Understanding how to effectively maintain winter machinery is essential for ensuring optimal performance during the colder months. Regular upkeep not only extends the lifespan of these devices but also enhances their efficiency, making it easier to tackle heavy snowfalls and icy conditions. This guide provides valuable insights into the care and troubleshooting of your essential winter gear.

From routine inspections to specific fixes, having a comprehensive approach can prevent minor issues from escalating into major problems. Familiarizing yourself with the components and their functions allows for a smoother operation and ensures that your equipment is always ready for action when needed.

Equipped with the right knowledge, you can tackle any challenges that may arise with confidence. Emphasizing the importance of proactive measures will lead to a more enjoyable and less stressful winter experience.

Understanding MTD Snow Throwers

The equipment designed for clearing pathways during winter storms plays a vital role in maintaining accessibility and safety. These machines are engineered to efficiently remove accumulated precipitation from driveways, sidewalks, and other surfaces, ensuring that mobility is not hindered by harsh weather conditions.

Key Features

These devices come equipped with various features that enhance their functionality. For instance, many models include adjustable speed settings, allowing users to customize performance according to the conditions. Additionally, the design often incorporates robust blades that effectively chop through compacted ice and snow, providing a thorough clean-up.

Maintenance Tips

Proper upkeep is essential for optimal performance. Regularly checking the engine oil and fuel levels can prevent operational issues. It is also advisable to inspect and sharpen the blades periodically to ensure efficient clearing. Following these guidelines can prolong the life of the equipment and enhance its reliability during the winter months.

Common Issues and Symptoms

Understanding frequent complications and their indicators is essential for effective maintenance of outdoor equipment. Recognizing these signs can lead to timely interventions and prolong the lifespan of the machinery. Below are typical problems encountered along with their corresponding symptoms.

| Issue | Symptoms |

|---|---|

| Engine Won’t Start | Unresponsive ignition, unusual noises, or fuel leaks. |

| Uneven Performance | Inconsistent operation, stalling, or sputtering during use. |

| Excessive Vibrations | Shaking components, rattling sounds, or loose parts. |

| Blockages | Reduced efficiency, inability to clear debris, or unusual smells. |

| Fuel Consumption Issues | Increased fuel usage, difficulty starting after refueling, or dark exhaust. |

Essential Tools for Repairs

Having the right instruments at hand is crucial for effectively maintaining and fixing various outdoor machinery. These implements not only streamline the process but also enhance the quality of work performed. Below is a list of indispensable items that every enthusiast should consider for optimal functionality.

Basic Hand Tools

Hand tools form the foundation of any maintenance toolkit. They are essential for a range of tasks, from assembly to troubleshooting. The following table outlines some of the most common hand tools and their uses:

| Tool | Use |

|---|---|

| Wrenches | Loosening and tightening bolts and nuts |

| Screwdrivers | Installing and removing screws |

| Pliers | Gripping and twisting wires or small objects |

| Socket Set | Working with various sizes of fasteners |

Specialized Equipment

In addition to basic tools, having specialized equipment can greatly assist in more complex tasks. These items ensure precision and efficiency in maintenance activities. Below are examples of specialized tools:

| Tool | Use |

|---|---|

| Torque Wrench | Ensuring fasteners are tightened to the correct specifications |

| Multimeter | Measuring electrical values for troubleshooting |

| Diagnostic Scanner | Identifying system errors and performance issues |

| Fuel Line Clamp | Temporarily closing fuel lines during maintenance |

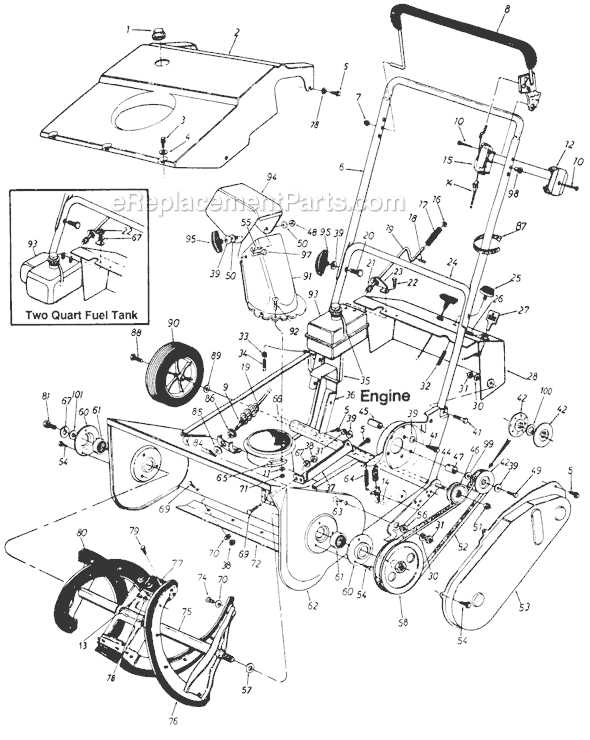

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. This guide provides a systematic approach to maintaining your machine, focusing on key aspects that contribute to its efficiency and reliability.

Begin by inspecting the various components for any signs of wear or damage. Check the belts, blades, and housing, ensuring they are free from debris. Regular cleaning helps prevent buildup that can affect functionality.

Next, lubricate moving parts to reduce friction and enhance performance. Use the appropriate lubricant recommended for your model, applying it to all necessary joints and bearings.

It is also crucial to change the oil and replace the filter at regular intervals. This practice not only improves engine efficiency but also extends its lifespan. Follow the manufacturer’s specifications for oil type and change frequency.

Finally, test the functionality of the electrical components and controls. Ensure that all switches and indicators are working properly to avoid operational issues during use.

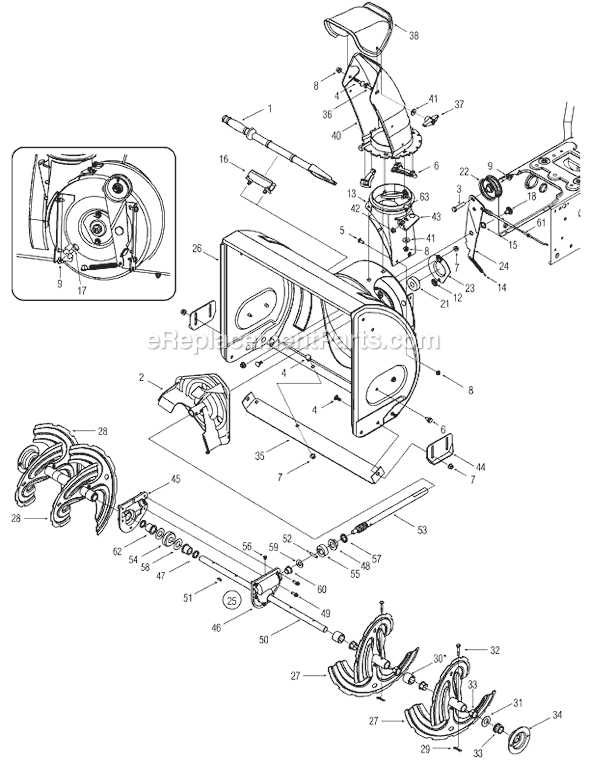

Replacing the Auger Assembly

When it comes to maintaining the efficiency of your equipment, swapping out the component responsible for moving materials is crucial. This process not only enhances performance but also ensures longevity. Below is a step-by-step guide to assist you in this replacement.

Before you begin, make sure you have the necessary tools and safety gear. Familiarize yourself with the specific model requirements, as they may vary.

| Step | Action |

|---|---|

| 1 | Disconnect the power source to ensure safety during the process. |

| 2 | Remove any protective coverings to access the assembly. |

| 3 | Loosen and take off the fasteners securing the current component. |

| 4 | Carefully extract the old unit from its housing. |

| 5 | Position the new part in place, ensuring it aligns correctly. |

| 6 | Reattach the fasteners and any coverings removed earlier. |

| 7 | Reconnect the power source and perform a functionality check. |

Following these steps will ensure a smooth replacement process. Regular maintenance can prevent future issues and keep your equipment in optimal condition.

Fixing the Drive Belt Problems

Addressing issues related to the belt drive system is crucial for maintaining optimal performance. These components are essential for the effective operation of your equipment, and recognizing common problems can prevent further damage and ensure longevity.

Common Symptoms of Drive Belt Issues

- Slipping or loss of power during operation

- Unusual noises such as squeaking or grinding

- Visible wear or damage on the belt surface

- Difficulty in engaging the drive system

Steps to Resolve Belt-Related Problems

- Inspect the Belt: Check for signs of wear, cracks, or fraying. Replace if damaged.

- Tighten the Tension: Ensure the belt is properly tensioned to prevent slippage. Adjust the tensioner as needed.

- Clean Components: Remove any debris or buildup on pulleys and the belt to maintain smooth operation.

- Check Alignment: Ensure that the pulleys are aligned correctly. Misalignment can lead to premature wear.

- Replace if Necessary: If problems persist, consider replacing the belt with a new one that meets the specifications.

Regular maintenance and timely intervention can significantly enhance the efficiency of the drive system, ensuring reliable performance during use.

Adjusting the Chute Direction

Proper alignment of the discharge chute is essential for optimal performance during winter tasks. Ensuring that the path of the expelled material is directed away from the user and obstacles enhances both efficiency and safety. Understanding how to adjust the chute direction can make a significant difference in how effectively you manage accumulated snow or debris.

To begin, locate the adjustment mechanism, which is typically positioned near the chute itself. This may involve either a lever or a crank that allows for smooth repositioning. When making adjustments, ensure the unit is turned off and properly secured to avoid any accidental engagement. Gradually move the chute to the desired angle, testing the range of motion to find the best setting for your needs.

Regularly checking the alignment and condition of the chute can prevent performance issues. If you notice any resistance or irregularities during operation, it may be time to inspect the adjustment components for wear or damage. Keeping these parts in good condition ensures your equipment remains reliable and functional throughout the winter season.

Winter Preparation Tips

As the cold season approaches, it’s crucial to ensure that your equipment is ready for the challenges ahead. Proper preparation not only enhances performance but also prolongs the lifespan of your tools. Following a few essential steps can make all the difference when winter weather strikes.

Check the Fuel System: Before the first snowfall, inspect the fuel system for any leaks or issues. Ensure that the fuel is fresh and free from contaminants. Old fuel can cause operational problems, so consider replacing it if necessary.

Inspect Belts and Cables: Regularly examine belts and cables for signs of wear and tear. Replace any damaged components to prevent breakdowns during heavy usage. A well-maintained system ensures smooth operation and efficiency.

Sharpen the Cutting Edges: Maintaining sharp cutting edges is essential for optimal performance. Dull blades can struggle to clear paths effectively. Regular sharpening will enhance cutting efficiency and make your tasks easier.

Store Properly: When the season ends, ensure your equipment is stored in a dry, sheltered area. This protects it from harsh weather conditions and potential damage. Regular cleaning before storage also helps maintain functionality for future use.

By taking these proactive measures, you can ensure your tools are ready to tackle winter’s challenges effectively and efficiently.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor equipment, adhering to safety guidelines is crucial to prevent accidents and injuries. Proper precautions ensure a secure working environment, allowing for efficient and effective service.

Before starting any work, it is essential to equip yourself with the right protective gear. This not only safeguards against potential hazards but also enhances overall safety during the process.

| Safety Gear | Description |

|---|---|

| Gloves | Protect hands from sharp edges and hazardous materials. |

| Safety Glasses | Prevent eye injuries from flying debris. |

| Ear Protection | Reduce noise exposure when using loud equipment. |

| Sturdy Footwear | Provide stability and protect feet from heavy objects. |

Additionally, ensure the workspace is well-ventilated and free from clutter. This minimizes the risk of tripping hazards and ensures proper air circulation when working with fuel or chemicals. Always disconnect power sources before beginning any task to prevent unintended operation.

When to Seek Professional Help

Understanding when to consult an expert can save time and prevent further complications. There are situations where attempting to address issues independently may lead to more significant problems. Recognizing these moments is crucial for maintaining equipment efficiency and safety.

Signs of Complex Issues

If you encounter persistent difficulties that do not improve with basic troubleshooting, it may be time to reach out for assistance. Symptoms such as unusual noises, erratic operation, or persistent malfunctions can indicate underlying concerns that require specialized knowledge.

Safety Considerations

Your safety should always be a priority. If any repairs involve potential hazards, such as electrical components or heavy machinery, it is advisable to consult a professional. Their expertise can ensure that repairs are conducted safely and effectively, minimizing risks to yourself and others.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and troubleshooting of outdoor equipment, aiming to provide clarity on various topics that users may encounter.

- What should I do if my equipment won’t start?

- Check the fuel level and ensure it is filled with fresh fuel.

- Inspect the battery to ensure it is charged and properly connected.

- Examine the spark plug for wear or damage and replace it if necessary.

- How can I improve performance during use?

- Regularly clean the air filter to ensure proper airflow.

- Inspect and sharpen the blades for optimal cutting efficiency.

- Ensure all moving parts are lubricated as recommended in the guidelines.

- What are the signs of a malfunction?

- Unusual noises during operation, such as grinding or rattling sounds.

- Reduced power output or uneven performance.

- Visible leaks of fuel or oil.

- How often should I perform maintenance tasks?

- Follow the suggested schedule in the documentation for routine upkeep.

- Perform a thorough inspection before and after each season of use.

- Address any issues immediately to prevent further damage.