Maintaining the efficiency of your laundry device is essential for a smooth home experience. This section delves into common issues that users encounter with their appliances and provides effective solutions to ensure they operate optimally. Understanding the nuances of these machines can empower you to handle minor glitches independently, ultimately saving time and money.

In the following paragraphs, we will explore a variety of challenges that may arise, from unusual noises to inefficient cycles. Each problem will be addressed with practical advice, enabling you to diagnose and potentially rectify these issues without the need for professional assistance. By familiarizing yourself with these troubleshooting techniques, you can enhance the longevity and performance of your household equipment.

Common Issues with Kenmore Elite HE3

When it comes to high-efficiency laundry appliances, users may encounter a range of typical problems that can disrupt their operation. Understanding these common malfunctions can help in troubleshooting and maintaining optimal performance.

Typical Problems

Many owners report similar challenges, including inadequate spinning, excessive noise, and error codes appearing on the display. These issues can stem from various factors such as load size, improper installation, or mechanical failures.

Troubleshooting Guide

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Poor Spin Performance | Unbalanced load, worn drive belt | Redistribute clothes, check and replace the belt |

| Unusual Noises | Foreign objects, damaged bearings | Inspect drum for debris, replace bearings if necessary |

| Error Codes | Electrical faults, sensor issues | Reset the machine, consult the troubleshooting section |

Diagnostic Steps for Washer Problems

When faced with issues in your laundry appliance, a systematic approach to diagnosing the malfunction can be crucial. This process involves evaluating various components to identify the root cause of the problem effectively. Following a structured method helps in pinpointing the exact issue, enabling more efficient solutions.

Step 1: Visual Inspection

Begin by conducting a thorough visual examination of the device. Look for any obvious signs of wear, loose connections, or damaged parts. Pay particular attention to the power source and ensure that the unit is properly plugged in. If there are any unusual sounds or leaks, note them down, as these can provide vital clues regarding the malfunction.

Step 2: Test Functions

Next, engage in testing the various functions of the appliance. Cycle through the settings, observing the performance of each function. Take note of any irregularities, such as failure to spin, drain, or fill with water. This step allows for a clearer understanding of which specific operations are compromised, guiding further investigation.

Understanding Error Codes and Messages

Error codes and messages serve as vital indicators of operational issues within a household appliance. These alerts provide insights into potential malfunctions, guiding users toward troubleshooting steps and necessary actions.

When faced with a notification, it is essential to interpret its meaning accurately. Different systems utilize a variety of codes, and understanding them can significantly enhance the troubleshooting process.

- Common Codes: Familiarize yourself with frequently encountered codes to expedite the diagnostic process.

- Manufacturer Resources: Consult official resources for detailed explanations and recommended actions related to each code.

- Contextual Clues: Pay attention to when and how the error appears; this context can provide clues about the underlying issue.

By recognizing and understanding these indicators, users can effectively address problems, ensuring the appliance operates efficiently and reliably.

Maintenance Tips for Longevity

Ensuring the durability of your appliance requires regular attention and care. By implementing effective maintenance strategies, you can extend its lifespan and enhance performance. Simple practices can make a significant difference in keeping your unit running smoothly.

First, routinely inspect and clean the exterior surfaces to prevent the buildup of dirt and grime. This not only helps maintain a neat appearance but also reduces the risk of corrosion. Pay attention to seals and gaskets, as they can wear out over time, leading to potential leaks.

Regularly check and clean the interior components to remove any residue or build-up that may occur during use. This can include filters, hoses, and drainage systems. Ensuring these elements are clear can help maintain efficiency and prevent malfunctions.

It is also beneficial to run the appliance through a maintenance cycle periodically. This function is designed to optimize the internal mechanisms and keep everything in good working order. Additionally, using high-quality detergents can prevent excessive wear and help maintain optimal performance.

Lastly, consider scheduling professional inspections annually. A qualified technician can identify potential issues before they become serious problems, ensuring that your appliance remains in top condition for years to come.

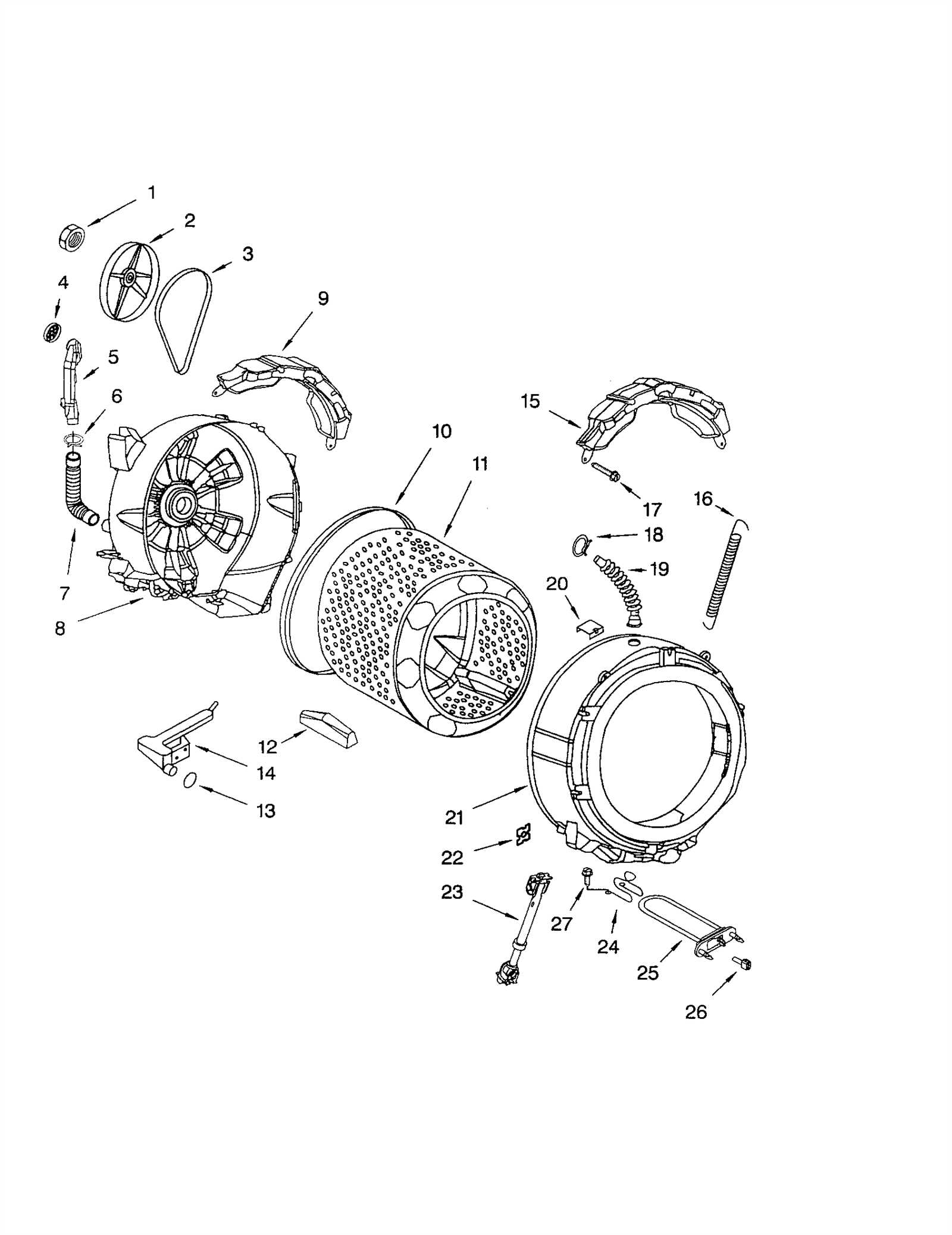

Parts Replacement Guide for HE3

This section aims to provide a comprehensive overview of the essential components that may need to be swapped out during maintenance. Understanding the function and replacement process of each part can help ensure optimal performance and longevity of the appliance.

Common Components Needing Replacement

Below is a list of frequently replaced parts, along with their functions and indications for when replacement may be necessary.

| Part Name | Function | Signs of Wear |

|---|---|---|

| Door Seal | Prevents leaks and maintains pressure during cycles. | Cracks, tears, or mold buildup. |

| Drain Pump | Removes water from the drum after cycles. | Unusual noises, water retention in the drum. |

| Drive Belt | Connects the motor to the drum for spinning. | Slipping sounds, failure to spin. |

Replacement Process Overview

Replacing components generally involves the following steps: disconnecting power, removing the outer casing, locating the faulty part, and carefully installing the new component. It is crucial to follow specific guidelines to ensure safety and proper functionality.

Tools Needed for Basic Repairs

When it comes to performing fundamental maintenance tasks, having the right instruments on hand can make the process more efficient and effective. Various tools can assist in troubleshooting issues, facilitating swift resolutions and prolonging the lifespan of your appliance.

Essential Tools

First and foremost, a basic toolkit should include a variety of screwdrivers, both flathead and Phillips, to tackle different types of fasteners. Additionally, a set of pliers, including needle-nose and channel-lock types, can be invaluable for gripping and manipulating small components.

Additional Instruments

For electrical issues, a multimeter is a must-have for testing voltage and continuity. Furthermore, having a socket set will help in loosening and tightening bolts that may require more torque than a standard screwdriver can provide. Lastly, keep a flashlight handy for illuminating hard-to-reach areas, ensuring you can see clearly while working.

Cleaning and Care Instructions

Proper maintenance and cleanliness are essential for ensuring the longevity and efficient performance of your appliance. Regularly following these care guidelines can prevent buildup and enhance functionality, leading to optimal results during use.

Begin by routinely checking and cleaning the interior components to eliminate any residue or odors. A clean environment is crucial for preventing clogs and maintaining the efficiency of the unit.

| Task | Frequency | Instructions |

|---|---|---|

| Clean the drum | Monthly | Run an empty cycle with hot water and a cup of white vinegar to disinfect and remove odors. |

| Wipe down the exterior | Weekly | Use a damp cloth and mild detergent to clean the outer surfaces. |

| Check and clean filters | Every 3 months | Remove lint and debris from filters to maintain optimal water flow. |

| Inspect hoses | Every 6 months | Check for wear and replace any damaged hoses to prevent leaks. |

Following these guidelines will help maintain your appliance in top condition, ensuring reliable performance for years to come.

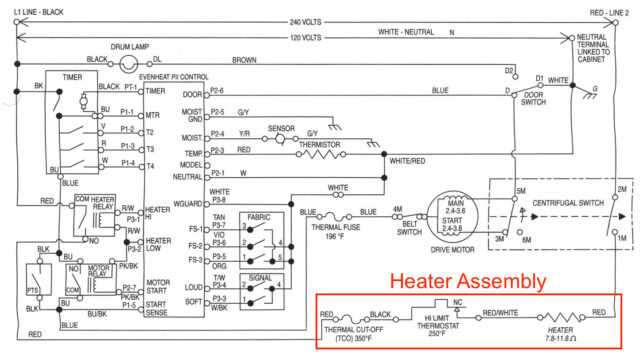

Electrical Troubleshooting Tips

Identifying electrical issues in your appliance can be challenging but crucial for effective functioning. This section provides valuable guidance to help you navigate through common electrical problems and solutions.

- Check Power Supply: Ensure that the unit is plugged in and that the outlet is functioning. Use a multimeter to test the voltage at the outlet.

- Inspect Circuit Breaker: Verify that the circuit breaker has not tripped. Reset it if necessary and monitor the appliance during operation.

- Examine Cords and Plugs: Look for any signs of damage or wear on power cords and plugs. Replace any frayed or damaged components immediately.

- Test Control Panel: If the appliance shows no signs of life, the control panel may be faulty. Inspect for loose connections or visible damage.

By following these steps, you can effectively diagnose and address electrical malfunctions, ensuring your device operates safely and efficiently.

Water Drainage Issues Explained

Effective water drainage is crucial for maintaining optimal performance in laundry appliances. When problems arise in this area, it can lead to inefficient cleaning and potential damage to the unit. Understanding the common causes of drainage issues is essential for troubleshooting and ensuring proper function.

Clogs and Blockages: One of the primary reasons for inadequate drainage is the presence of obstructions in the hoses or filters. Items such as lint, debris, or small clothing pieces can accumulate and create blockages, hindering water flow. Regular inspection and cleaning of these components can help prevent this problem.

Pump Malfunctions: The pump plays a vital role in expelling water from the appliance. If it becomes damaged or fails, the drainage process can be severely affected. Listen for unusual noises during operation, as they may indicate a pump issue that requires attention.

Hose Issues: The condition of the drainage hose is equally important. Kinks, bends, or improper installation can restrict water flow, leading to drainage failures. Ensure that the hose is installed correctly and is free from any obstructions.

Leveling the Appliance: An unbalanced unit can also contribute to drainage problems. If the appliance is not level, it may not allow water to flow out properly. Adjusting the feet to ensure a level position can improve drainage performance.

By addressing these common concerns, users can significantly enhance the efficiency of their laundry appliances and prolong their lifespan.

Addressing Spin Cycle Failures

Issues during the spinning phase can lead to inadequate drying and increased dampness in garments. Understanding common causes and solutions is essential for effective troubleshooting.

- Unbalanced Load: An uneven distribution of clothes can prevent the drum from spinning properly. Ensure that items are evenly placed to facilitate balanced rotation.

- Door Lock Malfunction: If the door latch is faulty, the cycle may not engage. Inspect the lock mechanism for any signs of wear or damage.

- Drainage Problems: Clogs in the drainage system can hinder the spinning process. Regularly check and clean the drain hose and filter to avoid blockages.

- Drive Belt Issues: A worn or broken belt can stop the drum from spinning. Inspect the belt for any signs of fraying or breakage, and replace it if necessary.

- Motor Malfunctions: A failing motor can prevent the drum from reaching the required speed. Testing the motor’s functionality is crucial if other solutions do not resolve the issue.

By systematically evaluating these components, users can effectively diagnose and address problems related to spin cycle performance.

How to Reset the Washer

Sometimes, appliances may encounter issues that require a reset to restore normal functionality. This process is straightforward and can resolve various operational glitches, ensuring the device runs smoothly again.

To initiate the reset, first, unplug the appliance from the power source. Wait for at least 30 seconds to allow any residual power to drain completely. After the waiting period, plug the device back in. This simple action often clears any minor errors that may have occurred.

If the issue persists, you can try a more comprehensive reset. Turn the dial to the normal wash cycle and then back to the off position. Repeat this process three times. This method can help in recalibrating the settings and restoring functionality.

Once completed, you should test the appliance by running a short cycle without any laundry inside. If everything operates correctly, the device is ready for use. If problems continue, further troubleshooting may be necessary.