Maintaining a marine engine is essential for ensuring optimal performance and longevity. This section delves into the intricacies of servicing a specific model designed for various watercraft, focusing on key components and procedures that contribute to a smooth operation.

Proper knowledge of the machinery can prevent potential issues, enhance reliability, and promote safe navigation. Regular checks and maintenance routines are vital for addressing wear and tear that can occur over time, ensuring that the engine continues to function efficiently in different marine environments.

Whether you are a seasoned enthusiast or a novice, understanding the intricacies of engine upkeep will empower you to tackle common challenges and enhance your boating experience. This guide serves as a comprehensive resource, providing insights into effective techniques and tips for maintaining your engine.

Essential Tools for Outboard Repair

Maintaining and enhancing marine engines requires a specific set of implements designed for precision and efficiency. The right tools not only facilitate the work but also ensure that the engine operates smoothly and safely. Understanding the essential instruments can significantly improve the process of service and upkeep.

Key Instruments

When engaging in service tasks, certain tools stand out as particularly beneficial. Below is a list of vital implements that every technician should have on hand:

| Tool | Description |

|---|---|

| Socket Set | Used for loosening and tightening bolts with various sizes for versatility. |

| Screwdriver Set | A collection of flathead and Phillips screwdrivers for different screw types. |

| Pliers | Essential for gripping, twisting, and cutting wires and other materials. |

| Torque Wrench | Helps ensure fasteners are tightened to the correct specifications. |

| Multimeter | Used for measuring electrical properties, critical for diagnosing issues. |

Additional Considerations

In addition to the fundamental tools, certain safety equipment is necessary. Gloves and goggles protect against injuries, while a first aid kit is essential for any unforeseen incidents. By assembling a comprehensive toolkit, anyone can be better prepared for effective maintenance and troubleshooting of marine engines.

Understanding Engine Components and Functions

In the realm of marine propulsion systems, comprehending the various elements and their roles is crucial for effective operation and maintenance. Each component plays a significant part in the overall functionality, contributing to the efficiency and performance of the engine.

Combustion Chamber: This is where the fuel-air mixture ignites, generating the power needed for propulsion. Its design affects the engine’s efficiency and power output.

Piston: The piston moves up and down within the cylinder, converting the pressure from combustion into mechanical energy. This movement is essential for driving the crankshaft.

Crankshaft: Acting as the heart of the engine, the crankshaft transforms the linear motion of the pistons into rotational energy, ultimately powering the propeller.

Fuel System: This system is responsible for delivering the right amount of fuel to the combustion chamber. Proper fuel management ensures optimal performance and prevents issues such as flooding or starvation.

Cooling System: Maintaining the engine’s temperature is vital to prevent overheating. This system circulates coolant, absorbing excess heat and ensuring efficient operation.

Ignition System: This system ignites the fuel-air mixture at the right moment, ensuring smooth operation. Timely ignition is crucial for maximizing power output and minimizing emissions.

Understanding these components and their functions not only enhances knowledge but also aids in troubleshooting and maintaining optimal performance in marine engines.

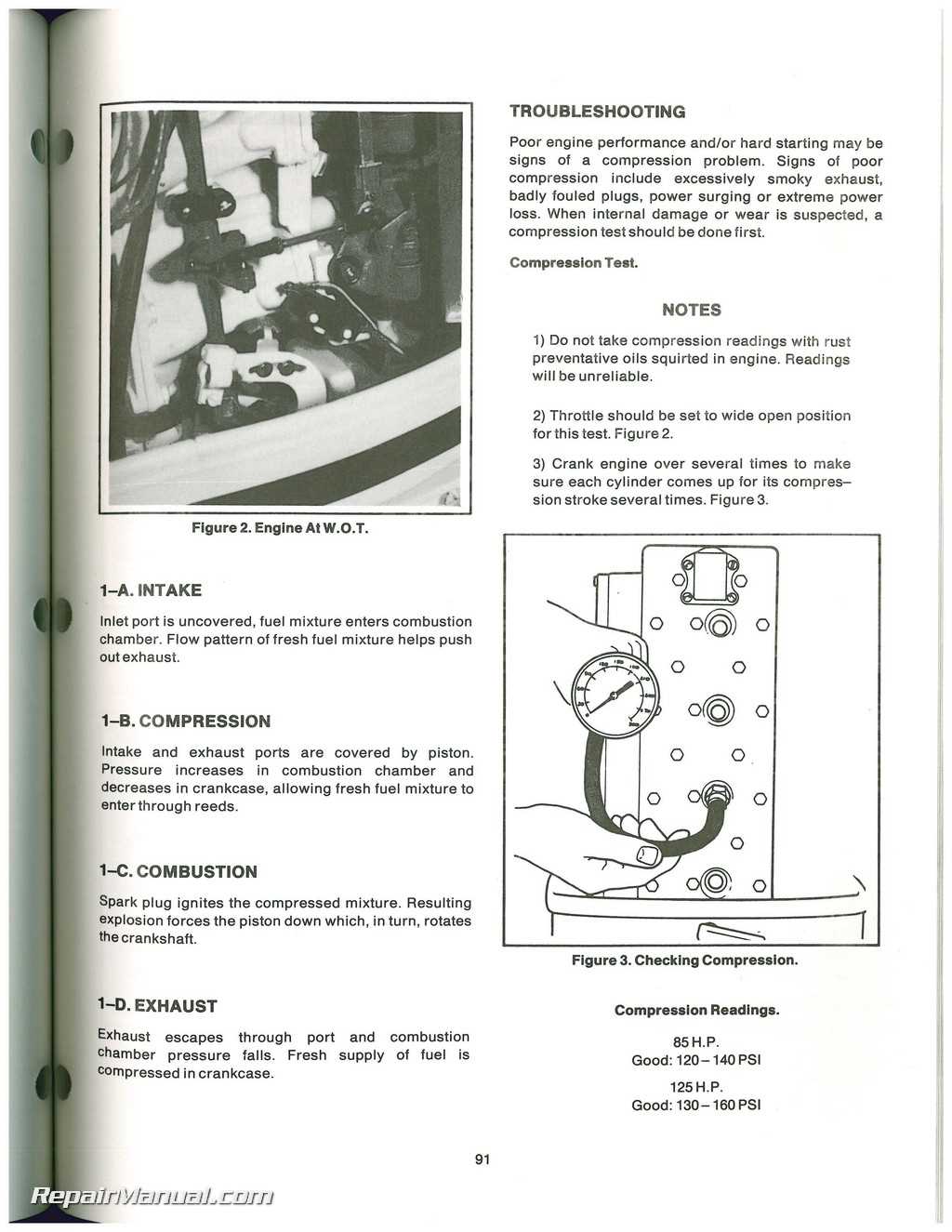

Troubleshooting Common Performance Issues

When dealing with various marine propulsion systems, it’s essential to identify and resolve performance challenges that may arise during operation. These issues can affect efficiency and overall functionality, making timely diagnosis crucial for optimal performance.

Here are some common issues and their potential causes:

- Engine Hesitation:

- Clogged fuel filter

- Incorrect air-fuel mixture

- Worn spark plugs

- Excessive Smoke:

- Improper oil-to-fuel ratio

- Faulty ignition timing

- Damaged piston rings

- Overheating:

- Insufficient cooling water flow

- Obstructed water intake

- Faulty thermostat

To effectively address these issues, follow a systematic approach:

- Start with a visual inspection of all components.

- Check fuel and oil levels, ensuring proper ratios.

- Perform diagnostic tests on electrical systems.

- Consult technical resources for detailed specifications.

By systematically diagnosing and addressing these common challenges, users can maintain performance and ensure reliable operation of their systems.

Maintenance Practices for Longevity

To ensure the extended lifespan of your marine engine, implementing regular upkeep routines is essential. Proper care not only enhances performance but also minimizes the risk of unexpected failures, making your time on the water more enjoyable. By following a few simple practices, you can keep your engine in optimal condition.

Routine Inspections

Conducting frequent examinations is key to identifying potential issues early. Look for signs of wear, corrosion, or damage, particularly in areas exposed to harsh marine environments. Addressing these problems promptly can prevent more significant complications down the line.

Fluid Checks and Changes

Maintaining proper fluid levels is crucial for the functionality of your engine. Regularly check and replace fluids as necessary, including lubricants and cooling agents. This practice ensures smooth operation and protects against overheating or wear.

| Maintenance Task | Frequency |

|---|---|

| Inspect engine components | Monthly |

| Change oil | Every 50 hours of operation |

| Check fuel filters | Every season |

| Examine electrical connections | Quarterly |

By adhering to these maintenance practices, you can significantly enhance the durability and efficiency of your marine engine, ensuring countless enjoyable outings on the water.

Step-by-Step Reassembly Guide

This section provides a comprehensive approach to reassembling your engine components efficiently and accurately. Following these steps will ensure that each part fits together correctly, restoring optimal performance.

-

Gather all necessary components and tools before beginning the process. This will streamline your efforts and minimize interruptions.

-

Start by aligning the main housing pieces. Ensure that all seals and gaskets are in place to prevent leaks.

-

Attach the power head to the lower unit, making sure to securely fasten each bolt to the specified torque settings.

-

Next, install the fuel system components. Verify that all hoses are connected correctly and free from obstructions.

-

Reconnect the electrical systems. Double-check connections to ensure they are tight and correctly placed.

-

Install the cooling system parts, making sure that the water passages are clear and free from debris.

-

Finally, conduct a thorough inspection of the entire assembly. Ensure that all tools are removed and all components are secured properly.

Following this structured process will help you successfully reassemble your engine, ensuring it operates at its best.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is paramount. Proper precautions can prevent accidents and injuries, promoting a secure environment for all involved. This section outlines essential measures to consider before and during any service activities.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and safety boots.

- Ensure the workspace is well-ventilated to avoid inhalation of harmful fumes.

- Keep the area free from clutter to reduce the risk of tripping or falling.

- Use tools that are in good condition to prevent malfunctions or injuries.

Electrical Safety Measures

- Disconnect all power sources before starting any service tasks.

- Avoid working with electrical components when wet or in damp conditions.

- Inspect wiring and connections regularly to ensure there are no frayed or exposed wires.

By following these safety measures, individuals can create a safer atmosphere, minimizing the likelihood of accidents during maintenance activities.

Identifying Electrical System Problems

Diagnosing issues within the electrical framework of marine engines is crucial for maintaining optimal performance. Recognizing signs of malfunction early can prevent more severe damage and costly repairs. A systematic approach to identifying these issues can help ensure reliability on the water.

Common indicators of electrical system failures include inconsistent power delivery, flickering lights, and difficulties in starting the engine. By understanding these symptoms, users can take appropriate action to troubleshoot and resolve problems.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Inconsistent power | Loose connections or corroded terminals | Inspect and tighten connections; clean terminals |

| Flickering lights | Faulty alternator or voltage regulator | Test alternator output; replace components if necessary |

| Engine won’t start | Dead battery or starter issues | Charge or replace the battery; check starter operation |

By being vigilant and proactive in identifying these signs, users can effectively address electrical system problems and maintain their vessel’s performance.

Fuel System Cleaning and Maintenance

Ensuring optimal performance of any engine requires diligent care of its fuel delivery system. Regular cleaning and maintenance help prevent clogs and deposits that can hinder efficiency and functionality. A well-maintained system promotes better combustion and longevity of the equipment.

Begin by inspecting the fuel filter, replacing it as needed to ensure unobstructed fuel flow. It’s essential to clean or replace any clogged components, including injectors and lines, to maintain proper pressure and performance. Using a high-quality fuel additive can also aid in keeping the system clean, breaking down deposits and preventing future buildup.

Periodic checks for leaks and ensuring all connections are secure will help avoid potential issues. Additionally, draining old fuel and replacing it with fresh gasoline can significantly enhance the overall efficiency of the engine. This proactive approach will not only improve performance but also extend the lifespan of critical components.

Understanding Propeller Selection Criteria

Choosing the right propeller is essential for optimizing performance and efficiency in marine applications. This decision involves evaluating various factors that influence the overall operation and effectiveness of the vessel.

Key elements to consider include size, pitch, material, and design type. Each aspect plays a significant role in how the craft performs under different conditions.

| Criteria | Description |

|---|---|

| Diameter | The distance across the circle formed by the blades, affecting speed and thrust. |

| Pitch | The angle of the blades, determining how far the boat moves with each rotation. |

| Material | Common options include aluminum, stainless steel, and composite, each with unique characteristics. |

| Blade Design | Various shapes and numbers of blades can impact acceleration and fuel efficiency. |

By carefully assessing these criteria, one can make an informed choice that enhances the overall performance and longevity of the vessel.

Diagnosing Overheating Issues

Overheating can significantly impact the performance and longevity of your marine engine. Identifying the root causes of excessive heat is essential to ensure optimal functionality. This section outlines the common factors contributing to elevated temperatures and offers guidance on troubleshooting methods.

Begin by checking the cooling system, as blockages or leaks can hinder effective temperature regulation. Inspect hoses, thermostats, and water pumps for any signs of wear or obstruction. A malfunctioning component in this system is often the primary culprit behind overheating.

Next, evaluate the engine’s operation parameters. Ensure that the fuel mixture is appropriate and that the ignition system is functioning correctly. An imbalance in fuel supply or ignition timing can lead to increased engine temperature.

Finally, monitor the environment in which the engine operates. High ambient temperatures or prolonged use at low speeds may contribute to overheating. Adjusting usage patterns can help mitigate these issues, ensuring a cooler operating temperature.

Best Practices for Winter Storage

Proper seasonal storage is essential for maintaining the longevity and performance of your marine equipment. Following a few key guidelines can help prevent damage and ensure your gear is ready for the next boating season.

Begin by thoroughly cleaning the equipment, removing any dirt, debris, or salt residue. This helps to prevent corrosion and mold growth during the off-season. Next, consider the following maintenance steps:

| Task | Description |

|---|---|

| Drain Fluids | Remove fuel and oil to avoid contamination and deterioration during storage. |

| Protect from Moisture | Store in a dry, well-ventilated area to prevent rust and mildew. |

| Cover the Equipment | Use a breathable cover to shield from dust and moisture while allowing ventilation. |

| Check Battery | Disconnect and store in a warm location, charging periodically to maintain health. |

| Inspect and Repair | Look for any signs of wear or damage and address them before the next use. |

By adhering to these best practices, you can significantly extend the lifespan of your equipment and ensure it is in optimal condition when spring arrives.

Locating Replacement Parts and Accessories

Finding suitable components and add-ons for your marine engine is essential for maintaining its performance and longevity. With a variety of options available, knowing where to look can save time and ensure you obtain high-quality items.

Begin by checking with authorized distributors who specialize in marine equipment. These retailers often carry a comprehensive selection of parts designed specifically for your engine model, ensuring compatibility and reliability. Additionally, online marketplaces provide a convenient platform to compare prices and availability across multiple sellers.

Another valuable resource is dedicated forums and communities focused on boating and engine maintenance. Engaging with fellow enthusiasts can lead to recommendations for reputable suppliers and insights on aftermarket alternatives that may suit your needs.

Finally, consider visiting local salvage yards or marine repair shops. These places can sometimes offer hard-to-find components at a fraction of the cost, while also providing the opportunity to consult with knowledgeable professionals about your specific requirements.