Maintaining the efficiency of a vehicle’s fuel delivery system is crucial for optimal performance. This section provides comprehensive insights into the intricacies of servicing critical components that ensure the smooth operation of your engine. Understanding these elements can significantly enhance the longevity and reliability of your vehicle.

Common Challenges: Over time, fuel components may face various issues, leading to decreased efficiency and performance. Identifying these challenges early can prevent more severe complications. With the right knowledge and tools, you can address these concerns effectively.

Key Considerations: Regular maintenance and timely interventions play a vital role in preserving the functionality of your system. By familiarizing yourself with the essential techniques and approaches, you can ensure that your vehicle runs at its best, adapting to changing conditions on the road.

Recognizing the indicators of malfunction in fuel delivery components is crucial for maintaining engine performance. When these elements fail, they can significantly impact the overall functionality of the vehicle. Awareness of the common symptoms can aid in timely diagnosis and intervention.

Several key signs may suggest issues with fuel delivery components:

| Symptoms | Description |

|---|---|

| Decreased Engine Performance | Noticeable reduction in power, acceleration, or responsiveness while driving. |

| Unusual Noises | Unexpected sounds, such as knocking or tapping, coming from the engine. |

| Increased Fuel Consumption | Higher than normal fuel usage, indicating inefficiency in the combustion process. |

| Engine Misfires | Irregular firing of the engine, leading to rough idling and performance issues. |

| Excessive Emissions | Higher levels of smoke or exhaust emissions, often linked to incomplete combustion. |

Identifying these symptoms early can help prevent further damage and costly repairs. Regular inspections and maintenance are essential to ensure optimal operation of the vehicle.

Tools Needed for Repairs

Effective maintenance and restoration tasks require a specific set of instruments to ensure precision and efficiency. Having the right tools at your disposal not only simplifies the process but also enhances the overall quality of the work performed. Below are essential items that will aid in achieving successful outcomes during the service of fuel delivery components.

Essential Instruments

First and foremost, a quality set of wrenches is crucial for loosening and tightening fittings. A torque wrench will also ensure that components are secured to the manufacturer’s specifications. Additionally, a diagnostic scanner can be invaluable for identifying issues and monitoring system performance, helping to streamline troubleshooting efforts.

Safety Equipment

Safety gear should not be overlooked. Gloves and goggles protect against potential hazards, while a well-ventilated workspace is essential for safe handling of components. Proper organization of tools and materials further enhances workflow, allowing for a more efficient and effective repair process.

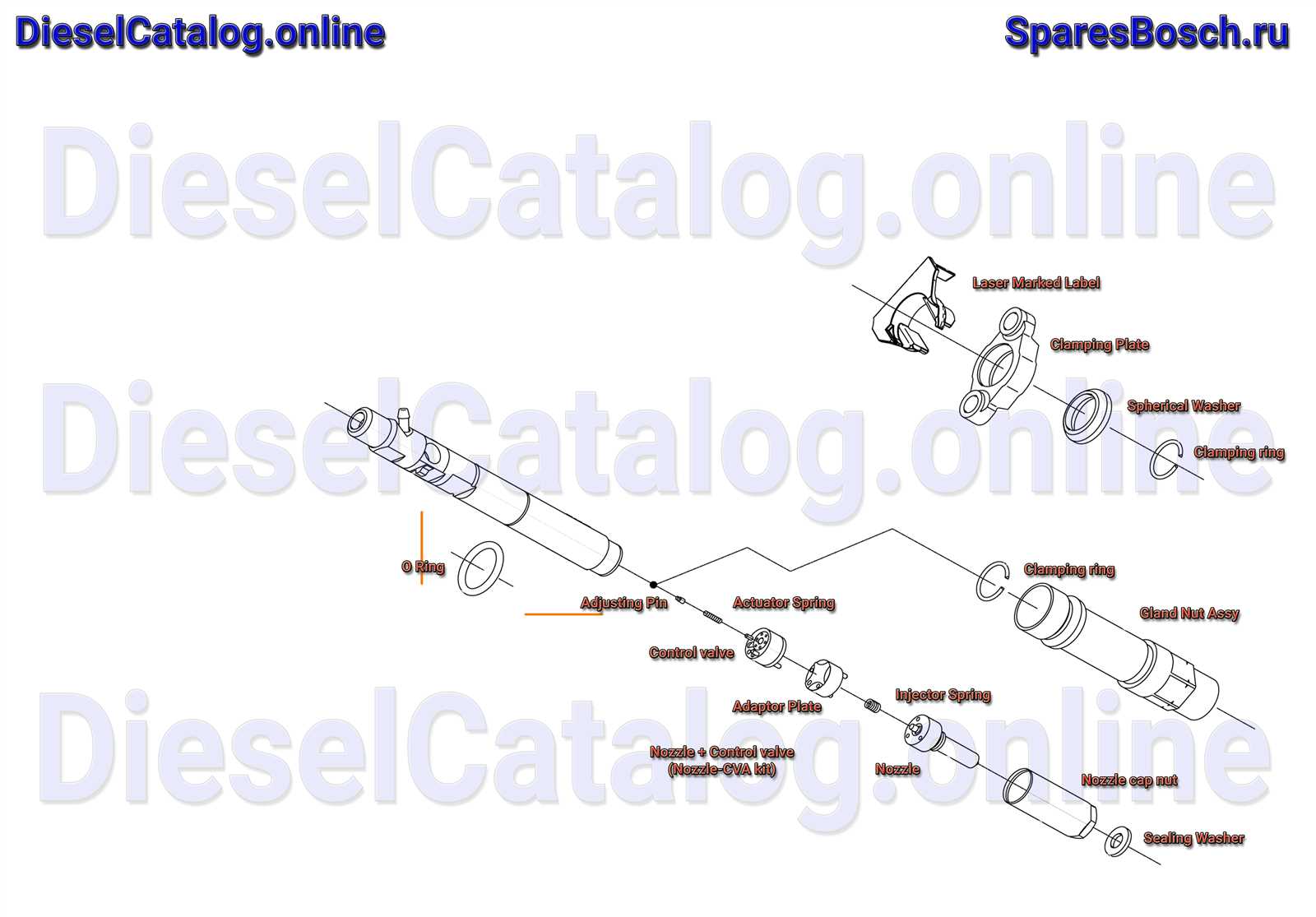

Disassembling the Injector Unit

This section provides a comprehensive overview of the process involved in separating the components of the fuel delivery mechanism. Understanding the assembly and its parts is essential for effective maintenance and troubleshooting.

The following steps outline the procedure to carefully dismantle the unit while ensuring that all components are handled with precision:

| Step | Description |

|---|---|

| 1 | Prepare a clean workspace to prevent contamination of parts. |

| 2 | Gather necessary tools, including wrenches, screwdrivers, and specialized equipment. |

| 3 | Remove any protective covers and fasteners securing the assembly. |

| 4 | Carefully detach the various components, taking note of their arrangement. |

| 5 | Inspect each part for wear and damage before proceeding with reassembly or replacement. |

By following these steps, you can ensure that the disassembly process is carried out efficiently and effectively, setting the stage for any necessary servicing or upgrades.

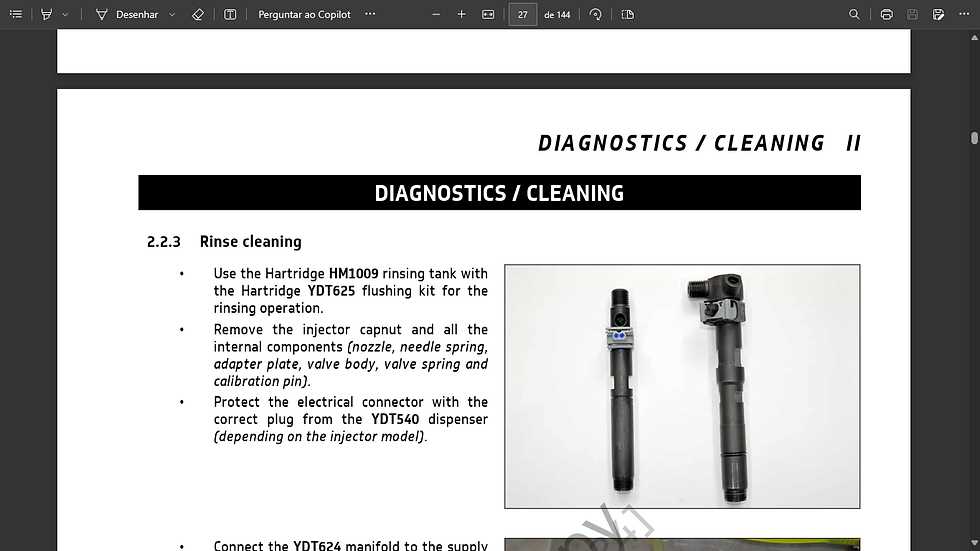

Cleaning Techniques for Injectors

Ensuring optimal performance of fuel delivery components is crucial for engine efficiency. Various methods exist to maintain and restore these parts, promoting better functionality and longevity.

One effective approach is using specialized cleaning solutions designed to dissolve deposits and contaminants. This process often involves soaking the components in a suitable solvent, allowing for the breakdown of stubborn residues.

Ultrasonic cleaning is another popular technique. By utilizing high-frequency sound waves, this method creates microscopic bubbles that agitate the cleaning solution, effectively removing dirt and grime from hard-to-reach areas.

Manual scrubbing can also be beneficial, particularly for surfaces that require more attention. Using soft brushes or cloths with gentle cleaning agents can help preserve the integrity of the parts while ensuring thorough cleanliness.

After cleaning, it’s essential to inspect the components for any signs of wear or damage, ensuring that they are in optimal condition before reinstallation. Proper care and maintenance of these parts will significantly enhance overall engine performance.

Reassembling the Injector Components

Putting together the various elements of a fuel delivery device requires precision and attention to detail. This process ensures that the system functions efficiently and reliably. Following the correct sequence and utilizing appropriate tools will lead to successful reassembly, minimizing the risk of future issues.

Step-by-Step Assembly Process

Begin by organizing all components, ensuring cleanliness to avoid contamination. Align the parts according to the manufacturer’s specifications. Gradually tighten the securing elements, following a cross-pattern method to distribute pressure evenly. This approach prevents misalignment and ensures a snug fit.

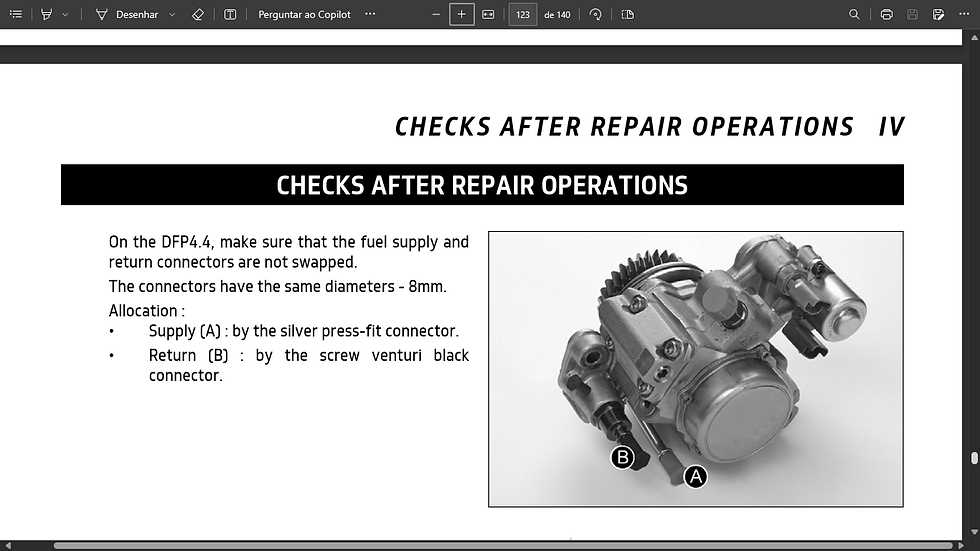

Final Checks and Testing

After assembly, conduct thorough inspections to verify that all components are properly seated and secured. It is crucial to perform functionality tests to confirm that the unit operates smoothly without leaks or malfunctions. These final checks are essential for maintaining optimal performance.

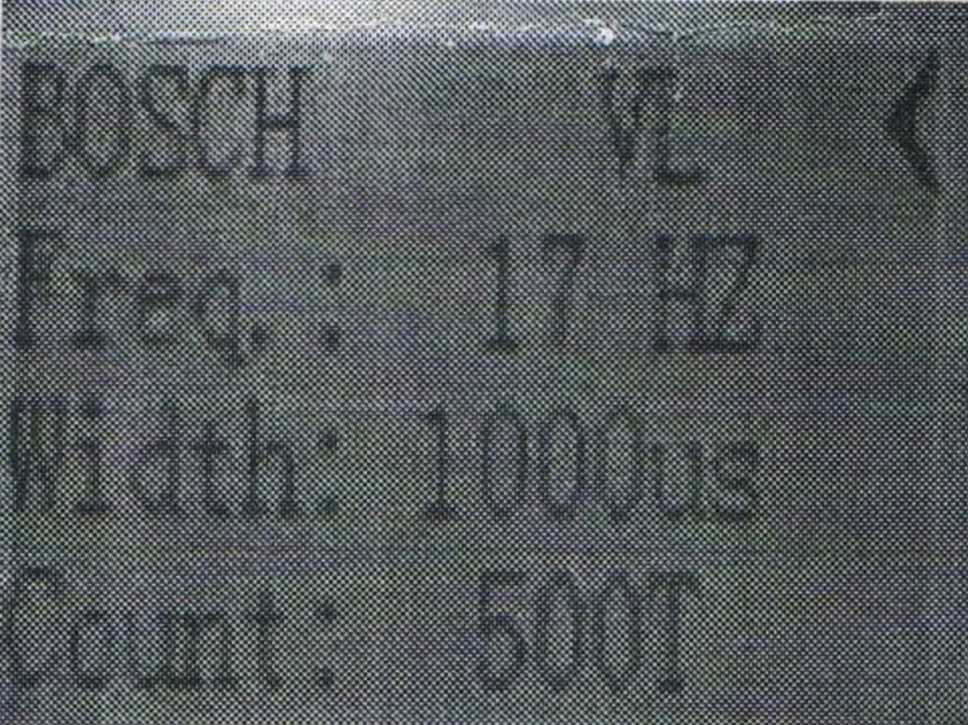

Testing Injector Performance

Evaluating the functionality of fuel delivery components is crucial for ensuring optimal engine operation. This process involves a series of checks to determine how well these parts are performing under various conditions.

To effectively assess performance, consider the following steps:

- Visual Inspection: Examine the component for any visible signs of wear, damage, or leaks.

- Flow Rate Measurement: Measure the amount of fuel delivered over a specific time period to ensure it meets the required specifications.

- Leak Test: Check for any unwanted fuel leaks when the system is pressurized.

- Spray Pattern Analysis: Evaluate the fuel spray pattern to confirm it is atomizing properly for efficient combustion.

- Electrical Testing: Test the electrical connections and resistance to ensure proper operation of solenoids.

By systematically conducting these evaluations, you can identify any performance issues and take the necessary steps to enhance functionality.

Common Mistakes to Avoid

When tackling the restoration of fuel delivery components, it’s crucial to be aware of frequent pitfalls that can lead to poor performance or even failure. Understanding these errors can save time, resources, and frustration during the process.

Inadequate Cleaning: Neglecting thorough cleaning of components can result in residue buildup, causing blockages and inefficiencies. Ensuring every part is free from contaminants is essential for optimal functionality.

Incorrect Assembly: Misplacing parts during reassembly can lead to malfunctions. It is vital to follow a systematic approach, verifying each component’s position against specifications.

Ignoring Manufacturer Guidelines: Straying from provided recommendations may result in improper usage of tools or materials, compromising the integrity of the entire system. Always refer to the appropriate guidelines for the best outcomes.

Overlooking Testing: Failing to perform tests post-restoration can lead to undetected issues. Conducting proper diagnostics ensures that everything is functioning as intended before reinstallation.

Understanding Fuel Quality Impact

The quality of fuel plays a crucial role in the overall performance and longevity of modern engine systems. Variations in fuel composition can significantly affect the efficiency and reliability of fuel delivery mechanisms. This section delves into how different fuel characteristics influence engine operation and maintenance needs.

Factors Affecting Fuel Quality

Several factors contribute to the quality of fuel, including the presence of impurities, the type of additives used, and the method of production. Each of these elements can either enhance or hinder engine performance.

Consequences of Poor Fuel Quality

Using substandard fuel can lead to various operational issues, including reduced efficiency, increased emissions, and accelerated wear on engine components. Understanding these impacts can help in making informed choices regarding fuel selection.

| Fuel Quality Factor | Potential Impact |

|---|---|

| Impurities | Clogged components and reduced flow rates |

| Additives | Enhanced performance or detrimental effects |

| Production Method | Consistency and reliability in fuel delivery |

Upgrading Injector Parts

Enhancing the performance of fuel delivery components is crucial for improving engine efficiency and overall functionality. This section explores various methods and considerations for upgrading essential parts, ensuring optimal operation and longevity.

Benefits of Upgrading Components

Investing in high-quality replacements can lead to significant improvements:

- Increased fuel efficiency

- Enhanced engine performance

- Reduced emissions

- Improved reliability and durability

Key Parts to Consider for Upgrades

When planning upgrades, focus on these critical components:

- Seals and O-rings: Opt for durable materials that withstand high pressure and temperature.

- Spring Mechanisms: Upgrading to stronger springs can enhance response times and performance.

- Electromagnetic Coils: Consider high-performance coils for better activation and efficiency.

- Precision Nozzles: Upgrading to precision-engineered nozzles ensures optimal fuel atomization.

Maintaining Your Injectors

Proper upkeep of fuel delivery components is crucial for ensuring optimal engine performance and longevity. Regular attention to these parts can help prevent issues that may arise from wear and contamination.

To maintain your fuel delivery components effectively, consider the following practices:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Every 6 months | Check for leaks, cracks, or signs of wear. |

| Cleaning | Annually | Use appropriate solvents to clean the components and remove carbon deposits. |

| Filter Replacement | Every 12 months | Replace fuel filters to prevent contamination and ensure smooth operation. |

| Performance Testing | As needed | Conduct tests to assess functionality and identify any discrepancies in performance. |

By following these guidelines, you can significantly enhance the reliability and efficiency of your fuel system, ensuring that it operates at its best.

When to Seek Professional Help

Recognizing the right moment to consult an expert is crucial for maintaining the efficiency and longevity of your vehicle’s performance components. Some issues may seem minor at first glance but could indicate more significant underlying problems that require specialized knowledge and tools.

If you encounter persistent performance issues, unusual noises, or warning lights on your dashboard, it is advisable to reach out to a qualified technician. Additionally, if you lack the necessary experience or equipment for proper diagnostics and repairs, seeking assistance from a professional ensures that the job is done accurately and safely.

Moreover, when faced with intricate systems that involve precise calibration, professional expertise becomes even more vital. Attempting to address these challenges without the right skills may lead to further complications, resulting in more costly repairs in the long run.