When your household laundry device encounters issues, it can disrupt your daily routine and lead to frustration. Understanding the common problems and their solutions can help restore functionality efficiently. This guide provides insights into various aspects of maintenance and troubleshooting for your appliance, ensuring you can tackle minor faults with confidence.

In the realm of home appliances, familiarity with the components and their operations is essential. By acquiring knowledge about the inner workings of your unit, you will be better equipped to diagnose issues and implement effective solutions. This resource aims to empower users with practical information and step-by-step instructions, enabling them to manage their equipment with ease.

From understanding error codes to exploring potential fixes, having access to the right information can save time and expenses. Whether you’re dealing with drainage problems, unexpected noises, or inefficient performance, this guide is designed to assist you in identifying and resolving the concerns that may arise, ensuring your laundry tasks run smoothly once again.

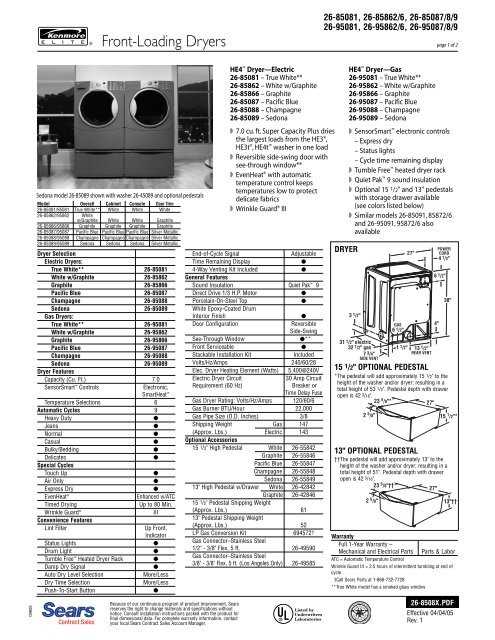

Understanding Kenmore HE3 Washer Basics

This section explores the fundamental aspects of a popular laundry appliance designed for efficiency and convenience. Understanding its key components and functions can help users optimize their laundry experience and troubleshoot common issues effectively.

Key Features

Modern laundry devices often come equipped with a range of features that enhance usability. These may include multiple wash cycles tailored for different fabric types, energy-efficient options, and intuitive controls that simplify operation. Familiarity with these features allows users to select the appropriate settings for various loads, ensuring optimal cleaning results.

Maintenance Tips

Regular upkeep is essential for longevity and performance. Users should routinely check and clean vital components such as filters and seals to prevent malfunctions. Additionally, keeping the drum clean and periodically running maintenance cycles can help maintain optimal efficiency. Being proactive in maintenance not only extends the appliance’s lifespan but also ensures it operates at peak performance.

Common Issues with Kenmore HE3

Every household appliance may encounter challenges over time, leading to frustration and inconvenience. Understanding frequent problems can help users troubleshoot effectively and maintain optimal functionality. Below are some of the typical concerns associated with this particular laundry device.

1. Insufficient Spinning

A common complaint involves the unit’s inability to achieve adequate spin cycles. This may result in clothes emerging excessively wet, leading to longer drying times. Several factors can contribute to this issue, including an unbalanced load, worn-out drive belts, or malfunctioning motor components. Regularly checking for even distribution of laundry and inspecting the drive mechanisms can often resolve this problem.

2. Unusual Noises

Unusual sounds during operation can indicate underlying mechanical issues. Users might hear clanking, buzzing, or grinding noises, which may signal loose parts, foreign objects trapped within the drum, or worn bearings. Prompt attention to these sounds is essential to prevent further damage. It is advisable to perform routine inspections and remove any debris that may disrupt the normal functioning of the device.

Tools Needed for Repairs

When addressing issues with your appliance, having the right equipment on hand is crucial for a smooth and effective process. Proper tools not only facilitate the work but also help ensure safety and precision during the tasks involved. Understanding what is necessary before starting can save time and prevent complications.

Essential Hand Tools

A basic toolkit should include items like screwdrivers, pliers, and wrenches. These instruments are vital for loosening or tightening various components. Additionally, having a pair of needle-nose pliers can be advantageous for reaching tight spaces and handling small parts with care.

Specialized Equipment

For more intricate jobs, specialized tools may be required. A multimeter is invaluable for testing electrical connections and diagnosing problems. Furthermore, a set of socket wrenches can simplify the removal of bolts and screws in confined areas, allowing for greater accessibility to the inner workings of the device.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered during operation. Following these systematic steps can help pinpoint problems and facilitate effective solutions, ensuring optimal performance.

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| No power | Power source disconnected, faulty cord, blown fuse | Check power outlet, inspect cord for damage, replace fuse if necessary |

| Water not filling | Blocked inlet screens, shut-off valve closed, faulty water supply | Clean screens, ensure valve is open, check water supply |

| No spinning | Unbalanced load, door not securely closed, motor issue | Redistribute load, check door latch, test motor operation |

| Unusual noises | Foreign objects in drum, worn bearings, loose components | Remove objects, inspect bearings, tighten any loose parts |

| Water leaking | Damaged hoses, worn door seal, faulty pump | Inspect and replace hoses, check seal integrity, evaluate pump functionality |

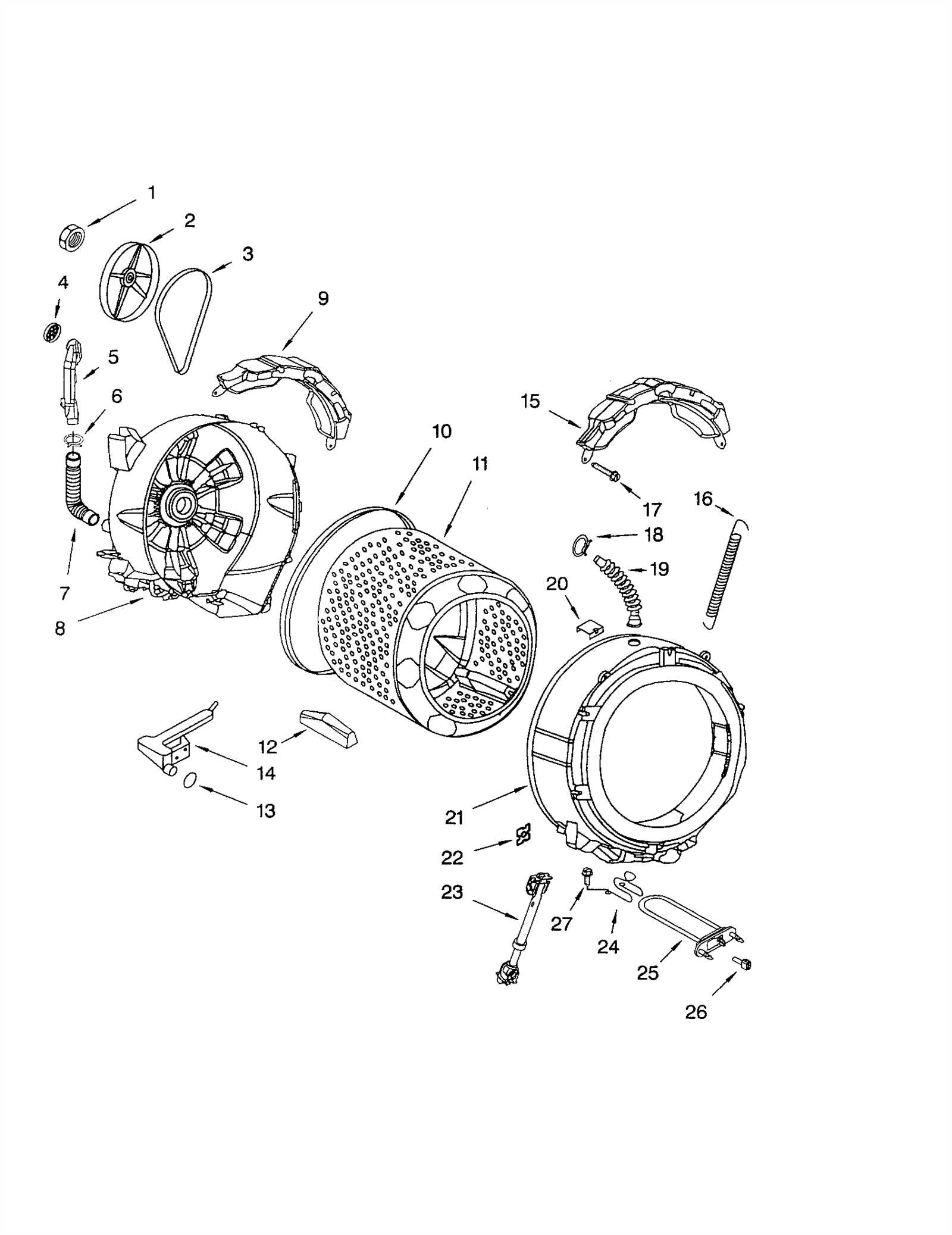

Replacing the Door Seal

Maintaining an airtight closure is essential for any appliance that involves water. Over time, seals can wear out, leading to leaks and inefficient operation. This section provides a detailed guide on how to replace the door seal, ensuring optimal performance and preventing water damage.

Tools and Materials Needed

- New door seal

- Screwdriver (flathead and Phillips)

- Towel or sponge

- Utility knife (if necessary)

Steps to Replace the Door Seal

- Unplug the appliance to ensure safety during the process.

- Remove the front panel by unscrewing the screws that hold it in place.

- Locate the existing seal and inspect it for any damage.

- Carefully pull the old seal away from the door frame, taking care not to damage surrounding components.

- If necessary, use a utility knife to cut away any stubborn pieces of the old seal.

- Clean the surface where the new seal will be applied, ensuring it is free of debris and residue.

- Fit the new seal into place, starting from one corner and working around the door frame.

- Press the seal firmly to ensure it adheres properly and creates a tight fit.

- Reattach the front panel and secure it with screws.

- Plug in the appliance and run a short cycle to check for leaks.

Following these steps will help you successfully replace the door seal, enhancing the efficiency and longevity of your appliance.

Cleaning the Drain Filter

Regular maintenance of the drainage system is essential for optimal performance and longevity of your appliance. One crucial component in this process is the drain filter, which can become clogged with lint, debris, and other residues. Keeping this part clean not only prevents blockages but also ensures efficient operation.

Steps to Access the Drain Filter

To begin, locate the access panel typically found at the bottom front of the device. Open the panel carefully and place a shallow container beneath the filter to catch any excess water. Gently unscrew or pull out the filter, taking care not to spill any trapped liquid.

Cleaning Process

Once the filter is removed, rinse it under warm water to eliminate any accumulated dirt. Use a soft brush or cloth to scrub away stubborn particles. After thoroughly cleaning, ensure that the filter is completely dry before reinserting it into the appliance. Finally, close the access panel securely to complete the process.

Fixing Spin Cycle Problems

Experiencing issues during the spin cycle can be frustrating, as it affects the overall performance of your laundry appliance. Understanding the common causes and solutions for these complications can help restore functionality and efficiency.

Here are some typical reasons for spin cycle issues:

- Imbalanced Load: An uneven distribution of laundry can prevent proper spinning.

- Blocked Drainage: Clogs in the drainage system may hinder water removal.

- Faulty Lid Switch: A malfunctioning lid switch can stop the spin cycle from activating.

- Worn Drive Belt: A worn or broken belt may lead to ineffective spinning.

To address these concerns, consider the following steps:

- Check Load Balance: Redistribute items evenly in the drum before starting the cycle again.

- Inspect Drainage System: Clear any blockages in hoses or filters to ensure proper water flow.

- Test the Lid Switch: Ensure the lid switch engages properly when the lid is closed; replace if defective.

- Examine Drive Belt: Look for signs of wear or damage, and replace if necessary.

By following these troubleshooting tips, you can effectively resolve spin cycle issues and enhance the performance of your appliance.

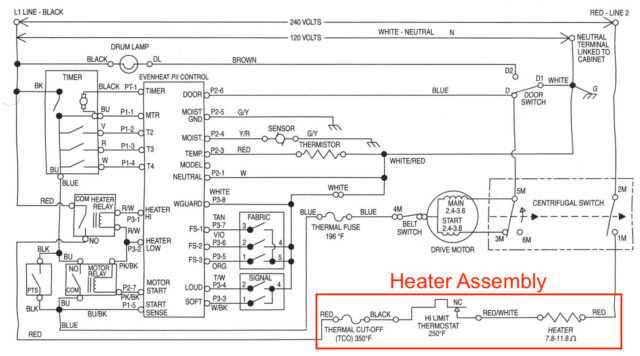

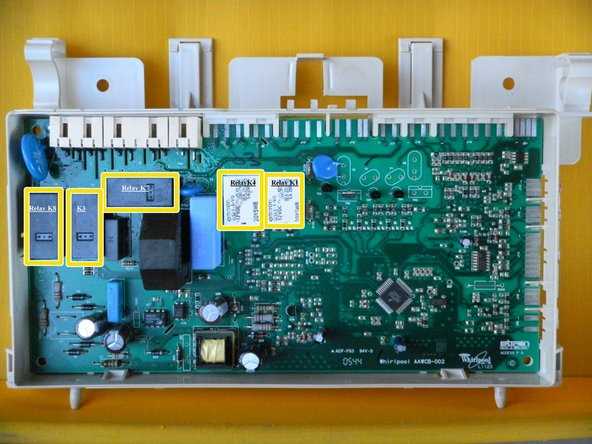

Electrical Components Overview

This section aims to provide a comprehensive understanding of the various electrical elements that play a crucial role in the functionality of modern cleaning appliances. Each component works in harmony to ensure optimal performance, reliability, and efficiency. By familiarizing yourself with these parts, you can gain insights into troubleshooting and maintenance practices.

Key Electrical Elements

Several fundamental parts contribute to the operation of these devices. Motors are essential for driving various mechanisms, while control boards manage the overall functions and settings. Additionally, power supplies deliver the necessary voltage to the system, ensuring that all components operate smoothly. Understanding how these elements interact is vital for anyone looking to enhance their knowledge of appliance technology.

Safety Considerations

When dealing with electrical systems, safety should always be a priority. It is important to ensure that all connections are secure and free from corrosion. Regular checks for short circuits or other anomalies can prevent potential hazards. Proper handling and understanding of electrical components not only extend the lifespan of the device but also promote safe usage.

Maintaining Your Washer for Longevity

Proper upkeep of your laundry appliance is essential for its durability and performance. By adopting a few simple habits, you can significantly extend its lifespan and ensure it operates efficiently. Regular attention to maintenance not only helps prevent unexpected breakdowns but also enhances the overall efficiency of the unit.

Start with routine cleaning of the drum and door seals to prevent mold and unpleasant odors. After each use, leave the door ajar to allow air circulation, reducing moisture buildup. Additionally, inspect and clean the filters periodically to ensure optimal water flow and prevent clogs.

Pay attention to the water supply hoses, checking for any signs of wear or leaks. Replacing old hoses can avert potential flooding and water damage. Furthermore, consider using a water softener if your area has hard water, as it can help minimize mineral buildup that may affect performance.

Regularly running a maintenance cycle with a suitable cleaner can also be beneficial. This helps eliminate residues and keeps the appliance functioning smoothly. Lastly, staying mindful of the load size and distribution can prevent excessive strain on the unit, further contributing to its longevity.

When to Call a Professional

Determining when to seek the expertise of a technician can be crucial for effectively addressing issues with your appliance. While some problems can be resolved with basic troubleshooting, others may require specialized knowledge or tools. Recognizing the right moment to enlist professional help can save time, prevent further damage, and ensure the longevity of your device.

One clear indication that it’s time to call an expert is when you encounter persistent issues that do not improve despite your efforts. If you’ve already attempted various solutions–such as checking the power source, cleaning filters, or resetting the device–without success, it may be wise to consult a professional.

Additionally, unusual noises or strange odors can signal a serious underlying problem. These symptoms often indicate mechanical failures or electrical malfunctions that could pose safety risks if not addressed promptly. In such cases, professional intervention is highly recommended to avoid hazards.

Furthermore, if your appliance is still under warranty, attempting repairs yourself may void that warranty. Contacting a qualified technician ensures that you maintain coverage while getting the necessary repairs done correctly.

In summary, recognizing the limits of your DIY skills and understanding the potential risks involved can guide you in deciding when to call for professional assistance. Prioritizing safety and efficiency will ultimately lead to better outcomes for your appliance and peace of mind for you.