In the world of outdoor equipment, ensuring the longevity and efficiency of your devices is crucial. Regular maintenance not only enhances performance but also prevents unexpected breakdowns, allowing you to tackle tasks with confidence. Understanding the inner workings and common issues associated with these powerful tools is essential for any user aiming for reliability.

When it comes to troubleshooting and upkeep, a comprehensive resource can be invaluable. Whether you’re facing minor glitches or more significant challenges, knowing how to address them effectively can save both time and money. This guide provides detailed insights into the steps needed to keep your machinery in optimal condition, empowering you to handle repairs with ease.

From basic adjustments to more intricate fixes, mastering the nuances of your equipment can transform your experience. With the right knowledge, you can swiftly diagnose problems, perform necessary tweaks, and ensure your tool remains a steadfast companion in your outdoor endeavors. Explore the essential techniques and tips that will equip you for success in maintaining your trusted machinery.

Overview of Husqvarna 51 Chainsaw

This section provides a comprehensive look at a popular model known for its reliability and efficiency in cutting tasks. With its robust design and user-friendly features, this tool has gained a strong following among enthusiasts and professionals alike.

Key features include:

- Powerful engine for optimal performance

- Lightweight body for ease of handling

- Ergonomic design that enhances user comfort

- Durable components that withstand heavy use

This model is particularly suited for:

- Residential property maintenance

- Light to medium-duty logging

- Landscaping and yard work

Users appreciate its combination of power and portability, making it a preferred choice for various cutting needs. Understanding its features and capabilities can help in maximizing its potential for any task at hand.

Common Issues and Troubleshooting Tips

When working with outdoor power equipment, encountering problems can be frustrating. However, understanding typical challenges and their solutions can help restore functionality quickly. This section outlines some prevalent issues and offers practical advice for resolution.

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear or damage.

- Examine the air filter for clogs.

- Poor Performance:

- Ensure the cutting tool is sharp and properly installed.

- Inspect fuel and oil mixture ratios.

- Check for air leaks around the intake system.

- Excessive Vibration:

- Verify that all components are securely fastened.

- Examine the blade for damage or imbalance.

- Check the condition of the anti-vibration mounts.

- Overheating:

- Ensure proper lubrication is being used.

- Check for blockages in the cooling system.

- Make sure the equipment is not being overloaded.

Addressing these common problems with the suggested solutions can enhance the longevity and efficiency of your equipment. Always refer to specific guidelines for detailed procedures and safety measures.

Essential Tools for Chainsaw Repairs

Maintaining and fixing your equipment requires a specific set of instruments that ensure efficient and safe operation. Having the right tools not only facilitates the process but also enhances the longevity and performance of your device. Understanding which tools are necessary can make a significant difference in tackling any issues that arise.

Basic Hand Tools

At the core of any maintenance job are basic hand tools. A reliable screwdriver set is essential for adjusting and securing various components. Additionally, wrenches are crucial for tightening bolts and nuts, ensuring all parts are securely fastened. Don’t forget a good pair of pliers, which can assist in gripping and manipulating small pieces effectively.

Specialized Equipment

In addition to standard tools, having specialized equipment can greatly enhance your ability to perform more complex tasks. A file is vital for sharpening cutting edges, while a spark plug wrench is necessary for maintenance of the ignition system. Lastly, an oil can is essential for lubrication, helping to keep all moving parts functioning smoothly.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with your outdoor cutting tool. By following these systematic instructions, you can troubleshoot and fix problems efficiently, ensuring optimal performance and longevity of your equipment.

Identifying the Problem

The first step in the process is to accurately diagnose the issue at hand. Observe the equipment during operation to note any unusual sounds, vibrations, or performance drops. Common problems may include difficulty starting, poor cutting efficiency, or fuel leakage. Document your findings to guide the next steps.

Disassembly and Inspection

Once the issue is identified, carefully disassemble the relevant components. Use appropriate tools to avoid damage. Inspect each part for wear and tear, ensuring to check filters, spark plugs, and fuel lines. Clean any debris or buildup, as this can significantly affect functionality. Replace any damaged components to restore proper operation.

Maintenance Practices for Longevity

Ensuring the durability and efficient performance of your outdoor power equipment requires regular upkeep and attention to detail. By following a consistent maintenance routine, you can enhance the lifespan of your tool and prevent unexpected failures. This section outlines essential practices that will help keep your device in optimal condition.

Regular Cleaning: After each use, it is crucial to clean the exterior and components of the machine. Debris, sap, and dirt can accumulate, affecting performance and leading to potential issues. Use a soft brush and appropriate cleaning solutions to remove contaminants without damaging any parts.

Blade Sharpening: Keeping the cutting edge sharp is vital for efficiency and safety. Regularly inspect and sharpen the blade to ensure smooth operation. A dull blade not only increases wear on the motor but can also lead to accidents due to reduced control.

Lubrication: Proper lubrication of moving parts is essential for reducing friction and wear. Check the manufacturer’s recommendations for the right type of lubricant and frequency of application. Consistent oiling can prevent parts from seizing and extend their lifespan.

Fuel Maintenance: Using fresh fuel and the correct fuel-to-oil ratio is critical for engine health. Stale fuel can lead to performance issues and damage internal components. Always store fuel properly and consider using fuel stabilizers for longer storage periods.

Storage Practices: When not in use, store your equipment in a dry, protected area. Avoid exposing it to extreme temperatures and humidity, which can cause corrosion and degradation of materials. Additionally, consider performing a seasonal check-up to ensure everything is functioning correctly before use.

By implementing these practices, you can significantly enhance the reliability and longevity of your outdoor equipment. A proactive approach to maintenance not only saves time and money but also ensures a safer and more enjoyable experience.

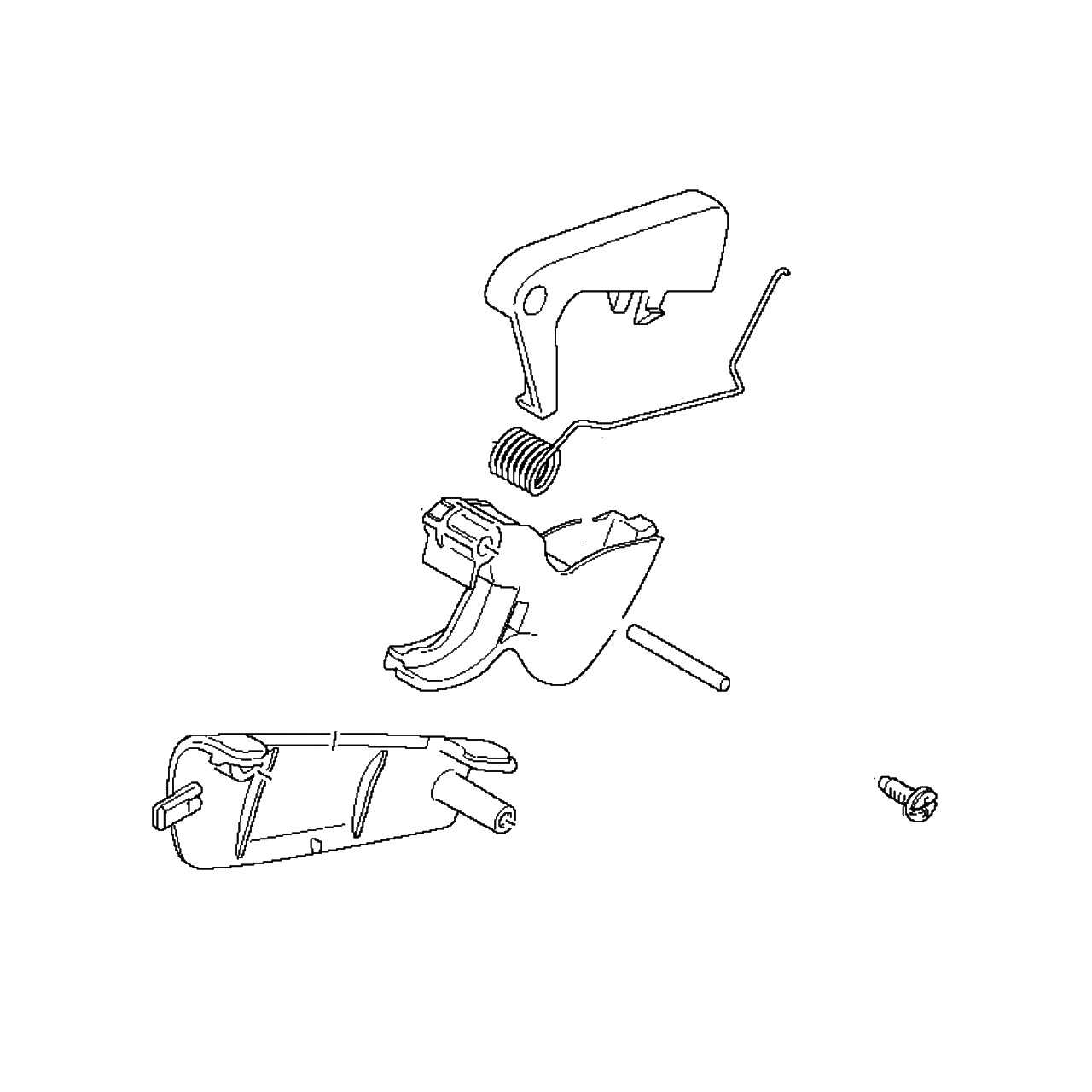

Understanding Chainsaw Components

Exploring the various elements that contribute to the functionality of power saws is essential for anyone seeking to enhance their knowledge or perform maintenance. Each part plays a significant role in ensuring optimal performance and safety during operation.

- Power Unit: The heart of the device, typically comprising a combustion engine or an electric motor, responsible for generating the necessary power.

- Guide Bar: A metal bar that supports and guides the cutting chain, dictating the width of the cut.

- Cutting Chain: A loop of metal links that features sharp teeth designed for slicing through wood, pivotal for the cutting process.

- Chain Tensioner: A mechanism that allows for the adjustment of the chain’s tightness, ensuring efficient operation and preventing accidents.

- Handle and Controls: The user interface, including grips and switches, that provides control over the tool’s functions, contributing to safety and maneuverability.

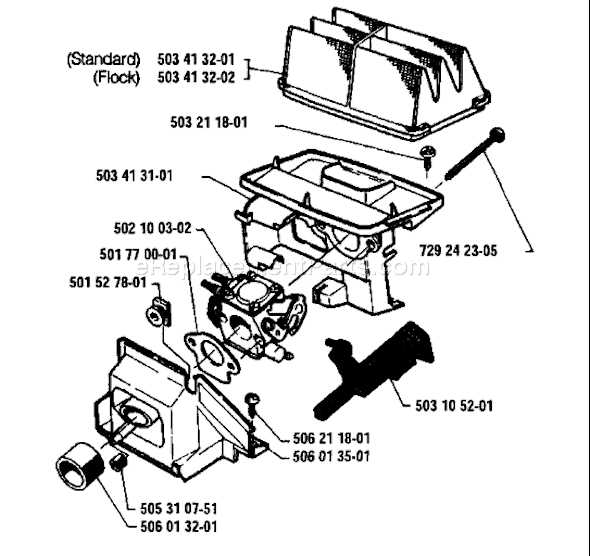

- Fuel System: This includes the fuel tank and lines, delivering energy to the engine and playing a crucial role in performance.

- Lubrication System: Essential for reducing friction between moving parts, thus prolonging the lifespan of the equipment.

Understanding these components not only aids in better operation but also enhances the ability to troubleshoot and maintain the tool effectively.

Safety Precautions During Repairs

When working on any mechanical device, prioritizing safety is crucial. Proper precautions can prevent accidents and ensure a smooth process. Being aware of your surroundings and following essential guidelines will help mitigate risks associated with maintenance tasks.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This gear will shield you from potential hazards, including sharp objects and flying debris. Additionally, keeping long hair tied back and avoiding loose clothing can prevent entanglement in moving parts.

Before beginning any work, ensure that the equipment is powered down and disconnected from any energy sources. This step is vital to avoid unintended starts that could lead to serious injuries. Additionally, keep your workspace organized to minimize the chances of accidents caused by clutter.

Familiarize yourself with the specific components you are dealing with. Understanding their function and potential hazards will enhance your ability to work safely. Always consult documentation or reliable sources for guidance on best practices and safety measures.

Finally, never hesitate to seek assistance if you are unsure about any aspect of the task. Having a knowledgeable partner can enhance safety and efficiency, ensuring that maintenance is conducted properly and without incident.

How to Replace the Chain

Replacing the cutting component is a crucial maintenance task that ensures optimal performance and safety. This process can seem daunting, but with the right guidance and tools, it can be accomplished efficiently. A well-maintained cutting element not only enhances functionality but also prolongs the life of the equipment.

Gather Necessary Tools

Before starting the replacement, it’s important to gather all the required tools. Typically, you will need a screwdriver, a wrench, and a new cutting element. Ensure that the replacement part is compatible with your specific model to avoid any complications during installation.

Steps for Replacement

Begin by ensuring the equipment is turned off and disconnected from any power source. Loosen the tensioning mechanism to relieve pressure on the existing component. Carefully remove the old cutting element along with the guide bar. Once removed, inspect the guide bar for wear and replace it if necessary. Position the new cutting element onto the guide bar, ensuring it is oriented correctly. Finally, tighten the tensioning mechanism to secure the new component in place and check for proper tension before use.

Engine Troubleshooting Techniques

Understanding and diagnosing issues within the power unit of outdoor equipment is essential for maintaining optimal performance. Identifying the root cause of malfunctions can often be the key to effective solutions. This section outlines various methods to systematically address engine problems, ensuring reliable operation and longevity.

Begin with visual inspections to identify any obvious signs of damage or wear. Look for leaks, cracks, or loose components that may indicate a larger issue. Additionally, pay attention to unusual sounds or vibrations during operation, as these can provide critical clues to underlying problems.

Next, consider conducting performance tests. Measure fuel flow and check the quality of the ignition system. A weak spark or inconsistent fuel delivery can lead to poor engine function. Utilizing a multimeter to evaluate electrical components can help isolate electrical faults that affect performance.

Lastly, consult the manufacturer’s specifications to verify that all components are functioning within acceptable parameters. Regular maintenance, including cleaning air filters and inspecting spark plugs, can prevent many common issues from arising. By systematically approaching engine troubleshooting, you can enhance reliability and extend the lifespan of your equipment.

Fuel System Cleaning Instructions

Maintaining the integrity of the fuel delivery system is essential for optimal performance and longevity of your outdoor equipment. Regular cleaning helps prevent clogs and ensures that fuel flows smoothly to the engine. This section outlines the steps necessary to effectively clean the components of the fuel system.

Required Tools and Materials

Before you begin, gather the following items:

- Cleaning solvent – a suitable option for fuel system components

- Soft brushes – for gentle scrubbing

- Compressed air – to blow out any debris

- Protective gloves – to safeguard your hands

- Container – to catch any residual fuel

Step-by-Step Cleaning Process

Follow these steps to clean the fuel system:

- Disconnect the fuel lines from the tank and carburetor. Ensure that the equipment is cool and that you are working in a well-ventilated area.

- Empty the fuel tank completely, disposing of any old fuel responsibly.

- Clean the fuel filter by soaking it in cleaning solvent and gently brushing it to remove debris. Rinse thoroughly with clean solvent.

- Inspect the fuel lines for any signs of wear or blockage. Use compressed air to clear out any obstructions.

- Clean the carburetor by removing it from the engine. Disassemble it carefully, and soak the components in cleaning solvent before brushing them clean. Use compressed air to ensure all passages are clear.

- Reassemble the components and reconnect the fuel lines, ensuring a secure fit.

After completing these steps, refill the system with fresh fuel. Regular cleaning and maintenance will significantly enhance performance and reliability.

Bar and Chain Lubrication Tips

Proper lubrication is essential for the efficient operation of cutting equipment. Maintaining adequate oil levels ensures that components function smoothly, reducing friction and wear. Regular attention to lubrication not only prolongs the lifespan of the tool but also enhances cutting performance.

Choosing the Right Lubricant

Selecting the appropriate oil is crucial. Here are some tips:

- Opt for high-quality, bar and chain oil specifically formulated for cutting tools.

- Avoid using vegetable oils as they can gum up and cause damage.

- Consider temperature conditions; some oils perform better in extreme heat or cold.

Lubrication Techniques

Implementing effective lubrication techniques will optimize performance:

- Check oil levels before each use to ensure adequate supply.

- Clean the bar and chain regularly to prevent debris buildup.

- Apply oil manually if automatic systems are not functioning properly.

- Monitor the cutting speed; if it slows down, re-evaluate lubrication levels.

Signs of Wear and Tear

Recognizing indicators of deterioration is essential for maintaining optimal performance in any tool. Over time, components may exhibit signs of aging, which can affect functionality and safety. Understanding these signs can help prevent further damage and ensure reliable operation.

Common Indicators

- Reduced Power: Noticeable decrease in performance during operation.

- Unusual Noises: Grinding, rattling, or other abnormal sounds can signal internal issues.

- Vibrations: Increased vibration levels may indicate loose or worn parts.

- Difficulty Starting: Struggles to initiate or requires multiple attempts to start up.

- Excessive Smoke: Unusual smoke emission can indicate internal wear or fuel problems.

Visual Signs

- Cracks or chips in housing or components.

- Discoloration or burn marks on surfaces.

- Worn or frayed belts and cables.

- Accumulation of debris or build-up around critical areas.

Regular inspection for these symptoms can significantly enhance the longevity of your equipment. Addressing issues promptly ensures better performance and reduces the risk of more extensive damage. Stay proactive to maintain the efficiency of your tools.

When to Seek Professional Help

Understanding when to enlist the assistance of an expert can be crucial for ensuring the longevity and effectiveness of your equipment. While some issues can be tackled independently, others may require specialized knowledge and tools. Recognizing these situations can save time and prevent further complications.

Consider seeking professional services in the following scenarios:

- Complex Technical Issues: If you encounter problems that are beyond basic troubleshooting, such as electrical failures or engine malfunctions.

- Safety Concerns: If there are risks of injury due to improper handling or if safety features are compromised.

- Repeated Failures: When the same problem persists despite your efforts to fix it, indicating a deeper underlying issue.

- Loss of Performance: If the device is not functioning as it should, affecting its efficiency and effectiveness.

- Warranty Considerations: If the product is under warranty, professional servicing might be necessary to avoid voiding it.

Recognizing these indicators will help ensure that your equipment remains in optimal condition, avoiding unnecessary stress and potential hazards.