In the world of automotive care, understanding the intricacies of a vehicle’s performance components is essential for any enthusiast or technician. This section delves into the nuances of a specific power unit, emphasizing the importance of regular upkeep and troubleshooting techniques. By gaining insights into this crucial aspect, one can ensure optimal functionality and longevity of their vehicle.

Effective maintenance not only enhances performance but also prevents potential issues that may arise over time. With the right knowledge, car owners can take proactive measures to address concerns before they escalate, ensuring a smooth driving experience. The following content will provide detailed instructions and guidelines aimed at facilitating a deeper understanding of these vital systems.

Equipped with the right tools and knowledge, anyone can tackle various challenges associated with their vehicle’s performance unit. Whether you are a seasoned mechanic or a passionate hobbyist, this guide will empower you to navigate through the complexities of maintenance, enabling you to achieve remarkable results and keep your automobile running smoothly.

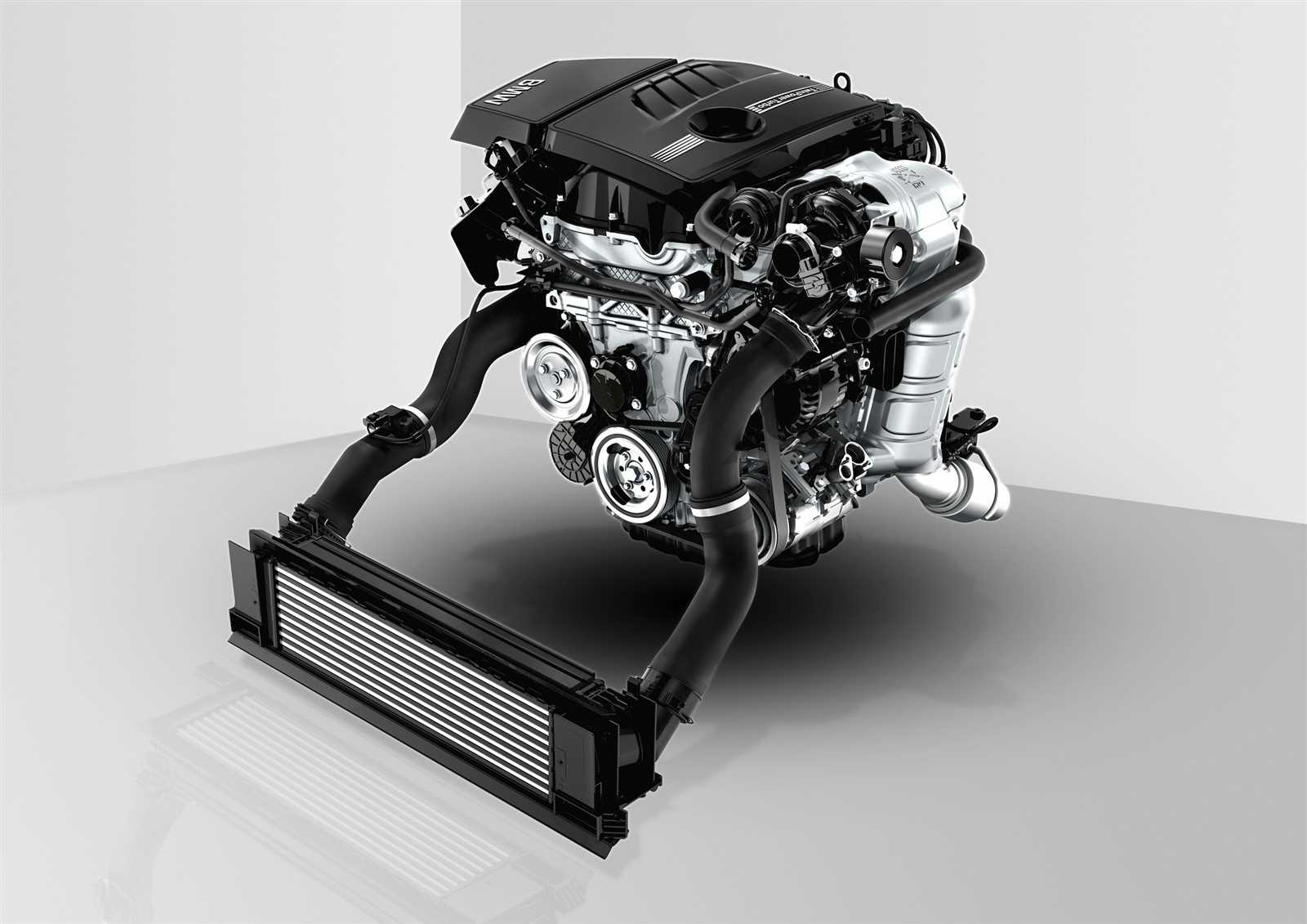

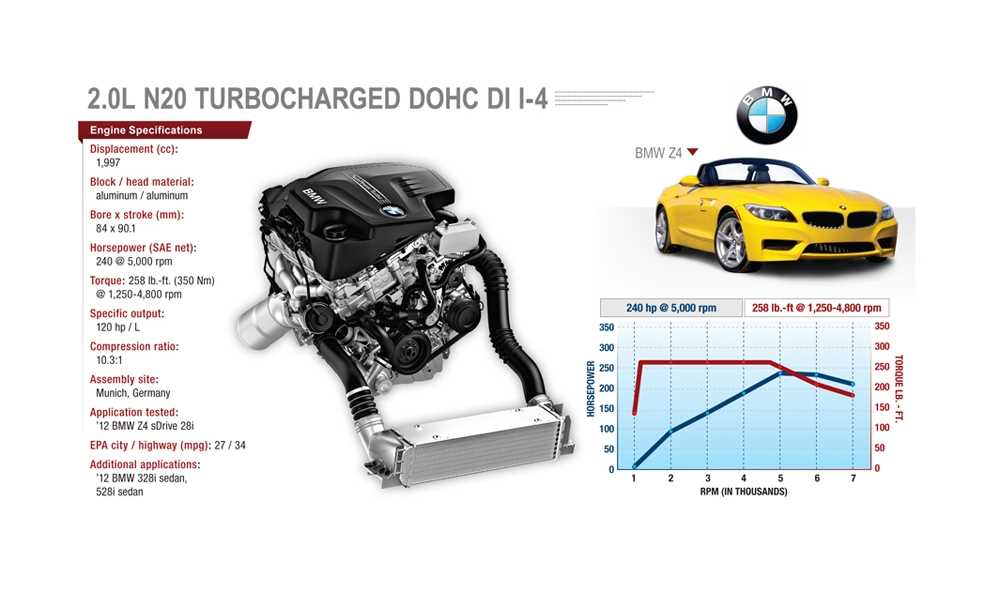

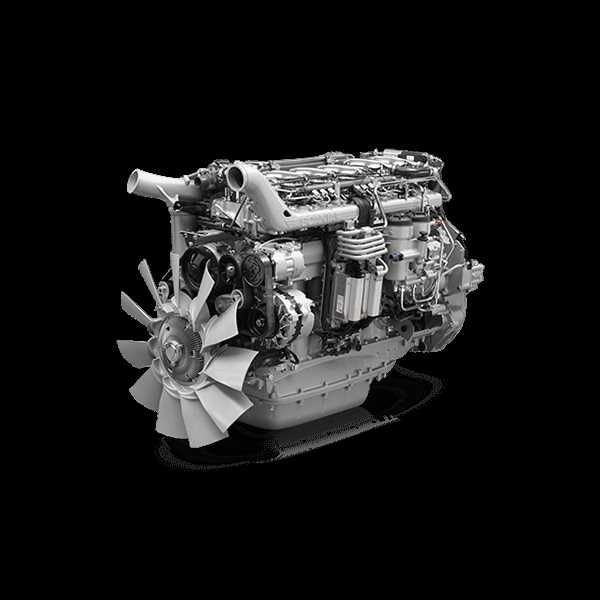

BMW N20 Engine Overview

This section provides an insightful look into a specific powertrain that has garnered attention for its performance and efficiency. Renowned for its innovative design, this unit offers a blend of technology and engineering that appeals to enthusiasts and everyday drivers alike.

Key Features and Specifications

The unit is characterized by its compact size, allowing for versatile applications across various models. Notably, it employs a turbocharging system that enhances power output while maintaining fuel economy. With a displacement of around 2.0 liters, it balances responsiveness with smooth operation.

Performance and Efficiency

Engineered for both agility and reliability, this power source delivers impressive torque at low RPMs, ensuring a dynamic driving experience. Additionally, its advanced thermal management system contributes to reduced emissions, aligning with modern environmental standards. Overall, this assembly represents a significant advancement in automotive technology.

Common Issues and Symptoms

This section addresses typical problems encountered with a specific type of automotive power unit. Understanding these challenges is essential for effective troubleshooting and maintenance, ensuring optimal performance and longevity of the vehicle.

Engine Performance Decline

A noticeable decrease in power output can indicate underlying issues. Drivers may experience sluggish acceleration, reduced responsiveness, or overall lack of vigor during operation. These symptoms can stem from various factors, including faulty components or inefficient fuel delivery.

Unusual Noises and Vibrations

Abnormal sounds, such as knocking, rattling, or excessive vibration, may signal mechanical problems. These disturbances often suggest that critical parts may be wearing out or failing. Timely identification of these symptoms can prevent more severe damage and costly repairs down the line.

Required Tools for Repair

When undertaking the task of restoring a performance unit, having the right equipment is crucial. The tools not only facilitate the process but also ensure that the work is done efficiently and accurately. Below is a list of essential items that will be beneficial during the maintenance procedure.

Essential Hand Tools

- Socket set with various sizes

- Wrenches (open-end and box-end)

- Screwdrivers (flathead and Phillips)

- Torque wrench for precise fastening

- Pliers (needle-nose and regular)

Diagnostic Equipment

- OBD-II scanner for troubleshooting

- Multimeter for electrical testing

- Compression tester for assessing performance

- Oil pressure gauge for system checks

Equipping yourself with these tools will significantly enhance your ability to perform tasks effectively and ensure the longevity of the components involved.

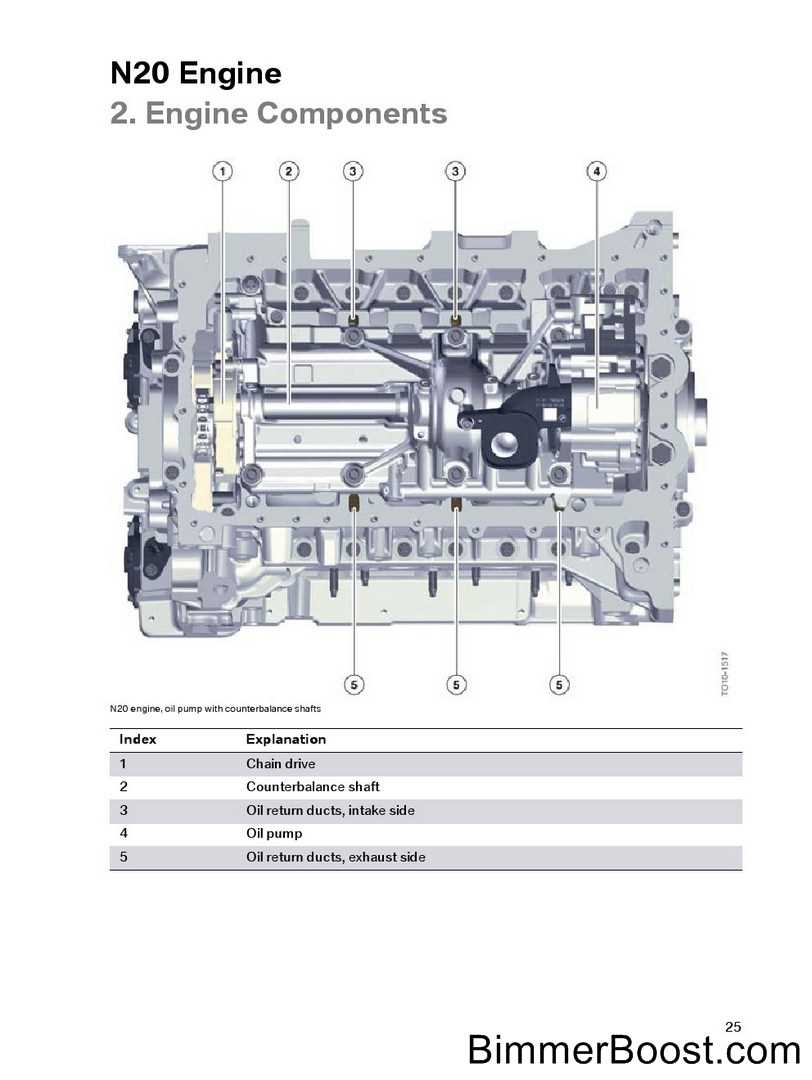

Engine Disassembly Instructions

Disassembling a power unit requires careful attention to detail and a systematic approach to ensure each component is handled properly. This section outlines the essential steps to effectively separate various parts, ensuring they can be serviced or replaced as needed.

Begin by gathering all necessary tools, such as wrenches, screwdrivers, and pliers, to facilitate the process. Before starting the disassembly, make sure the workspace is organized and free from distractions. Disconnect any electrical connections and remove fluids to prevent spills during the procedure.

Next, follow a logical sequence for removing components. Start with the outer elements, like covers and hoses, before moving to the inner assemblies. Take note of the order in which parts are removed, and consider labeling them to simplify reassembly. It is crucial to handle each part with care, especially those that are sensitive or easily damaged.

Once the exterior components are detached, focus on the internal sections. Utilize appropriate techniques for loosening bolts and screws, ensuring not to strip them. Be mindful of the torque specifications when reassembling, as this can significantly affect performance and longevity.

After all components are disassembled, conduct a thorough inspection of each part. Look for signs of wear, damage, or contamination that may require attention. Document any findings to guide the next steps in servicing or replacing parts.

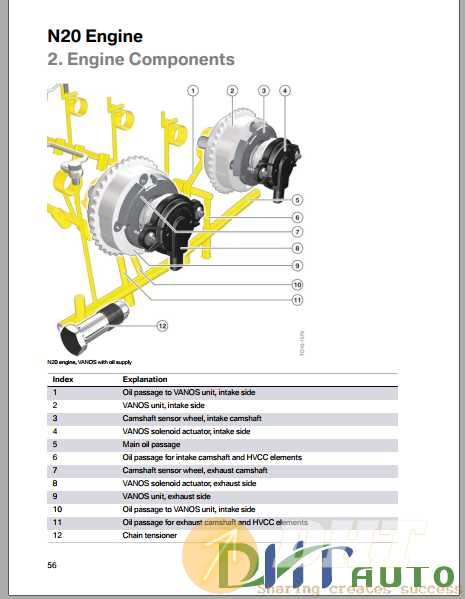

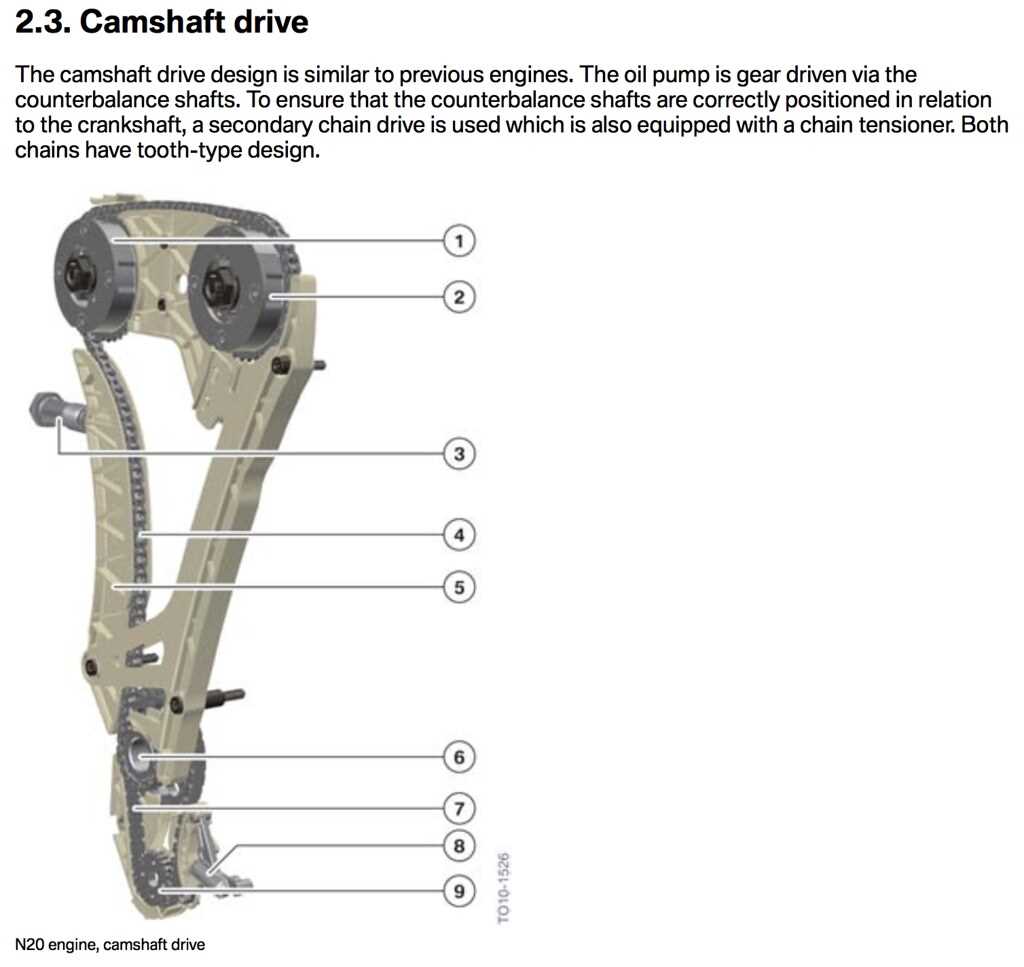

Replacing Timing Chain Components

Maintaining the timing chain system is crucial for ensuring optimal performance and longevity of the vehicle’s power unit. This section outlines the essential steps for replacing the various elements associated with the timing chain, which can significantly impact overall functionality.

Begin by ensuring the work area is clean and organized. Gather all necessary tools and replacement parts. It is vital to disconnect the battery to prevent any electrical issues during the process. Next, remove any components obstructing access to the timing chain area, such as covers and related fixtures.

Once access is gained, carefully inspect the chain, sprockets, and guides for wear or damage. If any components show signs of degradation, they should be replaced. Align the new components properly according to the manufacturer’s specifications, ensuring the timing marks are correctly positioned.

After installation, reassemble any removed parts in reverse order, double-checking that everything is securely fastened. Finally, reconnect the battery and start the unit to verify that the new components function smoothly and without noise.

Fuel System Diagnostics and Repair

This section focuses on evaluating and addressing issues within the fuel delivery mechanism. Proper functioning of this system is crucial for optimal performance and efficiency. Identifying and correcting any irregularities can enhance overall operation and longevity.

Common Symptoms of Fuel System Issues

- Engine misfires or hesitation during acceleration

- Poor fuel efficiency

- Difficulty starting the vehicle

- Unusual engine noises

- Excessive emissions

Diagnostic Procedures

- Visual Inspection: Check for leaks, damaged hoses, and loose connections.

- Fuel Pressure Test: Measure the pressure to ensure it meets manufacturer specifications.

- Injector Functionality: Test each fuel injector for proper operation and spray pattern.

- Fuel Filter Assessment: Inspect and replace the fuel filter if clogged or contaminated.

- Electronic Control Module: Use diagnostic tools to check for fault codes related to the fuel system.

Addressing issues in the fuel system requires systematic analysis and methodical troubleshooting. Following the outlined procedures will help pinpoint and resolve problems effectively.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for ensuring optimal performance and longevity of your vehicle’s components. Regular attention to this area can prevent overheating and related issues, ultimately enhancing the driving experience.

Start by checking the coolant level frequently. Maintaining the right amount is crucial, as it helps regulate temperature effectively. If the level is low, top it up with the recommended fluid type to prevent potential overheating.

Inspect hoses and connections for any signs of wear or leaks. Cracks or bulges can lead to coolant loss, which may compromise the system’s efficiency. Replace any damaged parts promptly to avoid further complications.

Flush the cooling system periodically to remove any debris or contaminants. This process helps maintain the effectiveness of the coolant and prevents blockages that could disrupt the flow of fluid.

Pay attention to the thermostat’s functionality. A malfunctioning thermostat can cause temperature fluctuations, leading to potential overheating or inefficient cooling. Regular testing or replacement as needed can ensure it operates correctly.

Lastly, ensure that the radiator is clean and free from obstructions. A dirty or blocked radiator cannot dissipate heat effectively, leading to increased engine temperatures. Cleaning the exterior and ensuring proper airflow is vital for optimal performance.

Electrical System Troubleshooting

Troubleshooting the electrical system is essential for ensuring the optimal performance of your vehicle. Electrical issues can manifest in various ways, affecting everything from starting capabilities to accessory operation. A systematic approach to identifying and resolving these problems can significantly enhance reliability and efficiency.

Here are some common steps to follow when diagnosing electrical faults:

- Check Battery Condition:

- Inspect for corrosion on terminals.

- Measure voltage using a multimeter.

- Ensure tight connections.

lessCopy code

- Locate the fuse box and identify the blown fuses.

- Replace with fuses of the same amperage.

- Verify that the replacement fuses are functioning properly.

- Look for frayed or damaged wires.

- Check for loose or disconnected connectors.

- Use electrical contact cleaner on corroded connections.

- Ensure all ground points are clean and secure.

- Use a multimeter to check continuity.

- Address any loose or corroded ground wires.

- Test relays for proper operation.

- Inspect switches and sensors for functionality.

- Replace any faulty components as needed.

Following these troubleshooting steps can help pinpoint electrical issues and restore functionality to your vehicle’s systems. Always consult detailed guidelines specific to your model for the best results.

Reassembly Steps Explained

The process of putting components back together is crucial for ensuring optimal performance and longevity. This section outlines the essential stages that should be followed to achieve a successful reassembly.

1. Preparation: Before starting, ensure that all parts are clean and free from debris. Having a well-organized workspace will make the task smoother. Gather all necessary tools and components for easy access during the reassembly.

2. Aligning Components: Begin by carefully aligning the various parts. Pay close attention to any specific markings or notches that indicate the correct positioning. Proper alignment is vital to avoid complications later on.

3. Securing Fasteners: As you reassemble, gradually secure fasteners in place. Use the appropriate torque specifications to ensure that each connection is tight but not over-tightened, as this could lead to damage.

4. Reconnecting Systems: Once the main components are in place, reconnect any necessary systems such as electrical or fluid lines. Double-check connections to prevent leaks or electrical failures.

5. Final Inspection: After reassembly, conduct a thorough inspection to confirm that everything is correctly positioned and secured. Look for any signs of wear or potential issues that could arise from improper assembly.

By following these steps, you can ensure a reliable and effective reassembly process, ultimately enhancing the performance and durability of the entire unit.

Testing Engine Performance

This section focuses on assessing the functionality and efficiency of the power unit in vehicles. Understanding how to properly evaluate its performance can help identify issues that may affect overall operation.

To initiate testing, it is essential to gather necessary tools such as a diagnostic scanner, pressure gauges, and tachometers. These instruments will facilitate a thorough analysis of various parameters, including power output, fuel consumption, and operational stability.

Begin the evaluation by connecting the diagnostic scanner to the vehicle’s onboard computer. This allows for the retrieval of error codes and data that can indicate underlying problems. Pay close attention to any anomalies that may suggest malfunctions.

Next, perform a pressure test to check for any leaks in the intake or exhaust systems. Strong pressure readings indicate a healthy system, while low readings could signal issues that need addressing.

Lastly, monitor the unit’s performance during a controlled drive. Observe acceleration, responsiveness, and any unusual noises. Taking notes during this process is crucial for comparing results with standard benchmarks.

In conclusion, regular performance evaluations are vital for maintaining optimal functionality and longevity of the power unit. By following these steps, vehicle owners can ensure their systems are operating efficiently and address any concerns proactively.

Preventative Maintenance Practices

Regular upkeep is essential for ensuring the longevity and reliability of any complex machinery. Implementing consistent maintenance routines can significantly reduce the likelihood of unexpected failures and costly repairs. By focusing on proactive strategies, owners can enhance performance and extend the lifespan of their vehicles.

One fundamental aspect of preventative care involves routine inspections. Checking fluid levels, belts, and hoses regularly allows for early detection of potential issues. Additionally, replacing filters at scheduled intervals ensures optimal operation and efficiency.

Another critical practice is adhering to recommended service intervals as outlined by manufacturers. This includes scheduled oil changes and system flushes, which play a vital role in maintaining optimal function. Keeping a detailed maintenance log can aid in tracking service history and planning future upkeep.

Moreover, the importance of proper storage and environmental considerations cannot be overstated. Keeping the vehicle in a sheltered area protects it from harsh weather conditions, which can lead to premature wear. Regular cleaning and waxing also help to preserve the exterior and prevent rusting.

Lastly, engaging a qualified technician for specialized services and diagnostics ensures that any underlying issues are addressed promptly. Investing in preventative measures today can yield substantial savings and peace of mind in the long run.

FAQs About N20 Repairs

This section addresses common inquiries regarding maintenance and troubleshooting of a specific power unit. Understanding the nuances of servicing can help vehicle owners make informed decisions and enhance the longevity of their machinery.

What are the common issues faced with this type of power unit?

Frequent challenges include oil leaks, overheating, and performance drops. Identifying symptoms early can prevent more extensive damage.

How often should routine maintenance be performed?

It is advisable to conduct maintenance checks every 5,000 to 7,500 miles, including oil changes and inspections of various components to ensure optimal functionality.

Can I perform maintenance tasks myself?

Many basic tasks, such as oil changes and air filter replacements, can be done by enthusiasts with the right tools and knowledge. However, more complex issues should be handled by professionals.

What tools are essential for working on this type of power unit?

Essential tools include socket sets, wrenches, and diagnostic equipment. Having the right tools on hand makes the process more efficient and effective.

Is it worth investing in specialized parts for repairs?

Using high-quality or OEM components often leads to better performance and durability, ultimately saving costs on future repairs.

Resources for Further Learning

To deepen your understanding and enhance your skills in vehicle maintenance, exploring a variety of educational materials is essential. This section provides valuable resources that can aid in expanding your knowledge and capabilities in automotive care.

Books and Guides

Comprehensive literature on automotive technology can serve as an excellent foundation. Seek out detailed texts that cover topics such as mechanical systems, diagnostics, and troubleshooting techniques. Look for titles that include illustrations and step-by-step procedures to facilitate learning.

Online Courses and Tutorials

Digital platforms offer a wealth of courses designed to teach essential skills in automotive service. Websites featuring instructional videos and interactive lessons can provide hands-on experience and practical insights. Participating in forums and communities can also enhance your learning by connecting you with experienced professionals and fellow enthusiasts.