In the realm of aquatic adventures, ensuring the optimal performance of your vessel’s propulsion system is paramount. Whether you are an avid fisherman or a leisurely cruiser, understanding the intricacies of your engine can enhance your experience on the water. This section delves into the essential knowledge and techniques required for keeping your marine engine in peak condition.

With various components working in harmony, maintaining your engine not only prolongs its lifespan but also ensures safety and efficiency during your voyages. Familiarizing yourself with troubleshooting methods, routine inspections, and essential upkeep tasks can save both time and resources. This guide serves as a valuable resource for enthusiasts looking to master their vessel’s mechanics.

From basic maintenance procedures to more complex adjustments, the insights provided here aim to empower you with the confidence needed to tackle engine-related challenges. By prioritizing care and attention to detail, you can enjoy the thrill of the open water without the worry of mechanical failures.

Overview of Yamaha Outboards

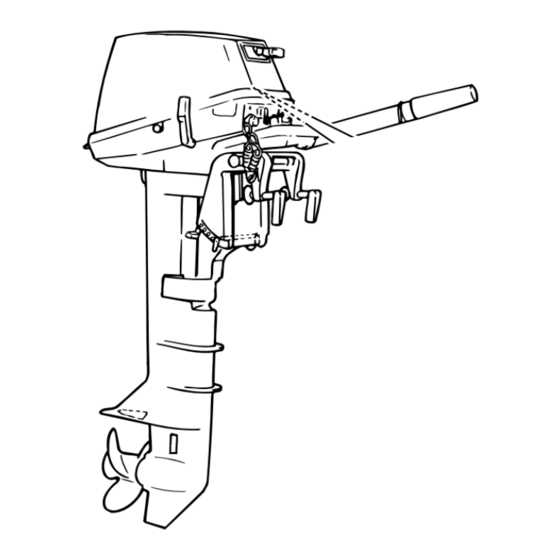

This section provides a comprehensive look into the world of marine propulsion systems, emphasizing their design, functionality, and benefits. Understanding these mechanisms is essential for both enthusiasts and professionals alike, as they play a crucial role in enhancing the boating experience.

Key Features

- Robust Engine Performance

- Fuel Efficiency

- Lightweight Construction

- Advanced Technology Integration

Types of Marine Motors

- Two-Stroke Engines

- Four-Stroke Engines

- Electric Motors

These propulsion systems cater to various boating needs, providing options for different activities, from leisurely cruising to high-speed adventures.

Common Issues in 2006 Models

Various marine engines from this era exhibit a range of typical problems that can affect performance and reliability. Understanding these common challenges can aid in proactive maintenance and ensure smooth operation on the water.

Fuel System Difficulties: One frequent issue involves the fuel delivery system. Clogs in the fuel filters or lines can lead to reduced engine efficiency and unexpected shutdowns. Regular inspections and timely replacements are essential to avoid these complications.

Cooling System Failures: Overheating is another concern, often caused by blockages in the cooling passages or a malfunctioning water pump. Keeping the cooling system clean and functional is critical for preventing serious engine damage.

Electrical Component Malfunctions: Electrical issues, such as faulty wiring or corroded connectors, can disrupt ignition and starting processes. Routine checks of the electrical system can help identify and rectify these problems before they escalate.

Wear and Tear on Components: Standard wear on parts like spark plugs, impellers, and seals can lead to diminished performance. Regular maintenance and timely replacements are vital to ensure optimal functionality and longevity of the engine.

Being aware of these prevalent issues can empower owners to take preventive measures, ultimately enhancing the overall performance and reliability of their marine engines.

Essential Tools for Repairs

When undertaking maintenance on marine equipment, having the right instruments at your disposal is crucial for ensuring efficiency and effectiveness. This section outlines the fundamental items that every enthusiast should consider for their toolkit, enabling smoother tasks and enhancing overall performance.

Basic Hand Tools

Essential hand tools form the foundation of any maintenance kit. These items not only facilitate disassembly and assembly but also contribute to the precision required in various operations.

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening and tightening bolts and nuts. |

| Screwdrivers | Essential for fastening or removing screws of different types. |

| Pliers | Great for gripping, twisting, and cutting wires or small parts. |

| Socket Set | Facilitates quick adjustments to various sizes of nuts and bolts. |

Specialized Equipment

In addition to basic tools, certain specialized equipment can significantly enhance your capabilities during maintenance tasks. These tools address specific needs and help tackle more complex issues effectively.

| Tool | Purpose |

|---|---|

| Multimeter | Measures electrical voltage, current, and resistance. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Fuel Line Cutter | Provides clean cuts on fuel lines to prevent leaks. |

| Marine Grease Gun | Essential for lubrication, preventing corrosion and wear. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of marine engines. Following a systematic approach allows for effective identification and resolution of potential issues. This section outlines a comprehensive guide to performing maintenance tasks that enhance reliability and efficiency.

Pre-Maintenance Checklist

Before commencing any service work, it’s crucial to gather the necessary tools and materials. The following table provides a checklist to help you prepare for maintenance tasks:

| Tools | Materials |

|---|---|

| Wrenches | Oil |

| Screwdrivers | Filters |

| Multimeter | Fuel |

| Cleaning supplies | Grease |

Basic Maintenance Steps

Once the necessary items are gathered, follow these steps to perform essential maintenance:

- Check and replace the oil and filter to ensure smooth engine operation.

- Inspect the fuel system for leaks or blockages, and replace filters as needed.

- Examine the cooling system, ensuring that all hoses are clear and connections are secure.

- Test electrical components, including batteries and wiring, for proper functionality.

- Clean the exterior of the engine to prevent corrosion and maintain aesthetics.

Understanding the Engine Components

Gaining insight into the various parts of a marine propulsion system is essential for effective maintenance and optimal performance. Each element plays a crucial role in ensuring smooth operation and reliability. Familiarity with these components allows operators to diagnose issues more accurately and implement appropriate solutions.

Main Parts of the Engine

- Powerhead: The core assembly that houses the cylinders and ignition system.

- Crankshaft: Converts the linear motion of the pistons into rotational motion.

- Pistons: Move up and down within the cylinders to create the power necessary for propulsion.

- Fuel System: Responsible for delivering the correct fuel mixture to the engine.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

Supporting Components

- Exhaust System: Channels exhaust gases away from the engine.

- Electrical System: Powers ignition, lights, and other electronic components.

- Lubrication System: Ensures that moving parts are adequately lubricated to reduce wear.

- Gearcase: Houses the gears that transmit power from the engine to the propeller.

Understanding these components and their functions is vital for anyone involved in marine engine operation or maintenance. By recognizing how each part contributes to overall performance, individuals can better appreciate the complexities of these systems and address potential problems effectively.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can be crucial for optimal performance. A systematic approach is essential to pinpoint the root causes of malfunctions in the electrical system. This section will guide you through various strategies to diagnose and rectify common complications effectively.

Check the Battery: Begin by inspecting the power source. Ensure that the battery is fully charged and connections are secure. Corroded terminals can lead to insufficient power delivery, so clean any buildup and tighten loose connections.

Examine Fuses and Circuits: Next, assess the fuses for any signs of damage or breakage. A blown fuse can interrupt the electrical flow, leading to system failures. If a fuse is blown, replace it with one of the same amperage to restore functionality.

Inspect Wiring and Connectors: Faulty wiring can cause intermittent issues. Check all wiring for wear, fraying, or disconnection. Ensure that connectors are free from dirt and corrosion, which can impede electrical flow.

Test the Switches and Controls: If you’re experiencing inconsistent operation, inspect the switches and controls. Use a multimeter to verify their functionality. A malfunctioning switch may need to be replaced to ensure proper operation.

Evaluate Ground Connections: Poor grounding can lead to various electrical problems. Make sure all ground connections are secure and free from corrosion. A solid ground is vital for reliable system performance.

By following these troubleshooting steps, you can systematically identify and resolve electrical issues, ensuring your equipment operates smoothly and efficiently.

Fuel System Inspection Tips

Regular examination of the fuel delivery components is crucial for ensuring optimal performance and reliability. Understanding how to effectively inspect these systems can help identify potential issues before they escalate, maintaining the overall efficiency of the engine.

Visual Checks

Start by visually inspecting fuel lines for any signs of wear, leaks, or damage. Ensure that connections are secure and free from corrosion. Pay close attention to filters; a clogged filter can restrict fuel flow, leading to poor engine performance.

Testing Fuel Quality

Assess the quality of the fuel by examining its color and consistency. Contaminated fuel can cause significant problems. It’s advisable to periodically test for water or debris, as these elements can compromise the fuel system’s integrity. Replacing old fuel with fresh can enhance performance and reduce the risk of engine issues.

Gearbox and Propeller Maintenance

Proper upkeep of the gearbox and propeller system is essential for optimal performance and longevity of marine engines. This segment highlights the critical practices necessary to ensure these components operate smoothly and efficiently, minimizing wear and enhancing overall functionality.

Inspection and Cleaning

Regular examination of the gearbox is vital. Look for any signs of leakage or corrosion, which can compromise performance. Clean all external surfaces to prevent the buildup of debris and salt, which can lead to premature deterioration. Additionally, ensure that the propeller is free from any obstructions, as this can affect propulsion efficiency.

Lubrication and Adjustment

Maintaining proper lubrication is crucial for the gearbox. Use the recommended type of lubricant and check levels frequently. If necessary, replace old oil to ensure smooth operation. For propellers, inspect the blades for nicks or damage and adjust them as needed to maintain the correct pitch, which is vital for performance. Regular maintenance routines will significantly extend the life of these essential components.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance on marine engines. Adhering to specific guidelines can prevent accidents and injuries, allowing you to focus on the task at hand.

Essential Guidelines

- Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes and gases.

- Keep a fire extinguisher nearby, as flammable materials are often present.

- Ensure that the engine is turned off and disconnected from any power source before beginning any work.

- Be aware of your surroundings and ensure the workspace is free of clutter and hazards.

Handling Tools and Materials

- Use tools that are specifically designed for the tasks you are undertaking.

- Inspect tools for any signs of damage before use, replacing any that are defective.

- Store hazardous substances, such as oils and chemicals, in labeled containers away from direct sunlight and heat sources.

- Dispose of waste materials properly, following local regulations to prevent environmental harm.

By following these precautions, you can significantly reduce risks associated with maintenance activities, ensuring a safer and more efficient experience.

When to Seek Professional Help

Recognizing when to call in an expert can significantly enhance the longevity and performance of your marine engine. While many enthusiasts enjoy tackling minor issues, some problems require specialized knowledge and tools that only a professional can provide.

Signs of Complex Issues

Pay attention to persistent malfunctions or unusual noises that don’t resolve with basic troubleshooting. Leakage or overheating are critical indicators that intervention is necessary. Ignoring these signs can lead to more severe damage.

Maintenance Knowledge Gaps

If you’re uncertain about the appropriate maintenance procedures or lack the necessary skills, it’s wise to consult a technician. Investing in expert assistance can save time and prevent costly mistakes in the long run.

Parts Replacement and Upgrades

Maintaining the performance of your marine engine is crucial for an enjoyable experience on the water. Regularly updating and substituting components can enhance efficiency, prolong the lifespan of your equipment, and ensure safety. Understanding the various parts that can be replaced or upgraded is essential for optimal operation.

Identifying worn-out components is the first step in the process. Parts such as spark plugs, filters, and propellers can significantly impact performance. Regular inspections allow you to spot signs of wear and take appropriate action. If a component is showing decreased functionality, it’s time to consider a replacement.

Upgrades can provide additional benefits beyond standard replacements. For instance, choosing a high-performance propeller can improve speed and fuel efficiency. Investing in quality materials often yields better results, as they tend to resist wear and tear more effectively. Additionally, modern technology may offer advanced features, such as enhanced corrosion resistance, which is crucial for marine environments.

Consulting with professionals or utilizing trusted resources can guide you in selecting the right parts. Proper installation is equally important, as incorrect fitting can lead to further complications. By focusing on both replacement and upgrades, you ensure your marine engine operates at its best for many outings to come.