Ensuring the optimal functionality of heavy machinery is crucial for productivity and longevity. This section provides an in-depth exploration of essential practices and techniques for the upkeep of hydraulic systems, which are integral to various industrial applications. Understanding these processes not only enhances performance but also minimizes downtime and repair costs.

Within the pages that follow, you will find detailed instructions, troubleshooting advice, and best practices aimed at fostering a thorough comprehension of these complex systems. Emphasizing the importance of routine checks and timely interventions, this guide serves as a valuable resource for both novice operators and seasoned technicians.

By adhering to the insights shared here, you can significantly improve the reliability and efficiency of your hydraulic equipment. Dive into the specifics of maintenance, and equip yourself with the knowledge necessary to ensure your machinery operates at peak condition.

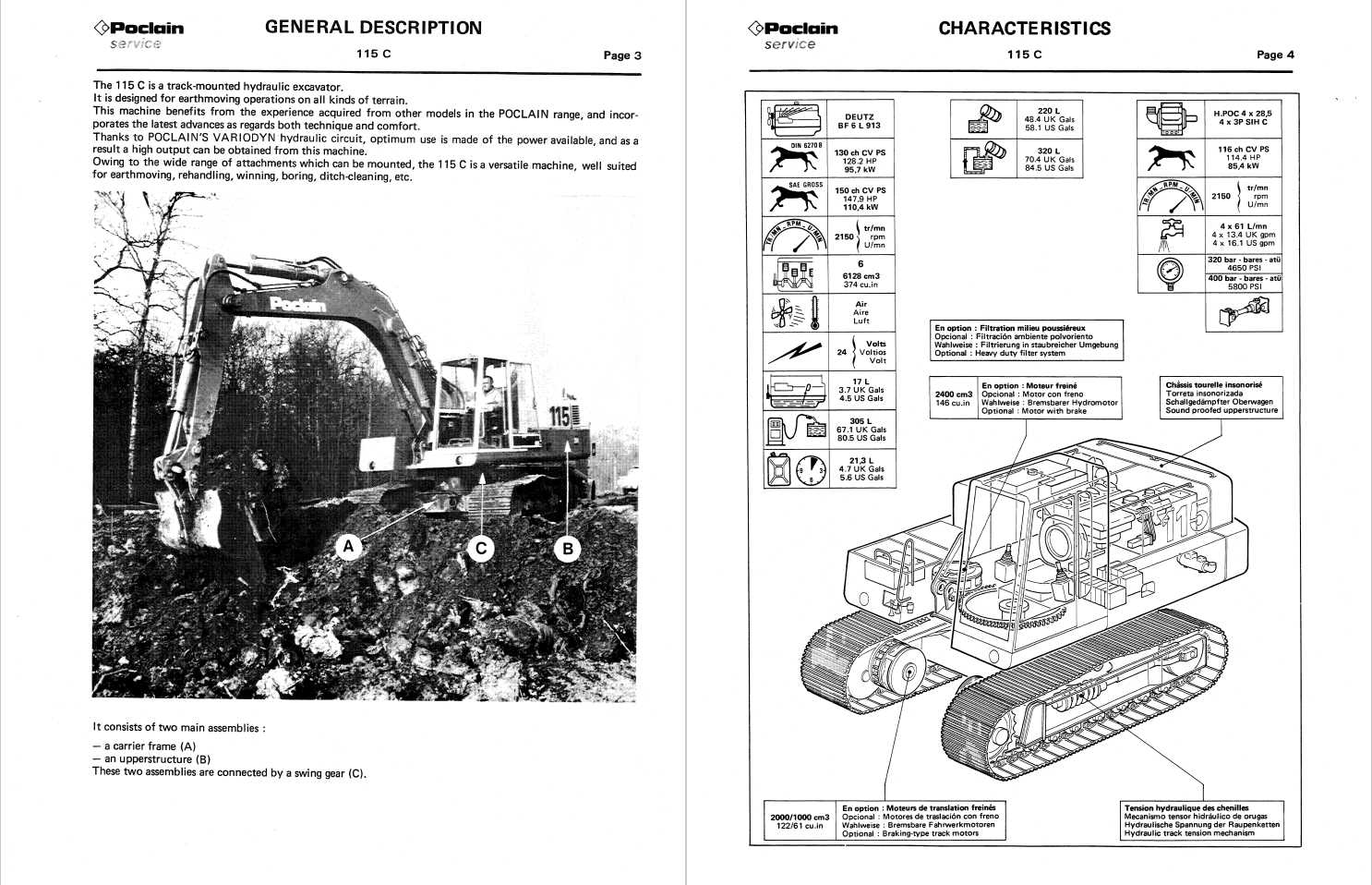

Poclain Motor Overview

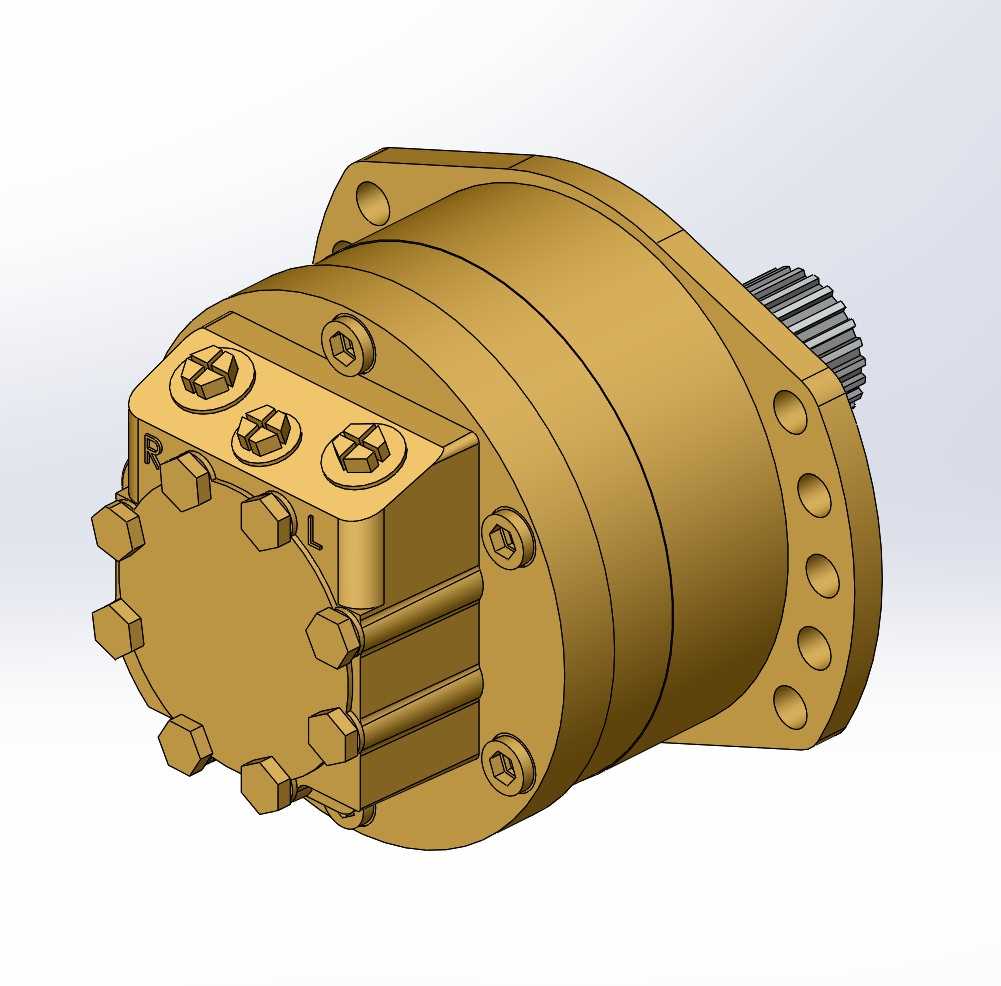

This section provides a comprehensive understanding of a specific type of hydraulic mechanism commonly utilized in various industrial applications. These devices are renowned for their efficiency and reliability, making them essential components in construction and agricultural machinery.

The functionality of this equipment revolves around the transformation of hydraulic energy into mechanical work. This process is crucial for powering a range of operations, from excavation to material handling.

Key features of this system include:

- High torque output for demanding tasks

- Robust design ensuring longevity

- Efficient energy conversion capabilities

- Versatility across different machinery

Regular maintenance and understanding of the operational principles are vital for optimal performance. Users should familiarize themselves with the following components:

- Hydraulic pumps

- Control valves

- Drive units

- Cooling systems

Awareness of common issues and solutions can significantly enhance the lifespan and productivity of these devices. Continuous training and technical support are recommended for operators and technicians alike.

Common Issues with Poclain Motors

Hydraulic systems often encounter various challenges that can hinder their efficiency and performance. Understanding these common problems is essential for maintaining optimal functionality and extending the lifespan of the equipment.

| Issue | Description | Possible Causes |

|---|---|---|

| Leakage | Fluid escaping from seals or connections, leading to pressure loss. | Worn seals, loose fittings, or damaged hoses. |

| Overheating | Excessive temperatures that can damage components. | Low fluid levels, poor ventilation, or contaminated fluid. |

| Noise | Unusual sounds during operation indicating potential issues. | Air in the system, worn parts, or improper installation. |

| Loss of Power | Reduced efficiency or performance during operation. | Blockages, internal wear, or fluid contamination. |

| Erratic Operation | Inconsistent performance, leading to unpredictable behavior. | Faulty controls, electrical issues, or fluid inconsistencies. |

Addressing these issues promptly can prevent more severe complications and ensure that the equipment operates smoothly. Regular maintenance and timely diagnostics play a crucial role in mitigating these problems.

Essential Tools for Repair

When it comes to maintaining heavy machinery, having the right instruments is crucial for achieving optimal performance and longevity. A well-equipped toolkit not only enhances efficiency but also ensures that each task is carried out with precision and care. This section outlines the fundamental tools necessary for effective maintenance work.

Basic Hand Tools

Every technician should have a reliable set of hand tools at their disposal. Items such as wrenches, screwdrivers, and pliers are indispensable for tackling a variety of tasks. These tools allow for adjustments, replacements, and general upkeep, making them the backbone of any maintenance kit.

Specialized Equipment

In addition to standard tools, certain specialized equipment can greatly aid in more complex procedures. Instruments like torque wrenches and diagnostic devices help in fine-tuning and troubleshooting. Investing in high-quality specialized tools can make a significant difference in both the efficiency and accuracy of your work.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues that may arise in hydraulic machinery. By following a systematic procedure, you can ensure that the process is efficient and effective, minimizing downtime and restoring optimal functionality.

Initial Assessment

The first step involves a thorough evaluation of the equipment. Identify the symptoms of malfunction and gather relevant data. Document any unusual noises, leaks, or performance issues. This assessment will guide subsequent actions and help in determining the root cause.

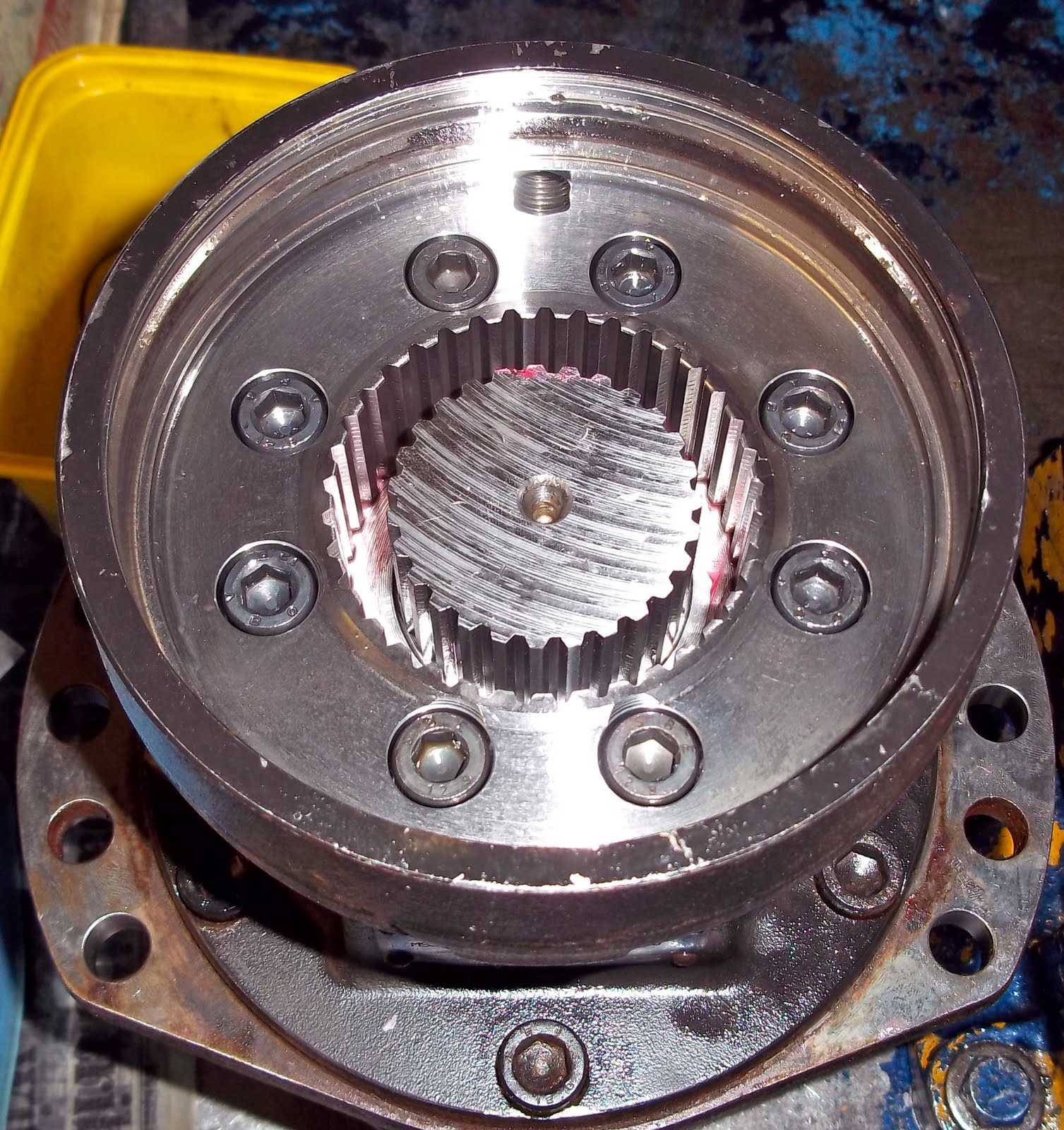

Disassembly and Inspection

Once the initial assessment is complete, proceed to disassemble the unit carefully. Ensure that all components are labeled and stored properly to avoid confusion during reassembly. Inspect each part for wear and damage, paying close attention to seals, bearings, and valves. This detailed inspection is crucial for identifying specific problems that need to be addressed.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance tasks. Proper precautions help prevent accidents and injuries, fostering a more efficient workflow. By adhering to established safety guidelines, individuals can protect themselves and their surroundings while addressing equipment issues.

Before commencing any servicing activities, it is essential to assess the workspace. A clutter-free area enhances visibility and reduces the risk of slips and falls. Additionally, the use of personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear is highly recommended to safeguard against potential hazards.

| Safety Measure | Description |

|---|---|

| Workspace Organization | Keep the area tidy and free of obstacles to prevent accidents. |

| PPE Usage | Wear appropriate protective gear to minimize injury risks. |

| Electrical Safety | Ensure all power sources are disconnected before starting any work. |

| Tool Maintenance | Regularly inspect and maintain tools to ensure they are in good condition. |

| Emergency Procedures | Familiarize yourself with emergency protocols and first aid measures. |

Following these guidelines not only enhances safety but also improves overall productivity. A proactive approach to risk management contributes to a successful and secure maintenance experience.

Maintenance Tips for Longevity

Ensuring the extended functionality of heavy machinery requires regular upkeep and attention to detail. By implementing a series of best practices, operators can significantly enhance the durability and performance of their equipment. This section outlines essential maintenance strategies that can help achieve optimal operational life.

Regular Inspection and Cleaning

Conducting routine checks is crucial for identifying wear and tear before it becomes a major issue. Regular cleaning of components helps prevent debris buildup that could impair functionality. Focus on areas prone to dirt accumulation and ensure that all moving parts are free of obstructions.

Lubrication and Fluid Management

Proper lubrication is vital for reducing friction and wear on moving parts. Regularly check and replenish lubricants and fluids to maintain optimal performance. Always follow the manufacturer’s recommendations regarding the type and frequency of lubrication.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for leaks, wear, and damage. |

| Cleaning Components | Monthly | Focus on filters and air intakes. |

| Lubrication | Monthly | Use recommended lubricants. |

| Fluid Replacement | Every 500 hours | Follow the guidelines for each specific fluid. |

Understanding Motor Components

Grasping the intricacies of machinery requires an awareness of its various parts and their functions. Each element plays a crucial role in ensuring efficient operation, and comprehending their interactions can enhance performance and longevity. This section delves into the fundamental components found within these systems, offering insights into their specific roles and significance.

- Housing: The outer shell that provides structural integrity and protection to internal elements.

- Drive Shaft: A crucial component that transmits rotational force from the engine to the operational parts.

- Seals: Essential for preventing leakage and ensuring that internal fluids remain contained, thus maintaining pressure and performance.

- Bearings: These facilitate smooth motion between moving parts, reducing friction and wear over time.

- Valves: Control the flow of fluids within the system, influencing performance and efficiency.

Understanding these components is vital for anyone involved in the operation or maintenance of heavy machinery. Recognizing how each part functions and interacts with others can lead to better troubleshooting, improved maintenance practices, and ultimately, enhanced operational success.

- Identify each component: Familiarize yourself with the various parts and their locations.

- Study their functions: Learn how each element contributes to the overall mechanism.

- Monitor performance: Regularly check for signs of wear or malfunction to ensure optimal operation.

By prioritizing knowledge of these components, operators can foster a more effective approach to machinery management, paving the way for sustained productivity and efficiency.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining optimal performance in any hydraulic system. This section provides insights into common electrical malfunctions and methods to effectively diagnose and address them. Understanding the underlying causes can significantly reduce downtime and enhance efficiency.

Common Symptoms of Electrical Failures

Electrical faults often manifest through various indicators. Inconsistent performance, such as erratic operation or sudden stops, may suggest issues with the power supply or control circuits. Unusual noises can indicate short circuits or component failures. Additionally, overheating components may signal inadequate insulation or overloading.

Diagnostic Steps

To troubleshoot effectively, start by checking the power connections to ensure they are secure and free of corrosion. Utilize a multimeter to measure voltage levels at different points in the circuit. If voltage readings are inconsistent, inspect wiring for damage or loose connections. Continuity tests can also help identify broken wires or faulty components.

Hydraulic System Inspection

Regular examination of hydraulic systems is crucial for maintaining optimal performance and preventing potential failures. This section outlines essential procedures and considerations for effectively assessing the hydraulic components, ensuring they operate efficiently and safely.

Key Components to Inspect

- Hydraulic fluid levels

- Filters and strainers

- Hoses and fittings

- Pumps and motors

- Valves and actuators

Inspection Procedures

- Check fluid levels and top off if necessary, using the appropriate type of hydraulic fluid.

- Inspect filters for clogs or debris; replace them as needed to maintain flow efficiency.

- Examine hoses for signs of wear, leaks, or bulging; replace damaged sections promptly.

- Test pumps and motors for unusual noises or vibrations, indicating potential issues.

- Evaluate the function of valves and actuators to ensure proper operation within the system.

By adhering to these guidelines, operators can identify potential problems early, ensuring the longevity and reliability of hydraulic systems.

Replacing Worn Parts Effectively

Maintaining optimal performance in any machinery often hinges on the timely replacement of deteriorated components. This process not only enhances functionality but also extends the lifespan of the equipment. Understanding how to identify and replace these parts efficiently is crucial for operators aiming to minimize downtime and reduce costs.

Identification of Worn Components

Recognizing signs of wear is the first step towards effective component replacement. Common indicators include unusual noises, decreased performance, and visible damage. Regular inspections play a vital role in catching these issues early, allowing for proactive measures.

Replacement Process Overview

Once worn parts are identified, the replacement process should be systematic. Follow these key steps to ensure a successful outcome:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement parts. |

| 2 | Disconnect power supply and secure the equipment. |

| 3 | Carefully remove the worn component. |

| 4 | Install the new part, ensuring proper alignment. |

| 5 | Reconnect the power and conduct a test run. |

By adhering to this structured approach, operators can ensure that the replacement of parts is executed smoothly, leading to improved machinery performance and reliability.

Resources for Further Learning

Enhancing your knowledge in machinery maintenance and troubleshooting can be a valuable investment. Numerous materials are available to help you deepen your understanding and refine your skills in this area. This section outlines various resources that can support your learning journey, from online courses to industry publications.

| Resource Type | Description | Link |

|---|---|---|

| Online Courses | Interactive courses covering fundamentals and advanced techniques in machinery servicing. | Coursera |

| Technical Journals | Peer-reviewed articles discussing the latest research and innovations in mechanical systems. | ScienceDirect |

| Books | Comprehensive guides and textbooks that provide in-depth knowledge and practical insights. | Amazon |

| YouTube Channels | Video tutorials and demonstrations from experts that illustrate various techniques and best practices. | YouTube |

| Forums | Online communities where enthusiasts and professionals share experiences, advice, and solutions. | Reddit – Mechanics |