Every household relies on its essential devices to perform efficiently and reliably. When these appliances encounter issues, it can disrupt daily routines and create unnecessary stress. Knowing how to address common problems can not only save time but also extend the lifespan of the equipment.

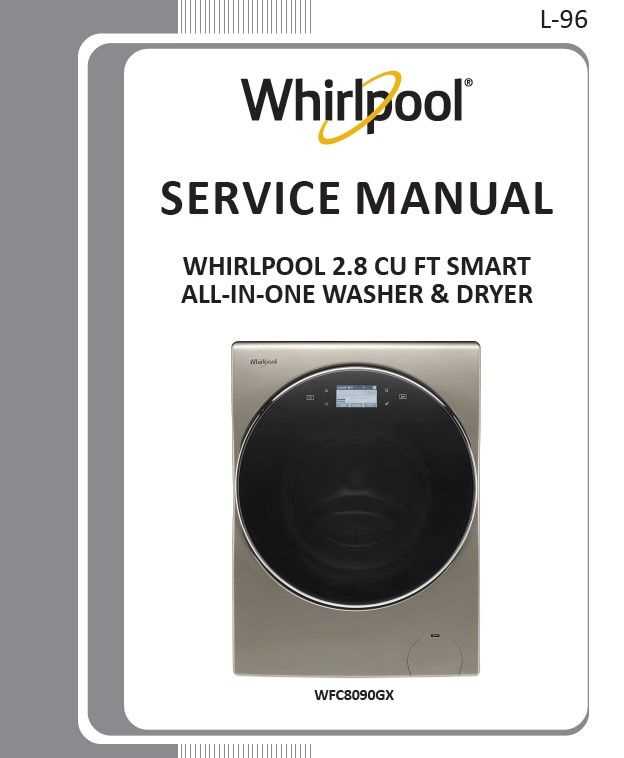

In this comprehensive guide, we delve into the intricacies of one particular model that has garnered significant attention for its performance and reliability. By familiarizing yourself with its components and potential issues, you will be better equipped to handle any challenges that may arise.

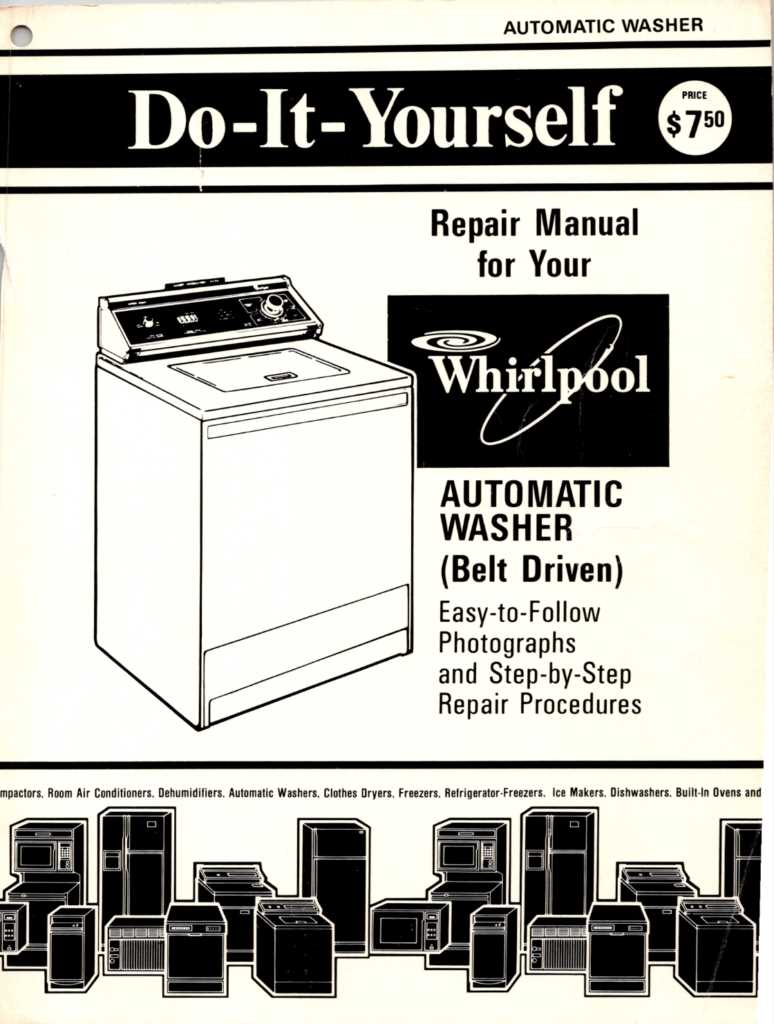

Arming yourself with the right information empowers you to tackle simple fixes with confidence. This resource will provide insights into typical malfunctions, effective troubleshooting techniques, and preventative measures to maintain optimal function. Whether you’re facing a minor hiccup or a more significant concern, understanding your appliance is the first step toward restoring its efficiency.

Understanding Your Whirlpool Washer

When it comes to managing household tasks, having a reliable appliance can make all the difference. This section will delve into the key features and functionalities of your unit, helping you to better appreciate its design and operation. With a thorough understanding, you can maximize its efficiency and longevity.

First and foremost, it’s essential to recognize the various settings and cycles available. Each option is tailored to handle specific types of fabrics and soil levels, ensuring that your garments receive the care they deserve. Familiarizing yourself with these features allows for optimized cleaning while preserving the quality of your items.

Additionally, maintenance plays a crucial role in keeping your appliance running smoothly. Regular checks on components, such as the drum, agitator, and filters, can prevent minor issues from escalating into major problems. Understanding how to perform these tasks can save you time and money in the long run.

Lastly, knowing the common indicators of potential issues can empower you to take action before a breakdown occurs. Whether it’s unusual noises, leaks, or error codes, being proactive can help maintain the performance of your machine.

Common Issues with Top Load Washers

Household appliances often encounter a range of problems that can disrupt laundry routines. Understanding these challenges can help in troubleshooting and maintaining functionality. Below are some frequent concerns experienced with these types of machines, along with potential causes and solutions.

Unusual Noises

One of the most common complaints involves unexpected sounds during operation. These noises may indicate issues such as loose components, foreign objects caught in the drum, or worn bearings. Regular maintenance and prompt attention to unusual sounds can prevent further damage.

Drainage Problems

Another prevalent issue is ineffective drainage, resulting in water accumulation after cycles. This can stem from clogs in the drain hose or pump malfunctions. Inspecting hoses for blockages and ensuring proper installation can often resolve this issue, allowing for efficient water removal.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing common issues that may arise with your appliance. By following these structured steps, you can identify problems effectively and take appropriate measures to resolve them.

Identify the Issue

Start by observing the symptoms. Is the machine failing to start, not spinning, or leaking? Make a list of the specific problems you notice. This will help you narrow down potential causes and streamline the troubleshooting process.

Follow Diagnostic Steps

Begin with basic checks, such as ensuring that the device is plugged in and that the outlet is functioning. Next, examine the water supply; confirm that valves are open and hoses are not kinked. If the machine operates but exhibits irregular behavior, refer to the appliance’s operational guidelines for troubleshooting tips on each identified issue.

Note: Documenting your observations and actions can be beneficial for future reference or if professional assistance becomes necessary.

By systematically working through these steps, you can often resolve many common issues on your own, saving time and resources.

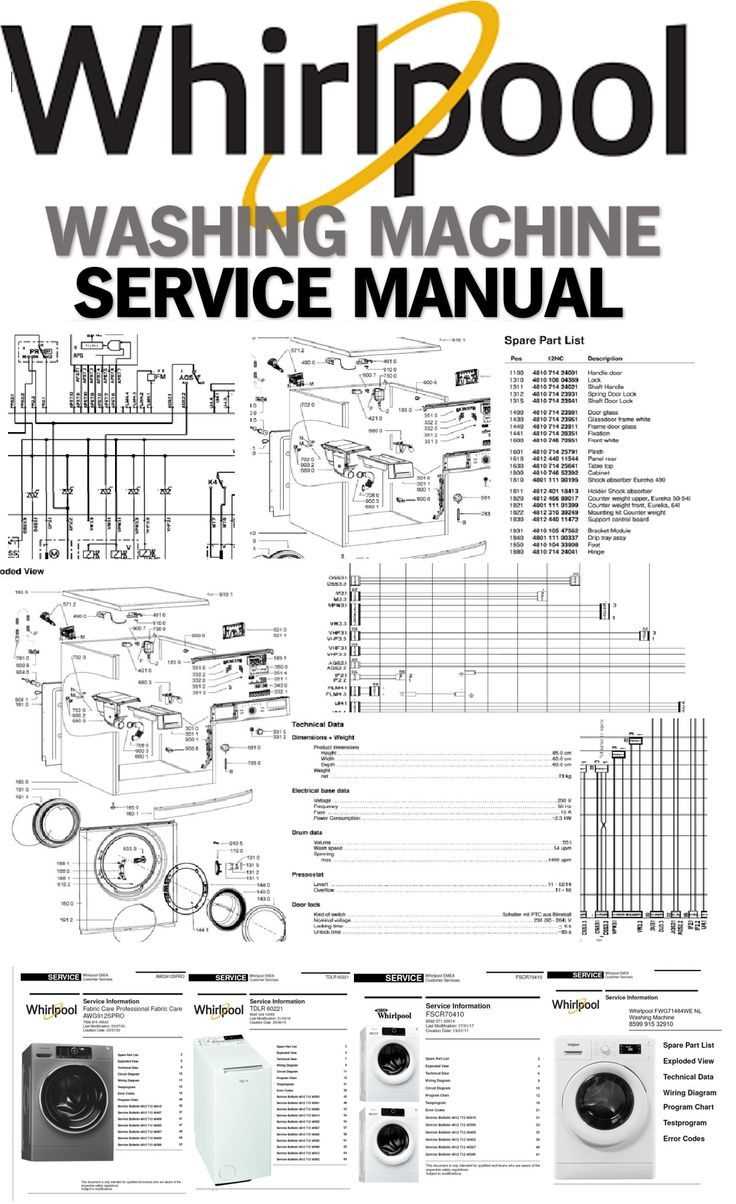

Essential Tools for Repairing Washers

When it comes to maintaining and fixing household appliances, having the right equipment can make all the difference. Whether you are troubleshooting minor issues or conducting more extensive work, the appropriate tools will enhance your efficiency and effectiveness. Below is a guide to the must-have instruments that every technician should consider in their toolkit.

1. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are essential for removing and securing panels. These basic tools allow for easy access to internal components.

2. Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening nuts and bolts. Their versatility makes them indispensable when working with various fittings and connections.

3. Pliers: Needle-nose and slip-joint pliers are helpful for gripping and manipulating wires and small parts, especially in tight spaces.

4. Multimeter: This device is vital for diagnosing electrical issues. It measures voltage, current, and resistance, enabling a precise assessment of the appliance’s functionality.

5. Replacement Parts: Keeping a stock of commonly needed components, such as belts, seals, and filters, can save time and ensure quick fixes when issues arise.

6. Cleaning Supplies: Maintaining cleanliness is crucial for the longevity of appliances. Use brushes and cloths to remove dust and debris from internal areas.

7. Safety Gear: Protecting oneself is paramount. Gloves and safety goggles should always be on hand to prevent injuries during maintenance tasks.

Equipping yourself with these tools will not only simplify the process of appliance maintenance but also contribute to achieving optimal performance and extending the life of your equipment.

How to Access Internal Components

Accessing the internal parts of a home appliance is a crucial step for troubleshooting and performing maintenance. This process requires careful attention to detail to ensure safety and prevent damage. Understanding the layout and mechanisms involved will help streamline any repair efforts.

Safety Precautions

Before attempting to open the unit, it is essential to take the following safety measures:

| Step | Action |

|---|---|

| 1 | Unplug the appliance to eliminate electrical hazards. |

| 2 | Gather necessary tools, such as screwdrivers and pliers. |

| 3 | Wear protective gloves to avoid injury from sharp edges. |

Accessing the Interior

To reach the internal components, follow these general steps:

- Remove any screws securing the outer casing.

- Gently detach the front or rear panel, depending on the design.

- Locate and inspect the internal parts, ensuring that you document their arrangement for reassembly.

Replacing the Drive Belt Effectively

Replacing the drive belt is a crucial task that ensures the smooth operation of your appliance. A worn or damaged belt can lead to performance issues, making this maintenance step essential for longevity and efficiency. Here’s how to effectively carry out this procedure.

Before starting, gather the necessary tools and materials:

- Replacement drive belt

- Screwdriver set

- Pliers

- Torque wrench

- Safety gloves

Follow these steps for a successful replacement:

- Unplug the Appliance: Safety is paramount; disconnect the power source to prevent any accidents.

- Access the Interior: Remove the back or front panel using the screwdriver to expose the belt area.

- Remove the Old Belt: Carefully detach the worn belt from the pulleys. You may need to use pliers for better grip.

- Install the New Belt: Position the new belt around the motor and drive pulleys, ensuring it is aligned correctly.

- Reassemble the Appliance: Replace the panel securely, making sure all screws are tightened appropriately.

- Test the Functionality: Plug the appliance back in and run a short cycle to check for proper operation.

Regular maintenance of the drive belt not only enhances performance but also extends the life of your unit. By following these steps, you can ensure a smooth and efficient replacement process.

Fixing Water Drainage Problems

Addressing issues related to water drainage is essential for maintaining the efficiency of your appliance. When water fails to exit properly, it can lead to various complications, including damage to clothing and unpleasant odors. This section focuses on identifying common drainage issues and providing practical solutions to restore optimal performance.

Common Causes of Drainage Issues

Several factors can contribute to ineffective drainage. Blockages in hoses or filters are frequent culprits, often caused by lint, debris, or foreign objects. Additionally, improper installation or kinked hoses can prevent water from flowing freely. Understanding these potential problems is the first step toward resolving them.

Troubleshooting Steps

To tackle drainage issues, start by examining the drain hose for any visible obstructions. Ensure that it is positioned correctly and not kinked. Next, check the filter and clean it thoroughly to remove any buildup. If problems persist, inspect the drain pump for functionality, as a malfunctioning pump can hinder water removal. By systematically addressing these components, you can effectively restore your appliance’s drainage capabilities.

Electrical Components and Safety Tips

Understanding the electrical elements of your laundry appliance is crucial for ensuring both functionality and safety. Familiarizing yourself with these components can help you troubleshoot issues and maintain optimal performance.

Here are the key electrical parts commonly found in such machines:

- Power Cord: The main connection to the electrical supply.

- Control Board: The brain of the appliance, managing all operations.

- Motor: Drives the drum’s movement and functions.

- Timer: Regulates the duration of various cycles.

- Water Inlet Valve: Controls the flow of water into the drum.

- Heating Element: Used in models that require warm water.

To ensure safe handling and operation, consider the following tips:

- Always unplug the appliance before performing any maintenance or inspections.

- Inspect the power cord for any signs of damage, such as fraying or exposed wires.

- Use a multimeter to check for electrical continuity in components.

- Avoid overloading the machine, as this can strain electrical parts.

- Consult the manufacturer’s guidelines for specific voltage requirements and fuse ratings.

- Ensure proper grounding to prevent electrical shocks.

By understanding the electrical components and following safety precautions, you can enhance the longevity of your appliance while minimizing risks associated with electrical malfunctions.

Adjusting the Agitator Mechanism

Properly calibrating the stirring component is crucial for optimal performance and efficiency in any washing appliance. Over time, the agitation system may become misaligned or worn, leading to ineffective cleaning cycles. This section provides essential guidelines to ensure that the agitator functions smoothly and effectively, restoring the appliance to its intended capabilities.

Identifying Misalignment Issues

The first step in adjusting the stirring mechanism is to recognize signs of misalignment. If the clothes do not seem to be getting thoroughly cleaned or if unusual noises are present during operation, it may indicate that the agitator is not moving as it should. Inspect the attachment points and ensure that all components are securely fastened. Any looseness can affect the overall performance.

Making Adjustments

Once misalignment is confirmed, adjustments can be made. Begin by gently lifting the top of the stirring mechanism to expose the underlying components. Carefully tighten any loose screws or connections. If the agitator has an adjustable collar, check if it needs repositioning to enhance the movement. Regular maintenance and periodic checks will help maintain optimal functionality.

In conclusion, ensuring the agitator is properly calibrated not only improves washing efficiency but also prolongs the lifespan of the appliance. Regular checks and adjustments are key to maintaining high performance.

Cleaning and Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficient operation of your appliance. By following systematic cleaning and maintenance practices, you can prevent issues and enhance performance over time. This section outlines crucial steps to keep your unit in optimal condition.

Routine Cleaning: Begin by regularly wiping down the exterior surfaces with a damp cloth to remove dust and grime. For the interior, it’s advisable to run a maintenance cycle using a suitable cleaning agent to eliminate residues and odors. Pay special attention to areas that may accumulate lint or dirt, as these can affect performance.

Component Inspection: Periodically inspect the essential components, including hoses and seals. Look for any signs of wear, leaks, or blockages. Ensuring that these parts are in good condition is vital for the effective operation of the machine.

Drainage System Care: Check and clean the drainage system regularly to prevent clogs. Remove any debris from the filter and ensure that the drainage hose is positioned correctly to facilitate proper water flow.

Monthly Maintenance: Consider conducting a more thorough check-up once a month. This includes deep cleaning, checking all electrical connections, and ensuring that all parts are functioning as they should. Regular attention to these details can significantly extend the lifespan of your appliance.

Storage Tips: If the appliance is not going to be used for an extended period, ensure it is properly stored. Disconnect from power, drain any residual water, and leave the door slightly ajar to allow air circulation, preventing mold and unpleasant odors.

When to Seek Professional Help

Understanding when to call in an expert can save time, effort, and potential further damage to your appliance. While some issues can be easily addressed by the owner, others may require specialized knowledge and tools. Recognizing the signs that indicate a problem is beyond your skill level is essential for effective troubleshooting.

Common indicators that it’s time to consult a professional include persistent malfunctions, unusual noises, or leaks that don’t resolve with basic maintenance. If you notice any of the following issues, seeking assistance from a trained technician is advisable:

| Issue | When to Call a Professional |

|---|---|

| Persistent error codes | If error codes continue to appear after attempts to reset. |

| Unusual noises | If clanking, grinding, or other abnormal sounds are present. |

| Water leaks | If there are signs of water pooling or leaks despite sealing connections. |

| Failure to start | If the appliance won’t power on after checking the outlet and circuit. |

| Excessive vibration | If there is significant shaking during operation that cannot be corrected. |

Taking the right steps early on can prevent more severe issues down the line. If you’re in doubt, don’t hesitate to reach out to a qualified technician for help.

Frequently Asked Questions About Repairs

This section aims to address common inquiries related to maintenance and troubleshooting of laundry appliances. Whether you’re experiencing issues or just seeking guidance, the following questions and answers can help clarify your concerns.

- What should I do if my appliance won’t start?

- Check if it is properly plugged in.

- Inspect the circuit breaker for any tripped switches.

- Ensure the lid or door is securely closed.

- How can I fix a leaking issue?

- Examine the hoses for any signs of wear or damage.

- Ensure connections are tight and secure.

- Look for any cracks in the appliance body.

- Why is my unit making unusual noises?

- Check for loose objects inside the drum.

- Listen for signs of motor or belt issues.

- Evaluate the leveling of the appliance on the floor.

- How do I resolve an error code on the display?

- Refer to the troubleshooting guide for specific codes.

- Try resetting the machine by unplugging it for a few minutes.

- Contact customer support if the issue persists.

These are just a few of the frequently asked questions that can guide users in addressing their concerns effectively. For more detailed assistance, consider consulting additional resources or professionals.