inspect each component for wear and damage. Replace any faulty parts with high-quality replacements to maintain reliability. Clean all surfaces thoroughly to prevent dirt accumulation and enhance the effectiveness of reassembly.

Reassemble the parts methodically, following the reverse order of disassembly. Ensure all fasteners are tightened to the manufacturer’s specifications to avoid any loose components during operation.

Finally, conduct a thorough inspection and test the motorcycle to confirm that all systems are functioning correctly. Regularly performing these tasks will keep your vehicle in optimal condition and ready for the road.

Electrical System Diagnostics

This section focuses on the evaluation and troubleshooting of the electrical components in a two-wheeled vehicle. Understanding the electrical framework is crucial for maintaining optimal performance and ensuring reliability. Diagnosing electrical issues can prevent breakdowns and enhance the longevity of the machine.

Common Issues

Frequent problems within the electrical system include malfunctioning lights, dead batteries, and irregularities in the ignition system. Identifying these issues early can help in implementing effective solutions, thereby improving the overall functionality of the vehicle.

Diagnostic Procedures

To effectively assess the electrical system, utilize specialized tools such as multimeters and circuit testers. Start by checking the battery voltage, followed by inspecting fuses and connections for signs of wear or damage. Systematic testing of components ensures that faults are accurately identified and resolved.

Engine Overhaul Guidelines

Conducting a comprehensive examination and refurbishment of the internal combustion unit is crucial for maintaining optimal performance and longevity. This process involves systematic steps that ensure each component functions effectively and adheres to manufacturer specifications.

- Preparation: Gather all necessary tools and equipment. Ensure a clean workspace to avoid contamination.

- Disassembly: Carefully remove the engine from the chassis. Document the order of disassembly for reference during reassembly.

- Inspection: Examine each part for wear and damage. Focus on critical components such as the crankshaft, pistons, and valves.

- Cleaning: Utilize appropriate solvents to remove carbon buildup and oil residues from all components.

- Replacement: Replace any worn or damaged parts with genuine or high-quality aftermarket alternatives.

- Reassembly: Follow the documented order and use the specified torque settings to ensure proper fitting of components.

- Testing: After reassembly, conduct tests to verify functionality. Monitor for any unusual noises or performance issues.

Regular overhauls can significantly enhance the reliability and efficiency of the engine. Adhering to these guidelines will help in achieving a successful refurbishment and prolong the life of the unit.

Brake System Inspection Techniques

Regular examination of the braking mechanism is essential for ensuring optimal performance and safety. This process involves a thorough assessment of various components, allowing for the identification of wear, damage, or potential malfunctions. Proper inspection techniques can significantly enhance the reliability of the entire system.

Visual Inspection: Begin with a detailed visual assessment of the braking elements. Look for signs of corrosion, cracks, or fluid leaks. Ensure that the brake pads and discs are in good condition, with no significant wear or scoring that could affect performance.

Fluid Level Check: Monitoring the hydraulic fluid level is crucial. Low fluid levels can lead to reduced braking efficiency. If the level is below the recommended mark, it may indicate leaks or other issues within the system.

Testing Brake Response: Conduct a functionality test by applying the brakes at low speeds. Pay attention to any unusual noises, vibrations, or inconsistent braking force. These indicators can help pinpoint underlying problems.

Component Condition Assessment: Inspect key components such as the calipers, hoses, and master cylinder. Ensure there are no obstructions or damages that could impede braking performance. Replace any worn or damaged parts promptly to maintain safety.

By adhering to these inspection techniques, one can effectively ensure the reliability and functionality of the braking system, ultimately contributing to a safer riding experience.

Wheel Alignment and Tire Care

Proper maintenance of wheel positioning and tire health is essential for optimal vehicle performance and safety. Ensuring that tires are correctly aligned can enhance handling, improve fuel efficiency, and extend the lifespan of tires. This section will delve into the significance of alignment and provide guidelines for effective tire management.

Regular checks and adjustments of the wheel alignment can prevent uneven wear and improve overall stability. Misalignment may result from various factors, including road conditions and driving habits. Therefore, it is advisable to have the alignment inspected periodically.

Additionally, maintaining tire condition is crucial. This includes monitoring tire pressure, checking tread depth, and rotating tires regularly to ensure even wear.

| Action | Frequency | Purpose |

|---|---|---|

| Check Tire Pressure | Monthly | Ensure optimal performance and safety |

| Inspect Tread Depth | Every 6 months | Prevent hydroplaning and enhance grip |

| Rotate Tires | Every 5,000 – 7,500 miles | Promote even wear and extend tire life |

| Wheel Alignment Check | Every 10,000 miles or after impact | Maintain stability and handling |

Following these guidelines will not only enhance safety but also contribute to a more enjoyable riding experience.

Oil Change and Fluid Management

Maintaining optimal performance of a motorcycle requires regular maintenance of its essential fluids. This section focuses on the importance of timely oil changes and proper fluid management to ensure smooth operation and longevity of the engine. Understanding the types of fluids required and the procedures for their maintenance is crucial for every rider.

Importance of Regular Oil Changes

Regular oil changes are vital to keep the engine running efficiently. Fresh oil lubricates moving parts, reduces friction, and helps dissipate heat. Over time, oil degrades and loses its effectiveness, potentially leading to engine wear and performance issues. It is essential to adhere to the recommended intervals for oil replacement to safeguard the engine’s health.

Fluid Management Guidelines

Effective fluid management involves monitoring and maintaining not just engine oil, but also other essential fluids. This includes coolant, brake fluid, and transmission fluid. Keeping these fluids at appropriate levels is necessary for optimal performance and safety.

| Fluid Type | Recommended Interval | Notes |

|---|---|---|

| Engine Oil | Every 3,000 miles | Use manufacturer-recommended oil type |

| Coolant | Every 2 years | Check levels regularly |

| Brake Fluid | Every 1 year | Replace if contaminated |

| Transmission Fluid | Every 12,000 miles | Ensure proper viscosity |

Accessories and Upgrades Recommendations

Enhancing your two-wheeled machine can significantly improve performance, comfort, and aesthetics. Whether you seek better handling, increased power, or a personalized look, a variety of enhancements are available to cater to different riding styles and preferences.

Performance Enhancements

For those aiming to boost engine efficiency and responsiveness, consider upgrading components such as exhaust systems and air filters. These modifications can lead to noticeable improvements in acceleration and overall ride quality.

Comfort and Safety Upgrades

To enhance the riding experience, investing in ergonomic accessories and safety gear is crucial. Options include upgraded seat cushions, handlebar grips, and advanced lighting systems to ensure better visibility on the road.

| Accessory/Upgrade | Benefit |

|---|---|

| Aftermarket Exhaust | Improved power and sound |

| High-Performance Air Filter | Enhanced airflow and throttle response |

| Comfort Seat | Increased comfort on long rides |

| LED Lighting Kit | Better visibility and safety |

| Handlebar Grips | Improved control and comfort |