Ensuring the longevity and efficiency of your cleaning apparatus is essential for optimal performance. This section provides insights into troubleshooting and enhancing the functionality of your equipment. By understanding common issues and solutions, you can maintain a smooth operation and achieve desired results.

Many users encounter challenges that may affect the effectiveness of their cleaning tools. Recognizing the signs of malfunction and knowing how to address them can save time and resources. This guide will walk you through various techniques and practices to ensure your equipment remains in peak condition.

Incorporating regular maintenance routines not only enhances performance but also extends the life of your machinery. By following the outlined suggestions and techniques, you will be equipped to tackle common challenges effectively. Embrace these practices to keep your equipment working efficiently and reliably.

Understanding how to pinpoint malfunctioning elements is crucial for maintaining optimal performance in cleaning devices. By recognizing the signs of wear or failure, users can ensure efficient operation and prolong the lifespan of their equipment.

Common indicators of problematic components include:

- Unusual noises during operation

- Inconsistent flow or pressure

- Visible leaks or drips

- Overheating or excessive vibrations

To systematically identify issues, follow these steps:

- Examine all external parts for any visible damage or wear.

- Check connections and hoses for blockages or leaks.

- Inspect internal components for signs of corrosion or build-up.

- Test functionality by running the device at various settings.

By methodically assessing these areas, users can effectively diagnose and address issues, ensuring their cleaning equipment remains reliable and efficient.

Step-by-Step Repair Process

This section outlines a systematic approach to troubleshooting and fixing common issues encountered with high-performance cleaning equipment. Following these steps can help restore functionality efficiently and effectively.

Initial Assessment

Begin by examining the device for any visible signs of damage or wear. Check the connections and ensure all components are securely fastened. Identify any unusual sounds or leaks during operation, which can provide clues to underlying problems.

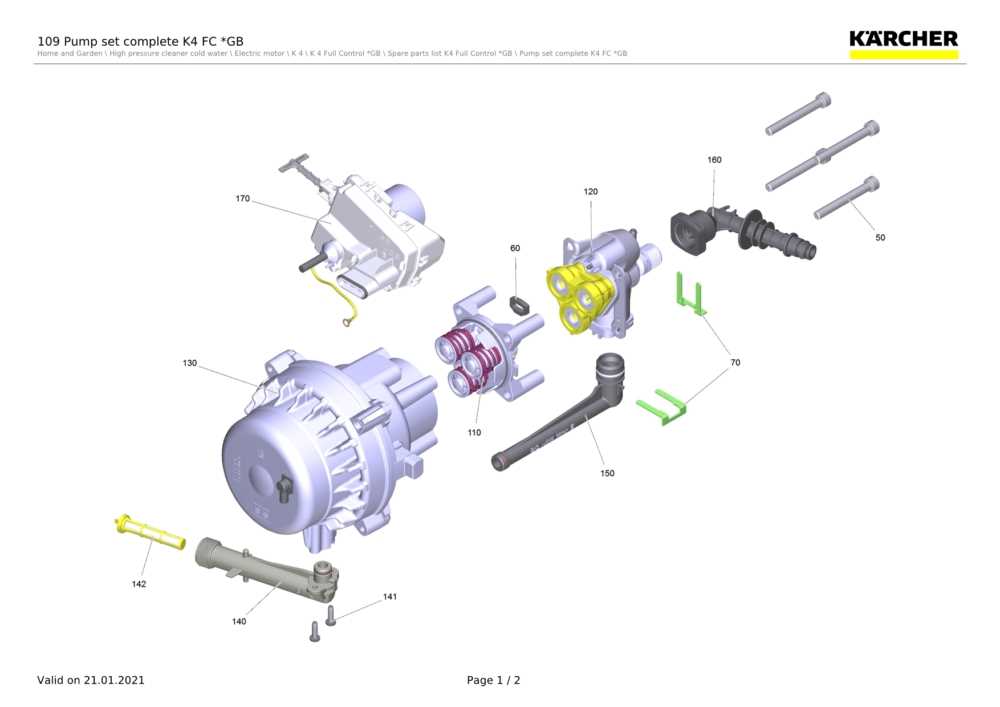

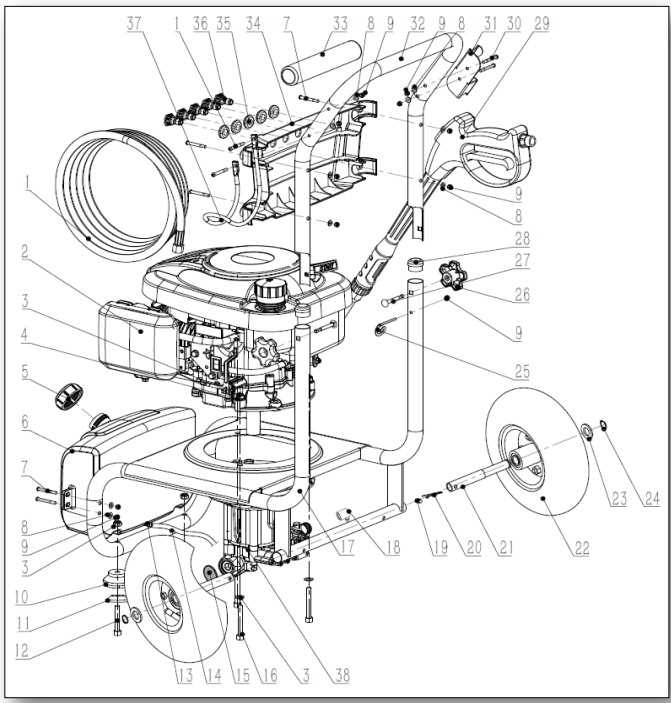

Disassembly and Inspection

Carefully dismantle the unit according to the guidelines provided. Inspect each part for defects or blockages, focusing on the internal mechanisms. Cleaning components thoroughly may resolve issues caused by dirt accumulation, while damaged parts should be replaced promptly.

Tools Needed for Repairs

To effectively address issues with your cleaning device, having the right instruments is essential. This section outlines the essential equipment that will facilitate the maintenance and troubleshooting processes, ensuring optimal performance and longevity of the machine.

Basic Hand Tools

A selection of basic hand tools is crucial for any maintenance task. These typically include a screwdriver, wrench, and pliers. Each of these items plays a significant role in loosening or tightening components, allowing for straightforward access to the interior of the device.

Specialized Equipment

In addition to standard hand tools, specialized instruments may be required for more complex issues. For instance, a multimeter can help diagnose electrical problems, while a pressure gauge can assess the output of the unit. Having these specialized tools on hand will enable you to perform more in-depth evaluations and repairs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your cleaning equipment involves regular upkeep and attention to detail. Implementing simple practices can significantly enhance performance and prevent premature wear.

Routine Inspections

Conduct periodic checks to identify any signs of wear or damage. Inspect hoses, connectors, and other essential components for leaks or cracks. Addressing issues early can prevent more significant problems later.

Proper Storage Practices

Store your equipment in a dry, sheltered location to protect it from harsh weather conditions. Using protective covers can also shield it from dust and debris, contributing to its overall durability.

How to Troubleshoot Effectively

When facing issues with your cleaning device, it’s essential to approach the problem methodically. Effective troubleshooting involves identifying potential causes and systematically testing solutions to restore optimal functionality.

Begin by ensuring that all connections are secure and that the power source is functioning correctly. Inspect hoses and attachments for any blockages or damage, as these can significantly impact performance. If the unit fails to start, check for tripped circuits or blown fuses.

If water flow is insufficient, examine the inlet filter for debris and ensure that the water supply is adequate. Pay attention to any unusual noises during operation, as these may indicate internal issues requiring further investigation. Documenting your observations can also help in diagnosing persistent problems more efficiently.

By following these steps and being attentive to detail, you can effectively troubleshoot and resolve common challenges, ensuring your device operates smoothly.

Replacing Worn Out Parts

Maintaining optimal performance of your cleaning device often requires the replacement of aged components. Identifying and substituting these worn elements is essential for ensuring efficiency and longevity.

Regular inspection of various parts will help you determine which components need attention. Below is a list of common parts that may need to be replaced along with their typical signs of wear:

| Component | Signs of Wear |

|---|---|

| Seals | Leaking fluids, reduced pressure |

| Hoses | Cracks, bulges, or kinks |

| Nozzles | Inefficient spray pattern, blockages |

| Filters | Clogging, decreased flow |

Replacing these components promptly can prevent further damage and ensure that your device operates at peak performance. Always consult the specifications for compatibility when sourcing replacements.

Safety Precautions During Repairs

When addressing maintenance tasks on cleaning equipment, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, ensuring a smooth and effective process. Understanding the potential hazards associated with these activities is essential for anyone involved in upkeep.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial. This includes gloves, safety goggles, and non-slip footwear to minimize risks. Such equipment serves as a barrier against potential injuries from various tools and substances encountered during maintenance.

Workspace Organization

Maintaining a tidy work environment can significantly enhance safety. Ensuring that tools are easily accessible and materials are organized reduces the likelihood of accidents. Adequate lighting is also vital, as it helps in identifying hazards and facilitates clear visibility while performing tasks.

Understanding Pressure Washer Functions

This section explores the essential roles and mechanisms of cleaning devices designed for outdoor tasks. By grasping these functions, users can maximize efficiency and effectiveness during various cleaning projects.

Components and Their Roles

Each element of these machines contributes uniquely to their overall performance. For instance, the motor serves as the heart, driving the water flow, while the nozzle adjusts the intensity of the stream, allowing for tailored cleaning options.

Operating Principles

The underlying principles involve converting energy into kinetic force, creating a powerful stream that effectively removes dirt and debris. Understanding these principles helps users operate the equipment with confidence and achieve desired results.

Common Mistakes to Avoid

When handling cleaning devices, there are several pitfalls that users frequently encounter. Understanding these errors can enhance efficiency and prolong the life of your equipment.

Neglecting Maintenance

Regular upkeep is essential for optimal functionality. Common oversights include:

- Failing to clean filters regularly

- Ignoring signs of wear on hoses and attachments

- Not checking for blockages in the intake or nozzles

Improper Usage Techniques

Using the equipment incorrectly can lead to damage or subpar results. Be cautious of the following:

- Using excessive force while operating

- Pointing the nozzle at people or pets

- Applying incorrect cleaning solutions that may damage components

When to Seek Professional Help

Understanding when to enlist the expertise of a technician can greatly enhance the longevity and efficiency of your cleaning device. While many issues can be resolved through basic troubleshooting, certain circumstances warrant professional intervention.

If you encounter persistent malfunctions despite following recommended maintenance procedures, it may indicate underlying problems that require specialized knowledge. Complex repairs, such as those involving electrical components or internal mechanisms, should be addressed by a trained expert to ensure safety and proper functionality.

Additionally, if the equipment shows signs of severe wear or damage, consulting a professional can provide insights into whether a repair is feasible or if replacement is the ultimate solution. Timely intervention can prevent further deterioration and save you from costly replacements down the line.