This section offers an extensive overview of the necessary steps and insights for effectively maintaining and addressing issues related to a specific model of outdoor power equipment. Understanding the intricacies of its components and functionalities can significantly enhance the longevity and performance of the device.

In the following parts, we will delve into detailed procedures, including identification of common problems, suitable solutions, and essential tips for routine care. By familiarizing yourself with these guidelines, you will be better equipped to ensure that your equipment operates efficiently, reducing the risk of unexpected breakdowns.

Additionally, this guide emphasizes the importance of using appropriate tools and techniques while performing maintenance tasks. Proper handling and care not only promote the effective operation of the equipment but also ensure your safety during use. Embrace the opportunity to deepen your knowledge and become adept at maintaining your valuable machinery.

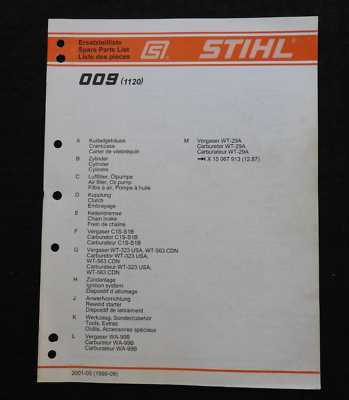

Overview of Stihl 009L Chainsaw

This section provides a comprehensive examination of a well-regarded cutting tool designed for both professional and personal use. Known for its reliability and efficiency, this model has become a staple among users who appreciate power combined with ease of handling. The device is particularly favored for its balanced performance, making it suitable for a variety of tasks, from trimming branches to felling small trees.

With a robust construction and user-friendly features, this chainsaw stands out in the competitive market. It boasts a lightweight design that facilitates maneuverability, enabling users to work for extended periods without excessive fatigue. The engine’s capability to deliver substantial power ensures effective cutting, regardless of the density of the wood.

| Feature | Description |

|---|---|

| Engine Type | 2-stroke engine designed for optimal performance |

| Bar Length | Varies between 12 to 16 inches, providing versatility |

| Weight | Approximately 10-12 lbs, ensuring easy handling |

| Fuel Capacity | Efficient tank size for extended operation |

| Safety Features | Equipped with chain brake and hand guard for user protection |

Key Features and Specifications

This section outlines the significant attributes and technical details of a widely recognized chainsaw model, highlighting its capabilities and design elements that contribute to its efficiency and performance.

Design and Build Quality

- Compact and lightweight structure for easy maneuverability.

- Durable materials that ensure longevity and reliability under various working conditions.

- Ergonomic handle design for enhanced comfort during extended use.

Performance and Engine Specifications

- Equipped with a powerful engine for high cutting performance.

- Fuel-efficient technology that reduces emissions while maximizing power output.

- Quick-start system that simplifies ignition and operation.

Common Problems with Stihl 009L

Various issues may arise with chainsaw models, affecting their performance and usability. Understanding these common challenges can help users address them efficiently, ensuring smooth operation and longevity of the equipment.

- Starting Difficulties: Users often experience trouble initiating the engine, which may result from fuel issues, spark plug problems, or carburetor malfunctions.

- Inconsistent Power Output: Fluctuations in power can be attributed to clogged air filters, fuel line blockages, or carburetor adjustments that require attention.

- Excessive Vibration: Increased vibration during operation may indicate worn or damaged components, such as the chain or bar, necessitating inspection and replacement.

- Chain Issues: Problems with the chain, such as it becoming dull or loose, can hinder cutting efficiency and safety. Regular maintenance is essential to avoid these issues.

- Fuel Leaks: Leakage from fuel lines or the tank can pose safety hazards and lead to operational inefficiencies. Users should regularly check for signs of wear or damage.

Being aware of these potential problems allows users to take preventive measures and perform necessary maintenance, ensuring reliable functionality and enhancing the lifespan of their equipment.

Identifying Performance Issues

Understanding the root causes of performance challenges in machinery is crucial for maintaining efficiency and effectiveness. Various factors can contribute to diminished functionality, including fuel quality, air intake, and mechanical wear. Recognizing these issues early can prevent further complications and ensure optimal operation.

Common Symptoms of Underperformance

Users may notice several indicators that suggest a decline in performance. These can include irregular engine behavior, reduced power output, or excessive emissions. Any unusual sounds or vibrations during operation can also signal underlying problems that need attention.

Steps to Diagnose Problems

To effectively diagnose issues, it is essential to conduct a thorough inspection of the equipment. Start by checking the fuel system for blockages or contamination, then assess the air filter for cleanliness. Additionally, inspecting the ignition system and examining the condition of spark plugs can reveal critical insights into the machine’s operational status.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving effective results. The following tools are fundamental for anyone looking to perform servicing or troubleshooting on their outdoor machinery. These implements not only enhance efficiency but also ensure safety and precision during the task.

Basic Hand Tools

Hand tools form the foundation of any servicing kit. They are indispensable for disassembling components and tightening fasteners. Essential items include:

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening and tightening nuts and bolts. |

| Screwdrivers | Essential for removing and fastening screws. |

| Pliers | Ideal for gripping and twisting wires or components. |

| Socket Set | Facilitates the removal of various-sized fasteners. |

Power Tools

In addition to hand tools, power tools can significantly speed up the maintenance process. They are particularly useful for tasks requiring more force or precision. Commonly used power tools include:

| Tool | Purpose |

|---|---|

| Drill | For creating holes or driving screws quickly. |

| Angle Grinder | Used for cutting and grinding metal components. |

| Impact Wrench | Provides high torque for loosening stubborn fasteners. |

| Saw | Ideal for cutting through various materials as needed. |

Gathering Necessary Equipment

Before embarking on maintenance tasks for your equipment, it is essential to assemble all required tools and materials. Having everything at hand ensures a smooth workflow and minimizes interruptions during the process. Below is a list of common items you may need to effectively carry out the procedures.

| Item | Purpose |

|---|---|

| Wrench set | For loosening and tightening bolts and nuts |

| Screwdriver set | To remove and replace screws of various sizes |

| Fuel container | For storing and mixing fuel as required |

| Safety goggles | To protect your eyes during maintenance |

| Gloves | To ensure hand protection while working |

| Oil can | For lubricating moving parts |

| Cleaning cloths | To keep the equipment and workspace tidy |

Step-by-Step Repair Process

This section outlines a comprehensive approach to fixing mechanical equipment, ensuring that users can effectively address common issues. By following a systematic sequence, individuals can restore functionality and enhance performance. The process encompasses assessment, disassembly, troubleshooting, and reassembly, guiding users through each crucial phase with clarity.

Assessment and Preparation

Before commencing any maintenance tasks, it is vital to conduct a thorough evaluation of the equipment’s condition. Begin by identifying symptoms and gathering necessary tools. Ensure that the workspace is organized and free from distractions, as this promotes efficiency and safety during the undertaking.

Disassembly and Troubleshooting

Once prepared, carefully disassemble the equipment, taking note of each component’s position and orientation. This attention to detail facilitates accurate reassembly. During disassembly, inspect parts for wear and damage. Replace any faulty components as needed, paying close attention to manufacturer specifications to ensure compatibility and reliability.

Disassembling the Chainsaw

To effectively access and maintain the internal components of a chainsaw, disassembly is essential. This process allows users to examine, clean, and replace any worn or damaged parts, ensuring optimal performance. Proper techniques must be employed to prevent damage during this intricate procedure.

Begin by ensuring the chainsaw is completely powered off and disconnected from any power source. Next, remove the guide bar and chain, which are typically secured with bolts. Use a suitable tool to loosen and detach these components, taking care to keep all hardware organized for reassembly.

After removing the exterior elements, focus on the casing of the device. Locate the screws or fasteners that secure the outer shell. Carefully unscrew and lift off the casing to reveal the inner mechanisms. At this stage, inspect the parts for wear or debris, cleaning as necessary.

Additionally, consider checking the fuel system and air filter during this disassembly phase. Ensuring these elements are clean can significantly enhance the chainsaw’s efficiency. Once all necessary inspections and repairs are completed, carefully reassemble the unit in the reverse order of disassembly, ensuring all components are securely fastened.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any outdoor power equipment. Implementing simple yet effective care practices can greatly enhance performance and reliability over time.

First and foremost, always keep the device clean. Dirt and debris can accumulate in various parts, leading to reduced efficiency and potential malfunctions. Use a soft brush or cloth to remove any build-up, paying special attention to air filters and cooling fins.

Additionally, check and replace filters as necessary. Clogged filters can restrict airflow and cause the engine to overheat. It is advisable to consult the specifications for recommended replacement intervals.

Proper lubrication is crucial for moving components. Regularly inspect and apply appropriate oil to chains and other parts as per the guidelines. This practice minimizes wear and ensures smooth operation.

Finally, store the equipment in a dry and sheltered location when not in use. Exposure to harsh weather conditions can lead to corrosion and damage, adversely affecting functionality. By following these maintenance tips, you can help ensure your equipment remains in peak condition for years to come.

Keeping Your Chainsaw in Top Shape

Regular maintenance is essential for ensuring that your cutting tool operates efficiently and safely. Proper care not only prolongs the lifespan of the equipment but also enhances performance during use. By following a few simple practices, you can keep your chainsaw running smoothly and effectively tackle any task.

Here are some important maintenance tasks to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check the Chain Tension | Before Each Use | Ensure the chain is properly tightened to avoid slippage and ensure safe operation. |

| Inspect the Bar and Chain | Weekly | Look for wear, damage, or debris that could hinder performance. |

| Clean the Air Filter | Every Few Uses | Remove dirt and debris to ensure optimal airflow and performance. |

| Sharpen the Chain | As Needed | A sharp chain cuts more efficiently, reducing strain on the engine. |

| Check Fuel and Oil Levels | Before Each Use | Ensure that both fuel and lubrication are adequate for safe operation. |

By adhering to these guidelines, you can maintain the functionality and reliability of your equipment, ensuring it remains an effective tool for your needs.

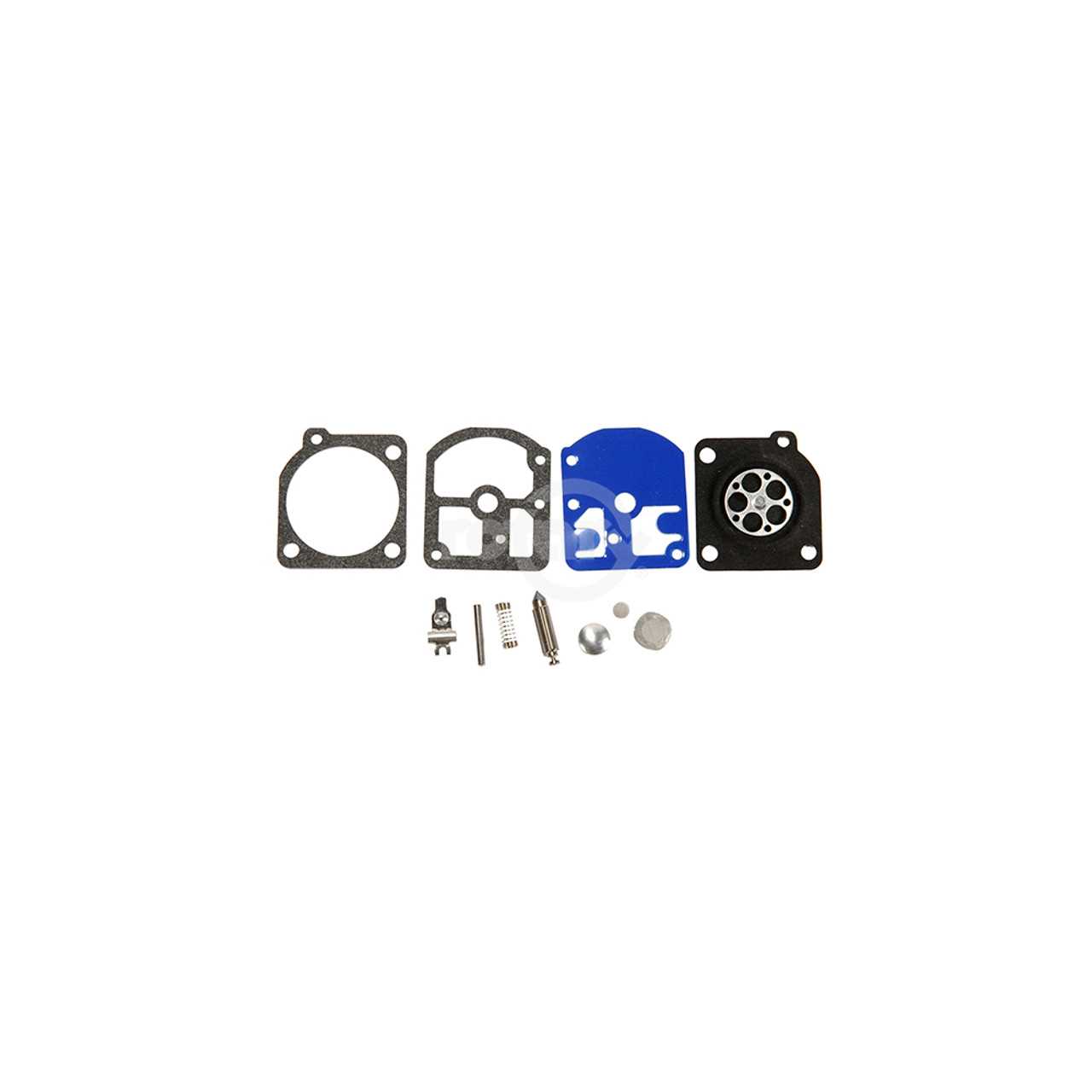

Replacing Worn Parts Effectively

Maintaining optimal performance of any mechanical equipment often involves timely replacement of components that have experienced wear and tear. Understanding when and how to replace these elements is crucial for ensuring longevity and efficiency. This section focuses on the process of identifying and substituting parts that are no longer functioning at their best, thereby enhancing overall equipment reliability.

Identifying Worn Components

Before initiating the replacement process, it is essential to accurately identify which parts have become worn or damaged. Regular inspections can reveal signs of fatigue, such as cracks, discoloration, or unusual noises during operation. By addressing these issues promptly, one can prevent further damage and ensure smooth operation.

Steps for Replacement

Once worn components have been identified, follow these steps to effectively replace them:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement parts. |

| 2 | Disconnect power to ensure safety during the process. |

| 3 | Carefully remove the worn part, noting any specific orientation or installation instructions. |

| 4 | Install the new component, ensuring proper alignment and securing it firmly. |

| 5 | Reconnect power and conduct a test to verify functionality. |

Identifying and Sourcing Components

When working on machinery, understanding how to recognize and procure essential parts is crucial for maintaining optimal performance. This process involves thorough knowledge of the specific elements that comprise the equipment, as well as knowing where to find reliable sources for replacements and upgrades. By familiarizing oneself with various components, users can ensure their devices operate efficiently and remain in good condition over time.

Recognizing Key Elements

Begin by studying the essential components of the machinery, including the engine, fuel system, and cutting apparatus. Each part plays a vital role in the overall function, and being able to identify them accurately will facilitate the process of sourcing appropriate replacements. Utilize diagrams or parts lists to enhance your understanding and create a reference guide for future use.

Finding Reliable Sources

Once the components are identified, sourcing quality parts becomes the next step. Local dealers, authorized retailers, and online marketplaces can provide access to genuine replacements. Always verify the credibility of the supplier to avoid counterfeit items. Furthermore, consider joining forums or communities dedicated to equipment maintenance, where members often share tips on where to find parts at competitive prices.

Fuel System Troubleshooting

This section aims to guide users in diagnosing and resolving issues related to the fuel delivery mechanism of their equipment. Understanding the signs of malfunction can lead to effective solutions, ensuring optimal performance.

When encountering fuel system problems, consider the following potential causes:

- Poor fuel quality or contamination

- Blocked fuel lines

- Faulty fuel filter

- Inadequate fuel flow from the tank

- Issues with the carburetor settings

To systematically troubleshoot these issues, follow these steps:

- Inspect the fuel tank for any signs of dirt or debris.

- Check the fuel lines for cracks or blockages.

- Replace the fuel filter if it appears clogged.

- Verify the fuel pump’s functionality, ensuring it is delivering adequate pressure.

- Adjust the carburetor settings according to the manufacturer’s specifications.

By addressing these areas, users can enhance the reliability of their equipment and prevent further complications.