Maintaining outdoor machinery is essential for optimal performance and longevity. Whether it’s a device for trimming grass or managing foliage, understanding its functionality and potential issues can save both time and money. This section delves into the essential aspects of keeping your garden apparatus in top shape.

In this informative piece, we will explore various strategies and techniques for diagnosing common problems. By becoming familiar with the inner workings and regular maintenance practices, users can ensure their equipment operates efficiently throughout the seasons. Proper attention to detail not only enhances performance but also contributes to a longer lifespan for your cherished tools.

Arming yourself with the right knowledge will empower you to tackle challenges head-on. From basic troubleshooting steps to more in-depth procedures, this guide aims to provide valuable insights that can aid in the upkeep of your essential gardening devices.

Understanding Common Mountfield Issues

Every machine may encounter difficulties over time, and recognizing these challenges is crucial for effective maintenance. Users often face a range of concerns that can affect performance and longevity. Understanding these common problems helps in implementing timely solutions, ensuring optimal functionality.

Typical Problems and Their Symptoms

- Engine Failing to Start

- Battery issues or insufficient charge

- Fuel delivery problems

- Clogged air filter

- Uneven Cutting Performance

- Dull blades

- Incorrect cutting height

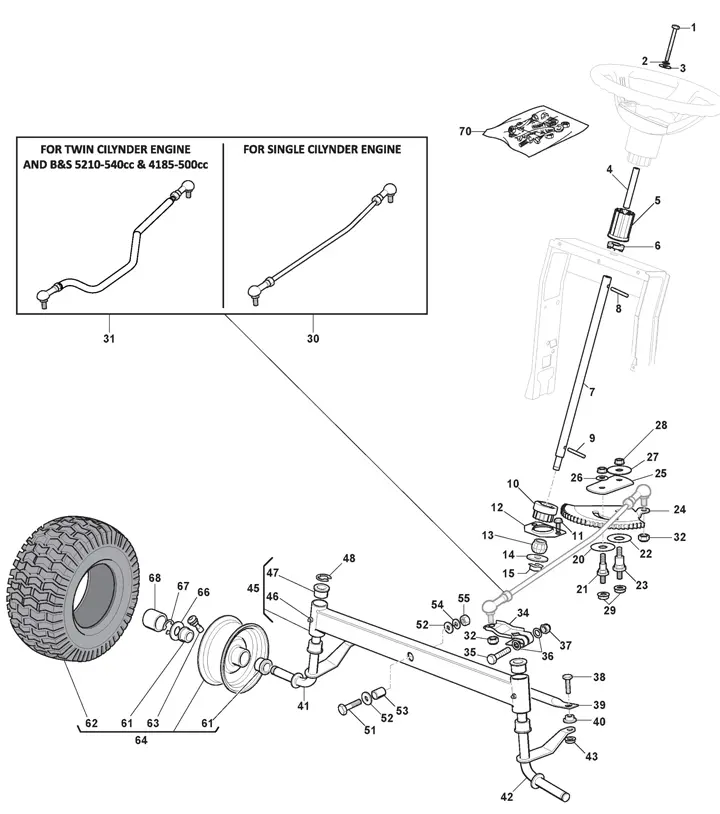

- Wheel misalignment

- Excessive Vibration

- Loose components

- Unbalanced blades

- Worn-out parts

Preventive Measures

- Regular Maintenance Checks

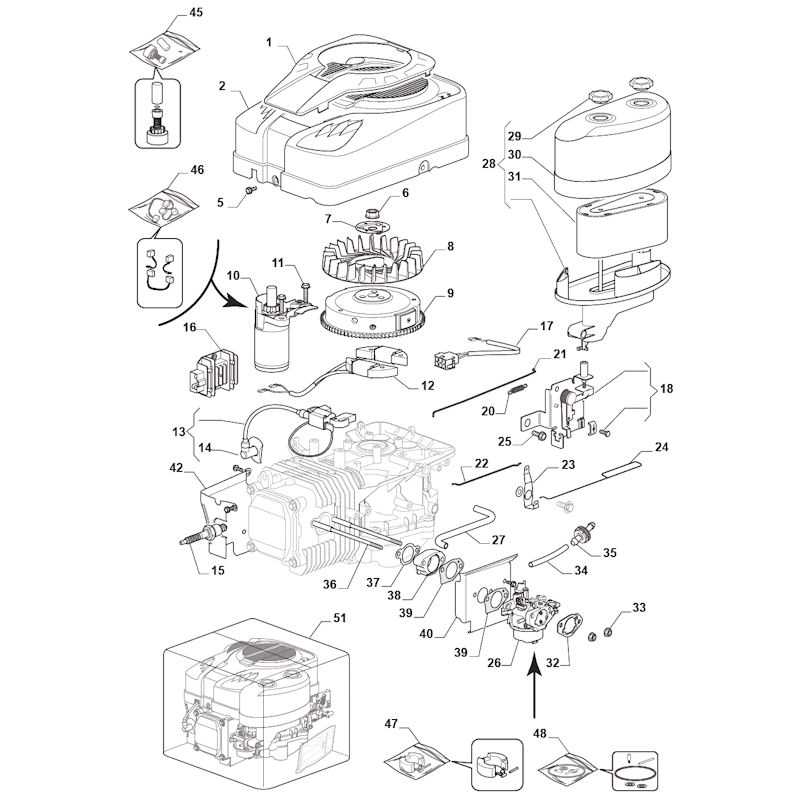

- Inspect and replace spark plugs

- Clean or replace air filters

- Sharpen or replace blades as needed

- Proper Fuel Management

- Use fresh fuel and avoid contamination

- Store fuel in a cool, dry place

- Routine Inspection of Components

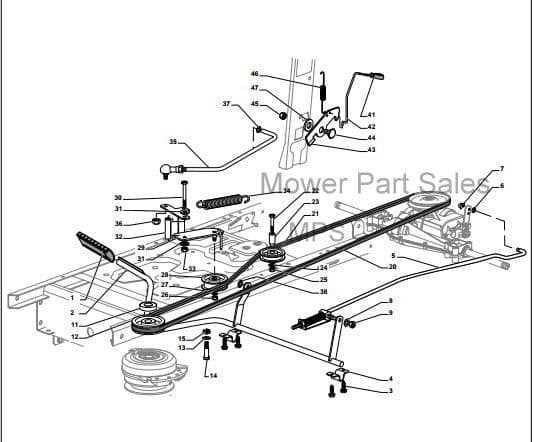

- Check belts and cables for wear

- Tighten screws and bolts regularly

Essential Tools for Lawn Mower Repairs

To effectively maintain and fix your gardening equipment, having the right instruments is crucial. The following items are fundamental for addressing common issues and ensuring optimal functionality. Equipped with these tools, you can tackle various tasks with confidence and ease.

Basic Hand Tools

Every enthusiast should have a set of reliable hand tools. Wrenches and screwdrivers in various sizes are essential for loosening and tightening components. Additionally, pliers can assist in gripping and twisting wires or small parts that may require extra attention.

Specialized Equipment

In addition to basic tools, certain specialized items can enhance your efficiency. A spark plug wrench is invaluable for replacing or cleaning the ignition source, while a multimeter helps in diagnosing electrical problems. Having a sturdy oil filter wrench can also make changing fluids much simpler.

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment ensures optimal performance and longevity. This section outlines essential tasks that will keep your device running smoothly. By following these straightforward procedures, you can avoid common issues and enhance efficiency.

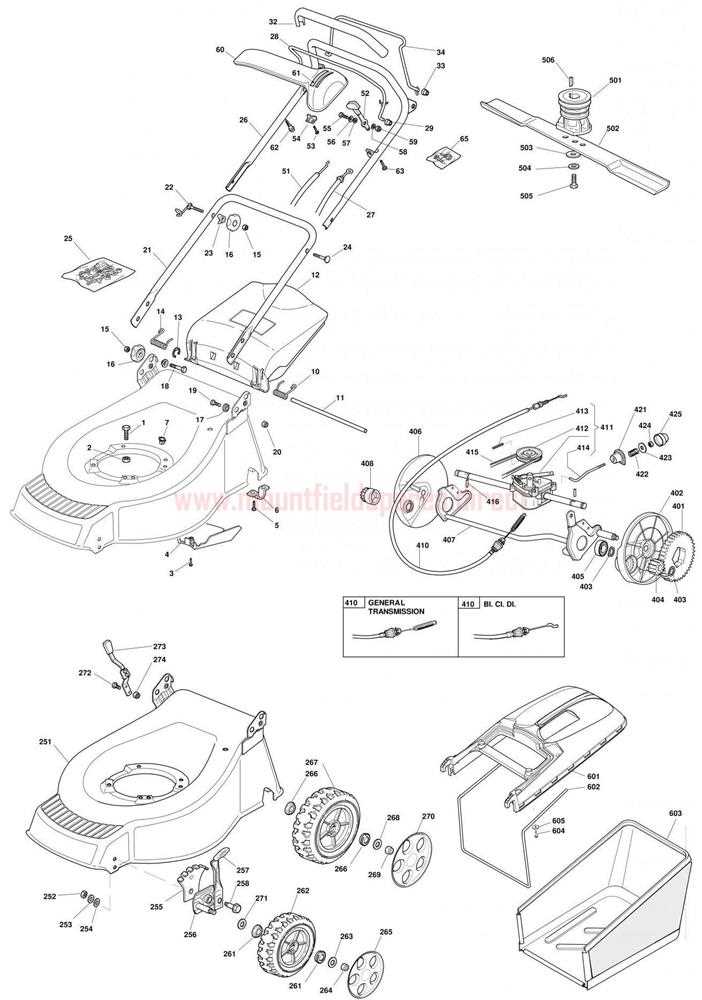

Checking and Replacing the Blades

Begin by ensuring the equipment is turned off and disconnected from any power source. Inspect the cutting edges for signs of wear or damage. If necessary, sharpen or replace the blades according to the manufacturer’s specifications. Properly maintained blades improve cutting performance and prevent unnecessary strain on the engine.

Cleaning the Chassis and Components

After each use, clean the outer surfaces to remove debris and grass clippings. Use a brush or cloth for hard-to-reach areas. Additionally, inspect the air filter and clean or replace it if it appears clogged. A clean chassis and unobstructed airflow are vital for maintaining engine efficiency and prolonging the life of your equipment.

Troubleshooting Engine Performance Problems

When facing issues with engine functionality, it’s essential to identify the underlying causes to restore optimal operation. Various factors can contribute to decreased performance, including fuel supply, ignition systems, and mechanical components. This section aims to provide a structured approach to diagnosing and resolving common performance-related issues.

Identifying Fuel Supply Issues

Inadequate fuel delivery can lead to poor engine performance. Check the fuel lines for clogs or leaks, as these can restrict flow. Additionally, ensure that the fuel filter is clean and free from debris. If fuel quality is in question, consider draining the tank and refilling it with fresh gasoline to see if that improves operation.

Examining Ignition Components

The ignition system plays a crucial role in engine efficiency. Faulty spark plugs or damaged ignition coils can result in misfires and reduced power. Inspect the spark plugs for wear and replace them if necessary. Testing the ignition coils with a multimeter can help determine if they are functioning correctly. Proper maintenance of these components is vital for maintaining strong engine performance.

Replacing Blades: A How-To Guide

Maintaining the cutting components of your garden equipment is crucial for optimal performance. Over time, blades can become dull or damaged, impacting the efficiency of your tool. This guide will walk you through the steps to successfully replace these essential parts, ensuring a clean cut and healthy growth for your outdoor spaces.

Before beginning, gather the necessary tools and safety gear. Familiarize yourself with the specific model’s requirements, as variations may exist. The following table outlines the essential items you will need for the replacement process:

| Tool/Item | Purpose |

|---|---|

| Wrench | To loosen and remove the old blades |

| Replacement Blades | To install new cutting components |

| Safety Gloves | To protect your hands during the process |

| Screwdriver | For securing the new blades in place |

Once you have gathered your materials, you can proceed with the replacement. Ensure that the machine is turned off and disconnected from any power source. Begin by carefully removing the old blades, taking note of how they are mounted. This will help you properly install the new ones. After positioning the new components, secure them tightly to avoid any issues during use.

Adjusting Cutting Heights Correctly

Setting the appropriate height for your cutting tool is crucial for achieving a well-maintained green space. This adjustment impacts not only the appearance but also the health of the vegetation. By selecting the right elevation, you can ensure that the grass receives adequate sunlight and moisture, promoting robust growth.

To begin, identify the specific requirements of your plant type. Different varieties thrive at various heights, so understanding these needs will guide your adjustments effectively. Most equipment features a mechanism that allows for easy elevation changes, ensuring convenience during your maintenance tasks.

Steps to Adjust:

1. Locate the height adjustment lever or knob on your device.

2. Depending on your preference, raise or lower the cutting apparatus. Aim for a height that aligns with the recommended range for your plant species.

3. Perform a test run in a small area to ensure the desired result. If necessary, fine-tune the elevation until you achieve optimal performance.

By regularly monitoring and adjusting the cutting height, you can maintain a healthy and vibrant green space, ensuring it flourishes throughout the seasons.

Cleaning the Fuel System Effectively

Maintaining the cleanliness of the fuel delivery mechanism is essential for optimal performance and longevity of your machine. A well-functioning system ensures that the engine receives the right amount of fuel without any blockages or contaminants. Regular cleaning can prevent issues such as poor starting, uneven running, and reduced efficiency.

Steps for Proper Cleaning

Begin by disconnecting the fuel lines and carefully removing the tank. Ensure that all residual fuel is drained to avoid spills. Next, use a suitable solvent to clean the interior surfaces of the tank. Pay special attention to any deposits or grime that may have accumulated over time. Afterward, flush the lines with the solvent to eliminate any blockages.

Final Checks

Once everything is thoroughly cleaned and dried, reassemble the system. It is advisable to replace filters to enhance the performance of the fuel supply. Finally, refill the tank with fresh fuel to ensure optimal operation. Regular maintenance of the fuel system not only extends the lifespan of your equipment but also enhances its overall efficiency.

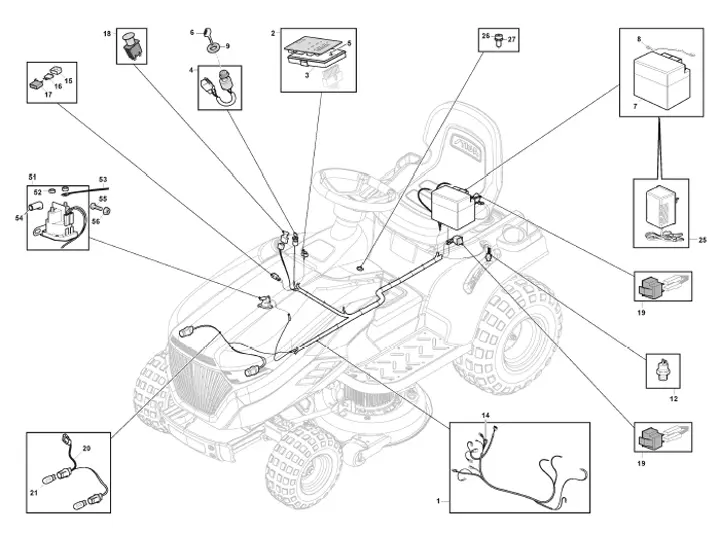

Electrical System Diagnosis Techniques

Identifying issues within the electrical framework of a gardening machine is crucial for ensuring optimal performance. This section explores various approaches to troubleshoot and assess the functionality of the electrical components, allowing users to maintain and enhance their equipment’s reliability.

One effective technique involves the use of a multimeter to measure voltage, resistance, and continuity throughout the circuit. This tool helps pinpoint faulty connections or damaged parts. Start by checking the power source, ensuring that it delivers the correct voltage. From there, systematically test each component, such as switches and connectors, to locate discrepancies.

Another valuable method is visual inspection. Regularly examining wiring for signs of wear, corrosion, or loose connections can reveal potential problems before they escalate. Ensuring that all components are securely connected is vital for maintaining a stable electrical flow.

For more advanced diagnostics, employing a circuit tester can aid in identifying short circuits or open circuits. By following the circuit path and verifying each point, users can effectively trace where the breakdown occurs. Combining these techniques will enhance the overall understanding of the system, leading to timely interventions and better upkeep.

Winterizing Your Lawn Mower

As the cold months approach, it’s essential to prepare your equipment for the off-season. Properly storing your gardening tool not only extends its lifespan but also ensures that it operates efficiently when you need it again. This process involves a few key steps that protect various components from the harsh winter elements.

Start by cleaning the equipment thoroughly. Remove any grass clippings, dirt, or debris that may have accumulated during use. This prevents rust and corrosion from developing during storage. Use a brush or compressed air to reach tight spots, ensuring a pristine condition before putting it away.

Next, address the fuel system. If you have fuel left in the tank, consider adding a stabilizer to prevent degradation. Alternatively, you may choose to drain the tank completely. This step is crucial, as old fuel can cause starting issues when spring arrives.

Finally, check the blades and other parts. Sharpening or replacing the blades ensures optimal performance when you bring your equipment back into action. Additionally, inspect belts and cables for wear and replace them as needed to avoid surprises in the coming season.

When to Seek Professional Help

Knowing when to call in an expert can save time and prevent further issues. While some tasks can be handled by a diligent individual, certain complications require specialized knowledge and tools. Recognizing the signs that indicate a need for professional intervention is essential for maintaining optimal performance.

Common Indicators for Professional Assistance

Several situations suggest that it’s best to consult a technician rather than attempt to fix the issue yourself. Here are a few scenarios to consider:

| Indicator | Description |

|---|---|

| Persistent Problems | If issues continue after multiple attempts at troubleshooting, it may indicate a deeper malfunction. |

| Unusual Noises | Strange sounds during operation often signal underlying mechanical problems that require expert evaluation. |

| Electrical Issues | Any electrical malfunctions, such as failing to start or erratic behavior, are best handled by a qualified professional. |

Benefits of Professional Support

Engaging a specialist can lead to faster resolution and ensures that the equipment is handled safely and effectively. Their experience allows for accurate diagnosis and repair, which can extend the lifespan of your equipment and enhance performance.

Frequently Asked Repair Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of garden machinery. Many users encounter similar issues, and understanding these challenges can lead to more effective solutions.

What should I do if my equipment won’t start?

If your device fails to initiate, first check the power source and ensure it’s adequately charged or connected. Inspect the ignition system and fuel levels, as these are often the culprits.

How can I improve cutting performance?

For enhanced cutting efficiency, ensure the blades are sharp and properly aligned. Regular cleaning of the undercarriage also prevents grass build-up, which can hinder performance.

What maintenance is required during the off-season?

During periods of inactivity, it’s crucial to store the machinery in a dry location. Drain fuel to prevent degradation and consider cleaning filters to maintain optimal functionality for the next season.

Why is there excessive vibration during operation?

Excessive vibrations can indicate an imbalance in the blades or loose components. Check for any wear and tear, and ensure that all parts are securely fastened.

How often should I replace the air filter?

The air filter should typically be replaced every season or after every 25 hours of use. A clean filter ensures optimal airflow and improves engine efficiency.