Understanding the intricacies of machinery is crucial for ensuring optimal performance and longevity. This section provides essential insights into the various aspects of upkeep, enabling users to tackle issues effectively. With a focus on practical solutions, it aims to empower operators and technicians alike.

From routine checks to advanced troubleshooting techniques, the information presented here is designed to enhance knowledge and facilitate informed decision-making. Whether you’re addressing minor concerns or preparing for major interventions, the following guidelines will serve as a valuable resource.

Equipped with the right knowledge, anyone can navigate through potential challenges and maintain peak functionality. This guide emphasizes hands-on approaches and practical tips that cater to all levels of expertise, ensuring that users feel confident in their ability to manage equipment with ease.

Many individuals encounter various challenges while operating their heavy machinery. Understanding these common problems can help owners maintain efficiency and prolong the lifespan of their equipment.

Mechanical Failures

One of the prevalent issues includes unexpected mechanical breakdowns. These failures often stem from wear and tear over time, leading to costly repairs and downtime.

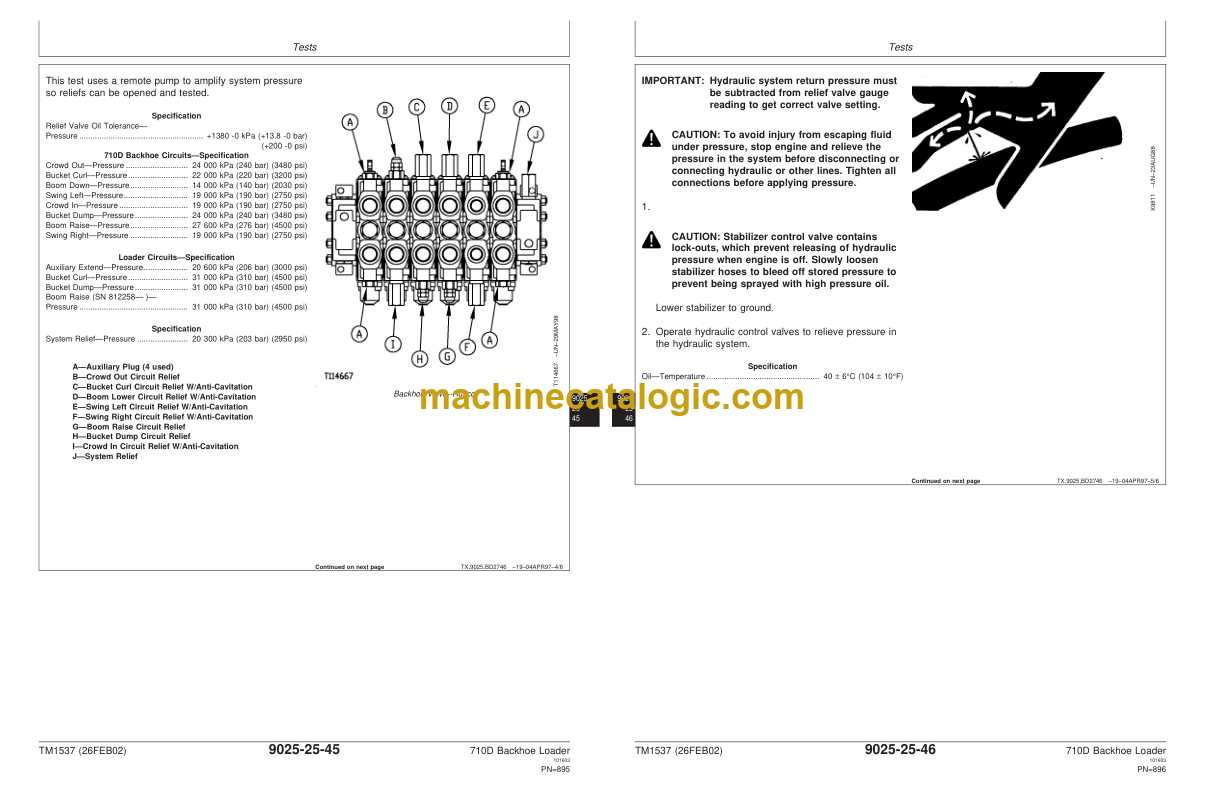

Hydraulic System Leaks

Another frequent concern involves leaks in the hydraulic system. Such leaks can reduce performance and necessitate immediate attention to prevent further damage.

| Issue | Description | Solution |

|---|---|---|

| Mechanical Failures | Unexpected breakdowns due to wear. | Regular maintenance and inspections. |

| Hydraulic System Leaks | Fluid leaks affecting performance. | Immediate repair of leaking components. |

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and restoring machinery efficiently. Various implements are necessary to ensure that tasks are completed effectively and safely. Understanding which tools are essential can make a significant difference in both the process and the results of maintenance efforts.

Wrenches are fundamental for loosening and tightening bolts, while screwdrivers come in handy for a variety of fastening applications. It’s also important to have pliers for gripping and bending materials.

Another vital category includes cutting tools, such as saws and knives, which allow for precise modifications. Additionally, measuring instruments ensure accuracy during the repair process, enabling users to gauge dimensions correctly and maintain specifications.

Finally, investing in a reliable toolbox to organize and store these implements is essential for accessibility and efficiency during any maintenance project. With the right set of tools, anyone can approach restoration tasks with confidence and competence.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing and resolving issues that may arise with your machinery. Following a structured method helps in identifying problems efficiently, ensuring a smoother operational experience.

Common Issues and Solutions

Below are some frequently encountered problems along with their corresponding solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Dead battery | Recharge or replace the battery |

| Unusual noises | Loose components | Tighten all connections and fasteners |

| Poor performance | Clogged filters | Clean or replace air and fuel filters |

Diagnostic Steps

To effectively troubleshoot, follow these steps:

- Begin by observing any warning indicators.

- Inspect fluid levels and check for leaks.

- Listen for abnormal sounds while the engine is running.

- Perform visual inspections of all major components.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of heavy machinery requires regular care and attention. By following a set of simple yet effective maintenance practices, operators can extend the lifespan of their equipment and enhance its efficiency.

Regularly check fluid levels, including oil, coolant, and hydraulic fluids, to prevent overheating and component wear. Keeping these fluids at recommended levels ensures smooth operation and reduces the risk of damage.

Routine inspections of key components such as filters, belts, and hoses are essential. Replacing worn parts promptly helps maintain performance and prevents costly breakdowns. Additionally, cleaning the equipment regularly removes dirt and debris that can hinder operation.

Proper storage is another critical aspect of maintenance. When not in use, storing machinery in a dry, sheltered area protects it from environmental elements that can cause rust and corrosion.

Lastly, adhering to a scheduled maintenance program recommended by the manufacturer provides a systematic approach to upkeep. This proactive strategy ensures all necessary checks and services are performed in a timely manner, safeguarding the investment for years to come.

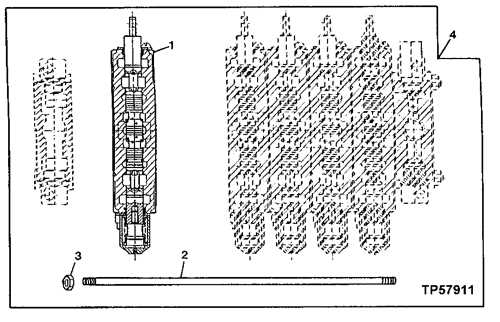

Parts Replacement: What You Need

When it comes to maintaining heavy machinery, understanding the essentials of component substitution is crucial. Knowing when and how to replace parts can significantly enhance the longevity and efficiency of your equipment.

Identifying Wear and Tear: Regular inspections help in detecting signs of deterioration. Look for unusual noises, leaks, or decreased performance, which may indicate that specific components require attention.

Choosing Quality Components: Always opt for high-quality parts that meet or exceed manufacturer specifications. This ensures compatibility and reliability, preventing further issues down the line.

Tools and Preparation: Before starting the replacement process, gather all necessary tools and components. A well-organized workspace and the right equipment streamline the task, making it more efficient and safer.

Follow Manufacturer Guidelines: Adhering to established protocols is essential. Consult documentation that provides detailed instructions for the replacement process, ensuring that you follow best practices for safety and functionality.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to protect both the individual and the equipment. Adhering to specific guidelines can prevent accidents and promote a secure working environment.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hard hats.

- Ensure that the workspace is clean and organized to minimize hazards.

- Disconnect power sources before starting any maintenance work to avoid accidental activation.

- Use tools that are suitable for the task at hand and in good condition.

- Keep a first aid kit accessible and know the location of emergency exits.

Following these precautions can significantly reduce the risk of injury and ensure a smooth working process. It is essential to be aware of surroundings and stay focused on the task.

Using the Manual Effectively

Leveraging a comprehensive guide can significantly enhance your understanding and management of complex machinery. This section focuses on maximizing the benefits of such documentation to ensure optimal performance and maintenance of your equipment.

To utilize the guide effectively, consider the following strategies:

- Familiarize Yourself: Before diving into specific tasks, take some time to read through the sections to understand the overall structure and organization.

- Identify Key Sections: Locate vital chapters that pertain to troubleshooting, maintenance schedules, and operational procedures to quickly address any concerns.

- Follow Step-by-Step Instructions: Adhering to detailed steps outlined in the document can prevent errors and enhance the reliability of your efforts.

- Utilize Diagrams and Illustrations: Visual aids can provide clarity and help in understanding complex processes, making them easier to follow.

- Refer Back Frequently: Regularly consult the guide throughout your tasks to ensure compliance with recommended practices and to refresh your memory on critical points.

By adopting these practices, you can ensure that you are making the most of the available resources, ultimately leading to improved outcomes and equipment longevity.

Where to Find Genuine Parts

Finding authentic components for heavy machinery is crucial for ensuring optimal performance and longevity. Utilizing reliable sources helps in maintaining the integrity of your equipment, providing peace of mind and enhancing overall efficiency.

Authorized Dealers

Authorized dealers are often the best option for acquiring genuine parts. They typically offer a wide range of original components, ensuring compatibility and quality. Checking with your local dealer can provide insights into the availability of the necessary parts.

Manufacturer’s Website

Another excellent resource is the manufacturer’s website. Many manufacturers have dedicated sections for parts and accessories, allowing you to search for specific components. This option ensures you are purchasing directly from the source, which can often provide warranty and support benefits.

Resources for Further Assistance

For individuals seeking additional support with their equipment, a variety of resources are available to enhance understanding and troubleshooting capabilities. Utilizing these references can significantly improve operational efficiency and maintenance procedures.

Online forums and communities often provide valuable insights from experienced users who have encountered similar challenges. Engaging with these platforms can facilitate knowledge sharing and offer practical solutions.

Furthermore, technical documentation, videos, and guides are essential for in-depth comprehension. Accessing these materials ensures that users can follow step-by-step instructions and best practices.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community discussions and troubleshooting tips. | Visit Forum |

| Technical Documentation | Official guides and specifications for reference. | Access Documentation |

| Video Tutorials | Visual guides demonstrating repair and maintenance tasks. | Watch Tutorials |