In the world of portable energy solutions, ensuring optimal performance is crucial for both efficiency and longevity. Whether you are a seasoned technician or a novice user, familiarizing yourself with the intricacies of these machines can significantly enhance their functionality. This section delves into the fundamental aspects of maintaining and troubleshooting your power devices, providing you with the knowledge needed to tackle common challenges.

Comprehensive guidance on diagnosing issues, performing essential upkeep, and implementing effective solutions is key to sustaining operational reliability. Mastering these principles not only saves time and money but also empowers users to take control of their equipment’s performance. By understanding the components and processes involved, you can approach maintenance tasks with confidence and precision.

As you explore the various facets of upkeep, remember that regular attention to detail can prevent minor hiccups from escalating into major setbacks. With the right techniques and insights, you can ensure that your devices remain in peak condition, ready to deliver power when you need it most. Let’s embark on this journey towards enhanced knowledge and improved efficiency.

Understanding Yamaha Generators

This section explores the intricacies of portable power sources designed for various applications. These devices are essential for providing electricity in off-grid scenarios, construction sites, and outdoor events. Knowing their components and functionality can greatly enhance the user experience and ensure efficient operation.

Key Features and Benefits

Portable power units come equipped with numerous features that cater to diverse needs. Portability is a significant advantage, allowing users to transport these machines easily. Additionally, many models boast a variety of output options, enabling the connection of multiple devices simultaneously. Their reliability in emergency situations is another crucial aspect, providing peace of mind during outages.

Maintenance and Care

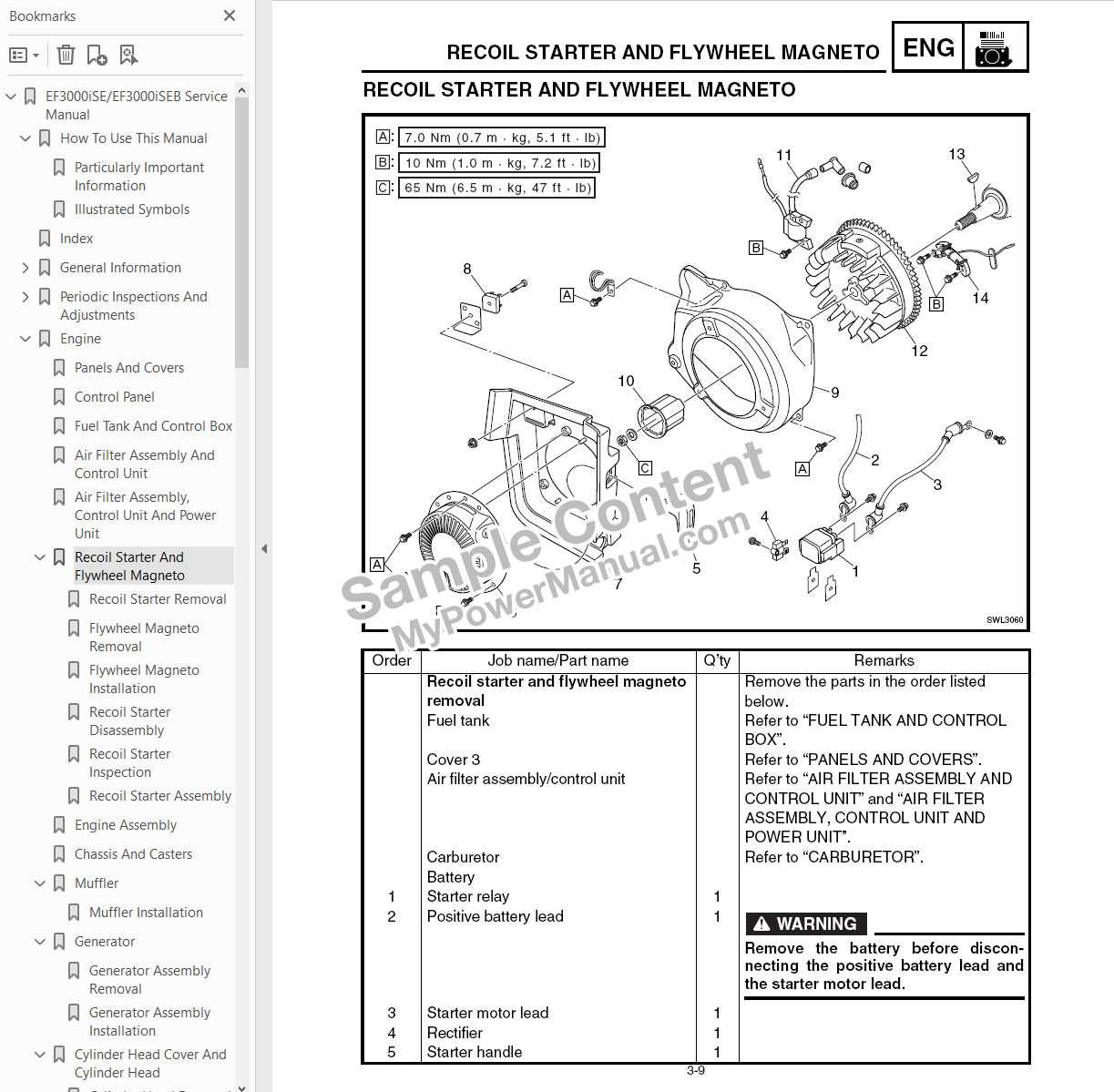

Proper upkeep is vital for optimal performance and longevity of these machines. Regular checks on fuel systems, air filters, and electrical connections can prevent potential issues. Understanding the importance of routine maintenance not only ensures consistent functionality but also enhances safety during operation. Following manufacturer guidelines can help users maintain their units effectively.

Common Issues with Yamaha Generators

When operating portable power sources, users may encounter various challenges that can affect performance and reliability. Understanding these common complications is essential for maintaining optimal functionality and ensuring a longer lifespan.

Frequent Problems

- Difficulty in Starting: Many users report that their units fail to start due to fuel issues or battery problems.

- Overheating: Insufficient ventilation or excessive load can lead to overheating, which may cause shutdowns.

- Noisy Operation: Unusual sounds often indicate internal issues, such as loose components or wear and tear.

- Power Fluctuations: Inconsistent voltage output may arise from faulty circuitry or fuel supply problems.

Maintenance Tips

- Regularly check and replace the oil to ensure proper lubrication.

- Inspect and clean the air filter to prevent blockages.

- Use high-quality fuel to minimize deposits in the system.

- Perform periodic inspections of electrical connections to detect wear.

Essential Tools for Repairs

When embarking on any maintenance task, having the right equipment at your disposal is crucial. Proper tools not only enhance efficiency but also ensure that the job is done safely and effectively. This section highlights the fundamental instruments that every technician should have for tackling various mechanical issues.

Basic Hand Tools

Basic hand tools are indispensable for most projects. These instruments allow for precise adjustments and facilitate the assembly and disassembly of components. Below is a table outlining some essential hand tools and their common uses:

| Tool | Use |

|---|---|

| Screwdriver Set | For tightening or loosening screws |

| Wrenches | For gripping and turning nuts and bolts |

| Pliers | For gripping, twisting, and cutting |

| Socket Set | For working with fasteners in tight spaces |

Specialized Equipment

In addition to basic tools, specialized equipment can greatly aid in more complex tasks. These tools are designed for specific functions and can make challenging jobs more manageable:

| Tool | Use |

|---|---|

| Multimeter | For measuring voltage, current, and resistance |

| Torque Wrench | For applying precise torque to fasteners |

| Compression Tester | For assessing engine performance |

| Fuel Pressure Gauge | For monitoring fuel system pressure |

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving issues that may arise with your power-producing unit. By following a systematic method, you can efficiently diagnose problems, ensuring optimal performance and longevity of your equipment.

Initial Checks

Begin by conducting a visual inspection of the device. Look for any obvious signs of damage, such as frayed wires or loose connections. Ensure that the fuel tank is filled and that the on/off switch is in the correct position. Additionally, verify that the oil level is adequate, as low oil can lead to operational failures.

Diagnostic Steps

If the initial checks do not reveal any issues, proceed to test the electrical components. Use a multimeter to measure voltage and continuity in the circuit. Check the spark plug for wear and replace it if necessary. Lastly, consult the user guidelines for any specific troubleshooting codes or indicators that may assist in pinpointing the problem.

By adhering to these steps, you can systematically address and resolve malfunctions, ensuring that your device functions efficiently and reliably.

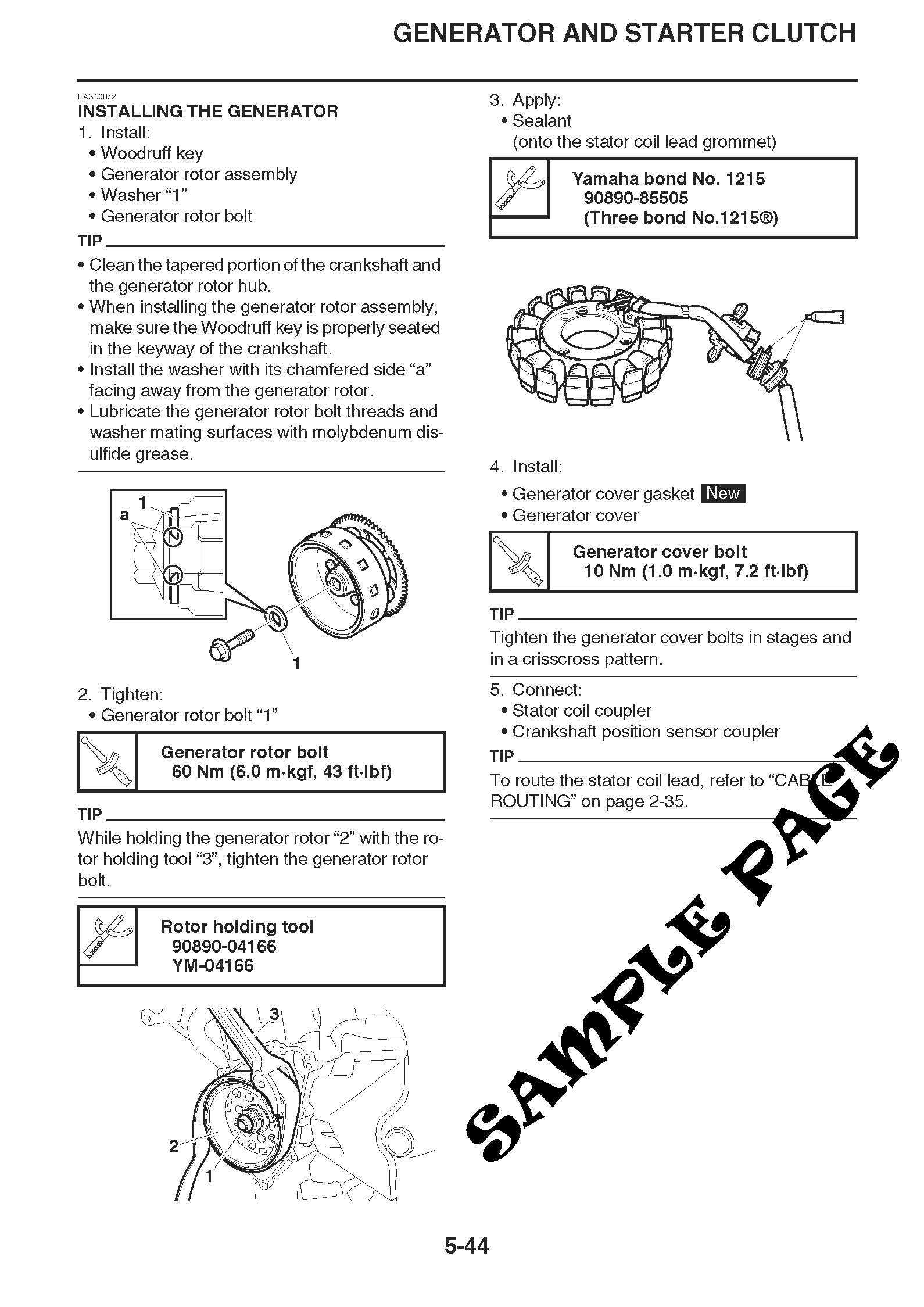

How to Replace Spark Plugs

Replacing the ignition components is crucial for maintaining optimal performance. This process can significantly enhance efficiency and extend the life of your equipment. Below is a straightforward guide to assist you in executing this task with ease.

- Gather Necessary Tools and Materials:

- New spark plugs

- Spark plug wrench or socket

- Torque wrench

- Gapping tool

- Anti-seize compound (optional)

- Ensure Safety:

- Disconnect the power source.

- Allow the engine to cool completely.

- Remove Old Spark Plugs:

- Locate the spark plug leads and carefully detach them.

- Use the spark plug wrench to unscrew the old plugs.

- Inspect the Old Plugs:

- Check for signs of wear or damage.

- Note any irregularities that could indicate engine issues.

- Prepare New Spark Plugs:

- Verify the gap using the gapping tool; adjust if necessary.

- Apply anti-seize compound on the threads if desired.

- Install New Spark Plugs:

- Carefully screw in the new plugs by hand to avoid cross-threading.

- Use the torque wrench to tighten them to the manufacturer’s specifications.

- Reconnect Spark Plug Leads:

- Ensure all leads are securely attached to the new plugs.

- Test the Equipment:

- Reconnect the power source and start the engine.

- Observe for smooth operation and listen for any unusual noises.

Following these steps will help ensure that your ignition components are functioning effectively, contributing to improved overall performance.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of your equipment. Regular attention to this area can prevent common issues and enhance efficiency. Below are some key practices to help maintain a healthy fuel system.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Fuel Quality | Monthly | Inspect the fuel for clarity and odor. Contaminated fuel can lead to performance issues. |

| Replace Fuel Filter | Every 100 hours | A clean filter ensures that impurities do not enter the system, enhancing efficiency. |

| Inspect Fuel Lines | Every 50 hours | Look for cracks, leaks, or deterioration that could lead to failures or leaks. |

| Clean Fuel Tank | Annually | Remove any sediment or debris that may accumulate, preventing blockages. |

| Monitor Fuel Levels | Before Use | Ensure that there is adequate fuel to avoid running the system dry, which can cause damage. |

By adhering to these maintenance guidelines, you can help ensure the reliability and efficiency of your equipment, allowing it to operate smoothly and effectively over time.

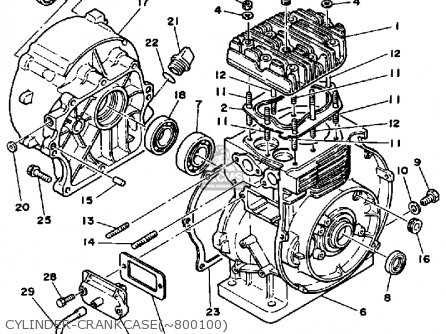

Electrical Components to Inspect

When maintaining any power-producing equipment, it is essential to examine various electrical elements to ensure optimal performance and safety. Understanding the key components and their functions can significantly aid in diagnosing issues and preventing potential failures.

Main Electrical Parts

- Battery: Check the battery condition, including charge levels and corrosion on terminals.

- Voltage Regulator: Ensure it is functioning properly to maintain consistent voltage output.

- Wiring Harness: Inspect for frays, cuts, or loose connections that could lead to shorts.

- Ignition System: Examine spark plugs, coils, and related components for wear and proper operation.

- Control Panel: Verify that all switches and indicators are working correctly.

Additional Checks

- Inspect connectors for signs of damage or overheating.

- Test circuit breakers to ensure they reset properly.

- Examine the starter motor for any signs of malfunction.

- Look for any unusual smells or sounds during operation that may indicate electrical issues.

- Ensure grounding connections are secure and free of rust or corrosion.

Regular inspection of these electrical components not only enhances performance but also prolongs the life of the equipment. Stay vigilant for any signs of wear or malfunction, and address issues promptly to maintain efficiency and safety.

Regular Maintenance Schedule Explained

Consistent upkeep is crucial for ensuring optimal performance and longevity of your equipment. Establishing a structured timeline for various maintenance tasks can help prevent unexpected issues and enhance reliability. This section outlines a typical maintenance schedule to keep your device running smoothly.

- Daily Checks:

- Inspect fuel levels to ensure adequate supply.

- Check for any visible leaks or damage.

- Examine electrical connections for corrosion or wear.

- Weekly Maintenance:

- Clean the air filter to prevent dust accumulation.

- Test the functionality of all control panels and indicators.

- Run the equipment for a brief period to maintain functionality.

- Monthly Upkeep:

- Change the oil and replace the oil filter if applicable.

- Inspect spark plugs and replace them as necessary.

- Check the battery condition and clean terminals.

- Quarterly Reviews:

- Examine the cooling system and clean any debris.

- Inspect belts and hoses for signs of wear.

- Calibrate settings to ensure accurate performance.

- Annual Maintenance:

- Conduct a comprehensive inspection of all components.

- Replace any worn or outdated parts as recommended.

- Perform a thorough cleaning of the entire unit.

Following this regular maintenance schedule can greatly enhance the functionality and extend the life of your machinery. Adjustments may be necessary based on specific usage conditions and manufacturer recommendations.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Following specific guidelines can help prevent accidents and promote a secure working environment. Adhering to these practices not only safeguards personal well-being but also enhances the efficiency of the process.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves and goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Ensure the power source is disconnected before starting any work.

- Keep a first aid kit nearby in case of emergencies.

- Stay organized to avoid clutter, which can lead to accidents.

Additional Tips for Safe Practices

- Read all instructions thoroughly before beginning any task.

- Use tools correctly and ensure they are in good condition.

- Never work alone; having a partner can provide assistance if needed.

- Be mindful of your surroundings to avoid tripping hazards.

- After completing the work, clean the area to prevent future incidents.

When to Seek Professional Help

Understanding when to call in an expert can be crucial for ensuring safety and efficiency. While some issues can be tackled with basic skills and knowledge, others may require specialized training and tools. Recognizing the signs that indicate the need for professional intervention is essential for effective troubleshooting.

Signs That Indicate a Need for Assistance

- Persistent issues despite troubleshooting efforts

- Unusual noises or vibrations during operation

- Frequent overheating or excessive emissions

- Complex electrical or mechanical failures

- Inability to identify the source of a problem

Benefits of Consulting a Professional

- Access to specialized tools and equipment

- Expert diagnosis of complex issues

- Ensured safety during repair processes

- Time efficiency, avoiding potential mishaps

- Long-term reliability and performance assurance

Parts Replacement for Optimal Performance

Ensuring that machinery operates at peak efficiency often hinges on the timely replacement of worn or malfunctioning components. Regularly assessing and updating critical parts not only enhances functionality but also prolongs the lifespan of the equipment. Understanding which elements require attention can significantly improve overall output and reliability.

Identifying key components that are prone to wear is essential. These may include filters, belts, and spark plugs, among others. Each plays a crucial role in the system’s performance. By regularly inspecting these parts and replacing them as needed, operators can avoid unexpected breakdowns and maintain consistent operation.

Moreover, utilizing high-quality replacement parts is paramount. Authentic components are designed to meet the specific requirements of the machinery, ensuring compatibility and optimal performance. Using substandard or generic alternatives can lead to inefficiencies and further complications down the line.

Finally, keeping a log of maintenance activities, including part replacements, can help track performance trends and highlight potential issues before they escalate. This proactive approach not only saves time and resources but also contributes to a safer and more efficient working environment.

Upgrading Your Yamaha Generator

Enhancing your power source can significantly improve performance and efficiency. By making targeted improvements, you can ensure reliable operation and extended lifespan. This section focuses on effective ways to elevate your equipment’s capabilities and address common limitations.

Choosing the Right Components

Identifying suitable parts for enhancement is crucial. Look for high-quality replacements that match or exceed original specifications. Upgrading the fuel system, electrical components, or air filtration can lead to noticeable gains in output and efficiency. Always verify compatibility before purchasing new elements.

Regular Maintenance Practices

Implementing a routine maintenance schedule is vital for optimal performance. Regularly checking and replacing filters, oil, and spark plugs can prevent issues and enhance functionality. Additionally, keeping the equipment clean and free from debris ensures that it operates smoothly, maximizing its potential.

FAQs About Generator Repairs

This section addresses common inquiries related to the maintenance and troubleshooting of portable power sources. Understanding these aspects can significantly enhance their longevity and performance.

- What are the signs that indicate a malfunction?

- Unusual noises during operation

- Difficulty starting or frequent stalling

- Inconsistent power output

- How often should routine checks be performed?

- Every 100 hours of operation

- At least once a year, regardless of usage

- Can I perform maintenance myself?

- Yes, many tasks like oil changes and filter replacements can be done independently.

- Refer to manufacturer guidelines for specific procedures.

- When should I seek professional help?

- If you encounter complex issues beyond basic troubleshooting.

- For internal component replacements or repairs.