Proper upkeep of garden machinery is essential for ensuring optimal performance and longevity. This resource serves as a vital tool for owners seeking to enhance their understanding of maintenance practices, troubleshooting techniques, and parts replacement for their outdoor equipment.

As with any complex machinery, familiarizing oneself with operational nuances and repair strategies can make a significant difference. By gaining insight into the specific components and common issues that may arise, users can tackle challenges with confidence and efficiency.

Whether you are a seasoned professional or a novice enthusiast, having access to detailed instructions and guidelines is invaluable. This guide aims to empower you with the knowledge needed to keep your equipment running smoothly and effectively, enabling you to focus on what truly matters: achieving a well-manicured lawn.

Overview of John Deere LX280

This section provides a comprehensive examination of a well-known riding machine designed for lawn care and maintenance. Recognized for its reliability and efficiency, this model is a popular choice among homeowners and professionals alike. It combines advanced engineering with user-friendly features, making it suitable for a variety of tasks.

Key Features

Equipped with a robust engine and an intuitive control system, this model offers a smooth and powerful performance. The design focuses on comfort and ease of use, ensuring that operators can navigate their lawns with minimal effort.

| Feature | Description |

|---|---|

| Engine Power | Efficient and powerful, ensuring optimal performance during operation. |

| Cutting Width | Offers a generous cutting width for quicker mowing sessions. |

| Transmission | Hydrostatic transmission provides seamless speed adjustments. |

| Comfort | Ergonomically designed seat and controls for a pleasant riding experience. |

Maintenance Considerations

Regular upkeep is essential to maintain performance and extend the lifespan of the machine. Users are encouraged to follow a routine that includes checking fluid levels, inspecting blades, and ensuring the overall functionality of the equipment.

Common Issues with LX280 Lawn Mowers

Understanding the frequent challenges faced by these garden machines can help owners maintain optimal performance and longevity. While they are designed for efficiency, various factors can lead to operational difficulties over time.

Starting Problems: One of the most common complaints is difficulty in starting. This can stem from a weak battery, faulty ignition system, or issues with the fuel supply. Regular checks on these components can prevent frustration during mowing sessions.

Uneven Cutting: Many users report inconsistent cutting heights, which can result from dull blades, incorrect tire pressure, or uneven deck adjustments. Ensuring blades are sharp and the mower is level can greatly improve cutting performance.

Overheating: Overheating may occur due to clogged air filters or insufficient oil levels. Regular maintenance, including cleaning filters and checking oil levels, is crucial for preventing overheating and ensuring smooth operation.

Grass Clumping: Another issue is grass clumping under the deck, often caused by wet grass or a build-up of debris. Cleaning the deck regularly and avoiding mowing in wet conditions can help mitigate this problem.

Transmission Issues: Users may experience difficulties with the transmission, which can be linked to low fluid levels or worn components. Regular inspections and timely replacements can enhance the longevity of the mower.

Addressing these common concerns through routine maintenance and timely interventions can ensure a smoother and more effective mowing experience.

Essential Tools for LX280 Repair

When maintaining and servicing your outdoor machinery, having the right equipment is crucial for efficiency and effectiveness. A well-equipped workspace not only streamlines the process but also enhances safety and accuracy during maintenance tasks. Understanding which instruments are necessary can make a significant difference in the overall experience and outcome of the work.

Basic Hand Tools

Start with a selection of basic hand tools that are indispensable for most maintenance activities. Wrenches, screwdrivers, and pliers are essential for loosening and tightening components. Ensure you have both metric and standard sizes to accommodate various fasteners. Additionally, a reliable socket set can save time and effort when tackling more complex assemblies.

Specialized Equipment

In addition to basic tools, some specialized instruments can greatly aid in specific tasks. A tire pressure gauge ensures your wheels are properly inflated, enhancing performance and safety. For electrical issues, a multimeter can help diagnose problems with the ignition and battery systems. Furthermore, a jack or lift is invaluable for gaining easy access to the underside of the machinery.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential for optimal performance and longevity. This guide provides a comprehensive approach to ensure your machine runs smoothly and efficiently. By following these structured steps, you can prevent potential issues and enhance the overall functionality of your device.

Routine Checks

Start with basic inspections to identify any visible wear or damage. Check the oil levels and look for any leaks around the engine. Ensure that the air filter is clean and free from debris. This initial assessment helps in spotting problems before they escalate.

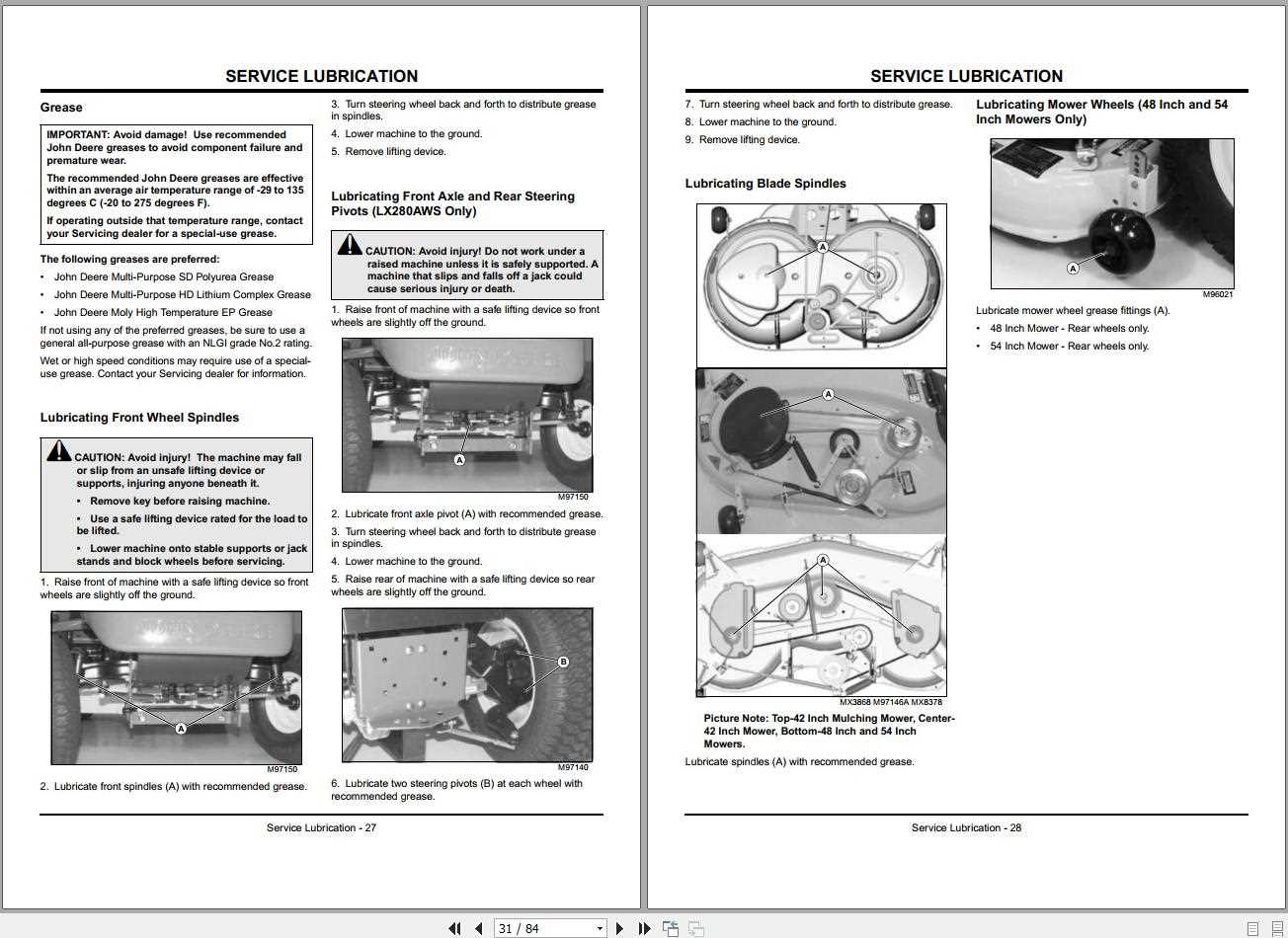

Cleaning and Lubrication

After conducting your checks, proceed with cleaning various components. Use a suitable cleaner to remove dirt and grime, particularly from the blades and undercarriage. Once clean, apply lubricants to moving parts to reduce friction and wear. Regular cleaning and proper lubrication are key to maintaining efficiency and preventing breakdowns.

Engine Troubleshooting Techniques

Diagnosing issues within an engine requires a systematic approach to identify potential problems effectively. Understanding the various symptoms and applying appropriate methods can lead to successful resolutions, ensuring optimal performance.

| Symptom | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Engine won’t start | Dead battery | Check battery voltage; jump-start if necessary. |

| Overheating | Coolant leak | Inspect hoses and radiator for leaks; refill coolant. |

| Excessive smoke | Oil contamination | Check oil level and quality; replace oil if dirty. |

| Loss of power | Clogged air filter | Inspect and clean or replace air filter. |

Understanding the Electrical System

The electrical system of any machinery plays a crucial role in its overall functionality. It encompasses various components that work together to ensure proper operation, providing power for starting, lighting, and other essential functions. A thorough understanding of this system is vital for diagnosing issues and maintaining efficiency.

This section will cover key elements of the electrical system, including wiring diagrams, battery functions, and circuit components. Familiarity with these aspects will enable better troubleshooting and enhance operational reliability.

| Component | Function |

|---|---|

| Battery | Stores electrical energy to start the engine and power accessories. |

| Alternator | Charges the battery and powers electrical systems when the engine is running. |

| Starter Motor | Engages the engine to initiate combustion. |

| Fuses | Protect circuits from overload by breaking the connection if current exceeds safe levels. |

| Wiring Harness | Connects all electrical components, facilitating communication and power transfer. |

Understanding these components will greatly aid in effective maintenance and troubleshooting, ensuring optimal performance of the equipment.

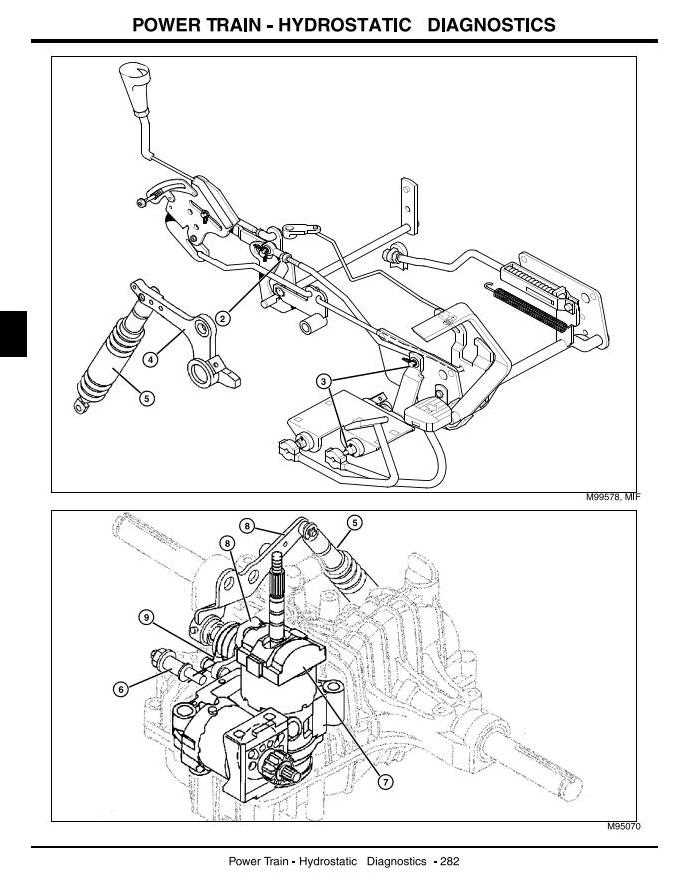

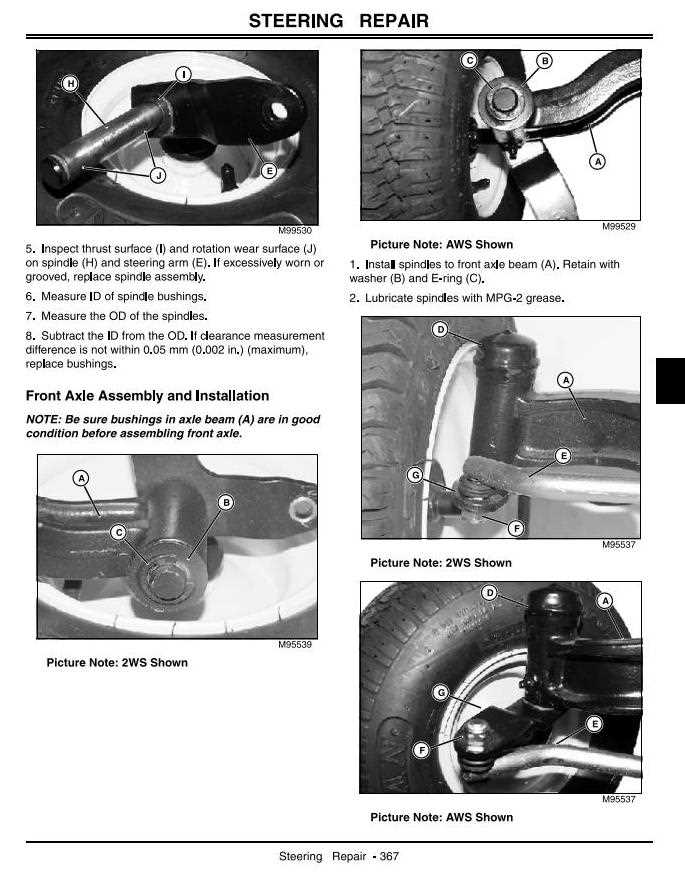

Transmission Repair and Adjustments

Effective management of the transmission system is essential for maintaining optimal performance and efficiency in your equipment. Regular assessments and modifications ensure that the components function smoothly, providing a reliable operation. Understanding the intricacies of adjustments can significantly enhance the longevity and effectiveness of the machinery.

Identifying Common Issues

Before undertaking any modifications, it’s crucial to recognize prevalent problems. Symptoms such as unusual noises, slippage, or difficulty in shifting gears can indicate underlying issues within the transmission. Regular inspections help in pinpointing these concerns early, allowing for timely interventions that prevent further complications.

Adjustment Techniques

Once issues are identified, appropriate adjustment techniques can be employed. Alignment of cables and linkages plays a critical role in ensuring smooth operation. For instance, ensuring that the shift linkage is properly aligned can eliminate shifting difficulties. Additionally, checking the fluid levels and quality is vital, as contaminated or low fluid can lead to poor performance. Always refer to the specific guidelines to ensure adjustments are executed accurately.

Incorporating these practices will not only enhance the functionality of the transmission system but also extend the overall lifespan of your equipment.

Deck and Blade Maintenance Tips

Proper upkeep of the cutting deck and blades is essential for optimal performance and longevity of your lawn care equipment. Regular attention to these components not only ensures a clean cut but also enhances the overall efficiency of your machine. Here are some essential tips to keep in mind for maintaining your deck and blades.

Regular Cleaning

After each use, it is crucial to clean the underside of the cutting deck. Grass clippings and debris can accumulate, affecting the cutting performance. Use a scraper or a pressure washer to remove buildup. Ensure the equipment is turned off and cool before starting this process to avoid accidents.

Blade Sharpening and Replacement

Maintaining sharp blades is vital for achieving a clean and even cut. Check the blades regularly for dullness or damage. A dull blade tears grass rather than cutting it, which can lead to lawn stress. Sharpen the blades as needed or replace them if they are excessively worn. Always follow the manufacturer’s guidelines for proper blade specifications.

Tip: When sharpening blades, maintain the original angle to ensure effective cutting performance.

By following these maintenance practices, you can significantly improve the efficiency of your equipment, leading to healthier grass and a beautifully manicured lawn.

Fuel System Cleaning Procedures

Maintaining the integrity of the fuel system is crucial for optimal performance and longevity of any engine. Regular cleaning helps to prevent issues such as clogging and poor fuel delivery, ensuring that the machine operates efficiently. This section outlines the essential steps and considerations for effectively cleaning the fuel system.

Preparation Steps

Before initiating the cleaning process, ensure that the engine is cool and positioned in a well-ventilated area. Gather all necessary tools and cleaning agents, including a fuel system cleaner, safety goggles, and gloves. Disconnect the battery to avoid any electrical hazards during the procedure. Always refer to the manufacturer’s recommendations for specific instructions related to the equipment being serviced.

Cleaning Process

Begin by draining any old fuel from the tank to prevent contamination during the cleaning. Next, introduce the fuel system cleaner into the tank, following the instructions on the product label for the correct ratio. Start the engine and let it run for a designated period, allowing the cleaner to circulate through the fuel lines, injectors, and combustion chamber. This action helps to dissolve deposits and improve overall system function. Afterward, replace the fuel filter and refill the tank with fresh fuel. Finally, conduct a brief test run to ensure that the system is performing optimally and that no leaks are present.

Identifying and Replacing Filters

Maintaining optimal performance of machinery involves regularly checking and replacing various components, including filters. These parts play a crucial role in ensuring that systems operate smoothly by trapping contaminants and ensuring clean fluid flow. Understanding how to identify and replace these elements is essential for anyone looking to keep their equipment in peak condition.

Types of Filters

There are several types of filters commonly found in machinery, including oil filters, air filters, and fuel filters. Each type serves a specific function: oil filters prevent impurities from circulating in the engine, air filters clean the air entering the engine, and fuel filters ensure that only clean fuel reaches the combustion chamber. Familiarizing yourself with the location and type of filters in your equipment is the first step towards effective maintenance.

Steps for Replacement

To replace a filter, first, locate the component according to the user guide or maintenance documentation. Once found, carefully remove the old filter, ensuring that any residual fluids are contained. Prepare the new filter by applying a thin layer of oil to the gasket, then install it securely. Always refer to specific guidelines for proper torque specifications and additional precautions to avoid any operational issues.

Winterizing Your LX280 Mower

Preparing your lawn equipment for the colder months is essential for maintaining its performance and longevity. Proper seasonal care ensures that your machine is ready to tackle the upcoming tasks when spring arrives. By following a few straightforward steps, you can safeguard your equipment against potential winter damage.

Start with Fuel Stabilization: Before storing your machine, add a fuel stabilizer to the gasoline. This will help prevent the fuel from deteriorating, which can cause starting issues in the spring. Run the engine for a few minutes to allow the stabilizer to circulate throughout the system.

Clean the Deck: Removing grass clippings and debris from the cutting deck is crucial. Any buildup can lead to corrosion and affect performance. Use a putty knife or a scraper to carefully clear away any remnants, followed by a thorough wash.

Check the Battery: Disconnecting the battery and storing it in a cool, dry place can extend its life. Consider charging it periodically throughout the winter to ensure it’s fully operational when you need it again.

Inspect and Change Fluids: Check the oil level and replace it if necessary. Clean oil keeps internal components lubricated and free from contaminants. Similarly, check the air filter and replace it if it shows signs of wear.

Protect from the Elements: If possible, store your equipment in a sheltered area. Covering it with a breathable tarp can provide protection from dust and moisture, further prolonging its lifespan.

By taking these preventive measures, you can ensure that your lawn equipment remains in optimal condition, ready to perform when the season changes.

Recommended Replacement Parts Sources

Finding high-quality components is crucial for maintaining the efficiency and longevity of your equipment. Below are several reliable sources where you can purchase essential replacement items to ensure your machinery operates smoothly.

- Authorized Dealers: These vendors often have the most accurate stock of parts designed specifically for your model. They typically provide expert advice and support.

- Online Retailers: Websites such as Amazon, eBay, and specialized machinery parts stores offer a vast range of components. Ensure you check the seller’s ratings and reviews for reliability.

- Local Hardware Stores: Many community hardware stores carry essential parts and can often place special orders for specific items you may need.

- Aftermarket Suppliers: Companies that manufacture compatible parts can be a cost-effective alternative. Be sure to compare quality and warranty options.

Always verify the compatibility of parts with your specific equipment model to avoid any potential issues during installation or operation.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on machinery is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the task but also safeguard the equipment itself. Following specific guidelines can help create a secure working environment.

Before beginning any maintenance activity, it is essential to familiarize oneself with the equipment and its components. Understanding how the machinery operates can significantly reduce risks. Always wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and sturdy footwear to shield against potential hazards.

| Safety Measure | Description |

|---|---|

| Power Off | Ensure that the equipment is turned off and disconnected from any power source before starting work. |

| Clear Workspace | Remove any clutter or unnecessary items from the work area to minimize trip hazards. |

| Use Tools Properly | Utilize the correct tools for the job and ensure they are in good condition to avoid malfunctions. |

| Stay Focused | Maintain concentration during the task and avoid distractions that could lead to mistakes. |

| Seek Assistance | Do not hesitate to ask for help if unsure about any procedures or handling heavy components. |

Adhering to these safety measures can significantly enhance the security of maintenance activities, making the process more efficient and effective. Prioritizing safety fosters a responsible work culture and reduces the likelihood of incidents.