This section provides an in-depth exploration of essential procedures for maintaining and troubleshooting various mechanisms commonly found in recreational vehicles. Understanding the intricacies of these components is vital for ensuring optimal functionality and longevity.

From identifying common issues to implementing effective solutions, this guide aims to empower users with the knowledge needed to address challenges confidently. With careful attention to detail and a focus on user-friendly practices, individuals can navigate through the complexities of their apparatus.

Whether you’re experiencing minor inconveniences or seeking to enhance performance, this resource serves as a comprehensive reference. By following the outlined steps, users will be equipped to make informed decisions and undertake necessary adjustments with ease.

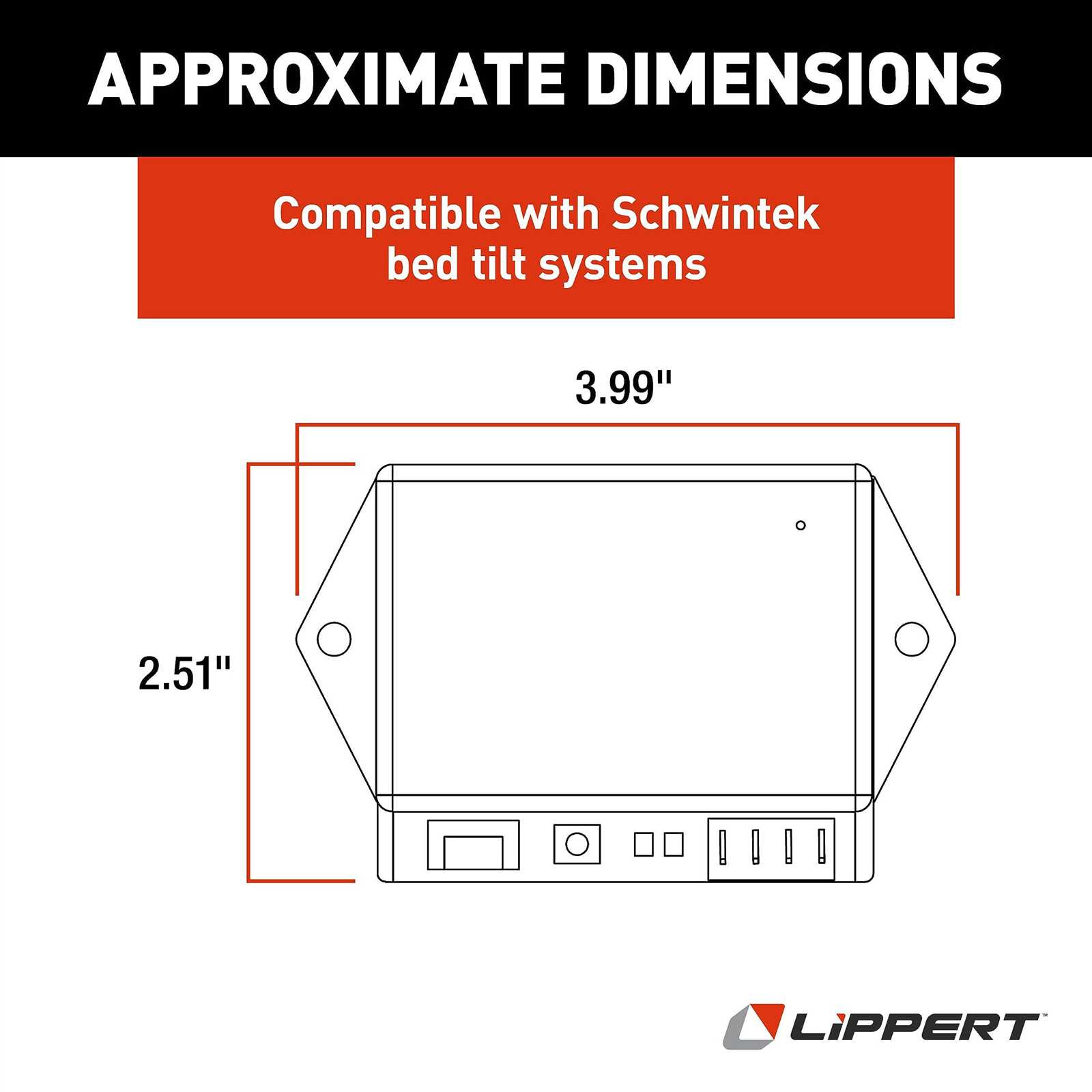

Bed Tilt System Overview

This section provides an insight into the functioning and components of a specific adjustment mechanism used in recreational vehicles and trailers. Understanding this setup can enhance usability and maintenance practices for users.

The primary function of this mechanism is to facilitate the angling of sleeping surfaces, enabling optimal comfort and convenience. Below are key aspects to consider:

- Components: The system comprises various elements that work together, including motors, linkages, and control interfaces.

- Operation: The mechanism is typically controlled by a switch or remote, allowing users to easily adjust the angle as needed.

- Maintenance: Regular checks on connections and functionality are crucial for ensuring long-term reliability and performance.

Overall, familiarizing oneself with this mechanism’s structure and operations can significantly improve user experience and safety during travels.

Common Issues with the System

This section highlights frequent complications encountered with the mechanism designed for elevation adjustments. Understanding these issues is essential for effective troubleshooting and maintaining optimal performance.

Mechanical Failures

One of the most prevalent concerns arises from mechanical breakdowns, which can hinder the device’s functionality. Wear and tear over time may lead to misalignment or obstruction of moving parts, resulting in decreased reliability.

Electrical Problems

Electrical malfunctions can also contribute to operational failures. Issues such as faulty connections or damaged wiring may interrupt power flow, causing the mechanism to become unresponsive.

| Issue Type | Symptoms | Potential Solutions |

|---|---|---|

| Mechanical Failures | Inconsistent movement, grinding noises | Lubricate moving parts, realign components |

| Electrical Problems | No response, flickering lights | Inspect wiring, replace damaged connectors |

Tools Required for Repairs

To successfully address issues related to the adjustment mechanism, a variety of essential instruments are necessary. Having the right equipment not only facilitates the process but also ensures safety and efficiency during the work.

Below is a list of the basic tools you will need:

- Socket Wrench Set

- Phillips and Flathead Screwdrivers

- Torque Wrench

- Pliers (both regular and needle-nose)

- Adjustable Wrench

- Wire Cutters

- Multimeter (for electrical checks)

In addition to the basic tools, you may also find the following items useful:

- Lubricants (to ensure smooth operation)

- Safety Goggles (for eye protection)

- Gloves (to protect your hands)

- Flashlight (for visibility in tight spaces)

Gathering these tools beforehand will help streamline the process and allow for a more effective and organized approach to maintenance tasks.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues encountered in specific adjustment mechanisms. Following these steps can help ensure effective restoration of functionality and enhance overall performance.

- Initial Assessment:

- Examine the device for any visible damage or wear.

- Identify any unusual sounds or behaviors during operation.

- Gather necessary tools and materials for the task.

- Disassembly:

- Carefully detach the components to access internal mechanisms.

- Organize parts systematically to facilitate reassembly.

- Inspection:

- Inspect all parts for damage, corrosion, or fatigue.

- Clean components to remove dirt and debris that may hinder function.

- Replacement or Repair:

- Replace any broken or compromised parts with compatible alternatives.

- For minor damages, apply suitable repair techniques.

- Reassembly:

- Reattach all components in the reverse order of disassembly.

- Ensure all connections are secure and properly aligned.

- Final Testing:

- Conduct tests to verify functionality and stability.

- Monitor for any issues during operation.

Following this comprehensive procedure will help restore optimal performance, ensuring reliability in use.

Testing the Tilt Mechanism

This section focuses on evaluating the functionality of the adjustment apparatus, ensuring its reliable operation. Proper assessment is crucial for maintaining optimal performance and addressing any potential issues effectively.

Begin by preparing the necessary tools and ensuring a safe workspace. Follow the outlined steps to perform a thorough examination:

| Step | Description |

|---|---|

| 1 | Inspect the components visually for any signs of wear or damage. |

| 2 | Check for proper alignment of the mechanisms. |

| 3 | Manually operate the adjustment mechanism to assess smoothness and functionality. |

| 4 | Test the control switches and wiring for responsiveness. |

| 5 | Measure the output force to ensure it meets specified requirements. |

By following these steps, you can effectively determine the operational state of the apparatus and identify any areas requiring attention.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent attention and care. Regular maintenance not only enhances performance but also prevents unexpected failures. By following simple practices, you can significantly extend the lifespan of your apparatus.

Regular Inspections

Frequent assessments are essential for identifying wear and tear before they escalate into major issues. Check for any signs of damage or irregularities in components, and address them promptly. Make it a habit to examine connections, joints, and any moving parts to ensure they are functioning smoothly.

Proper Lubrication

Applying the appropriate lubricants to mechanical elements is crucial for reducing friction and preventing rust. Select high-quality products that are recommended for your specific apparatus. Ensure that all necessary parts are adequately greased and wipe away any excess to avoid attracting dirt and debris.

In summary, diligent maintenance practices, such as regular inspections and proper lubrication, will help maintain optimal functionality and extend the life of your equipment.

Wiring and Electrical Considerations

This section addresses essential aspects related to the electrical connections and circuitry involved in the mechanism’s functionality. Understanding these components is crucial for ensuring reliable performance and safety during operation.

Connection Integrity

Maintaining solid connections is vital for the efficient operation of any electrical setup. Regular inspections can help identify loose wires or corroded terminals that may hinder performance. Utilizing appropriate connectors and ensuring a tight fit can significantly enhance reliability.

Power Supply and Circuit Protection

Providing the correct voltage and current is imperative for optimal operation. Incorporating fuses or circuit breakers can protect the circuitry from overloads, thereby preventing potential damage. Always refer to the specifications to select the right power source and protective devices.

Proper grounding is also essential to mitigate electrical hazards. Ensuring that all components are grounded appropriately can enhance safety and reduce the risk of malfunctions.

In summary, meticulous attention to wiring and electrical components is fundamental for the longevity and safe operation of the mechanism. Regular maintenance and adherence to specifications will contribute to a dependable performance.

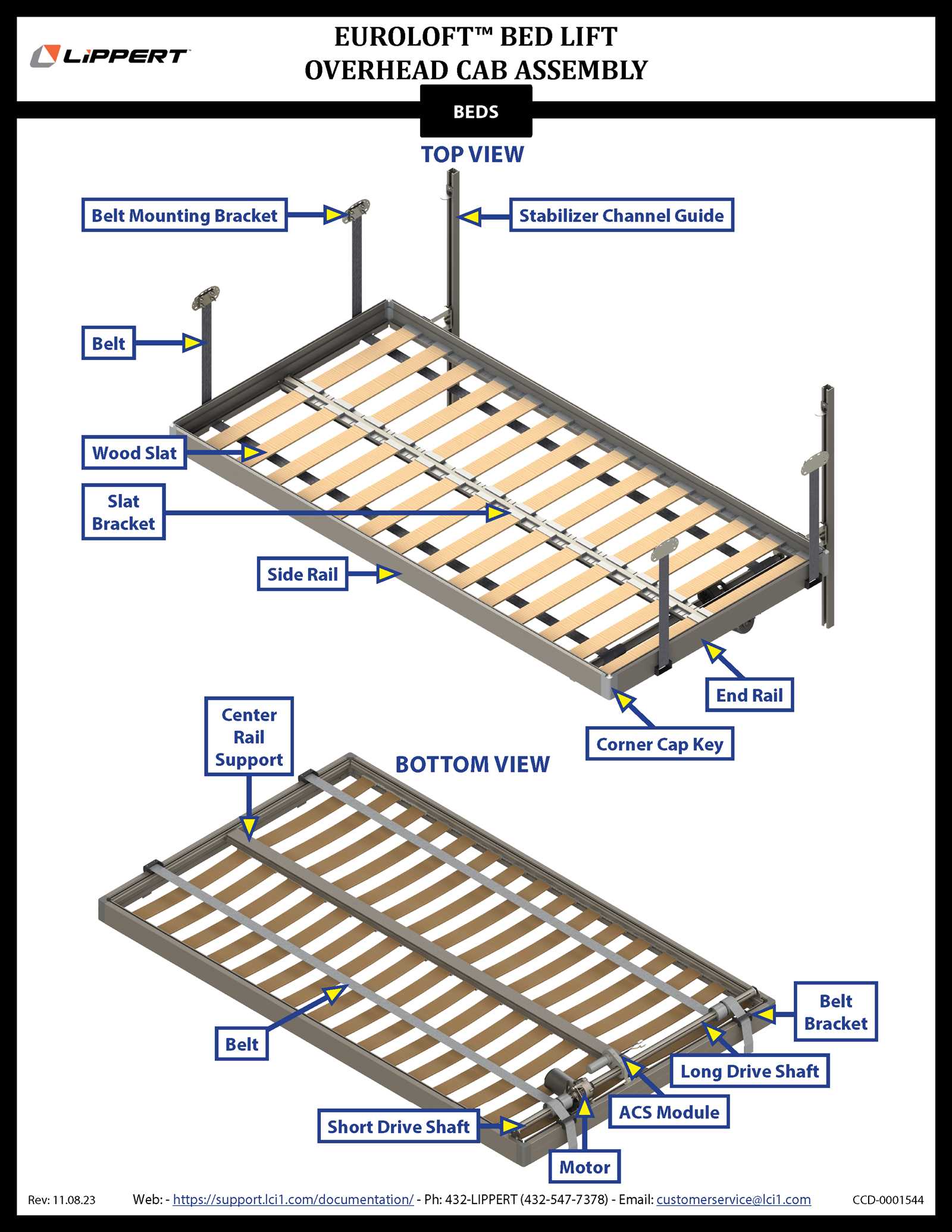

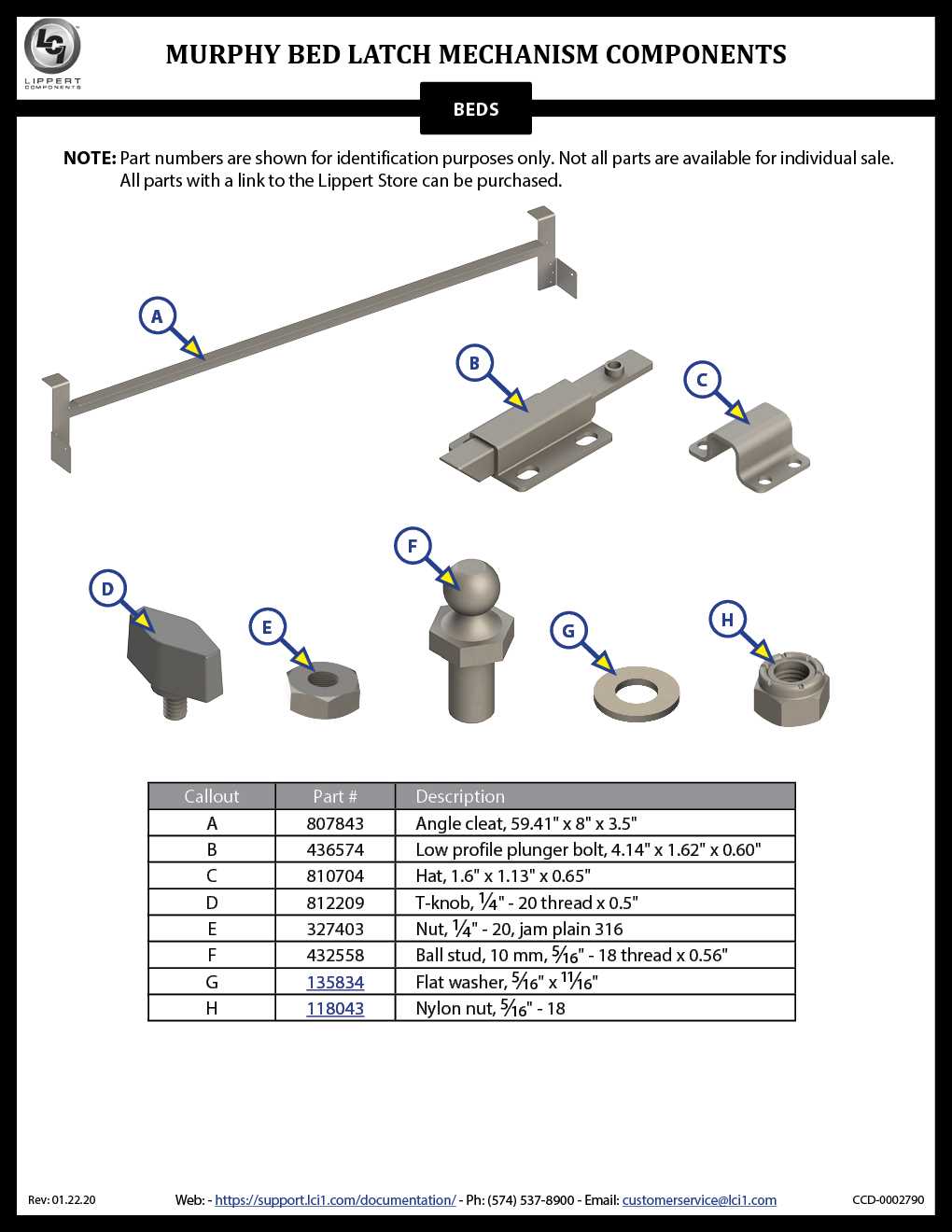

Identifying Parts and Components

This section provides a comprehensive overview of various elements and mechanisms essential for effective functionality. Understanding these components is crucial for maintenance and troubleshooting, enabling users to ensure optimal performance.

Key components to recognize include:

- Actuators: Devices that convert energy into motion, playing a vital role in adjustments.

- Frames: The structural elements that provide support and stability.

- Controls: Interfaces used to manage the operation, often including switches and remotes.

- Sensors: Instruments that monitor conditions and provide feedback for safe operation.

- Connectors: Components that facilitate the linking of various parts for effective communication.

To properly identify and understand the function of each part, consider the following steps:

- Familiarize yourself with the layout and arrangement of components.

- Refer to diagrams or schematics when available to visualize connections.

- Inspect each part for any signs of wear or damage, which may affect performance.

- Utilize manufacturer specifications for detailed information on each component.

By recognizing these elements, users can effectively troubleshoot and enhance the overall functionality of their equipment.

Safety Precautions During Repairs

When conducting maintenance on any mechanical assembly, ensuring safety should be the top priority. Proper precautions can prevent accidents and injuries, allowing for a more efficient and effective troubleshooting process.

Before beginning any maintenance tasks, it is essential to consider the following safety measures:

- Always disconnect the power source to prevent electrical hazards.

- Use appropriate personal protective equipment (PPE), including gloves, goggles, and hard hats.

- Ensure the workspace is clean and free of clutter to avoid tripping hazards.

- Verify that all tools and equipment are in good working condition before use.

Additionally, familiarize yourself with the operational guidelines of the mechanism. This knowledge can help identify potential risks and ensure proper handling during the maintenance process.

When working with heavy components, consider the following:

- Use proper lifting techniques or mechanical aids to prevent injury.

- Secure all parts before beginning work to avoid unexpected movement.

- Have a plan for emergency situations, including first aid and contact information for assistance.

By adhering to these guidelines, you can create a safer environment and reduce the risk of accidents during maintenance activities.

Troubleshooting Frequent Problems

This section addresses common issues that may arise with your adjustment mechanism, providing insights into identifying and resolving them effectively. By understanding typical symptoms and their potential causes, you can ensure a smoother experience.

- Inconsistent Movement:

If the adjustment mechanism does not operate smoothly, check for:

- Obstructions in the path.

- Wear and tear on the components.

- Loose connections or fasteners.

- Unusual Noises:

Noises during operation can indicate several issues, such as:

- Improper lubrication of moving parts.

- Misalignment of components.

- Damaged or worn-out parts that require replacement.

- Failure to Respond:

If the adjustment fails to respond to controls, consider checking:

- Battery charge or power source.

- Control wiring for damage or disconnection.

- Control switches for proper functionality.

- Uneven Adjustment:

When the adjustment appears uneven, look into:

- Calibration settings that may need adjustment.

- Damage to linkage components.

- Regular maintenance practices that might be overlooked.

By systematically addressing these common issues, you can enhance the performance and longevity of your adjustment mechanism.

Resources for Replacement Parts

Finding suitable components for maintenance or upgrades is essential for ensuring optimal performance. Various sources provide high-quality parts that can meet the specific needs of your equipment.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide range of components. These sites often provide detailed descriptions and customer reviews, making it easier to select the right items for your needs.

Manufacturer Websites: Visiting the official sites of manufacturers can yield reliable resources for original parts. Many companies offer direct purchasing options or a list of authorized dealers, ensuring authenticity and quality.

Local Suppliers: Exploring nearby hardware or specialty stores may reveal valuable components. Local suppliers often have knowledgeable staff who can assist in identifying the right parts for specific repairs or enhancements.

Forums and Community Groups: Engaging with online communities dedicated to similar interests can provide insights into where to source parts. Members often share their experiences and recommend reputable suppliers, which can save time and effort.

Second-Hand Marketplaces: Websites that facilitate the buying and selling of used items can be a treasure trove for finding affordable components. While caution is advised, many sellers offer quality parts at a fraction of the original cost.

Consulting Professional Help

When faced with challenges in maintaining or fixing mechanical equipment, seeking the expertise of qualified technicians can be invaluable. These professionals possess the necessary skills and experience to diagnose issues accurately and provide effective solutions. Engaging with specialists not only ensures that problems are resolved efficiently but also helps in avoiding potential future complications.

Benefits of Professional Assistance

One significant advantage of consulting experts is their access to specialized tools and resources. These tools are often essential for comprehensive assessments and repairs that may be beyond the capabilities of standard equipment. Additionally, professionals stay updated on industry standards and innovations, ensuring that the solutions provided are both modern and reliable.

Choosing the Right Expert

When selecting a technician or service provider, consider their qualifications and reviews from previous clients. It’s important to choose someone who is experienced with the specific type of equipment in question. Gathering recommendations and conducting thorough research can help in making an informed decision that aligns with your needs.