This section provides a thorough overview of essential practices for ensuring the longevity and optimal functionality of your textile apparatus. Understanding the intricacies of care can enhance performance and prevent potential issues, allowing for a seamless crafting experience.

Equipping yourself with the right knowledge and techniques is crucial. From routine assessments to more complex interventions, a structured approach can make all the difference. Here, we delve into the fundamentals, offering insights that empower you to maintain your apparatus effectively.

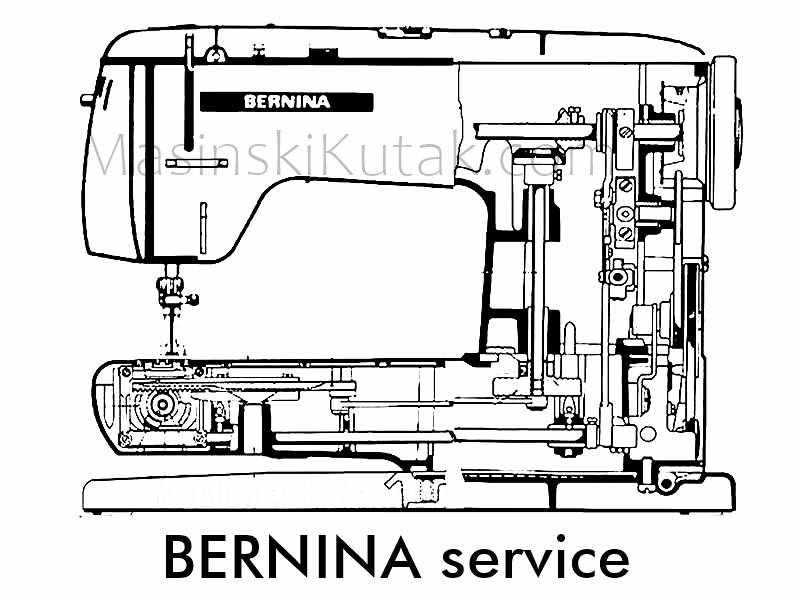

Whether you’re addressing minor adjustments or exploring detailed troubleshooting methods, familiarity with your equipment’s components is paramount. This guide aims to furnish you with the ultimate resources needed to navigate maintenance tasks confidently.

Comprehensive Guide to Bernina Repairs

This section provides a detailed overview of how to address common issues encountered with textile devices, ensuring smooth operation and longevity. Whether you are dealing with performance hiccups or functionality concerns, understanding the essential components and their maintenance can greatly enhance your experience.

Understanding Common Issues

Devices can face various challenges, such as inconsistent stitching or unusual sounds. Identifying the root cause is crucial for effective troubleshooting. Regular maintenance practices, including cleaning and lubrication, can often prevent these problems from arising.

Step-by-Step Troubleshooting Techniques

When difficulties arise, following a systematic approach can be beneficial. Begin by examining the threading mechanism, as improper setup can lead to many complications. Next, assess the tension settings, as incorrect adjustments can significantly impact performance. Additionally, ensuring that the device is free of debris and lint will promote optimal functionality.

For more complex issues, consulting a professional may be advisable. Having a solid understanding of the device’s components will empower you to make informed decisions regarding maintenance and repairs.

Understanding Your Sewing Machine

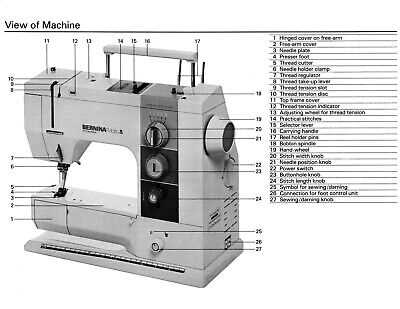

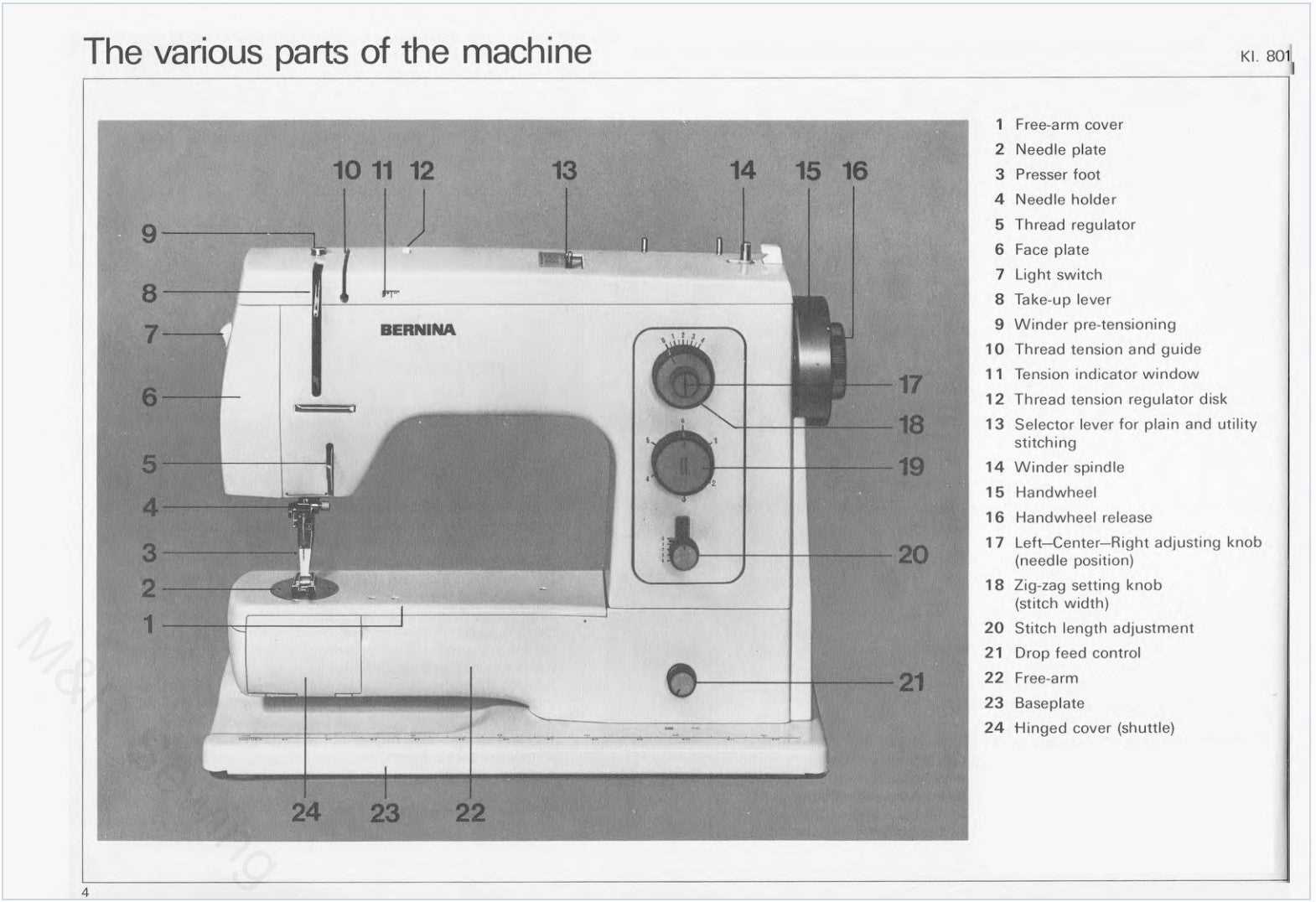

Gaining insight into your textile creation device is essential for achieving optimal performance. Familiarity with its components and functions can significantly enhance your crafting experience. This knowledge not only facilitates smooth operation but also empowers you to troubleshoot issues effectively.

The heart of your apparatus lies in its mechanism, which combines various elements to produce precise stitches. Recognizing the purpose of each part, from the feed dogs to the needle, will help you understand how they work together harmoniously. Proper maintenance is crucial for ensuring longevity and reliability. Regularly checking and cleaning these components prevents common problems that can disrupt your workflow.

Additionally, mastering the settings and controls allows for greater creativity in your projects. Exploring different stitch options and adjustments can transform your work, leading to unique outcomes. Taking the time to explore and learn will elevate your skills and inspire confidence in your abilities.

Common Issues with Bernina Models

When it comes to crafting tools, users may encounter various challenges that can affect their overall experience. Understanding these typical concerns can help in addressing them effectively, ensuring smooth operation and longevity of the equipment.

One frequent problem involves thread tension. Improper adjustments can lead to uneven stitching, causing frustration during projects. It is essential to regularly check and calibrate the tension settings to achieve optimal results.

Another common challenge is needle issues. Dull or bent needles can result in skipped stitches or fabric damage. Regularly replacing needles and selecting the appropriate type for different materials can enhance performance significantly.

Users might also face bobbin complications. Issues such as improper threading or incorrect bobbin type can lead to jams or inconsistent stitching. Familiarizing oneself with the specific bobbin requirements can mitigate these concerns.

Finally, motor sounds can indicate underlying issues. Unusual noises may suggest mechanical wear or obstructions. It is advisable to conduct periodic maintenance checks to ensure the internal components are functioning smoothly.

Tools Needed for Repair

When undertaking maintenance tasks, having the right instruments at your disposal is essential. These tools facilitate the process, ensuring efficiency and precision. A well-equipped toolkit not only simplifies the job but also enhances the overall experience.

Essential Instruments

- Screwdrivers: A variety of sizes, including Phillips and flathead, is crucial for accessing different components.

- Wrenches: Adjustable wrenches help in loosening and tightening various nuts and bolts.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small parts.

- Scissors: A good pair of sharp scissors is necessary for cutting threads and fabrics.

Additional Accessories

- Lubricants: Oils and greases are important for maintaining moving parts.

- Cleaning cloths: Soft, lint-free cloths are ideal for keeping surfaces clean.

- Flashlight: A bright light source helps illuminate hard-to-see areas during inspections.

- Measuring tools: Rulers and measuring tapes are useful for precise measurements of materials.

Step-by-Step Troubleshooting Process

When facing issues with your textile creation tool, following a systematic approach can help identify and resolve problems effectively. This process involves several key steps that guide you in diagnosing and addressing the underlying causes of malfunction.

- Begin by observing the behavior of the device. Note any unusual sounds or movements that may indicate a specific issue.

- Check the power source. Ensure that the unit is properly plugged in and that the outlet is functioning.

- Examine the threading. Verify that the thread is correctly positioned and that there are no tangles or breaks.

- Inspect the tension settings. Adjust the tension as needed to ensure optimal performance.

- Look for blockages. Clear any debris or fabric remnants that might be obstructing the components.

- Run a test. After making adjustments, perform a small test to determine if the issue has been resolved.

If problems persist, consider consulting additional resources or seeking professional assistance for more complex challenges.

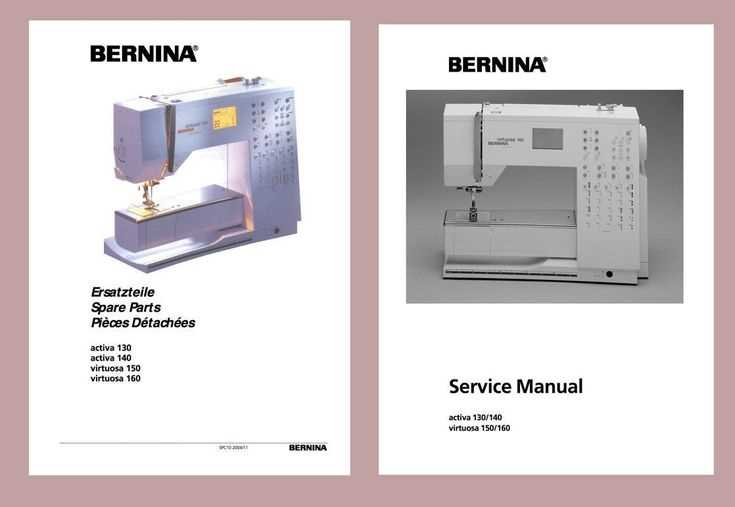

Replacing Worn Out Parts

Maintaining optimal functionality involves addressing the replacement of aged components. Regularly assessing the condition of critical elements ensures continued efficiency and performance. When parts show signs of wear, timely intervention is essential to prevent further issues.

Identifying Deteriorated Components

Begin by inspecting each crucial section for any visible signs of damage or excessive wear. Listen for unusual noises and observe any irregularities during operation. Proactive evaluation can save time and resources in the long run.

Steps for Replacement

Once worn parts are identified, consult reliable sources for appropriate replacements. Carefully remove the damaged components and install the new ones following detailed instructions. Ensuring proper alignment and secure fittings will enhance longevity and reliability.

Maintaining Your Bernina Machine

Regular upkeep is essential for ensuring optimal performance and longevity of your textile creation device. Implementing simple care practices can enhance functionality and prevent future complications. This section outlines key procedures to follow for preserving your apparatus in excellent condition.

Daily Care Tips

Incorporating a few daily habits can significantly impact the efficiency of your device. Ensure to clean the area around the needle and remove any fabric debris. Lubricating moving parts regularly will facilitate smoother operation and reduce wear over time.

Long-Term Maintenance Strategies

For sustained performance, consider conducting thorough inspections and servicing your device periodically. Checking electrical connections and ensuring that the tension is set correctly can prevent potential issues. Furthermore, storing your apparatus in a protective cover when not in use will shield it from dust and environmental factors.

| Maintenance Task | Frequency |

|---|---|

| Clean the needle area | Daily |

| Lubricate moving parts | Weekly |

| Check electrical connections | Monthly |

| Store in a protective cover | Always |

Cleaning Techniques for Optimal Performance

Maintaining the functionality of your fabric crafting device is essential for achieving high-quality results. Regular cleansing practices not only enhance performance but also prolong the lifespan of the equipment. Implementing effective methods ensures that dust and debris do not hinder operations.

Routine Maintenance is crucial for optimal efficiency. Establish a schedule for cleaning to prevent buildup that can affect performance. Utilize a soft brush or cloth to remove lint and particles from accessible areas, ensuring all components operate smoothly.

Lubrication is another vital aspect of upkeep. Apply appropriate oils to moving parts, following the guidelines provided by the manufacturer. This practice minimizes friction and promotes seamless functionality.

Storage Considerations also play a significant role. When not in use, cover the device to protect it from dust. A clean and organized workspace contributes to overall efficiency and ease of access.

By adopting these cleaning techniques, you will enhance the overall performance of your crafting device, ensuring it remains reliable and effective for all your creative projects.

Adjusting Tension and Stitch Quality

Proper tension and stitch quality are crucial for achieving flawless results in textile crafting. Understanding how to manipulate these factors allows for improved outcomes in various projects, ensuring that each creation meets the desired standards.

Importance of Tension Settings

Achieving the right balance in tension settings can significantly impact the overall appearance and durability of the final product. A correctly adjusted tension allows threads to interlock perfectly, preventing puckering or loose stitches. It is essential to test and fine-tune these settings regularly, especially when changing materials or patterns.

Evaluating Stitch Quality

Regular evaluation of stitch quality can help identify any issues before they escalate. Look for consistent spacing and evenness in the stitching. If discrepancies arise, adjustments in tension or technique may be necessary. Pay attention to any irregularities, as they can indicate underlying problems that need to be addressed promptly for optimal results.

Understanding Error Messages and Codes

Error notifications and numerical indicators can often be perplexing for users. These signals serve as vital communication tools that inform the operator about potential issues or malfunctions within the apparatus. Recognizing and interpreting these alerts is essential for effective troubleshooting and maintaining optimal functionality.

Common Error Indicators

Various alerts may arise, each corresponding to specific conditions. Familiarizing oneself with these common indicators can streamline the diagnostic process. For instance, a flashing light might signify a threading issue, while a specific code could point to a malfunction in the internal mechanisms.

Interpreting Numerical Codes

Numerical codes often provide deeper insights into the nature of the problem. Each code typically aligns with a distinct malfunction, offering a clearer direction for corrective actions. Consulting the corresponding reference guide can elucidate the meaning behind each code, facilitating timely resolutions and ensuring smooth operation.

Resources for Further Assistance

For individuals seeking guidance and support, numerous platforms offer valuable insights and troubleshooting tips. These resources are essential for enhancing understanding and resolving issues effectively.

Online Communities

Participating in forums and social media groups can provide a wealth of knowledge. Enthusiasts often share experiences and solutions, creating a supportive environment for all skill levels.

Professional Services

Consulting with skilled technicians or visiting specialized shops can offer personalized help. These professionals are equipped to address specific concerns and provide expert advice tailored to individual needs.

When to Seek Professional Help

Recognizing the right moments to consult an expert can significantly enhance the longevity and functionality of your crafting tool. While many issues can be resolved independently, some situations necessitate the skills and insights of a seasoned professional to ensure optimal performance.

Signs of Complex Issues

If you encounter persistent malfunctions or unusual noises that do not resolve with basic troubleshooting, it may indicate deeper complications. Ignoring these symptoms can lead to further damage, making timely intervention crucial.

When Self-Help Fails

In instances where standard adjustments and maintenance yield no improvement, seeking assistance becomes essential. A qualified technician can provide specialized knowledge, diagnosing problems that may not be evident to the untrained eye. Their expertise ensures your equipment is restored to peak condition, allowing for seamless creative endeavors.