Every owner of outdoor machinery eventually encounters challenges that require attention and expertise. Understanding the intricacies of your equipment can enhance its longevity and performance, allowing you to tackle any issue with confidence. This section aims to provide insights and practical advice to ensure your device remains in optimal condition.

From routine upkeep to identifying common faults, this resource equips you with the knowledge necessary to navigate typical scenarios. By familiarizing yourself with essential components and operational guidelines, you’ll be better prepared to address potential setbacks and maintain efficiency.

Emphasizing preventative measures and straightforward solutions, this guide serves as a valuable companion for enthusiasts and casual users alike. Whether you seek to resolve a minor glitch or conduct comprehensive checks, the information presented here will empower you to take proactive steps toward effective management of your equipment.

Essential Tools for Lawn Mower Repair

Having the right equipment is crucial when addressing issues with your gardening machine. A well-equipped toolkit can make maintenance tasks more efficient and less frustrating. Below, we outline the key instruments that will assist you in performing various tasks related to your equipment.

Basic Hand Tools

Starting with the fundamental instruments, a few hand tools are indispensable for routine tasks. These items are versatile and can help with numerous adjustments and fixes.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For adjusting screws on various components. |

| Pliers | For gripping and bending wires or other materials. |

| Socket Set | For dealing with fasteners in tight spaces. |

Specialized Tools

In addition to basic tools, some specialized items can enhance your ability to address specific issues effectively. These tools may vary based on the type of machinery you are working on.

| Tool | Purpose |

|---|---|

| Blade Sharpener | For maintaining sharpness and efficiency of cutting edges. |

| Fuel Line Wrench | For safely disconnecting fuel lines during service. |

| Compression Tester | For assessing engine performance and diagnosing issues. |

Common Lawn Mower Problems Explained

Maintaining a grass cutting machine can sometimes feel challenging, especially when issues arise unexpectedly. Understanding the frequent complications can help users diagnose problems effectively and enhance the longevity of their equipment. This section delves into typical malfunctions, providing insights into their causes and possible solutions.

Starting Difficulties

One of the most frustrating issues is when the engine fails to start. This can stem from various factors, such as a depleted fuel tank, stale gasoline, or a malfunctioning spark plug. Checking these elements can often reveal the root cause. Ensure the fuel is fresh and that the spark plug is clean and functioning properly to resolve this issue.

Uneven Cutting Performance

Another common concern is uneven grass trimming. This problem can occur due to a dull blade, improper height settings, or uneven tire pressure. Regularly sharpening the blades and adjusting the cutting height can greatly improve performance. Additionally, checking the tire inflation can help maintain even contact with the ground, ensuring a smooth cut.

Step-by-Step Repair Process Overview

This section outlines a systematic approach to restoring functionality to your outdoor equipment. By following a structured process, you can efficiently identify issues, perform necessary adjustments, and ensure optimal performance.

Preparation Phase

- Gather essential tools and materials.

- Ensure a clean and organized workspace.

- Review safety precautions to avoid accidents.

Diagnostic Steps

- Inspect the equipment for visible signs of damage.

- Check fuel levels and ensure proper flow.

- Test electrical connections for continuity.

- Assess moving parts for wear and tear.

Following these steps will facilitate a thorough evaluation and enable you to carry out effective interventions. Keeping a methodical approach will enhance the likelihood of successful outcomes and prolong the lifespan of your equipment.

How to Maintain Your Craftsman Mower

Proper upkeep is essential for ensuring optimal performance and longevity of your grass-cutting equipment. By following a few key practices, you can keep your machine running smoothly and efficiently throughout the seasons.

Regular Inspections

Routine checks can prevent issues before they become significant problems. Examine the blades for any signs of dullness or damage; sharp blades provide a cleaner cut. Additionally, inspect the fuel system, ensuring there are no leaks or blockages. Checking the air filter regularly is also crucial, as a clean filter allows for better airflow and engine efficiency.

Maintenance Schedule

Establishing a consistent timetable for upkeep is vital. Change the oil as recommended by the manufacturer, typically after every 50 hours of use. Replace the spark plug annually to ensure easy starting and efficient combustion. Cleaning the exterior and undercarriage after each use will help prevent rust and buildup, contributing to the overall health of your machine.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor machinery, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the task but also ensure the longevity and functionality of the equipment being serviced.

1. Personal Protective Equipment (PPE): Always wear appropriate gear such as gloves, safety goggles, and sturdy footwear. This equipment shields against sharp edges, flying debris, and potential hazards that may arise during the process.

2. Work Environment: Ensure that the workspace is clean and free from clutter. A well-organized area minimizes the risk of tripping or misplacing tools, creating a safer atmosphere for any undertaking.

3. Equipment Inspection: Before beginning, examine the machinery for any signs of damage or wear. Addressing these issues beforehand can prevent further complications and promote a safer working environment.

4. Fuel Handling: If working with fuel, take care to store it in appropriate containers away from heat sources. Always refuel in a well-ventilated area to avoid inhaling harmful fumes.

5. Follow Manufacturer Guidelines: Adhering to specific instructions provided by the equipment maker ensures that safety protocols are respected and reduces the likelihood of errors during service.

By implementing these safety measures, individuals can confidently engage in maintenance activities, ensuring both personal well-being and the efficient operation of their machinery.

Identifying and Fixing Engine Issues

When facing performance challenges with your machine, it is essential to diagnose and address potential engine complications effectively. Understanding the signs and symptoms of these issues will enable you to take appropriate actions, ensuring your equipment operates smoothly and efficiently.

Common Symptoms of Engine Problems

Several indicators can suggest underlying engine troubles. Pay attention to unusual noises, excessive vibrations, or difficulties starting the unit. Stalling during operation or inconsistent power output may also signal a need for examination. Additionally, monitoring fuel consumption can provide clues; a sudden increase may hint at inefficiencies within the engine.

Troubleshooting Steps

To address identified issues, begin with a systematic approach. Check the spark plug for wear or fouling, as this component plays a crucial role in ignition. Inspecting the air filter is also vital; a clogged filter can restrict airflow and hinder performance. Ensure fuel lines are clear and free of blockages, and consider examining the carburetor for any necessary adjustments or cleaning. Regular maintenance can prevent many complications and extend the lifespan of your equipment.

Replacing Blades: A Simple Guide

Maintaining optimal performance of your gardening equipment is essential for achieving a well-manicured yard. One crucial aspect of upkeep involves ensuring that the cutting components are in good condition. Regularly changing these parts can significantly enhance efficiency and extend the lifespan of your device.

Before beginning the process, ensure you have the necessary tools on hand, such as a socket wrench, safety gloves, and protective eyewear. Always disconnect the power source to prevent any accidental activation during the procedure.

Start by lifting the machine to access the cutting components easily. Secure it on a stable surface to avoid any slips. Locate the bolts that fasten the blades and use the socket wrench to remove them carefully. Take note of the blade orientation, as this will be important for installing the new ones correctly.

Once the old components are detached, it’s time to install the new ones. Position the replacement blades in the same orientation as the originals and hand-tighten the bolts to hold them in place. Then, use the socket wrench to secure them firmly, ensuring they are tightly fastened to prevent any movement during operation.

After replacing the blades, lower the equipment back to the ground and reconnect the power source. It’s advisable to conduct a brief test run to ensure everything operates smoothly. Regularly checking and replacing these components will keep your equipment running efficiently and help you achieve a pristine outdoor space.

Fuel System Troubleshooting Techniques

Identifying issues within the fuel delivery system is crucial for ensuring optimal performance of your equipment. By understanding the common symptoms and their underlying causes, you can effectively diagnose and address any complications that may arise.

Visual Inspection: Begin with a thorough examination of the fuel lines, connectors, and filters. Look for signs of cracks, leaks, or blockages that could impede fuel flow. Ensuring that all components are securely attached is also essential.

Fuel Quality Check: The quality of the fuel can greatly affect functionality. Inspect the fuel for contamination, such as dirt or water, which can disrupt the combustion process. If necessary, replace the fuel with a fresh supply to see if performance improves.

Pressure Assessment: Verify that the fuel system maintains the proper pressure. Low pressure may indicate a failing pump or a clogged filter. Utilize a pressure gauge to confirm the readings and determine if further action is needed.

System Flushing: In cases of persistent issues, flushing the fuel system can be beneficial. This process removes accumulated debris and contaminants, ensuring that fuel can flow freely and efficiently.

Component Testing: Test individual components such as the fuel pump, injectors, and carburetor. Ensure each part operates correctly, as a malfunction in one area can affect the entire system’s performance.

By employing these techniques, you can systematically pinpoint and resolve fuel-related challenges, enhancing the reliability and efficiency of your equipment.

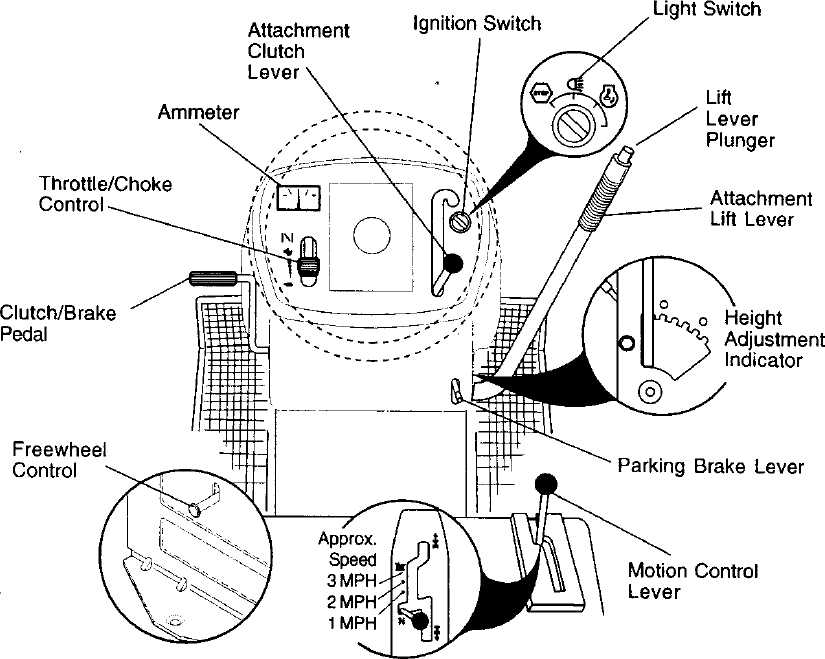

Electrical System Diagnosis and Repair

This section focuses on identifying and addressing issues within the electrical components of your equipment. Proper evaluation and correction are crucial to ensure optimal functionality and prevent further complications. Understanding the basic principles of the electrical system can lead to effective troubleshooting.

Common Issues

- Battery failure

- Faulty ignition system

- Wiring problems

- Malfunctioning switches

Diagnostic Steps

- Check the battery voltage using a multimeter.

- Inspect connections for corrosion or looseness.

- Test the ignition system components, including coils and spark plugs.

- Examine wiring for any signs of damage or wear.

- Assess switches for proper functionality.

By systematically following these steps, you can effectively identify the root causes of electrical malfunctions and take appropriate action to restore the system’s performance.

Maintaining Tires and Wheels Effectively

Proper upkeep of the tires and wheels is essential for optimal performance and longevity of your equipment. Regular attention to these components not only ensures safe operation but also enhances overall efficiency. Understanding the best practices for maintenance can significantly reduce wear and tear, ultimately saving you time and resources.

Checking Tire Pressure is one of the most critical aspects of maintenance. Incorrect pressure can lead to decreased traction and increased fuel consumption. Use a reliable gauge to monitor the air pressure regularly, and adjust it according to the manufacturer’s specifications. This simple task can prevent uneven wear and improve handling.

Inspecting Tread Depth should be done frequently. Worn-out tread can compromise safety and performance. Look for signs of wear, such as flat spots or bald patches, and consider replacing the tires if they do not meet the required depth. Maintaining proper tread ensures better grip on various terrains.

Cleaning Wheels is often overlooked but is vital for preventing rust and corrosion. Use a mild detergent and a soft brush to remove dirt and debris. Regular cleaning not only prolongs the life of the wheels but also enhances their appearance. After cleaning, inspect for any signs of damage or deterioration.

Balancing and Aligning the wheels contributes to smoother operation and prevents excessive wear. Misalignment can cause uneven tire wear and affect handling. Consult a professional if you notice vibrations or pulling to one side, as they can properly balance and align your equipment.

By incorporating these maintenance practices into your routine, you can ensure that your tires and wheels remain in excellent condition, contributing to the overall performance and reliability of your machinery.

When to Seek Professional Help

Understanding the right moments to call in an expert can save you time and prevent further complications. While many tasks can be managed independently, certain situations require the specialized knowledge and tools of a professional. Identifying these circumstances can enhance the longevity and efficiency of your equipment.

Signs That Indicate Professional Assistance is Needed

When facing issues beyond basic troubleshooting, it’s important to recognize specific indicators. Here are some common signs that suggest it’s time to consult an expert:

| Indicator | Description |

|---|---|

| Unusual Noises | If you hear grinding, knocking, or any unfamiliar sounds, it could signal a serious problem. |

| Persistent Performance Issues | Consistent difficulties in starting or maintaining operation are often best addressed by a trained technician. |

| Leaking Fluids | Any signs of fluid leakage should be investigated promptly to prevent damage. |

| Electrical Malfunctions | Issues related to wiring or electrical components can be hazardous and require professional assessment. |

Benefits of Professional Intervention

Engaging a specialist not only ensures a proper resolution but also provides peace of mind. Experts possess the experience and equipment necessary to diagnose and fix problems efficiently. Moreover, their interventions often extend the lifespan of your equipment and improve overall performance.

Using OEM vs. Aftermarket Parts

The choice between original equipment manufacturer (OEM) components and those produced by third parties is crucial for maintaining optimal performance and longevity of outdoor machinery. Each option presents distinct advantages and potential drawbacks that can influence both functionality and cost-effectiveness.

Advantages of OEM Parts

OEM components are specifically designed to match the original specifications of your equipment, ensuring compatibility and reliability. They often come with warranties and are manufactured to meet rigorous quality standards, which can provide peace of mind for users. Utilizing these parts can also help preserve the overall value of the machinery, as they maintain its integrity over time.

Benefits of Aftermarket Components

Aftermarket options can offer cost savings and availability that OEM parts may lack. Many third-party manufacturers produce enhanced versions of original components, potentially improving performance or adding features. Additionally, a wider variety of choices allows users to find solutions that may better suit their specific needs or preferences.