When it comes to maintaining your high-performance equipment, understanding its intricacies is crucial. This section aims to provide valuable insights into the nuances of servicing and troubleshooting various cutting tools, ensuring optimal functionality and longevity. Whether you’re a seasoned user or a newcomer, having a reliable resource at your fingertips can make all the difference.

Regular upkeep not only enhances performance but also prevents unexpected breakdowns. Familiarizing yourself with common issues and solutions allows you to tackle problems with confidence. This guide will walk you through essential techniques and tips that can help you keep your machinery in top shape.

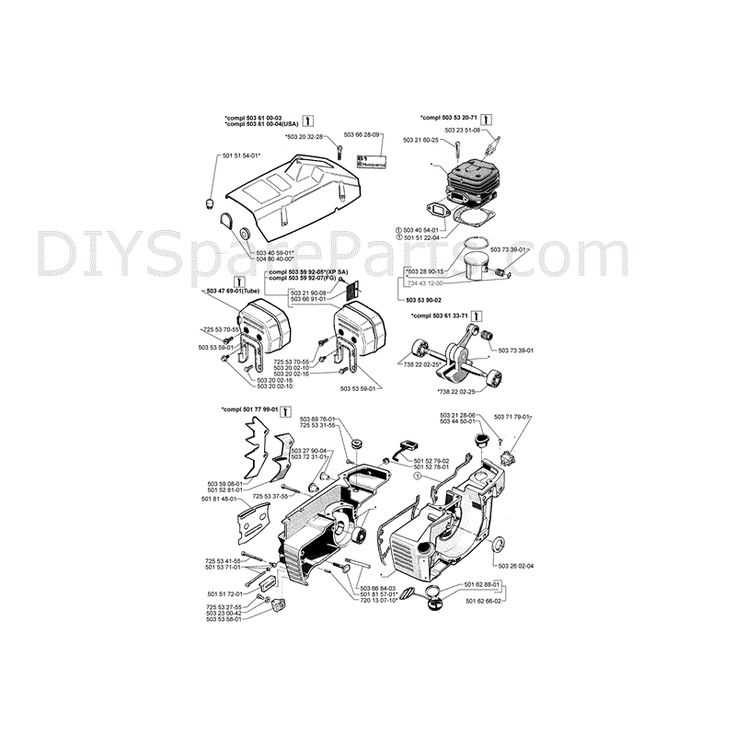

Additionally, knowing the specific components of your equipment and how they interact is vital. Each tool has its unique features and requirements, and understanding these will empower you to address challenges effectively. In the following sections, you’ll discover detailed instructions and recommendations that will equip you to handle maintenance tasks like a pro.

Understanding Your Husqvarna Chainsaw

To effectively manage and maintain your cutting tool, it’s essential to grasp its fundamental components and operational principles. A thorough understanding not only enhances performance but also ensures safety during use. Familiarizing yourself with the intricate parts and their functions will empower you to make informed decisions about care and troubleshooting.

The Engine: The power unit is at the heart of the device, providing the necessary force to drive the cutting mechanism. Understanding how it operates, including its fuel requirements and maintenance needs, is crucial for optimal performance.

The Cutting Mechanism: This section includes the blade and the drive system, which work in tandem to deliver precision cuts. Recognizing how to properly tension and sharpen the blade can greatly impact efficiency and the quality of work.

Safety Features: Various built-in safeguards are designed to protect the user. Familiarity with these features, such as the chain brake and throttle lock, enhances safety and prevents accidents during operation.

Maintenance: Regular upkeep is vital for prolonging the lifespan of your tool. Understanding how to clean, lubricate, and inspect key components ensures that your equipment remains in peak condition.

By deepening your knowledge of these aspects, you can enhance your skills, maximize productivity, and ensure safe operation throughout your projects.

Common Chainsaw Problems and Solutions

Every outdoor power tool can encounter issues that may hinder its performance. Understanding these challenges and their remedies can significantly enhance the longevity and efficiency of your equipment. Below are some frequently experienced difficulties along with their potential solutions.

- Engine Won’t Start

- Check the fuel level and ensure it’s fresh and properly mixed.

- Inspect the spark plug for wear or damage; replace if necessary.

- Examine the air filter for clogs that could impede airflow.

- Tool Loses Power During Use

- Clean the air filter to improve airflow.

- Inspect the fuel lines for blockages or leaks.

- Check the ignition system for faults that may affect performance.

- Excessive Vibration

- Ensure all bolts and screws are tightened properly.

- Inspect the blade for damage or dullness; sharpen or replace as needed.

- Examine the rubber mounts for wear and replace them if they are compromised.

- Chain Sticking or Slipping

- Check the tension of the chain and adjust it according to the manufacturer’s guidelines.

- Inspect the guide bar for wear and replace if necessary.

- Lubricate the chain regularly to reduce friction.

- Fuel Leaks

- Examine the fuel lines and connections for cracks or loose fittings.

- Inspect the fuel tank for damage and replace if needed.

- Ensure all caps and seals are secured tightly.

By addressing these common issues, users can ensure their equipment operates smoothly and effectively, allowing for a more enjoyable and efficient experience in outdoor tasks.

Essential Tools for Chainsaw Repair

When it comes to maintaining and fixing outdoor power equipment, having the right instruments is crucial. Proper tools not only ensure efficiency but also enhance safety during the process. Here is a list of must-have equipment for anyone looking to perform maintenance or troubleshooting tasks.

- Wrenches: Adjustable and socket wrenches are essential for loosening and tightening various nuts and bolts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for accessing components and making adjustments.

- Chain tool: This specialized tool is vital for adjusting and removing the cutting link, making it easier to work on the unit.

- Torque wrench: Ensuring that bolts are tightened to the manufacturer’s specifications is critical for safe operation.

- File: A sharpening file keeps the cutting edge in optimal condition, which is key for performance.

- Safety gear: Gloves, goggles, and hearing protection should always be worn to prevent injury during any maintenance activity.

In addition to these essential tools, having a clean workspace and a good organizational system for parts can significantly improve the overall experience. Being well-prepared allows for smoother operations and better outcomes.

Step-by-Step Maintenance Guide

Proper upkeep of your cutting tool is essential for optimal performance and longevity. Regular attention to key components ensures smooth operation and reduces the risk of unexpected failures. This guide outlines essential procedures to maintain your equipment effectively.

| Task | Frequency | Tools Needed | Steps |

|---|---|---|---|

| Clean air filter | Every 10 hours of use | Screwdriver, cleaning brush |

|

| Sharpen the cutting blade | As needed | File, sharpening tool |

|

| Check fuel system | Before each use | None |

|

| Inspect spark plug | Every 25 hours of use | Wrench, replacement plug (if needed) |

|

| Oil the guide bar | Every 5 hours of use | Chain oil |

|

Regular maintenance not only enhances performance but also extends the lifespan of your equipment. Follow these steps diligently to ensure reliable operation throughout its service life.

How to Replace the Chain

Replacing the cutting component is an essential maintenance task that ensures optimal performance and safety. This process involves removing the old unit and installing a new one, which can greatly enhance the efficiency of your tool. Below is a step-by-step guide to assist you in this straightforward yet crucial task.

| Step | Description |

|---|---|

| 1 | Ensure the device is powered off and unplugged for safety. |

| 2 | Locate the tension adjustment mechanism and loosen it to relieve tension on the existing component. |

| 3 | Remove the cover plate securing the old unit, typically held by screws or bolts. |

| 4 | Carefully take off the worn-out cutting component and set it aside. |

| 5 | Place the new cutting element in the correct orientation, ensuring it fits properly. |

| 6 | Reattach the cover plate and secure it firmly. |

| 7 | Adjust the tension according to the manufacturer’s specifications to ensure proper function. |

| 8 | Perform a final check to confirm everything is securely in place before powering on. |

By following these steps, you can easily replace the cutting component, improving the efficiency and safety of your tool. Regular maintenance is key to prolonging its lifespan and performance.

Troubleshooting Engine Performance Issues

Addressing performance concerns in power equipment can significantly enhance efficiency and longevity. Identifying the root causes of poor functionality often involves systematic checks and adjustments. This section will guide you through common symptoms and practical solutions to restore optimal operation.

Loss of Power: If you notice a decrease in engine output, it may be due to a clogged air filter or fuel supply issues. Inspect the air intake system and replace any obstructed components. Additionally, ensure that the fuel lines are clear and that the fuel itself is fresh and uncontaminated.

Excessive Vibration: Vibrations can indicate an imbalance or misalignment. Check the attachment of all components, including blades and bars, ensuring they are securely fastened. Worn or damaged parts should be replaced to minimize instability.

Difficulty Starting: Starting problems can stem from various sources, such as spark plug failure or battery issues. Examine the ignition system and ensure the spark plug is clean and properly gapped. If the unit features an electric start, verify that the battery is charged and connections are secure.

Overheating: An overheating engine can signal insufficient lubrication or blocked cooling fins. Ensure the oil reservoir is filled and check for any debris obstructing airflow around the engine. Regular maintenance of cooling systems is essential for preventing overheating.

By methodically addressing these common performance problems, you can enhance the reliability and efficiency of your equipment, ensuring it functions at its best for years to come.

Cleaning and Maintaining Filters

Regular upkeep of filtration components is crucial for optimal performance and longevity of any mechanical device. Proper maintenance ensures that air and fuel flow remain unobstructed, contributing to efficient operation. Neglecting these elements can lead to decreased performance and potential damage.

Types of Filters

There are generally two types of filters that require attention: air filters and fuel filters. Air filters trap dust and debris, preventing contaminants from entering the engine. Fuel filters, on the other hand, cleanse the fuel before it reaches the combustion chamber. Understanding the role of each type is essential for effective maintenance.

Cleaning Procedures

To clean the air filter, remove it according to the manufacturer’s instructions and gently tap it to dislodge dirt. For deeper cleaning, wash it with soapy water, rinse thoroughly, and allow it to dry completely before reinstalling. Fuel filters typically require replacement rather than cleaning, but consult the guidelines for your specific device to confirm the best practices. Regular inspection and maintenance of these filters will significantly enhance performance and extend the life of the equipment.

Fuel System Repairs Explained

The efficiency of any cutting tool heavily relies on its fuel mechanism. Understanding how to address issues within this system can significantly enhance performance and longevity. This section provides insight into common problems and solutions associated with fuel delivery and management.

Common Fuel System Issues

- Clogged Fuel Filter: A blockage can restrict fuel flow, causing the engine to stall or run poorly.

- Fuel Leaks: Leaks can lead to diminished performance and pose safety hazards.

- Contaminated Fuel: Impurities in the fuel can cause misfires and erratic operation.

- Defective Fuel Pump: A malfunctioning pump can impede fuel delivery to the engine.

Steps to Address Fuel System Problems

- Inspect the Fuel Filter: Regularly check and replace the filter as needed to ensure proper flow.

- Examine Fuel Lines: Look for cracks or damage that could lead to leaks.

- Flush the System: Clean the fuel tank and lines to remove contaminants.

- Test the Fuel Pump: Ensure it is operating correctly by checking the pressure output.

By systematically addressing these areas, users can maintain optimal functionality and prevent future complications within the fuel system.

Safety Tips During Repair Work

When engaging in maintenance tasks on power tools, ensuring personal safety should always be the top priority. Familiarity with the equipment and awareness of potential hazards are essential to prevent accidents and injuries.

Wear Appropriate Personal Protective Equipment (PPE): Always don protective gear, including gloves, safety goggles, and ear protection. This minimizes the risk of injury from flying debris or loud noises.

Maintain a Clean Work Area: Keep your workspace tidy to avoid tripping hazards. A clutter-free environment allows for better focus and reduces the chance of accidents.

Use Tools Correctly: Follow the manufacturer’s guidelines for tool usage. Incorrect handling can lead to malfunctions or injury. Always ensure that tools are in good working condition before use.

Be Mindful of Your Surroundings: Make sure your work area is well-lit and free from distractions. This helps maintain concentration and awareness of your environment.

Keep First Aid Supplies Accessible: Always have a first aid kit nearby in case of emergencies. Knowing how to use it can be crucial in the event of an injury.

Take Breaks and Stay Hydrated: Prolonged work can lead to fatigue, increasing the risk of mistakes. Regular breaks and staying hydrated can help maintain focus and energy levels.

When to Seek Professional Help

Understanding when to call in an expert can be crucial for ensuring safety and effectiveness. Some issues may seem manageable, but they can pose significant risks or lead to further complications if not addressed properly. Recognizing these situations can save time, money, and potential injury.

Signs That Indicate the Need for Professional Assistance

- Persistent Malfunctions: If the equipment continues to exhibit issues after your attempts to fix it, professional evaluation is warranted.

- Unusual Sounds or Smells: Any strange noises or odors during operation should be taken seriously, as they may indicate serious problems.

- Safety Concerns: If you feel unsure about the safety of operating the tool, it’s better to consult an expert.

- Complex Repairs: Tasks that involve intricate parts or specialized knowledge are best left to professionals.

Benefits of Professional Intervention

- Expert Diagnosis: Professionals have the experience to accurately identify underlying issues.

- Quality Repairs: They possess the tools and knowledge necessary for effective fixes, ensuring the equipment operates safely.

- Time Savings: Hiring an expert can be more efficient than troubleshooting and attempting repairs yourself.

- Peace of Mind: Knowing the job is done correctly can alleviate stress and concern over potential hazards.