Proper upkeep of a two-wheeled vehicle is essential for ensuring optimal performance and longevity. Understanding the intricacies of its components and systems allows owners to maintain their ride effectively. This section delves into the key aspects of maintenance, providing insights into troubleshooting and enhancing the overall riding experience.

Regular checks are crucial for identifying potential issues before they escalate. By following a systematic approach to inspections, enthusiasts can address wear and tear, ensuring their vehicle remains in peak condition. This guide outlines various procedures that can help in preserving the integrity of your machine.

In addition to routine maintenance, enhancing performance through adjustments and upgrades is a rewarding endeavor. Knowledge of essential modifications can lead to improved efficiency and responsiveness, catering to the rider’s preferences. This comprehensive overview will equip owners with the necessary tools to navigate their maintenance journey successfully.

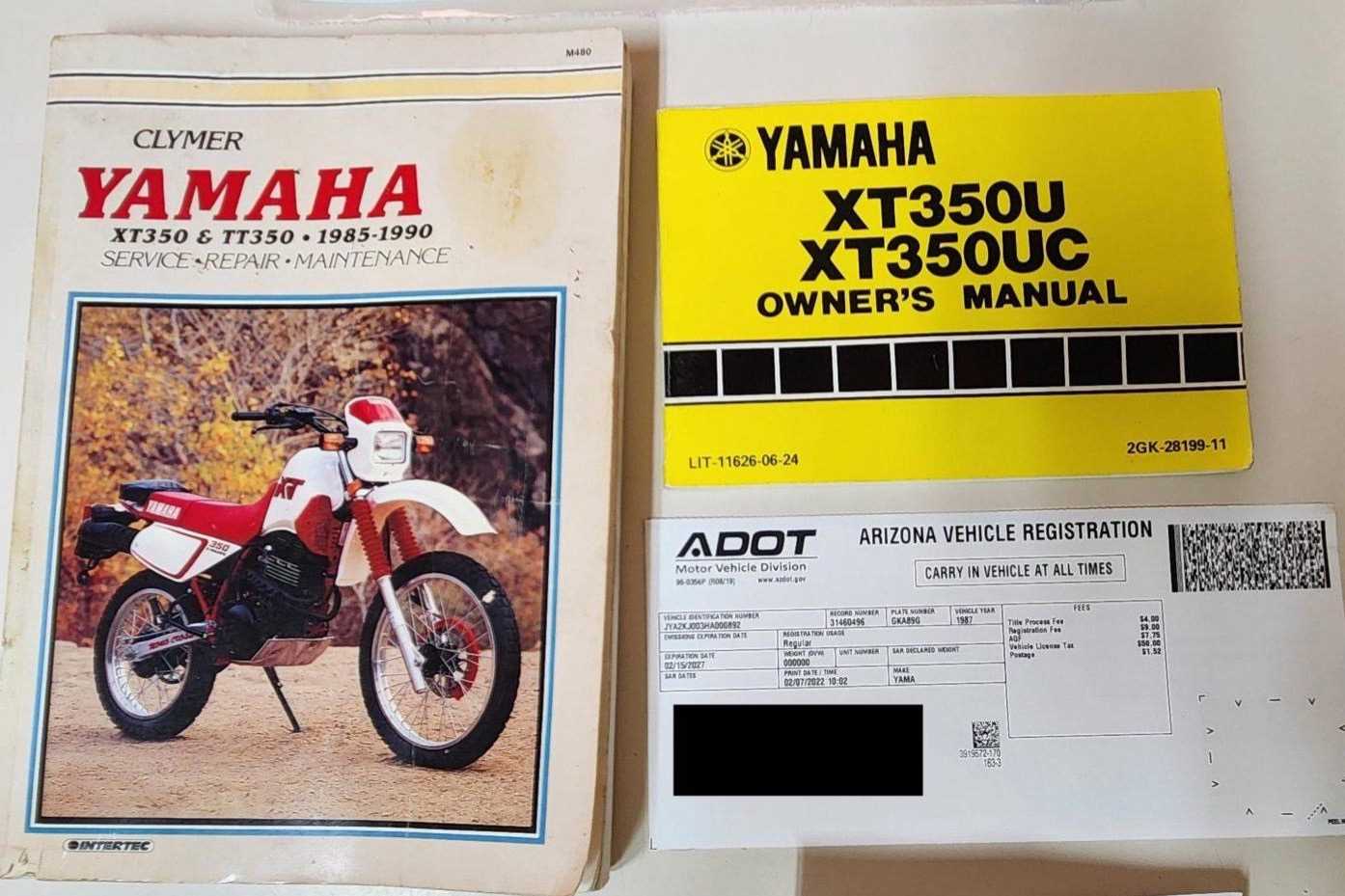

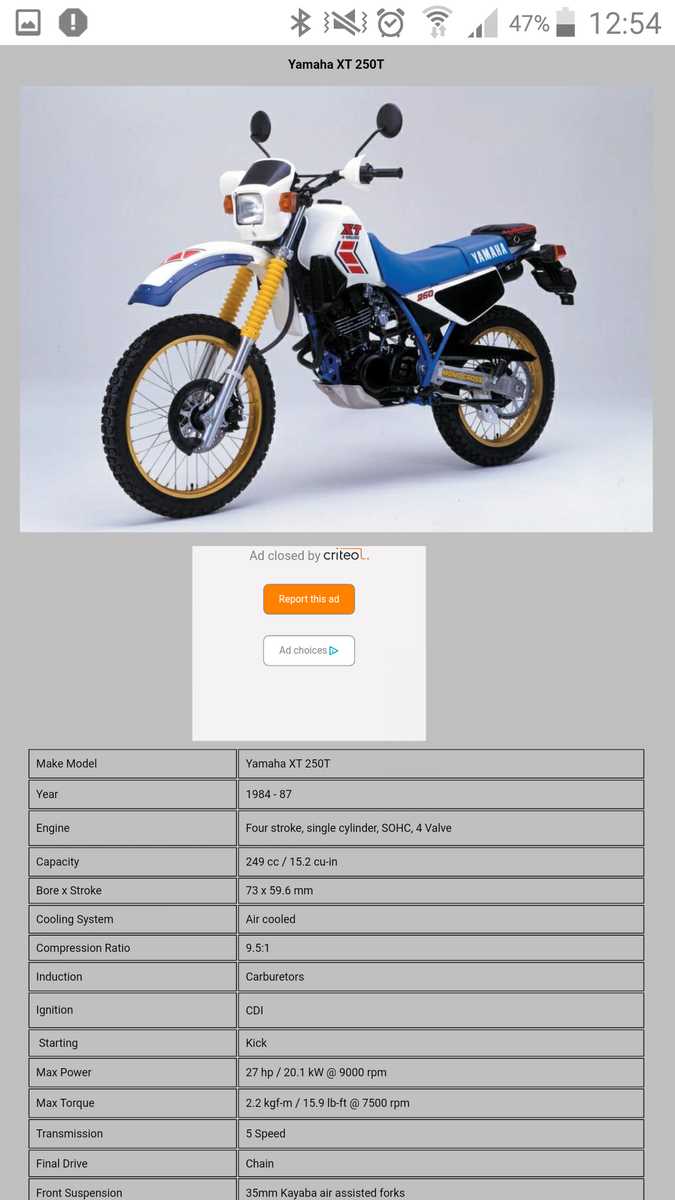

This section provides an insightful introduction to a versatile two-wheeled vehicle known for its reliability and performance. Designed for both on-road and off-road adventures, it has captured the attention of enthusiasts and riders alike. Understanding its features and capabilities can enhance the riding experience and ensure optimal maintenance practices.

Key Features

This vehicle boasts several characteristics that make it a favorite among riders. Below are some essential attributes:

| Attribute | Description |

|---|---|

| Engine Type | Single-cylinder, air-cooled design |

| Displacement | Close to 350cc |

| Weight | Lightweight, enhancing maneuverability |

| Suspension | Long-travel front and rear suspension for comfort |

Performance Overview

The riding experience is complemented by a balance of power and efficiency. The engine provides ample torque, making it suitable for various terrains. Riders appreciate its agility and stability, especially in challenging conditions. Regular maintenance is key to preserving its functionality and enhancing its lifespan.

Common Issues with XT350

This section discusses frequent problems encountered with this particular two-wheeler model. Understanding these issues can assist riders in maintaining optimal performance and enhancing their overall experience.

Engine Performance Troubles

Many users report difficulties related to engine functionality, such as inconsistent idling or reduced power output. These symptoms may arise from factors like fuel system blockages or ignition faults. Regular inspections can help identify underlying causes and ensure smoother operation.

Electrical System Challenges

Electrical malfunctions are another prevalent concern. Riders often experience issues with lighting or battery performance, which can stem from faulty wiring or degraded components. Addressing these problems promptly is crucial for safe riding conditions.

Essential Tools for Repairs

When it comes to maintaining and fixing motorized vehicles, having the right instruments is crucial. A well-equipped toolkit not only facilitates efficient work but also enhances safety and accuracy during the process. Below are some key tools that every enthusiast should consider having on hand.

Basic Hand Tools

- Wrenches: Adjustable and socket wrenches for various nut sizes.

- Screwdrivers: A selection of flathead and Phillips screwdrivers for different screws.

- Pliers: Needle-nose and cutting pliers for gripping and cutting wires.

- Torque Wrench: To ensure proper tightness on critical fasteners.

Specialized Equipment

- Jack and Stands: For lifting and securely supporting the vehicle.

- Diagnostic Tools: Electronic testers and multimeters to troubleshoot electrical issues.

- Oil Filter Wrench: For easy removal of oil filters during maintenance.

- Chain Tool: For adjusting or replacing the drive chain when necessary.

Equipping yourself with these essential instruments will significantly enhance your ability to tackle various maintenance tasks effectively.

Step-by-Step Maintenance Guide

This section provides a detailed approach to ensuring optimal performance and longevity of your two-wheeled vehicle. Following a systematic routine can help identify potential issues before they escalate, making maintenance a straightforward and effective process.

Essential Tools and Supplies

- Socket set

- Wrenches

- Oil filter wrench

- Torque wrench

- Cleaning materials

Maintenance Tasks

- Check Oil Levels: Regularly inspect and replace engine oil as needed to maintain engine health.

- Inspect Tires: Examine tire pressure and tread for safety and performance.

- Clean Air Filter: Ensure the air filter is clean to support optimal engine breathing.

- Brake Inspection: Regularly check brake pads and fluid levels for safe stopping power.

- Chain Maintenance: Lubricate and adjust the chain to ensure smooth operation.

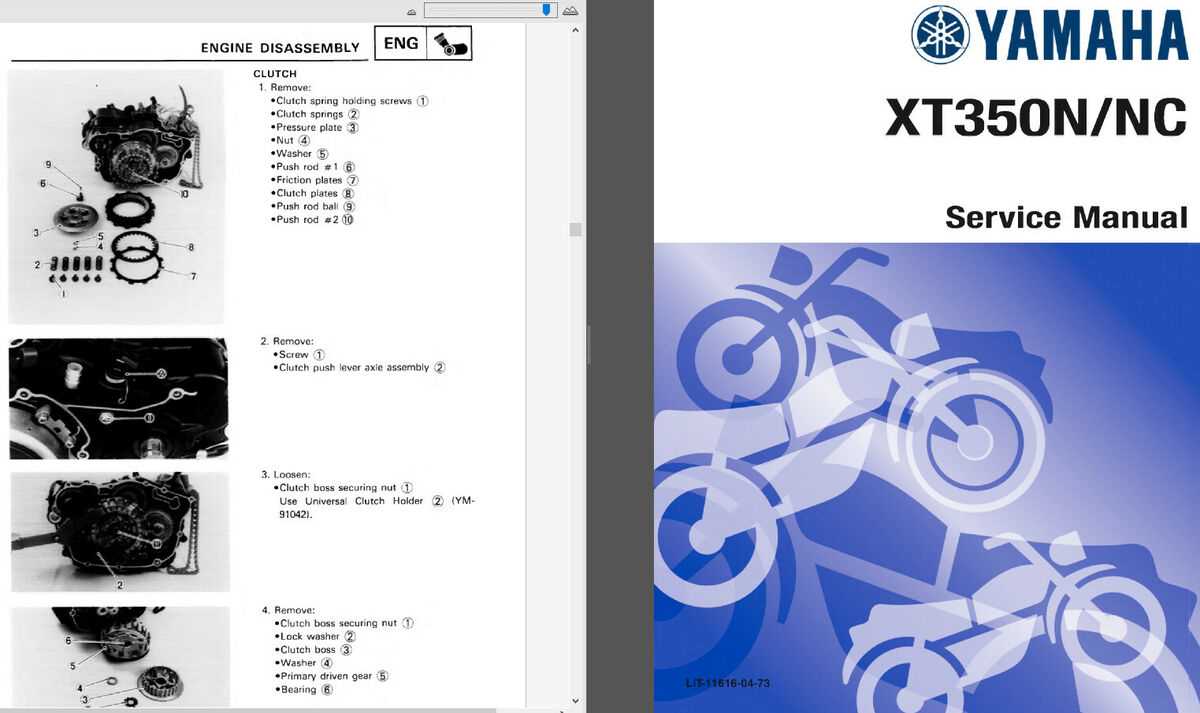

Engine Troubleshooting Techniques

Diagnosing issues within an engine is essential for maintaining optimal performance. By understanding common problems and their symptoms, one can effectively identify the root causes of malfunctions. This section outlines various methods to pinpoint and resolve engine-related challenges.

Begin by conducting a thorough visual inspection. Look for any obvious signs of wear, leaks, or damage. Ensure that all connections are secure and that no hoses are cracked or disconnected. Pay attention to unusual noises, as they can provide vital clues about underlying issues.

Next, utilize diagnostic tools such as compression gauges and multimeters. Measuring compression in each cylinder can reveal problems with valves or piston rings. An electrical tester can help assess the functionality of ignition components and wiring. These tools aid in narrowing down potential faults efficiently.

Additionally, monitoring engine performance during operation is crucial. Note any irregularities in acceleration, idling, or fuel consumption. This real-time data can help pinpoint issues with fuel delivery or ignition timing, guiding further investigation.

Lastly, refer to technical resources and forums where experienced individuals share insights. Learning from others’ experiences can provide valuable strategies and techniques for troubleshooting engine problems effectively.

Electrical System Diagnostics

Understanding the intricacies of the electrical framework in a vehicle is crucial for ensuring optimal performance. This segment focuses on identifying and troubleshooting issues within the electrical components, which can significantly impact the overall functionality.

Begin the diagnostic process by checking the battery voltage. A fully charged battery should read around 12.6 volts or higher. If the voltage is low, it may indicate a need for charging or replacement. Next, examine the connections and cables for signs of corrosion or wear, which can lead to poor conductivity.

Utilize a multimeter to assess the continuity of various circuits. This tool can help verify whether the electrical current flows correctly through the system. Additionally, testing individual components, such as fuses and relays, ensures that each part functions as intended.

It is also advisable to consult the electrical schematic for specific configurations and wiring diagrams. This reference can aid in locating issues and understanding the relationships between different parts. Regular diagnostics not only prevent unexpected breakdowns but also enhance the longevity of the vehicle’s electrical system.

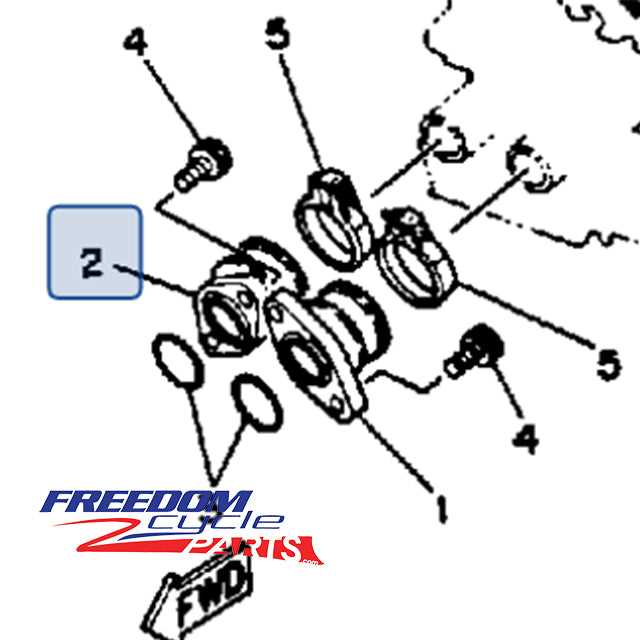

Carburetor Cleaning Procedures

Maintaining the fuel delivery system is crucial for optimal engine performance. Regular cleaning of the carburetor helps to prevent blockages and ensures smooth operation. This process enhances fuel efficiency and extends the life of the engine components.

Required Tools and Materials

Before beginning the cleaning process, gather the necessary tools and materials. Essential items include a socket set, screwdrivers, a carburetor cleaner solution, a soft brush, and safety gloves. Having these items ready will facilitate a more efficient cleaning experience.

Cleaning Steps

Start by removing the carburetor from the engine. Carefully disassemble it, taking note of the parts’ arrangement. Soak the components in a carburetor cleaner for the recommended duration. After soaking, use a soft brush to remove any remaining deposits. Rinse the parts with clean solvent and allow them to dry completely before reassembly. Ensure all gaskets are replaced to avoid air leaks.

Brake System Inspection Tips

Regular examination of the braking components is crucial for ensuring optimal safety and performance. This section outlines key practices to effectively assess the braking system, allowing for timely detection of potential issues.

Visual Inspection

Begin by conducting a thorough visual inspection of all brake components. Look for signs of wear, leaks, or damage that could compromise functionality. Pay special attention to:

- Brake pads and shoes for thickness

- Brake lines for cracks or abrasions

- Calipers and cylinders for fluid leaks

Functional Testing

In addition to visual checks, performing functional tests is essential. Ensure that the brakes respond appropriately when applied. This can be assessed by:

- Pressing the brake lever or pedal to evaluate responsiveness

- Listening for unusual noises during operation

- Checking for vibrations or pulling to one side

| Component | Inspection Frequency | Notes |

|---|---|---|

| Brake Pads | Every 1,000 miles | Replace if less than 1/8 inch thickness |

| Brake Fluid | Every 2 years | Check moisture content; replace if necessary |

| Brake Lines | Every 5,000 miles | Inspect for leaks and wear |

Wheel and Tire Maintenance

Proper upkeep of wheels and tires is essential for optimal performance and safety. Regular inspections and maintenance can extend the lifespan of these components and enhance the overall riding experience.

Regular Inspection

Conducting frequent checks can prevent potential issues. Focus on the following aspects:

- Tread depth: Ensure sufficient tread for traction.

- Air pressure: Maintain recommended levels for better handling.

- Visual damage: Look for cracks, punctures, or bulges.

Cleaning and Protection

Keeping wheels and tires clean is vital. Consider these steps:

- Wash with mild soap and water to remove dirt and debris.

- Use a brush to clean hard-to-reach areas.

- Apply a protective spray to enhance durability and appearance.

Upgrading Yamaha XT350 Components

Enhancing your motorcycle’s performance and longevity involves strategic upgrades to its various parts. By focusing on key components, riders can significantly improve handling, speed, and overall riding experience. This section outlines some essential modifications that can elevate your two-wheeler’s capabilities.

Engine Performance Enhancements

Boosting engine efficiency can lead to noticeable improvements in power output. Consider installing a high-performance air filter and optimizing the exhaust system. These modifications allow for better airflow, which can enhance combustion and overall engine response. Additionally, tuning the carburetor can fine-tune the air-fuel mixture for optimal performance.

Suspension and Handling Improvements

Upgrading the suspension system is crucial for achieving better handling and comfort. Replacing stock forks with aftermarket options can provide improved damping and adjustability, catering to different riding conditions. Moreover, investing in quality tires will not only enhance grip but also contribute to a smoother ride.

Safety Precautions for Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions ensure a secure environment, allowing for efficient and effective work.

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Ensure that the workspace is well-ventilated to avoid inhaling harmful fumes or dust.

- Keep tools organized and within reach to prevent unnecessary movement and distractions.

- Disconnect the power source or remove the battery before starting any work to prevent electrical hazards.

- Be aware of your surroundings and ensure that the area is free of clutter to reduce trip hazards.

Adhering to these guidelines contributes to a safer working environment and enhances the overall quality of the task at hand.