This section provides essential insights into the upkeep and troubleshooting of small engines commonly used in various outdoor equipment. Understanding the inner workings of these machines is crucial for ensuring their longevity and optimal performance.

Proper maintenance not only enhances the efficiency of the engine but also helps in identifying potential issues before they escalate. With a focus on systematic approaches and best practices, this guide aims to empower users with the knowledge needed to tackle common challenges encountered during operation.

By familiarizing yourself with the fundamental aspects of engine care, you can confidently undertake maintenance tasks and enhance the reliability of your equipment. This resource serves as a valuable tool for both novice and experienced users seeking to improve their skills in engine management.

Common Issues with Model 12F802

This section discusses typical challenges faced by users of this particular engine model. Understanding these issues can help in identifying and addressing problems effectively, ensuring optimal performance and longevity of the unit.

Starting Difficulties

Many users report difficulties when attempting to start the engine. This can often be attributed to fuel-related issues, such as stale gasoline or improper fuel mixture. Regular maintenance of the fuel system is essential to prevent these common starting problems.

Overheating Problems

Another frequent issue is overheating, which can lead to significant damage if not addressed promptly. Factors contributing to this include insufficient airflow or blocked cooling fins. Ensuring that the cooling system is clean and unobstructed is crucial for maintaining optimal operating temperatures.

Tools Needed for Effective Repairs

Having the right instruments at your disposal is crucial for successful maintenance tasks. This section highlights essential equipment that can facilitate the troubleshooting and servicing of small engines. By using appropriate tools, you can ensure efficiency and precision in your work.

Basic Hand Tools

Start with a collection of basic hand tools. A set of wrenches and sockets is vital for loosening and tightening various components. Additionally, screwdrivers of different sizes will aid in accessing hard-to-reach screws. Having pliers and wire cutters can also be beneficial for handling electrical connections.

Specialized Equipment

Incorporating specialized equipment into your toolkit can greatly enhance your repair capabilities. For instance, a compression gauge helps assess engine performance, while a multimeter is essential for diagnosing electrical issues. Investing in a torque wrench ensures that fasteners are tightened to the correct specifications, preventing future problems.

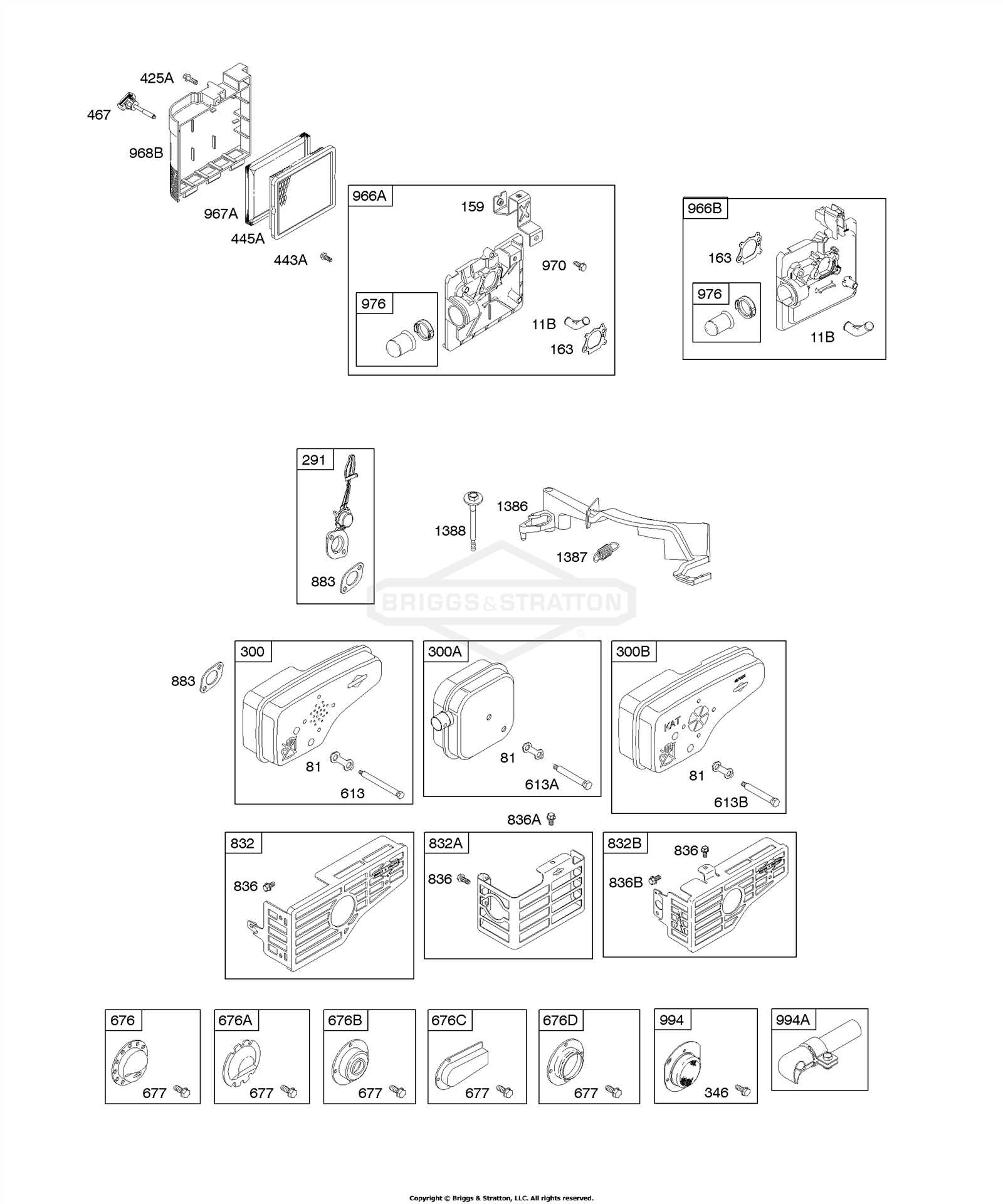

Step-by-Step Disassembly Process

This section outlines a systematic approach to disassembling the engine unit, ensuring that each component is carefully removed for inspection and maintenance. Proper techniques are essential to avoid damage and facilitate smooth reassembly.

Preparation and Safety Measures

Before starting the disassembly, ensure that the workspace is clean and organized. Disconnect the power source to prevent accidental starts. Utilize appropriate tools and wear safety gear such as gloves and goggles to protect against potential hazards.

Sequential Component Removal

Begin by removing the outer casing, which often involves unscrewing various bolts. Carefully detach the fuel system components next, followed by the electrical connections. Documenting the order of disassembly can be beneficial. Proceed to the core parts, ensuring that each piece is kept in a designated area to prevent loss. Pay special attention to small components that may easily be overlooked.

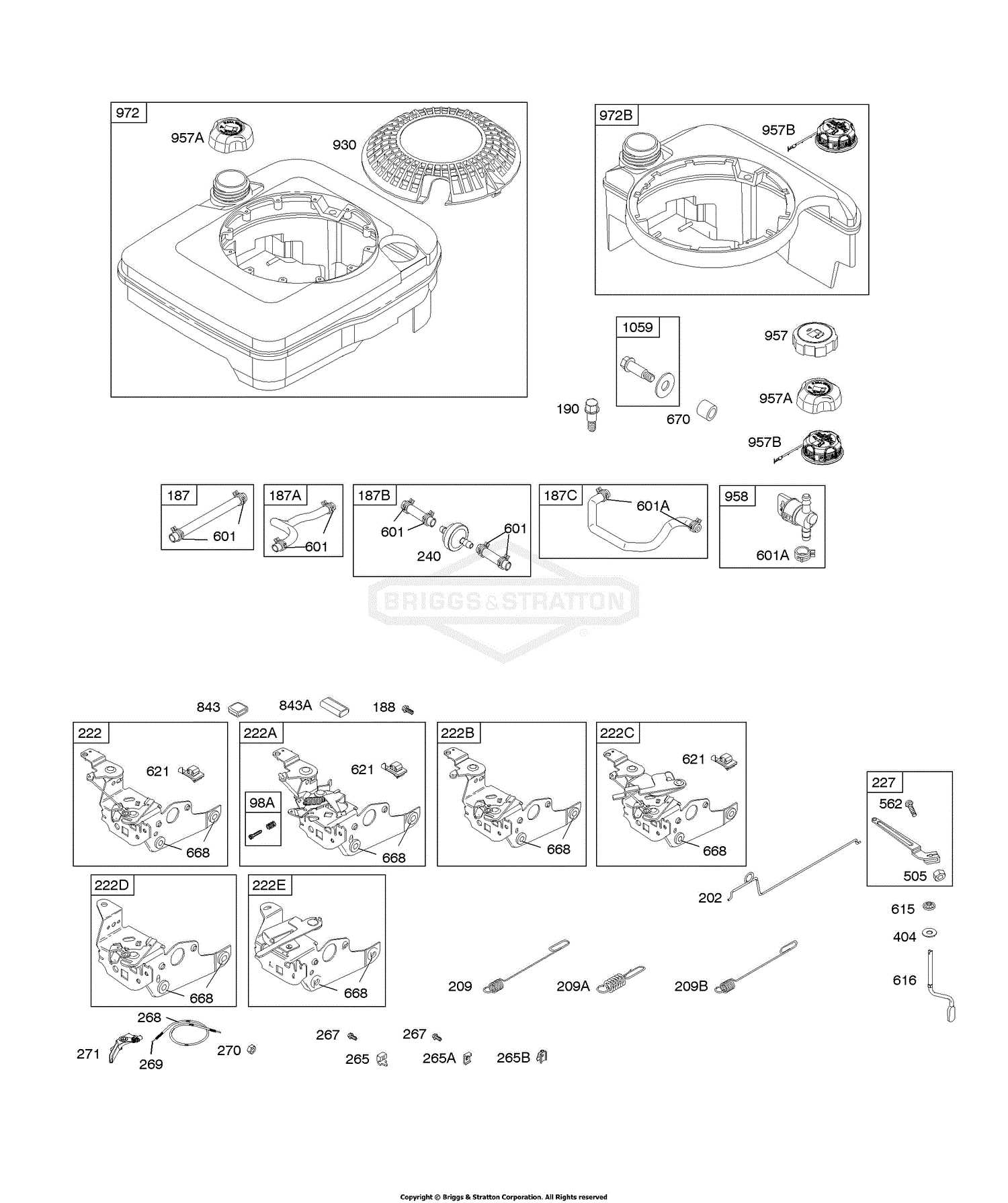

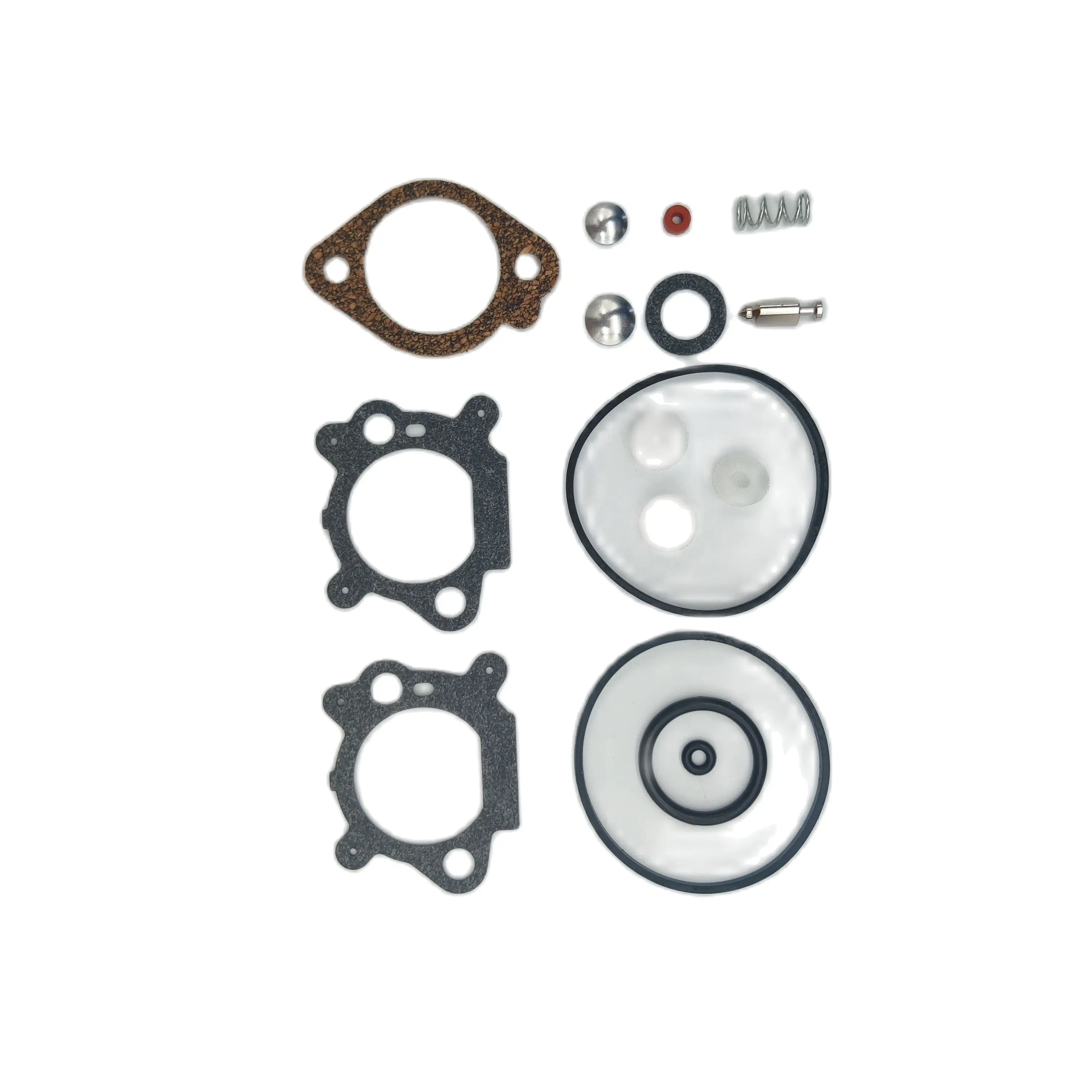

Identifying Worn Components and Parts

Recognizing signs of wear in various components is crucial for maintaining optimal performance in machinery. Worn parts can lead to decreased efficiency, increased fuel consumption, and potential failure if not addressed promptly. Understanding the typical indicators of deterioration can help in ensuring longevity and reliability.

Start by inspecting surfaces for scratches, cracks, or discoloration. These physical changes often signal that components are nearing the end of their service life. Additionally, pay attention to unusual noises during operation, which can indicate friction between parts that should have a smooth interaction.

Another key aspect is the examination of gaskets and seals. Over time, these materials may become brittle or lose their elasticity, leading to leaks or loss of pressure. Ensuring these components are in good condition is essential for overall system integrity.

Lastly, keep an eye on moving parts, such as bearings and rods. Excessive play or rough movement can be early signs of failure, requiring immediate attention to prevent further damage. Regular checks and timely replacement of worn components will significantly enhance the reliability of your equipment.

Reassembling the Engine Correctly

Putting the engine back together requires precision and attention to detail. Ensuring that each component is properly aligned and secured is essential for optimal performance. This section outlines the key steps to follow during the reassembly process, helping to avoid common pitfalls that can arise if components are incorrectly fitted.

Step-by-Step Assembly

Begin by gathering all parts and tools necessary for reassembly. Start with the base and carefully attach each component in the correct order. Referencing a detailed diagram can be beneficial to ensure that parts are placed accurately. Take your time to verify that seals and gaskets are intact to prevent leaks and ensure a tight fit.

Final Checks

Once the engine is fully assembled, conduct a thorough inspection. Check for any loose bolts or misaligned parts, as these can lead to malfunctions. Manually rotate the crankshaft to confirm that everything moves smoothly without obstruction. Completing these final checks will ensure that the engine operates efficiently and reliably.

Essential Maintenance Tips for Longevity

Proper upkeep is vital for extending the lifespan of your equipment. By following a few key practices, you can ensure that your machine remains in optimal working condition for years to come. Regular attention to maintenance not only enhances performance but also prevents costly repairs.

Regular Oil Changes: Changing the oil at recommended intervals helps to keep the engine lubricated and free from debris. Fresh oil reduces friction and wear, ensuring smoother operation.

Air Filter Maintenance: Keeping the air filter clean is essential for maintaining airflow and performance. A clogged filter can lead to reduced efficiency and potential damage over time. Clean or replace the filter as needed.

Check Spark Plug Condition: Inspecting the spark plug regularly can help identify issues that may affect starting and efficiency. Replacing a worn or fouled spark plug can lead to improved ignition and overall functionality.

Inspect Fuel System: Ensure that the fuel lines and filter are free from blockages. Stale fuel can lead to performance issues, so using fresh fuel and stabilizers can significantly enhance reliability.

Seasonal Tune-Ups: Performing a tune-up at the start of each season can help identify potential problems before they escalate. This proactive approach can save time and money while ensuring optimal performance.

Understanding Engine Specifications and Features

Gaining insight into engine specifications and features is crucial for effective maintenance and optimal performance. These attributes define how well an engine operates under various conditions and can significantly impact its longevity and efficiency.

Key Specifications to Consider

- Engine Type: Identifying whether the engine is two-stroke or four-stroke can influence its operation and maintenance needs.

- Displacement: The engine’s displacement, measured in cubic centimeters (cc) or liters, affects its power output and fuel consumption.

- Power Rating: Measured in horsepower (HP) or kilowatts (kW), this rating indicates the engine’s capacity to perform work.

- Torque: The amount of rotational force produced, usually measured in foot-pounds (ft-lb), is vital for understanding performance under load.

Essential Features for Performance

- Cooling System: Effective cooling mechanisms are essential to prevent overheating and ensure consistent performance.

- Fuel System: The type of fuel delivery system, whether carbureted or fuel-injected, impacts efficiency and responsiveness.

- Ignition System: The design of the ignition system affects starting reliability and engine efficiency.

- Lubrication: A well-designed lubrication system reduces wear and tear, contributing to the engine’s lifespan.

Diagnosing Fuel System Problems

Understanding issues within the fuel delivery system is essential for maintaining optimal engine performance. A thorough examination can help identify any malfunctions that may be impacting functionality.

Common Symptoms of Fuel System Issues

- Engine stalling or difficulty starting

- Poor acceleration or loss of power

- Increased fuel consumption

- Unusual engine noises

Steps to Diagnose Problems

- Check fuel levels to ensure there is sufficient supply.

- Inspect fuel lines for any leaks or blockages.

- Examine the fuel filter and replace if clogged.

- Assess the fuel pump’s operation to confirm it’s delivering adequate pressure.

Electrical System Troubleshooting Guide

This section aims to assist users in diagnosing issues related to the electrical components of small engines. Understanding common problems and their solutions can lead to effective repairs and maintenance.

Before diving into specific issues, it is essential to ensure all safety precautions are observed. Disconnect the power source and allow components to cool down to prevent accidents.

| Problem | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Dead battery | Charge or replace the battery. |

| Intermittent electrical failures | Loose connections | Tighten or clean electrical connections. |

| Blown fuse | Short circuit | Inspect wiring for damage and replace the fuse. |

| Battery drains quickly | Faulty charging system | Test the alternator and replace if necessary. |

By following this guide, users can effectively identify and resolve common electrical issues, ensuring optimal performance of their engines.

Cleaning and Caring for Your Engine

Maintaining the cleanliness of your engine is essential for its optimal performance and longevity. Regular care not only enhances efficiency but also helps prevent potential issues. This section outlines effective strategies to keep your engine in top shape.

Essential Cleaning Steps

- Ensure the engine is cool before beginning the cleaning process.

- Remove any debris and dirt from the surface using a soft brush or cloth.

- For tougher grime, a mild detergent mixed with water can be used. Apply gently and rinse thoroughly.

- Check and clean the air filter regularly to ensure proper airflow.

Routine Maintenance Tips

- Inspect oil levels frequently and change the oil as recommended by the manufacturer.

- Keep all moving parts lubricated to minimize wear and tear.

- Store your engine in a dry and sheltered area to protect it from the elements.

- Conduct regular checks for leaks or any unusual sounds during operation.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial. Proper precautions help prevent accidents and injuries, allowing for a smooth and efficient process. Being aware of the surrounding environment and adhering to guidelines can significantly enhance safety standards.

Use Personal Protective Equipment: Always wear appropriate safety gear such as gloves, goggles, and masks to shield yourself from potential hazards. This equipment is essential in protecting against harmful substances and debris.

Work in a Well-Ventilated Area: Proper airflow is vital when working with machinery. Ensure the workspace is well-ventilated to minimize the risk of inhaling harmful fumes or gases released during the maintenance process.

Disconnect Power Sources: Before starting any work, disconnect all power sources to prevent accidental activation. This step is fundamental to maintaining a secure working environment and safeguarding against unexpected movements.

Organize Tools and Materials: Keep your workspace tidy by organizing tools and materials. This practice reduces the risk of tripping and ensures that all necessary items are easily accessible, streamlining the maintenance process.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of small engine maintenance and troubleshooting techniques. Various resources are available to provide insights, practical advice, and detailed methodologies for effective care and repair.

Online Forums and Communities

Engaging with online forums and communities dedicated to small engine enthusiasts can be incredibly beneficial. These platforms allow users to share experiences, ask questions, and access a wealth of shared knowledge. Active participation can lead to discovering tips and tricks that are not found in traditional literature.

Instructional Videos

Visual learning through instructional videos can provide step-by-step guidance on various procedures. Many content creators focus on practical demonstrations, making complex tasks more approachable. Searching platforms dedicated to video content can yield numerous tutorials specific to engine maintenance.