Maintaining outdoor cleaning devices is essential for ensuring their longevity and optimal performance. This section offers insights into the common issues encountered with high-pressure cleaners and provides valuable guidance on addressing these challenges effectively. Whether dealing with reduced output or unusual noises, understanding the underlying mechanics can significantly aid in restoring functionality.

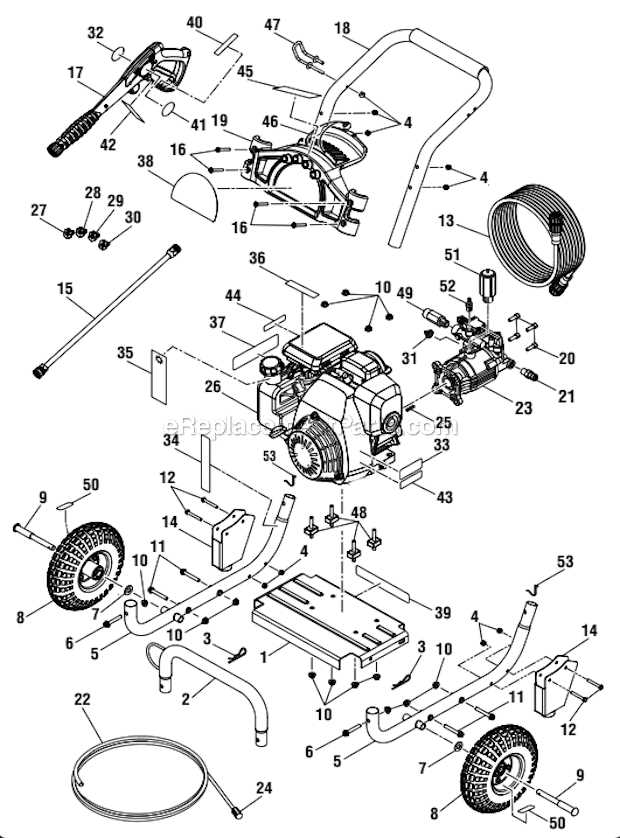

Essential knowledge about the components and operation of these machines will empower users to diagnose problems independently. By familiarizing oneself with various parts and their functions, one can easily identify potential faults and determine the appropriate steps for resolution. This proactive approach not only saves time but also minimizes the need for professional assistance.

Additionally, proper maintenance practices play a critical role in preventing future complications. Regular checks and timely interventions can enhance performance and extend the lifespan of the equipment. Embracing a routine that incorporates these practices will ensure that the cleaning tasks remain efficient and effective throughout the year.

Understanding Homelite Pressure Washers

In the realm of outdoor cleaning tools, certain models stand out due to their reliability and efficiency. These devices are designed to handle a variety of tasks, making them a favorite among homeowners and professionals alike. Whether for routine maintenance or intensive cleaning, knowing the ins and outs of these machines can enhance their performance and longevity.

Key features that make these cleaning units popular include:

- Powerful engines that provide high performance

- Variety of nozzles for different cleaning tasks

- User-friendly controls for easy operation

- Durable construction for long-lasting use

To maximize the benefits of these machines, it’s important to understand their components and how they function together. This knowledge can aid in troubleshooting common issues and maintaining optimal performance.

- Engine: The heart of the unit, providing the necessary power.

- Pump: Responsible for generating the water pressure needed for cleaning.

- Nozzles: Allow for customization of water flow and intensity.

- Hoses: Facilitate the movement of water from the source to the target area.

By familiarizing yourself with these key elements, you can ensure effective usage and extend the life of your outdoor cleaning equipment. Regular maintenance and attention to detail will further enhance the functionality of these invaluable tools.

Common Issues with 2700 PSI Models

When utilizing high-powered cleaning devices, users may encounter a variety of challenges that can affect performance. Understanding these typical problems can help in troubleshooting and maintaining efficiency during operation.

Frequent Challenges

- Loss of Pressure: One of the most common issues is a noticeable reduction in cleaning power, which can stem from various sources.

- Unusual Noises: Strange sounds during operation may indicate internal complications or wear.

- Water Leakage: Excess fluid escaping from the unit can be a sign of faulty seals or connections.

- Starting Difficulties: Problems initiating the machine can often frustrate users, typically linked to fuel or ignition system issues.

Potential Causes

- Check for clogged filters or nozzles that may restrict flow.

- Inspect hoses for kinks or damage that could impede operation.

- Examine the motor and power source for any irregularities.

- Look for signs of wear in internal components that might require replacement.

Addressing these issues promptly can help maintain optimal functionality and extend the lifespan of your cleaning equipment.

Essential Tools for Repairs

Having the right instruments is crucial when addressing any malfunctioning equipment. A well-equipped workspace can significantly enhance the efficiency of the troubleshooting and fixing process. Below is a list of indispensable tools that will aid in ensuring a successful restoration.

Basic Hand Tools

- Wrenches: Adjustable and fixed sizes for various fasteners.

- Screwdrivers: Both flathead and Phillips to tackle different screws.

- Pliers: Needle-nose and slip-joint for gripping and manipulating components.

- Socket set: For removing and tightening bolts easily.

Specialized Instruments

- Multimeter: Essential for diagnosing electrical issues.

- Pressure gauge: Helps in measuring output for performance checks.

- Oil can: Necessary for lubrication of moving parts.

- Cleaning tools: Brushes and cloths for maintenance and upkeep.

With these essential instruments at hand, you will be better prepared to tackle any issues that may arise, ensuring longevity and optimal performance of your equipment.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered with cleaning equipment. By following these systematic steps, users can efficiently diagnose problems and restore functionality to their devices.

Begin by examining the machine for any visible signs of malfunction. It is essential to check connections, hoses, and other components before delving deeper. If issues persist, refer to the table below for a structured troubleshooting process.

| Issue | Possible Cause | Solution |

|---|---|---|

| No power | Disconnected power source | Ensure the unit is plugged in and the outlet is functioning. |

| Low pressure | Clogged nozzle | Clean or replace the nozzle to restore pressure. |

| Leaks | Deteriorated seals | Inspect and replace worn seals as necessary. |

| Engine won’t start | Fuel issues | Check fuel levels and ensure clean fuel is being used. |

| Unusual noise | Loose components | Tighten any loose screws or bolts and inspect for damage. |

By systematically addressing each issue, users can ensure optimal performance and longevity of their equipment. If problems persist beyond these solutions, professional assistance may be required.

Replacing the Pressure Washer Hose

Maintaining the efficiency of your cleaning equipment often involves replacing worn-out components. One crucial part that may require attention is the flexible tubing that carries the cleaning solution. Ensuring this element is in good condition is vital for optimal performance and preventing leaks.

Identifying When to Replace

Several signs indicate that the tubing needs to be replaced:

- Visible cracks or frays along the length of the hose.

- Leaking at the connection points or along the tube.

- Loss of water flow or pressure during operation.

- Unusual noises or vibrations while in use.

Steps for Replacement

Follow these steps to successfully replace the flexible tubing:

- Start by disconnecting the equipment from its power source and ensure all pressure is released.

- Carefully remove any attachments from the old tubing, noting how they connect for easier reinstallation.

- Use a wrench if necessary to loosen any fittings that are too tight.

- Measure the length of the existing tubing to ensure the new one matches.

- Attach the new tubing, ensuring all fittings are secure and tight to prevent leaks.

- Reconnect all attachments and power source, then test the equipment to confirm proper operation.

By following these guidelines, you can maintain your cleaning apparatus in peak condition and ensure effective operation for your cleaning tasks.

Cleaning the Spray Gun Nozzle

Maintaining the nozzle of your cleaning equipment is essential for optimal performance. A clogged or dirty nozzle can hinder the efficiency of your tool, resulting in uneven cleaning and wasted time. Regular upkeep not only prolongs the lifespan of your equipment but also ensures that it operates at peak efficiency.

To begin the cleaning process, gather the necessary supplies: a soft brush, a bucket of warm soapy water, and a small pin or needle. Start by disconnecting the nozzle from the spray gun to avoid any accidental sprays during the cleaning procedure. Rinse the nozzle under warm water to remove any loose debris.

Next, use the soft brush to scrub away any stubborn grime that may be clinging to the nozzle. Pay special attention to the tiny orifices, as these can easily become blocked. If any openings remain obstructed, gently insert the pin or needle to dislodge the debris, taking care not to damage the nozzle.

After thoroughly cleaning the nozzle, rinse it again with clean water to ensure all soap and loosened dirt are removed. Once dry, reattach the nozzle to the spray gun and test it to confirm that water flows freely and the spray pattern is even.

Regular cleaning of your nozzle is a simple yet effective way to maintain your cleaning equipment, ensuring that it remains reliable and efficient for all your tasks.

Maintaining the Pump System

Proper upkeep of the fluid delivery system is crucial for ensuring optimal performance and longevity. Regular checks and maintenance tasks can prevent common issues that may arise from wear and tear, leading to improved efficiency and reliability during operation.

Routine Maintenance Tasks

To keep the pump system functioning smoothly, consider the following essential maintenance activities:

| Task | Frequency | Description |

|---|---|---|

| Check Oil Levels | Every Use | Ensure that the oil reservoir is filled to the recommended level for optimal lubrication. |

| Inspect Hoses | Monthly | Look for cracks, wear, or blockages in the hoses to prevent leaks and pressure loss. |

| Clean Filters | Every 3 Months | Remove and clean filters to maintain efficient fluid flow and prevent contamination. |

| Examine Seals | Annually | Inspect seals for signs of damage and replace if necessary to avoid leaks. |

Best Practices for Longevity

Implementing best practices can significantly extend the life of the pump system. Always use the recommended fluids and follow operational guidelines. Storing the unit in a dry, clean environment will also help minimize wear and ensure readiness for use.

Diagnosing Engine Problems

Understanding engine issues is crucial for maintaining optimal performance and longevity of any equipment. Identifying the root cause of malfunctions can save time and resources, ensuring efficient operation. In this section, we will explore common symptoms and diagnostic techniques to troubleshoot engine difficulties effectively.

Common Symptoms of Engine Malfunctions

Several signs may indicate underlying problems with the engine. Excessive smoke can suggest oil leakage or combustion issues, while unusual noises might point to mechanical wear or loose components. Additionally, difficulty starting could be a result of fuel system issues or battery failure. Observing these symptoms can guide you towards a more precise diagnosis.

Diagnostic Techniques

To accurately assess engine problems, begin with a visual inspection. Check for any visible leaks, loose parts, or corrosion. Using diagnostic tools, such as a multimeter or compression gauge, can provide valuable insights into the engine’s health. Furthermore, reviewing the maintenance history can help pinpoint recurring issues, allowing for more effective troubleshooting and preventive measures.

Winterizing Your Pressure Washer

Preparing your cleaning equipment for the colder months is essential to ensure its longevity and optimal performance. Taking the time to properly protect it from frost and freezing temperatures can prevent damage and costly repairs. Follow these steps to effectively winterize your machine.

Steps to Prepare Your Equipment

- Start by draining all water from the unit.

- Remove any attachments and store them in a dry place.

- Run the engine until it runs out of fuel to clear the system.

- Consider using a fuel stabilizer to prevent deterioration.

- Clean the exterior to remove dirt and debris.

Protecting Components

- Check the oil level and change it if necessary.

- Inspect hoses and fittings for wear and replace if needed.

- Store the equipment in a sheltered location to minimize exposure to harsh weather.

- Cover the unit with a protective tarp to shield it from dust and moisture.

By following these guidelines, you can ensure your cleaning device remains in top condition and ready for use when the warmer weather returns.

Recommended Replacement Parts

When maintaining your cleaning device, selecting the right components for replacement is crucial for optimal performance. High-quality parts not only enhance efficiency but also extend the lifespan of your equipment. Below are some essential items to consider when looking for replacements.

Essential Components

Key elements such as pumps, hoses, and nozzles should be inspected regularly for wear and tear. Replacing worn-out pumps ensures consistent water flow and pressure, while durable hoses prevent leaks and blockages. Additionally, various nozzle types can enhance versatility, allowing for different cleaning applications.

Additional Accessories

Consider investing in filters and connectors to further improve functionality. A high-quality filter can protect the internal mechanisms from debris, while reliable connectors ensure secure fittings. These accessories contribute significantly to the overall performance and reliability of your device.

Safety Tips During Repairs

When undertaking maintenance tasks on any equipment, prioritizing safety is essential. Proper precautions not only protect you from potential injuries but also ensure that the job is completed efficiently and effectively. Familiarizing yourself with safety guidelines can significantly reduce the risk of accidents during the process.

Always wear appropriate personal protective equipment, such as gloves and safety goggles, to shield yourself from debris and other hazards. Additionally, ensure your workspace is clean and organized to prevent tripping or falling over tools and materials. It’s also important to work in a well-ventilated area, particularly if you are dealing with chemicals or fumes.

Before beginning any task, disconnect power sources to eliminate the risk of accidental activation. Double-check that all tools are in good condition and suitable for the job. Never attempt repairs while under the influence of drugs or alcohol, as this can impair judgment and reaction times.

Lastly, stay focused on your task and avoid distractions. If you feel fatigued or overwhelmed, take a break before continuing. Adhering to these safety tips will help ensure a smooth and secure maintenance experience.

When to Seek Professional Help

Maintaining outdoor equipment can be a straightforward task for many users; however, there are instances when it becomes necessary to consult a professional. Recognizing these moments can save time, money, and further complications.

Here are some key indicators that suggest it might be best to call in an expert:

| Signs of Trouble | Recommended Action |

|---|---|

| Unusual Noises | Seek professional diagnosis to prevent damage. |

| Loss of Power | Consult a technician to identify underlying issues. |

| Persistent Leaks | Contact an expert to address potential seals or fittings problems. |

| Visible Damage | Get professional assistance to ensure safe operation. |

| Unresponsive Controls | Seek help to evaluate electrical components. |

In situations where the equipment exhibits one or more of these signs, seeking expert help can ensure the longevity and safety of the machinery, allowing for proper and effective operation.

Preventative Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of your cleaning equipment. Implementing a structured maintenance routine can help prevent issues before they arise, saving you time and money in the long run.

Here are some key practices to consider:

- Routine Cleaning: Remove dirt and debris from the exterior to prevent buildup that can lead to corrosion.

- Check Fluid Levels: Regularly inspect and refill essential fluids, including fuel and oil, to ensure proper operation.

- Inspect Hoses and Fittings: Look for signs of wear, cracks, or leaks in hoses and connections to maintain efficiency.

- Test the Equipment: Perform routine tests to ensure all components are functioning as intended.

- Replace Filters: Change air and fuel filters according to the manufacturer’s recommendations to enhance performance.

By following these practices, you can significantly reduce the likelihood of breakdowns and enhance the effectiveness of your equipment. Make it a habit to include maintenance checks in your regular schedule.