Proper upkeep of outdoor machinery is essential for ensuring optimal performance and longevity. Understanding the intricacies of your equipment can make a significant difference in its efficiency. This section offers insights into troubleshooting common issues and implementing effective solutions to keep your device running smoothly.

In this guide, we will delve into various techniques and best practices that cater to both novice and experienced users. From routine inspections to addressing specific challenges, the information provided aims to enhance your knowledge and skills in handling essential tools for your gardening tasks. Empower yourself with the confidence to tackle any situation that may arise.

Whether you’re looking to enhance the functionality of your gear or simply maintain its condition, our comprehensive overview will serve as a valuable resource. With a focus on practical approaches and user-friendly advice, this guide seeks to demystify the process of maintaining your essential outdoor equipment.

Understanding Common Issues

When operating outdoor equipment, users may encounter various challenges that can hinder performance. Recognizing these frequent problems is essential for maintaining efficiency and ensuring longevity. This section outlines some of the most typical difficulties one might face, along with helpful insights into their resolution.

Engine Performance Troubles

One of the primary concerns involves the engine not starting or running irregularly. This can stem from issues such as insufficient fuel, a clogged filter, or electrical malfunctions. Regular maintenance, including checking the fuel system and inspecting ignition components, can significantly reduce these occurrences.

Cutting Efficiency Problems

Another common issue is related to cutting precision. Equipment may fail to provide an even cut due to dull blades or improper height settings. It’s advisable to routinely sharpen blades and adjust the cutting height as necessary to achieve the desired results. Additionally, checking for obstructions in the cutting area can help maintain optimal performance.

Essential Maintenance Tips

Regular upkeep is crucial for ensuring the longevity and efficiency of your outdoor equipment. By adhering to a few fundamental practices, you can enhance performance and minimize the risk of unexpected failures. This section outlines key strategies to keep your machine in optimal condition.

1. Keep It Clean: Accumulation of debris can impede functionality. After each use, ensure that all surfaces are free from grass clippings and dirt. Utilize a brush or cloth to maintain cleanliness.

2. Check the Blades: Dull cutting edges can lead to poor performance and stress on the engine. Inspect the blades regularly and sharpen or replace them as necessary to ensure a clean cut.

3. Monitor Fluid Levels: Regularly check and replenish oil and fuel levels. Maintaining appropriate fluid levels is vital for smooth operation and to prevent overheating.

4. Inspect Belts and Cables: Worn or frayed belts can cause malfunctions. Examine all belts and cables periodically, replacing any that show signs of wear to ensure reliable operation.

5. Store Properly: After each season, store your equipment in a dry, protected area. This helps prevent rust and damage caused by environmental factors.

By incorporating these essential maintenance practices into your routine, you can significantly extend the lifespan and performance of your equipment.

Replacing the Blades

Swapping out the cutting edges on your equipment is a crucial maintenance task that enhances performance and ensures a neat finish. Dull or damaged edges can lead to uneven trimming and increased strain on the engine. This section outlines the steps and precautions for effectively changing the cutting components.

Before you begin, gather the necessary tools:

- Wrench or socket set

- Safety gloves

- New cutting edges

- Greaseless cloth or brush

Follow these steps to complete the replacement:

- Ensure the machine is turned off and cool to the touch.

- Disconnect the power source to prevent accidental activation.

- Lift the cutting deck for easier access to the edges.

- Remove the fasteners holding the current edges in place using the wrench.

- Carefully detach the old edges and inspect the mounting area for debris.

- Position the new edges, aligning them with the mounting holes.

- Secure the new edges using the fasteners, ensuring they are tightened properly.

- Lower the cutting deck and reconnect the power source.

After replacing the components, perform a test run to ensure everything is functioning correctly. Regular maintenance will prolong the lifespan of your equipment and keep it operating efficiently.

Engine Troubleshooting Guide

This section offers essential insights for diagnosing common issues encountered in small engine operation. Identifying symptoms accurately is crucial for effective resolution and optimal performance.

Begin by checking the fuel supply. Ensure that the tank is filled with fresh, clean fuel, as stale or contaminated gasoline can lead to starting difficulties. Inspect the fuel lines for any signs of leaks or blockages.

If the engine fails to start, examine the spark plug. A worn or fouled plug may prevent ignition. Replacing it can often resolve starting issues. Additionally, ensure that the ignition system is functioning correctly, as electrical problems can inhibit engine operation.

Listen for unusual sounds while the engine is running. Knocking or excessive vibration may indicate internal problems that require further investigation. Regular maintenance checks can help prevent these issues from escalating.

Finally, refer to the specific operational manual for more detailed troubleshooting steps tailored to the engine model. This ensures that the approach is comprehensive and addresses unique concerns effectively.

Adjusting Cutting Height

Achieving the desired length for your grass is essential for maintaining a healthy and aesthetically pleasing yard. Proper height adjustment can enhance the overall appearance of your greenery while promoting robust growth. This section will guide you through the process of modifying the cutting height effectively.

Understanding Height Settings

Before making adjustments, familiarize yourself with the various height settings available on your equipment. Different grass types require specific cutting heights for optimal health. Here are some common height categories:

- Low: 1 to 2 inches

- Medium: 2 to 3 inches

- High: 3 to 4 inches

Adjustment Procedure

Follow these steps to modify the cutting height:

- Ensure the equipment is turned off and positioned on a flat surface.

- Locate the height adjustment lever or knob.

- Choose the desired height setting based on the type of grass.

- Lock the lever or knob into place to secure the setting.

- Perform a test run to confirm the height adjustment is suitable.

Regularly check and adjust the cutting height to accommodate seasonal growth changes and maintain the health of your turf.

Fuel System Maintenance

Proper upkeep of the fuel mechanism is essential for ensuring optimal performance and longevity of your equipment. A well-maintained fuel system helps prevent operational issues and promotes efficiency. Regular attention to this area will not only enhance reliability but also improve overall functionality.

Here are key aspects to consider for effective maintenance:

- Regular Inspection: Frequently check for leaks, cracks, or signs of wear in fuel lines and connections.

- Clean Fuel Filter: Ensure the fuel filter is clean and free from debris. Replace it according to the manufacturer’s recommendations.

- Inspect the Fuel Tank: Look for any contamination or sediment buildup in the tank. Empty and clean if necessary.

- Fuel Quality: Use fresh fuel to prevent gum and varnish buildup. Avoid using old or contaminated fuel.

- Check for Air Leaks: Ensure all seals and connections are airtight to prevent air from entering the fuel system.

By adhering to these guidelines, you can maintain a reliable fuel system that supports the efficient operation of your equipment.

Cleaning the Air Filter

Maintaining optimal performance in your equipment requires regular upkeep of crucial components, such as the air filtration system. A clean filter ensures that the engine receives adequate airflow, which is vital for efficient operation and longevity.

To effectively clean the air filter, follow these steps:

- Turn off the engine and allow it to cool.

- Locate the air filter housing, typically secured by clips or screws.

- Remove the filter from its housing, taking care not to damage any surrounding components.

Once the filter is removed, proceed with the cleaning:

- If it is a foam filter, wash it in warm, soapy water and rinse thoroughly.

- For paper filters, gently tap it to remove loose dirt and debris; avoid using water.

- Allow the filter to dry completely before reinstalling.

After cleaning, reinsert the filter into its housing, ensuring it fits snugly. Secure the housing with clips or screws. Regularly checking and cleaning the air filter can significantly enhance the performance and efficiency of your machinery.

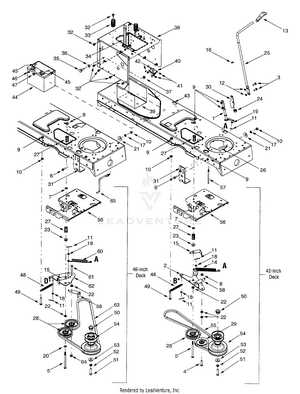

Wiring Diagrams Explained

Understanding electrical schematics is essential for anyone looking to troubleshoot or modify machinery. These visual representations provide clear insights into how various components are interconnected, allowing users to follow the flow of electricity throughout the system. By decoding these diagrams, one can effectively identify potential issues and ensure proper functionality.

Each diagram typically consists of symbols representing different elements such as power sources, switches, and loads. Lines indicate connections, guiding the user through the circuitry. Familiarity with these symbols is crucial, as it empowers individuals to interpret the diagrams accurately and apply the necessary adjustments or repairs.

Additionally, wiring schematics may vary between different models or brands, making it vital to consult the correct version for your specific unit. This ensures that any modifications or troubleshooting efforts are based on the accurate information, ultimately leading to successful maintenance and performance improvements.

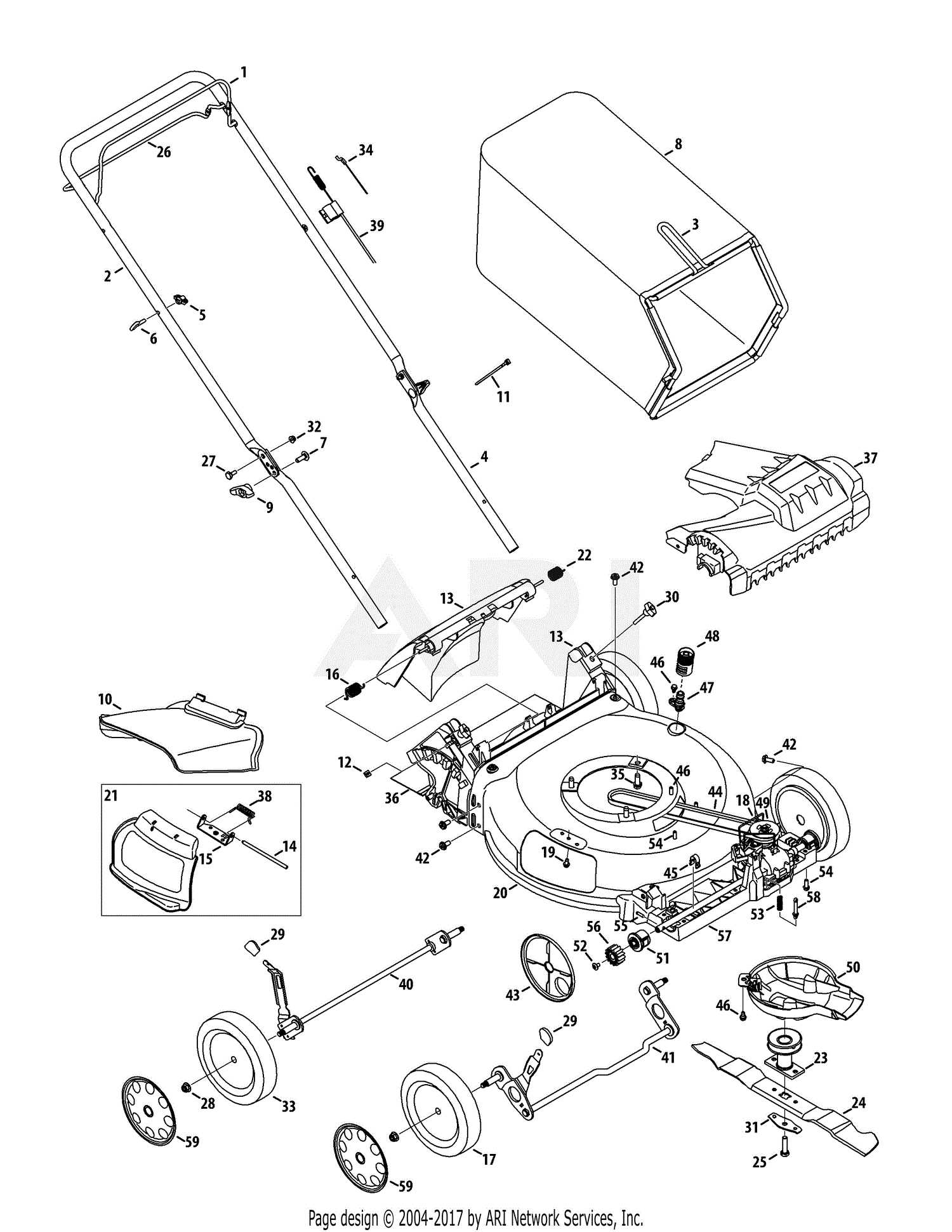

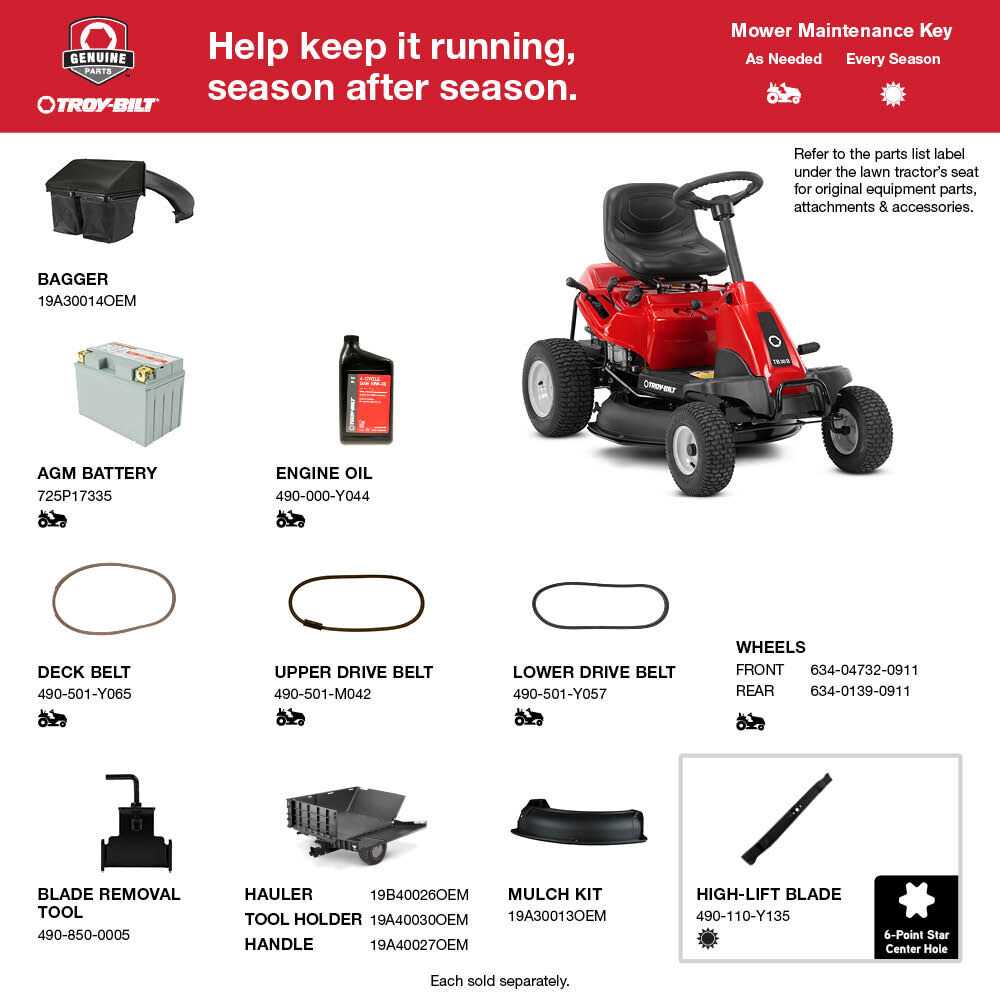

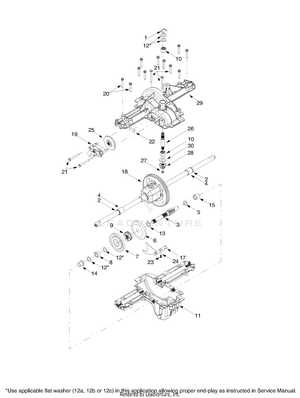

Identifying Spare Parts

Understanding the components of your equipment is essential for effective maintenance and ensuring longevity. Accurately identifying the necessary elements can simplify the process of obtaining replacements and enhance the overall performance of your device.

Common Components

Familiarize yourself with the typical parts that may require replacement over time. These can include the engine, belts, blades, and wheels. Knowing these elements will aid in quick identification when troubleshooting issues or conducting routine checks.

Utilizing Resources

Consulting diagrams, online databases, or manufacturer specifications can significantly assist in recognizing the correct components. Utilizing these resources ensures that you select the appropriate replacements tailored to your specific model.

Tip: Always keep a list of part numbers for easy reference when sourcing replacements.

Safety Precautions During Repair

When engaging in maintenance tasks for machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to recommended practices not only protects the individual working on the equipment but also ensures the longevity of the device itself. Proper preparation and mindfulness can significantly reduce risks associated with mechanical work.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes items such as gloves, goggles, and sturdy footwear. Gloves shield hands from sharp edges and chemicals, while goggles protect eyes from flying debris. Additionally, durable shoes provide support and guard against heavy objects that may fall.

Workspace Organization

Maintaining a tidy workspace is vital for safety. A clutter-free area minimizes the chance of accidents. Ensure that all tools are stored properly when not in use, and that the floor is free from obstacles. Good organization not only enhances efficiency but also creates a safer environment for working on mechanical devices.