In the world of mechanical systems, the functionality and longevity of cleaning units are paramount. Understanding the intricacies of these devices ensures they operate at peak efficiency, preventing costly downtime. This section delves into essential information and guidelines for maintaining and troubleshooting these invaluable tools.

By familiarizing oneself with the components and functions of these units, users can identify common issues and apply appropriate solutions. Clear insights into assembly and disassembly processes enhance the overall user experience, empowering individuals to take charge of their equipment’s upkeep.

Whether addressing minor inconveniences or conducting thorough assessments, this resource provides vital knowledge. With a focus on practical application, readers will gain confidence in handling challenges that arise during operation, ultimately contributing to improved performance and durability.

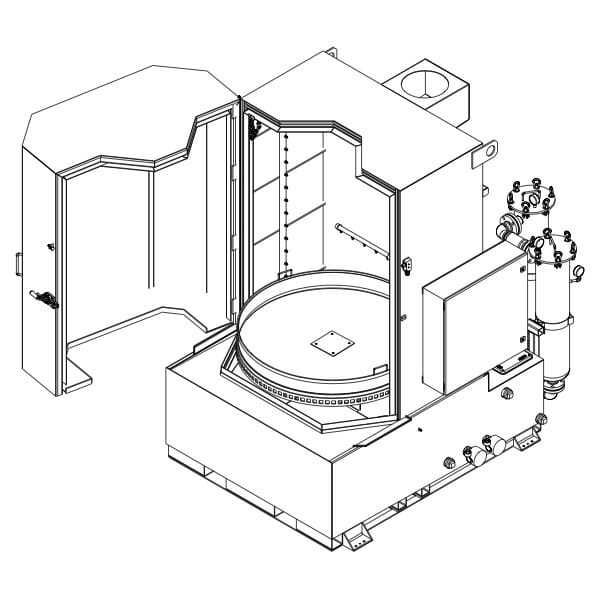

Understanding the Parts Washer System

This section delves into the intricacies of a cleaning apparatus designed for effective maintenance and preservation of various components. By examining its core functionalities and essential elements, users can gain insight into the operational principles that ensure optimal performance.

At the heart of this apparatus lies a combination of mechanical and fluid dynamics that work together to remove contaminants. Understanding these fundamental aspects is crucial for troubleshooting and enhancing efficiency.

| Component | Description |

|---|---|

| Tank | Holds the cleaning solution and components to be cleaned. |

| Filter | Traps debris and particles to maintain solution clarity. |

| Heater | Raises the temperature of the cleaning solution for improved effectiveness. |

| Pump | Circulates the cleaning solution, ensuring even coverage. |

| Nozzle | Directs the flow of the solution onto the components for thorough cleaning. |

Familiarity with each element not only aids in understanding the overall functionality but also equips users with the knowledge necessary for maintenance and efficiency optimization.

Common Issues and Troubleshooting Tips

This section addresses frequent challenges encountered with maintenance equipment and provides guidance for resolving them effectively. Understanding these common complications can help users maintain optimal functionality and prolong the lifespan of their devices.

One prevalent concern is insufficient cleaning efficiency. This may result from a clogged filter or insufficient fluid levels. Regularly checking and replacing filters, as well as ensuring adequate liquid supply, can greatly enhance performance.

Another issue often faced is unusual noises during operation. This can indicate mechanical wear or misalignment. Inspecting moving components for damage or debris and ensuring proper alignment can mitigate this problem.

Inconsistent temperature regulation may also arise, impacting the cleaning process. This could be due to faulty heating elements or thermostat issues. Regularly testing these components for functionality can help maintain the desired operating conditions.

Finally, electrical malfunctions such as tripped circuits or non-responsive controls can hinder operation. Checking the power source and inspecting wiring for any signs of damage are essential steps in troubleshooting these electrical challenges.

Essential Maintenance Procedures Explained

Regular upkeep is vital for ensuring optimal performance and longevity of your cleaning apparatus. Implementing specific routines can significantly enhance efficiency and prevent unexpected breakdowns. This section outlines key practices that should be integrated into your maintenance schedule.

1. Daily Inspection: Conducting a thorough check at the beginning of each day helps identify any potential issues. Look for signs of wear, leaks, or unusual noises that could indicate underlying problems.

2. Cleaning Solutions: Regularly refreshing the cleaning agents used within the machine ensures effective operation. Choose high-quality solutions that are compatible with your equipment to maximize performance.

3. Filter Maintenance: Regularly replacing or cleaning filters is crucial for maintaining optimal airflow and preventing contamination of cleaning solutions. Schedule filter checks at consistent intervals to avoid clogs.

4. Lubrication: Keeping moving parts adequately lubricated minimizes friction and reduces wear. Use appropriate lubricants as specified by the manufacturer to prolong the lifespan of mechanical components.

5. Component Checks: Periodically inspect all components, including pumps and hoses, for signs of damage or deterioration. Timely replacement of worn parts can prevent more extensive repairs later.

6. Record Keeping: Maintaining a log of maintenance activities helps track the history of upkeep and repairs. This information can be invaluable for future troubleshooting and scheduling routine checks.

Incorporating these essential procedures into your routine will ensure your cleaning equipment operates smoothly and efficiently, reducing downtime and enhancing overall productivity.

Tools Required for Effective Repairs

To ensure a successful restoration process, having the right instruments is crucial. This section highlights essential items that can facilitate efficient troubleshooting and maintenance, ultimately prolonging the lifespan of your equipment.

Basic Instrumentation

At a minimum, a comprehensive toolkit should include a variety of wrenches, screwdrivers, and pliers. These fundamental tools are necessary for loosening or tightening components, allowing for quick access and adjustments. A multimeter is also beneficial for diagnosing electrical issues.

Specialized Equipment

For more complex tasks, certain specialized instruments may be required. A pressure gauge can help monitor fluid levels, while a filter wrench aids in the removal of tightly secured filters. Additionally, having a supply of cleaning agents and lubricants will enhance the effectiveness of the overall maintenance process.

Step-by-Step Repair Process Overview

This section outlines a systematic approach to restoring functionality to a cleaning apparatus. The following steps will guide you through the necessary actions to ensure efficient operation and longevity of the equipment.

| Step | Description |

|---|---|

| 1 | Begin with a thorough inspection to identify any visible damage or wear. |

| 2 | Gather the required tools and replacement components to facilitate the process. |

| 3 | Disconnect all power sources to ensure safety during the procedure. |

| 4 | Carefully disassemble the unit, taking note of the arrangement of parts. |

| 5 | Replace any faulty components and clean surfaces to remove any accumulated residue. |

| 6 | Reassemble the unit, ensuring all parts are securely fitted and aligned. |

| 7 | Reconnect the power sources and conduct a test to confirm proper functionality. |

Identifying and Replacing Worn Components

Regular maintenance is crucial for ensuring the longevity and efficiency of any cleaning apparatus. Recognizing when elements begin to deteriorate can prevent more significant issues and extend the lifespan of the equipment. This section focuses on the signs of wear and the steps to take for their replacement.

Common indicators of component wear include:

- Increased noise levels during operation

- Inconsistent cleaning results

- Visible signs of corrosion or damage

- Leaking fluids

Once worn components have been identified, the replacement process can be initiated. Here are the steps to follow:

- Disconnect the unit from any power source to ensure safety.

- Refer to the specifications for compatible replacements.

- Carefully remove the damaged components, taking note of their arrangement.

- Install the new parts, ensuring they are secured correctly.

- Reconnect the power source and conduct a test run to confirm proper operation.

By adhering to these guidelines, users can maintain optimal performance and reduce the likelihood of future malfunctions.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth workflow. Understanding potential hazards and implementing protective measures is essential for anyone involved in the process.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Disconnect power sources before starting any task to eliminate electrical hazards.

- Keep a fire extinguisher nearby and familiarize yourself with its use.

- Store flammable materials in designated containers away from heat sources.

Tool and Equipment Safety

- Regularly inspect tools for damage and maintain them properly.

- Use tools for their intended purpose to avoid malfunctions and injuries.

- Keep the workspace organized to prevent accidents caused by clutter.

- Be cautious when handling sharp objects and dispose of them safely.

Cleaning and Care Techniques

Maintaining optimal performance of your cleaning equipment is essential for longevity and efficiency. Proper upkeep not only enhances functionality but also ensures safe operation, preventing potential issues down the line.

Start by routinely inspecting components for debris and residues that may affect performance. Utilize appropriate cleaning agents that are compatible with the materials involved, ensuring a thorough cleanse without causing damage. Regularly check seals and connections for wear, replacing them as necessary to maintain integrity.

In addition, ensure that the environment around the unit remains tidy, minimizing the chances of contaminants entering the system. Establish a consistent schedule for detailed cleaning to keep all surfaces and internal mechanisms in top condition. By following these practices, you can extend the lifespan of your equipment while maximizing its effectiveness.

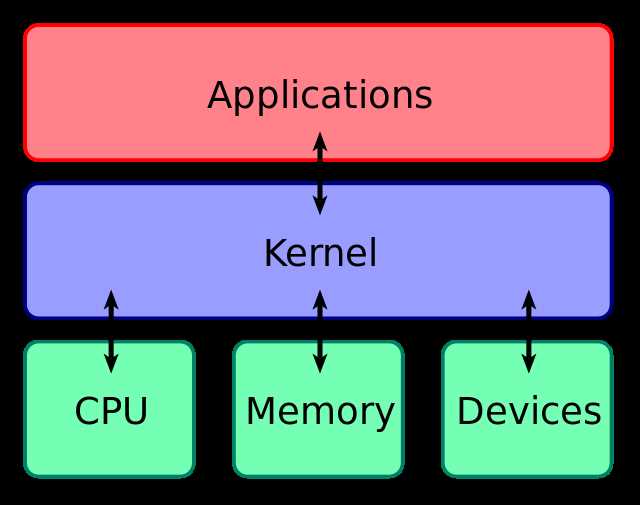

Improving Efficiency in Operation

Enhancing productivity during cleaning processes involves optimizing workflows and ensuring that resources are utilized effectively. By focusing on several key strategies, users can achieve significant gains in performance and reduce downtime.

- Regular Maintenance: Keeping equipment in top condition minimizes unexpected failures.

- Training Personnel: Educating staff on proper techniques maximizes the benefits of the machinery.

- Streamlining Procedures: Simplifying steps in the cleaning routine can lead to quicker turnaround times.

- Utilizing Technology: Implementing advanced monitoring systems helps in tracking performance and identifying issues promptly.

By applying these strategies, users can ensure a more efficient and effective cleaning environment, resulting in improved overall performance and satisfaction.

Parts Washer Specifications to Know

Understanding the essential characteristics of a cleaning unit is crucial for effective usage and maintenance. These specifications guide users in selecting the appropriate model and ensuring optimal performance during operations. Knowledge of these details contributes to enhancing the longevity and efficiency of the equipment.

Key Features and Dimensions

When considering a cleaning unit, attention should be paid to dimensions, capacity, and weight. The size of the unit influences its suitability for various applications, while capacity indicates the volume of items that can be accommodated. Weight can affect portability and ease of placement, making it an important factor in selection.

Operating Conditions and Requirements

Another critical aspect involves understanding the operational environment and requirements. This includes power specifications, temperature limits, and compatibility with various cleaning solutions. Ensuring that the unit meets these criteria is vital for achieving desired results without compromising safety or functionality.

Cost-Effective Replacement Parts Guide

Finding affordable components for maintenance tasks can significantly reduce expenses while ensuring optimal functionality. This section provides insights into budget-friendly alternatives that maintain quality without breaking the bank.

When seeking substitutes, it’s essential to prioritize compatibility and reliability. Many reputable suppliers offer economical options that meet or exceed original specifications. Consider researching reviews and ratings to identify the best choices for your needs.

Additionally, bulk purchasing can lead to further savings. By acquiring multiple items at once, you may qualify for discounts, making it a smart strategy for both individual users and businesses alike. Always compare prices across different vendors to maximize your investment.

Lastly, do not overlook refurbished or reconditioned options. These can provide substantial savings while still delivering reliable performance. Ensuring that products come with a warranty can add peace of mind to your purchases.

When to Seek Professional Help

There are instances when attempting to resolve an issue independently may not yield the desired outcome. Recognizing these moments can save time, resources, and ensure safety. Consulting an expert may be essential in certain scenarios.

Signs It’s Time for Assistance

- The problem persists despite multiple attempts at troubleshooting.

- You notice unusual noises or smells that indicate a deeper issue.

- Parts are damaged or worn beyond reasonable repair.

- You lack the necessary tools or expertise for complex tasks.

Benefits of Professional Services

- Access to specialized knowledge and experience.

- Ensured compliance with safety regulations and standards.

- Time efficiency in resolving complex issues.

- Potential cost savings by preventing further damage.

When faced with significant challenges, seeking expert assistance can provide peace of mind and ensure the longevity of your equipment.