Achieving the best performance from your equipment requires proper understanding and regular upkeep. Knowing the essentials of upkeep for small engines can lead to longer-lasting machinery and optimal efficiency, ensuring your devices remain in excellent working order.

In this guide, we delve into the fundamentals of maintaining compact engines, focusing on key practices and troubleshooting tips to help prevent common issues. From examining vital components to performing routine inspections, each step of this guide is designed to empower you with valuable skills.

With accessible advice and clear instructions, you’ll be prepared to address minor challenges before they become major issues. Strengthening your knowledge on essential practices will help you handle your equipment with confidence and precision, supporting smooth and reliable operation every time.

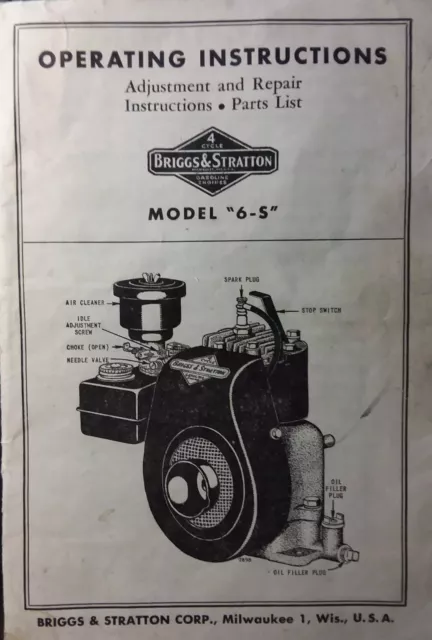

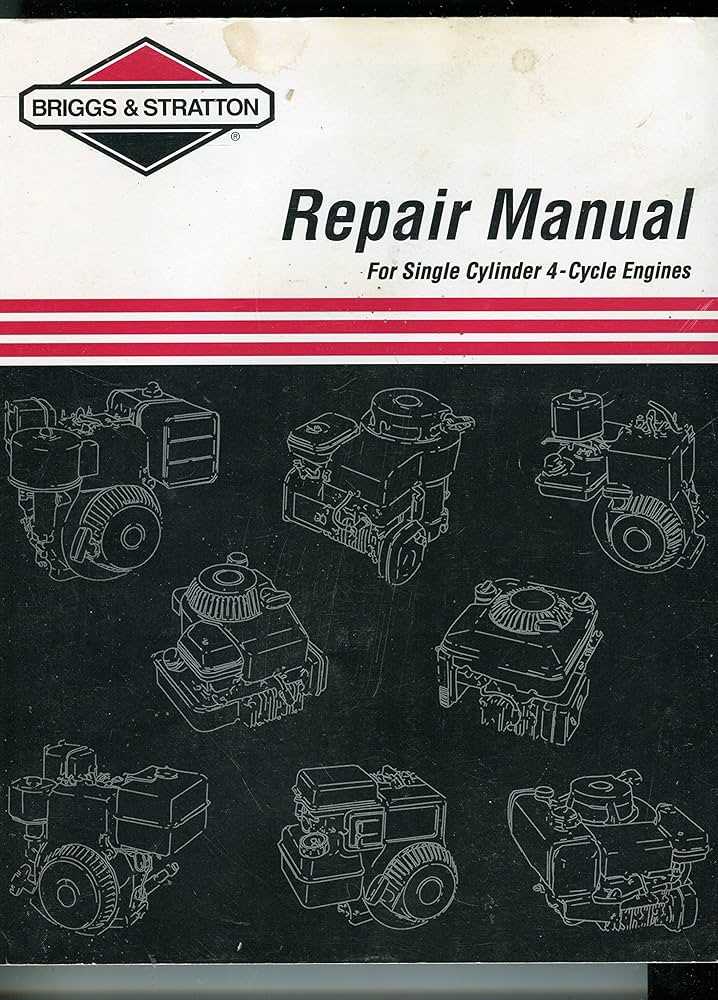

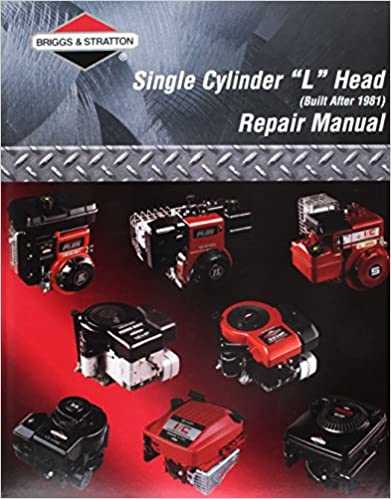

Briggs and Stratton Motor Repair Manual

Maintaining the performance and extending the lifespan of your outdoor power unit requires a solid understanding of its inner workings. This section provides essential guidance on regular upkeep, diagnostics, and part replacements for optimal functionality. With straightforward steps, it enables even novice users to handle routine tasks confidently, enhancing both efficiency and durability.

Understanding Essential Components

To ensure smooth operation, it is crucial to familiarize yourself with the main components of the engine system. Key parts like the fuel system, ignition module, and air intake work together to power the unit. Recognizing early signs of wear or malfunction in these areas can help prevent costly repairs and extend usage.

Basic Troubleshooting Tips

When performance issues arise, some basic troubleshooting steps can help pinpoint the root of the problem. Simple checks on fuel levels, spark plug conditions, and air filters often reveal common issues that affect

Understanding Engine Components

Comprehending the key parts of an engine is essential for maintaining and troubleshooting its performance. Knowing how each element functions and interacts within the system allows for a deeper understanding of overall mechanics and helps identify issues more efficiently.

Key Components Overview

An engine is comprised of multiple essential parts, each with a unique role in generating power and ensuring efficient operation. The cylinder forms the core where fuel combustion occurs, creating the force that drives the engine. Surrounding this core, other parts like the piston and connecting rod work together to translate the energy generated into movement.

Supportive Systems

Beyond the core components, supportive systems play a vital role in engine stability. The lubrication system reduces friction among moving parts, while the cooling mechanism keeps temperature levels in check, preventing overheating. Together, these systems contribute to prolonged and reliable engine operation.

Common Issues and Troubleshooting Tips

Understanding the most frequent mechanical issues can simplify maintenance and reduce operational downtime. The following section outlines typical challenges and practical solutions to keep your equipment running smoothly.

- Starting Problems: If the machine fails to start, check the fuel level and quality. Old or contaminated fuel can cause ignition issues. Inspect the spark plug for wear or damage, and replace it if needed.

- Overheating: Overheating can result from a blocked air filter or insufficient ventilation. Ensure the air filter is clean, and clear any debris around the cooling vents.

- Power Loss: Reduced performance often indicates a clogged fuel line or carburetor issues. Cleaning these components regularly can restore optimal power output.

- Excessive Vibration: Intense vibrations may be due to loose parts or an unbalanced blade. Tighten any bolts and check the blade alignment to reduce vibration.

By addressing these common concerns proactively, you can ex

How to Maintain Optimal Engine Performance

Keeping your engine running at its best requires regular attention and a proactive approach to maintenance. By following essential steps and inspecting key components periodically, you can ensure longevity and high efficiency, reducing unexpected issues.

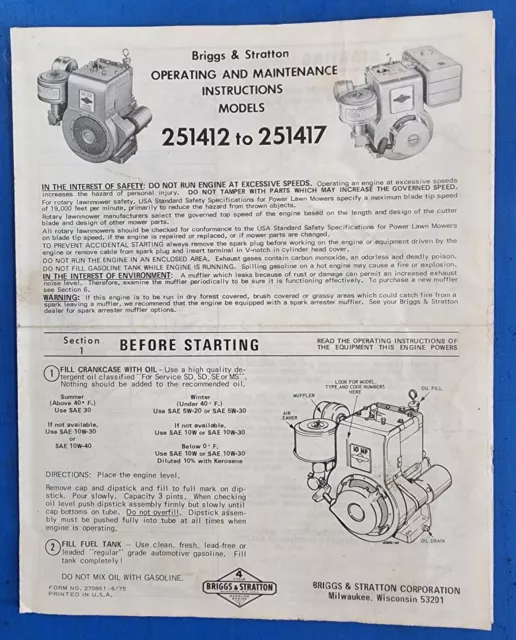

1. Regular Oil Changes

Changing the oil at recommended intervals is crucial. Fresh oil maintains proper lubrication, reduces friction, and minimizes wear. Consult your engine’s specifications to determine the best type of oil and replacement frequency.

- Use high-quality oil for better protection

- Regularly check oil levels and top up as needed

- Dispose of old oil responsibly

2. Air Filter Maintenance

The air filter plays a significant role in engine health by trapping dust and debris

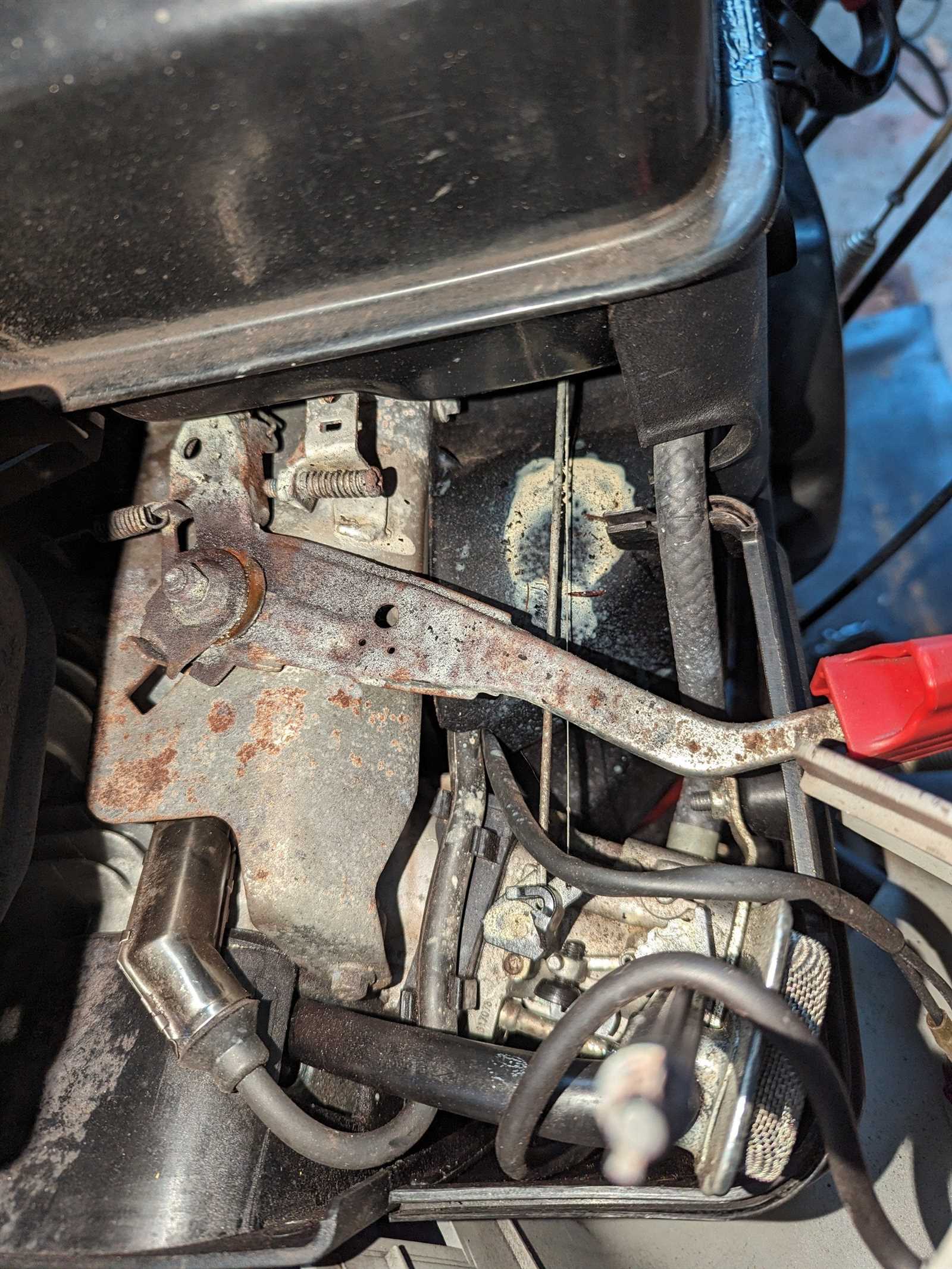

Replacing Worn-Out Parts Safely

Ensuring a smooth and safe replacement process for old components requires careful attention to detail and proper handling of tools. By following recommended guidelines and using suitable protective gear, the replacement procedure can be efficient and risk-free.

- Prepare the Area: Make sure the workspace is clean and organized. Remove any unnecessary items to prevent accidental trips or misplacement of parts.

- Wear Protective Gear: Use gloves, eye protection, and sturdy footwear to minimize risks when working with metal components or tools.

- Disconnect Power Sources: Always detach any power sources before beginning, ensuring there’s no chance of accidental operation during the process.

- Inspect Replacement Parts: Check each replacement part carefully for defects. Using flawed parts can lead to further issues and potentially unsafe operation.

- Follow Torque Specifications: When securing

Essential Tools for Engine Repair

When it comes to maintaining and restoring small engines, having the right instruments is crucial for efficient and effective work. A well-equipped toolkit can significantly simplify the process, ensuring that each task is completed accurately. This section highlights the fundamental devices every technician should consider for successful engine work.

Basic Hand Tools

Hand tools are the foundation of any maintenance project. These instruments are versatile and essential for disassembly and reassembly tasks. Common examples include:

Tool Function Wrenches Used for loosening and tightening nuts and bolts. Screwdrivers Ideal for various screws; different types fit various needs. Pliers Helpful for gripping, bending, and cutting wires or small parts. Specialized Equipment

In addition to hand tools, certain specialized equipment can enhance the efficiency of maintenance efforts. These tools often target specific tasks, making them invaluable for thorough examinations and fixes:

Tool Purpose Compression Tester Measures the engine’s compression to assess its health. Spark Plug Wrench Designed specifically for removing and installing spark plugs. Torque Wrench Ensures fasteners are tightened to the correct specifications. Cleaning and Preparing the Engine

To ensure optimal performance and longevity of your engine, it is crucial to carry out regular maintenance. This section outlines the essential steps for cleaning and preparing the engine, which can help prevent issues and enhance efficiency.

Initial Cleaning Steps

Begin by removing any dirt and debris from the exterior surfaces. Use a soft brush and a suitable cleaning solution to gently scrub away any buildup. Pay special attention to the air intake and cooling fins, as these areas can affect airflow and overall functionality.

Internal Preparation

Once the exterior is clean, it is time to address the internal components. Inspect and replace the air filter, ensuring it is free from obstructions. Additionally, check the fuel system for any signs of contamination, and clean the fuel tank if necessary. Regular cleaning not only improves performance but also extends the life of your engine.

Diagnosing Starting Problems

When facing issues with initiating a small engine, it is essential to methodically assess various components to identify the root cause. Understanding the common factors that can lead to starting difficulties is crucial for effective troubleshooting.

Checking Fuel Supply

One of the primary reasons for starting issues is inadequate fuel delivery. Ensure that the fuel tank is filled with fresh gasoline and that the fuel lines are free of obstructions. Inspect the fuel filter for clogs and verify that the carburetor is functioning correctly, allowing fuel to flow smoothly.

Inspecting Electrical Connections

Electrical components play a vital role in the starting process. Begin by examining the battery to confirm it is fully charged. Check the connections for corrosion or loose wires that may disrupt power flow. Additionally, assess the ignition system, ensuring that the spark plug is clean and properly gapped to ignite the fuel mixture effectively.

Adjusting Carburetor Settings Correctly

Achieving optimal performance in small engines often hinges on the precision of the fuel delivery system. Properly configuring the settings of the carburetor ensures efficient combustion and smooth operation, which ultimately enhances the longevity of the equipment.

Understanding the Importance of Calibration

Calibration plays a vital role in maintaining engine efficiency. Incorrect adjustments can lead to various issues, such as:

- Poor fuel efficiency

- Unstable engine idling

- Excessive emissions

- Difficulty starting the engine

Steps to Adjust the Carburetor

Follow these steps to achieve the correct settings:

- Start by gathering necessary tools, including a screwdriver and a tachometer.

- Warm up the engine to its normal operating temperature.

- Locate the adjustment screws–typically the idle and mixture screws.

- Adjust the idle screw until the engine runs smoothly without stalling.

- Fine-tune the mixture screw for optimal performance, listening for changes in engine sound.

- Test the engine under load to ensure proper operation before finalizing adjustments.

Engine Cooling System Maintenance

Maintaining the cooling system is crucial for optimal performance and longevity of your equipment. Proper care helps prevent overheating and ensures that the engine operates smoothly under various conditions. Regular checks and timely interventions can significantly enhance the efficiency of the cooling mechanism.

Regular Inspections

Conducting routine inspections of the cooling components is essential. Look for signs of wear or damage, such as cracks in the hoses or leaks from the radiator. Ensure that the coolant level is adequate, as insufficient fluid can lead to overheating.

Cleaning and Flushing

Cleaning the cooling system regularly helps remove dirt and debris that can impede flow. Flushing the system at recommended intervals ensures that the coolant remains effective. Use appropriate cleaning solutions to avoid damaging any components.

Long-Term Care for Briggs and Stratton Motors

Maintaining the longevity of small engines requires consistent attention and care. Implementing a routine maintenance schedule not only enhances performance but also extends the lifespan of the equipment. This section outlines essential practices for ensuring optimal functionality over time.

Regular inspections are critical in identifying potential issues before they escalate. Focus on key components such as air filters, spark plugs, and fuel systems. Cleaning or replacing these parts as needed helps prevent unnecessary wear and tear.

Maintenance Task Frequency Description Change Oil Every 50 hours of operation Replace engine oil to ensure smooth operation and prevent buildup of contaminants. Clean Air Filter Every 25 hours of operation Remove and clean air filter to maintain proper airflow and engine efficiency. Inspect Spark Plug Every 100 hours of operation Check spark plug condition and replace if necessary to ensure reliable ignition. Examine Fuel System At the start of each season Inspect fuel lines and filters for cracks or clogs to maintain optimal fuel flow. In addition to these tasks, storing equipment properly during off-seasons is vital. Use a clean, dry area and consider using fuel stabilizers to keep the fuel fresh. By adopting these practices, users can significantly improve the durability and performance of their engines.