In the realm of off-road riding, understanding the intricacies of your vehicle’s operation is paramount. This section aims to provide essential insights and guidance for enthusiasts looking to enhance their knowledge and ensure the longevity of their all-terrain companion. Whether you are a seasoned rider or new to the sport, having a solid grasp of maintenance practices can significantly impact your riding experience.

Regular upkeep not only maximizes performance but also minimizes potential issues that could arise during your adventures. With the right techniques and troubleshooting strategies, you can keep your vehicle in top-notch condition, ready to tackle any terrain. Here, we will explore various aspects of care, including key components, common challenges, and effective solutions to maintain your machine’s efficiency and reliability.

By arming yourself with the right information, you can confidently navigate through any obstacles that may come your way. A well-maintained vehicle opens the door to exhilarating experiences and unforgettable journeys, making it essential for every off-road enthusiast to prioritize understanding their machine.

This section aims to provide a comprehensive overview of various models within a specific category of vehicles, highlighting their unique features, specifications, and common issues that users may encounter. By understanding these aspects, individuals can enhance their knowledge and effectively address maintenance and troubleshooting needs.

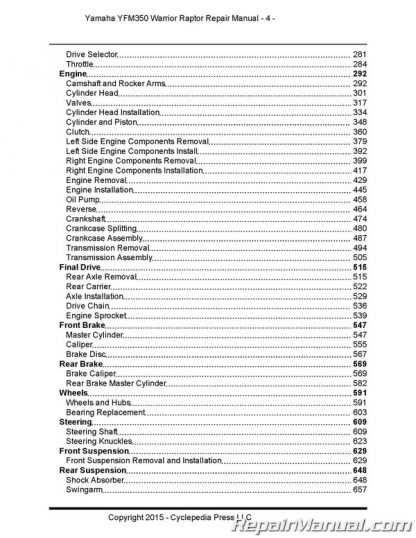

| Model Name | Engine Type | Year of Manufacture | Common Issues |

|---|---|---|---|

| Model A | 4-stroke, Single-cylinder | 2010 | Fuel system problems, Electrical issues |

| Model B | 4-stroke, V-twin | 2015 | Overheating, Transmission failures |

| Model C | 2-stroke, Single-cylinder | 2018 | Carburetor adjustments, Suspension wear |

Common Issues with Yamaha Warriors

When operating all-terrain vehicles, enthusiasts often encounter a variety of challenges that can affect performance and reliability. Understanding these common complications is essential for maintaining optimal functionality and enjoying a smooth riding experience.

One frequent issue involves engine performance. Riders may notice difficulties in starting or irregular idling, which can stem from problems with the fuel system or ignition components. Ensuring proper maintenance of these parts is crucial for preventing further complications.

Another common challenge relates to suspension. Over time, the components may wear down, leading to reduced stability and handling. Regular inspections and timely replacements of worn parts can significantly improve the vehicle’s performance on rough terrain.

Additionally, brake issues are often reported, with users experiencing diminished stopping power. This can be attributed to worn brake pads or fluid leaks, necessitating prompt attention to ensure rider safety.

Lastly, electrical failures can disrupt the operation of various systems, including lights and gauges. Investigating wiring connections and battery health can help address these electrical challenges, allowing for a more reliable ride.

Essential Tools for Repairs

Having the right set of instruments is crucial for conducting effective maintenance and troubleshooting on your vehicle. Proper tools not only facilitate the process but also ensure that the work is completed efficiently and safely. Below are some indispensable instruments that every enthusiast should consider for their toolkit.

Basic Hand Tools

Start with a fundamental assortment of hand tools, which typically includes wrenches, screwdrivers, and pliers. Wrenches are essential for loosening or tightening bolts, while screwdrivers come in various sizes and types to fit different screw heads. Pliers are useful for gripping, twisting, and cutting wires.

Specialized Equipment

In addition to basic tools, specialized equipment can greatly enhance your ability to perform detailed tasks. Torque wrenches are necessary for applying precise tension to fasteners, while socket sets allow for quick access to various sizes of nuts and bolts. Investing in a multimeter can help diagnose electrical issues, ensuring a comprehensive approach to maintenance.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your vehicle in optimal condition. Regular upkeep is essential for enhancing performance, extending lifespan, and ensuring safety. Follow these systematic steps to ensure that every aspect of the machine receives the attention it deserves.

1. Regular Inspections: Begin with routine checks of essential components such as the engine, brakes, and tires. Look for signs of wear or damage that could affect functionality.

2. Fluid Levels: Ensure that all fluid levels, including oil, coolant, and brake fluid, are within recommended ranges. Top off any fluids that are low and replace them as necessary.

3. Air Filter Maintenance: Check the air filter for dirt and debris. Clean or replace it as needed to maintain optimal airflow to the engine, which is crucial for performance.

4. Battery Care: Inspect the battery for corrosion and ensure connections are tight. Clean terminals and check the battery charge to avoid unexpected failures.

5. Tire Maintenance: Monitor tire pressure regularly and ensure that tread depth is sufficient. Rotate tires as needed and align wheels to enhance handling and prolong tire life.

6. Brake System Checks: Examine brake pads and discs for wear. Replace any components that show signs of excessive wear to maintain safety and performance.

7. Chain and Sprocket Maintenance: Keep the chain lubricated and properly tensioned. Inspect sprockets for wear and replace them if they show significant damage.

8. Final Check: After completing all maintenance tasks, conduct a final inspection to ensure everything is secure and functioning properly. Test drive the vehicle to confirm that all systems operate as intended.

By adhering to this maintenance guide, you can ensure that your machine remains reliable and performs at its best for years to come.

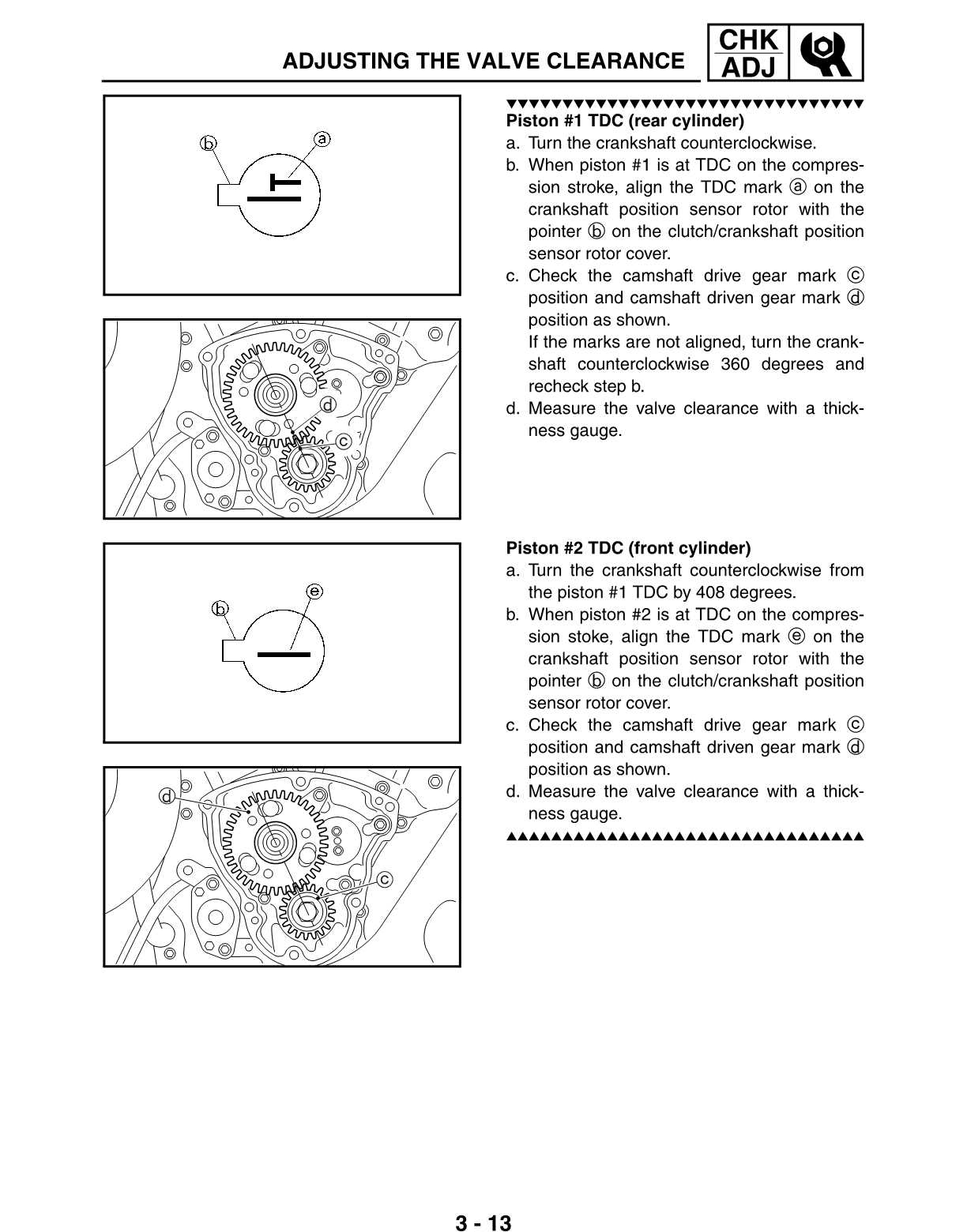

Engine Troubleshooting Tips

Identifying issues with your engine can be challenging, but with systematic approaches, you can effectively diagnose and resolve problems. This section provides essential guidance to help you pinpoint common engine malfunctions and implement appropriate solutions.

Check the Fuel System: Ensure that the fuel is reaching the engine properly. Inspect the fuel lines, filter, and pump for any blockages or leaks. A clogged filter can restrict flow, leading to performance issues.

Monitor Engine Sounds: Unusual noises can indicate underlying problems. Listen for knocking, grinding, or excessive vibrations, which may suggest issues with internal components or misalignment.

Inspect the Ignition System: A faulty ignition system can lead to starting difficulties and poor performance. Check the spark plugs for wear and replace them if necessary. Ensure that the ignition timing is set correctly for optimal combustion.

Examine Fluid Levels: Low levels of oil or coolant can cause significant engine damage. Regularly check and top off fluids as needed. Overheating due to insufficient coolant can lead to severe engine failure.

Utilize Diagnostic Tools: Employ diagnostic equipment to read error codes if available. This technology can provide valuable insights into the specific issues affecting engine performance.

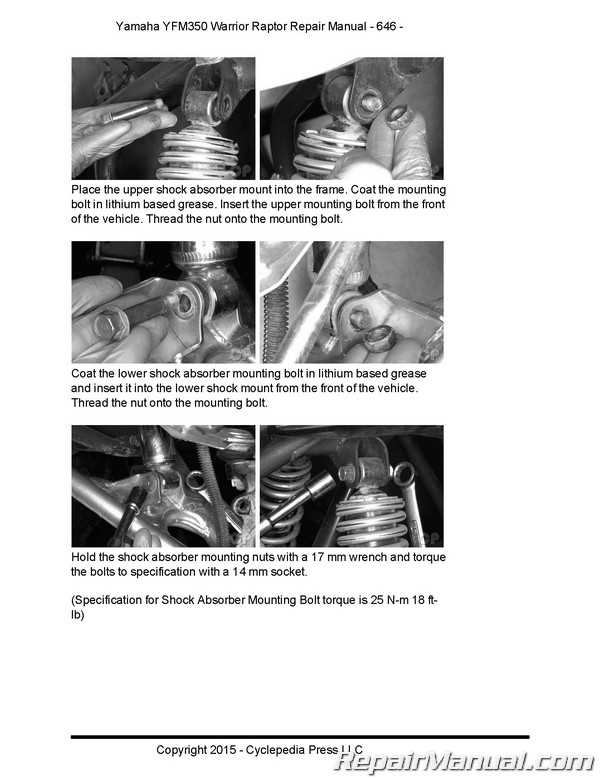

Replacing Key Components Safely

When undertaking the task of exchanging essential parts in a vehicle, it is crucial to prioritize safety and efficiency. Proper procedures and precautions not only enhance the longevity of the machine but also ensure the safety of the individual performing the work. This section aims to provide guidance on executing these tasks with care and precision.

Before beginning any component replacement, make sure to gather all necessary tools and materials. Preparation is key to a smooth process. Ensure that you have a clean workspace, free of clutter, to minimize distractions and potential hazards. Additionally, refer to detailed guides that outline the specific steps for your vehicle type.

Safety gear, such as gloves and goggles, should always be worn to protect against any potential injuries. Disconnecting the battery before starting work is essential to prevent electrical shocks and accidental starts. Familiarize yourself with the parts you will be handling, as knowing their functions will aid in a more effective and careful approach to the task.

As you proceed with the replacement, take your time to follow each step methodically. Double-check all connections and fittings to ensure everything is secured properly. After completing the installation, conduct a thorough inspection to confirm that no tools or loose parts remain in the engine compartment. This practice will help avoid future complications and ensure optimal performance.

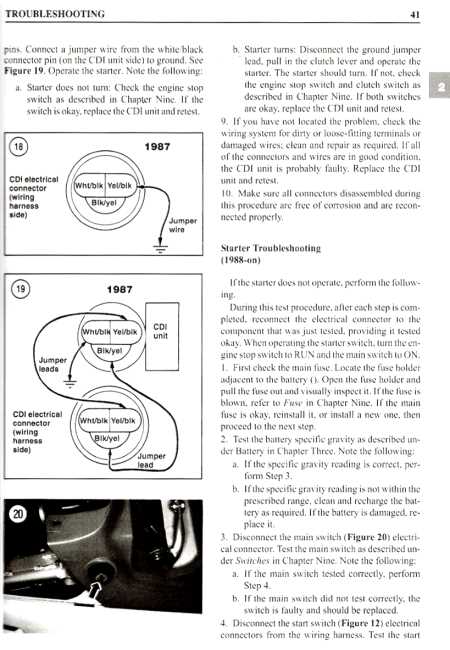

Electrical System Diagnostics

The electrical system of any vehicle plays a crucial role in its overall performance and functionality. Proper diagnosis of electrical issues is essential for maintaining reliability and ensuring safety. Understanding how to assess various components, such as wiring, connectors, and circuits, can help identify potential problems before they lead to significant failures.

Common Electrical Issues

Several typical problems can arise within the electrical framework. Recognizing these issues is the first step towards effective troubleshooting. The following table outlines some frequent electrical complications and their potential causes:

| Issue | Description | Possible Causes |

|---|---|---|

| Dim Lights | Illumination is weaker than expected. | Weak battery, corroded connections, or faulty alternator. |

| Dead Battery | The power source is completely discharged. | Parasitic drain, old battery, or alternator failure. |

| Starter Issues | Difficulty in starting the engine. | Faulty starter motor, wiring issues, or battery problems. |

Diagnostic Procedures

To effectively diagnose electrical system faults, follow a systematic approach. Begin by inspecting the battery and its connections for corrosion and tightness. Utilize a multimeter to check voltage levels across various components. This methodical evaluation can reveal underlying issues and help ensure the electrical system operates efficiently.

Upgrading Performance Parts

Enhancing the capabilities of your vehicle can lead to a more exhilarating riding experience. By focusing on the right components, you can achieve improved speed, handling, and overall efficiency. Upgrading various parts not only boosts performance but also allows for greater customization tailored to your specific riding style.

Essential Components for Improvement

When considering upgrades, several key components can significantly enhance your machine’s performance. These include the exhaust system, air intake, and suspension modifications. Each part plays a crucial role in optimizing power delivery and handling characteristics.

| Component | Benefits |

|---|---|

| Exhaust System | Increases power output and enhances engine efficiency. |

| Air Intake | Improves airflow, resulting in better combustion and performance. |

| Suspension | Enhances handling and stability, especially during aggressive maneuvers. |

Considerations for Upgrades

Before proceeding with any modifications, it is vital to consider compatibility and potential impacts on warranty and regulations. Researching products and consulting with professionals can ensure that your upgrades are effective and suitable for your vehicle.

Maintaining Suspension Systems

Proper upkeep of suspension systems is crucial for ensuring optimal performance and comfort during rides. Regular maintenance helps in identifying potential issues early, enhancing the longevity of the components, and improving the overall riding experience.

Key practices for maintaining these systems include:

- Regular Inspections: Periodically check for any signs of wear or damage, such as leaks in shock absorbers or worn bushings.

- Cleaning Components: Keep the suspension parts clean from dirt and debris to prevent corrosion and ensure smooth operation.

- Adjusting Settings: Make necessary adjustments to preload, compression, and rebound settings to suit riding conditions and personal preferences.

- Replacing Fluids: Change the suspension fluid according to the manufacturer’s recommendations to maintain performance.

- Professional Servicing: Consider professional inspections and services periodically to address any complex issues that may arise.

By following these maintenance guidelines, riders can ensure their suspension systems operate effectively, providing a smoother and safer riding experience.

Recommended Fluids and Lubricants

Proper maintenance of your vehicle is essential for optimal performance and longevity. One crucial aspect of this maintenance is the selection of appropriate fluids and lubricants. Using the right products ensures that all components operate smoothly and efficiently, minimizing wear and potential damage.

Here are some recommended categories of fluids and lubricants:

- Engine Oil:

- Choose high-quality synthetic oil for enhanced protection.

- Check the viscosity rating to ensure it meets engine specifications.

- Transmission Fluid:

- Use the manufacturer-recommended fluid for optimal shifting performance.

- Regularly check levels and replace as necessary to maintain efficiency.

- Coolant:

- Select a coolant that provides excellent heat transfer and corrosion protection.

- Consider a 50/50 mix of antifreeze and distilled water for optimal performance.

- Brake Fluid:

- Use a fluid that meets the required specifications for your braking system.

- Replace periodically to ensure consistent braking performance.

- Grease:

- Utilize a high-quality grease for bearings and other moving parts.

- Ensure compatibility with the materials used in your vehicle.

By selecting the right fluids and lubricants, you contribute to the efficiency and longevity of your vehicle, ensuring that it performs at its best for years to come.