Understanding the intricacies of high-performance cleaning devices is essential for their longevity and efficiency. This section aims to provide valuable insights into the upkeep and troubleshooting of these machines, ensuring optimal performance in various applications.

Regular maintenance not only enhances the functionality of your equipment but also extends its lifespan. It is important to familiarize oneself with the essential components and typical issues that may arise, allowing for timely interventions and solutions.

By following the guidelines presented here, users can effectively manage their equipment, ensuring it remains in peak condition. This knowledge empowers owners to tackle common challenges and make informed decisions regarding maintenance and care.

Understanding Common Pressure Washer Issues

Many users encounter a variety of challenges when utilizing their cleaning devices. Recognizing these common difficulties can help in troubleshooting and enhancing performance. This section will explore frequent problems and potential solutions to ensure optimal functionality.

Typical Problems Faced

- Device fails to start

- Inadequate water flow

- Unusual noises during operation

- Inconsistent cleaning results

Possible Solutions

- Check for fuel and oil levels to ensure adequate supply.

- Inspect hoses for blockages or leaks that may hinder performance.

- Examine the nozzle for clogs and clean as necessary.

- Review settings and adjustments to optimize efficiency.

Tools Needed for Effective Repairs

To ensure smooth and successful maintenance tasks, having the right instruments is essential. Proper tools not only facilitate the process but also enhance safety and efficiency during various fixing endeavors.

Essential Instruments

- Socket set

- Wrenches

- Screwdrivers (both flat and Phillips)

- Pliers

- Utility knife

- Measuring tape

Safety Equipment

- Gloves to protect hands

- Safety goggles for eye protection

- Dust mask to avoid inhalation of particles

Having these tools and safety gear on hand will significantly contribute to effective and safe maintenance practices.

Troubleshooting Starting Problems

If your cleaning device is having difficulty initiating, there are several factors to consider. Addressing these common issues can help restore functionality and ensure efficient operation.

Common Issues to Check

- Fuel Supply: Ensure that the fuel tank is filled with fresh fuel. Stale fuel can cause starting difficulties.

- Oil Levels: Check the oil level, as low or dirty oil can affect engine performance.

- Battery Condition: If applicable, verify that the battery is charged and free of corrosion on the terminals.

- Air Filter: Inspect the air filter for clogs. A clean filter is essential for proper air intake.

Steps to Resolve Issues

- Examine the fuel system and replace any old fuel with fresh fuel.

- Check the oil level and replace the oil if it appears dirty or is below the recommended level.

- Inspect the battery connections and clean any corrosion found.

- Replace or clean the air filter if it is blocked or dirty.

By following these guidelines, you can address common starting issues and ensure your cleaning equipment operates smoothly.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your cleaning equipment. Implementing simple practices can significantly enhance its performance and durability, allowing for optimal functionality over time.

Routine Cleaning

Keep the exterior and interior components free from debris and contaminants. Cleaning the surfaces after each use prevents buildup that can affect performance. Pay special attention to filters and vents to ensure proper airflow.

Scheduled Inspections

Conduct periodic evaluations of all parts to identify wear and tear. Replacing worn components promptly can prevent further damage. Additionally, check hoses and connections for leaks, which can impact efficiency.

Cleaning Techniques for Optimal Performance

Maintaining your equipment is essential for ensuring its efficiency and longevity. Proper cleaning techniques not only enhance the device’s performance but also prevent potential issues that can arise from neglect. This section explores various methods to keep your equipment in top condition, allowing for maximum effectiveness during use.

Routine Maintenance Practices

Establishing a consistent cleaning schedule is vital. Regularly removing dirt and debris helps maintain optimal function. Here are some effective practices:

| Technique | Description |

|---|---|

| Pre-Cleaning Inspection | Check for loose parts and accumulated grime before cleaning. |

| Surface Wiping | Use a damp cloth to wipe down surfaces, ensuring all dirt is removed. |

| Component Detailing | Focus on cleaning individual parts with appropriate tools to avoid damage. |

Advanced Techniques for Enhanced Results

In addition to routine practices, employing advanced cleaning techniques can significantly improve performance. Techniques such as using specialized solutions can help in removing stubborn stains and buildup.

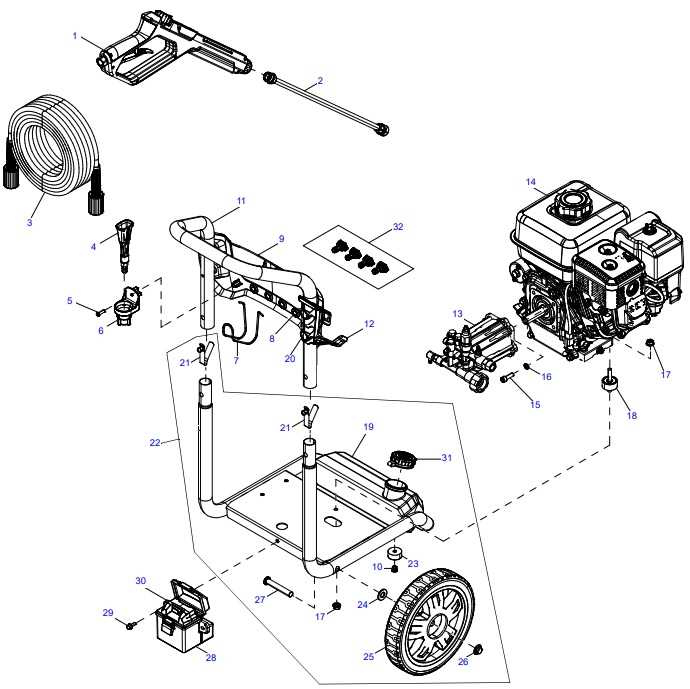

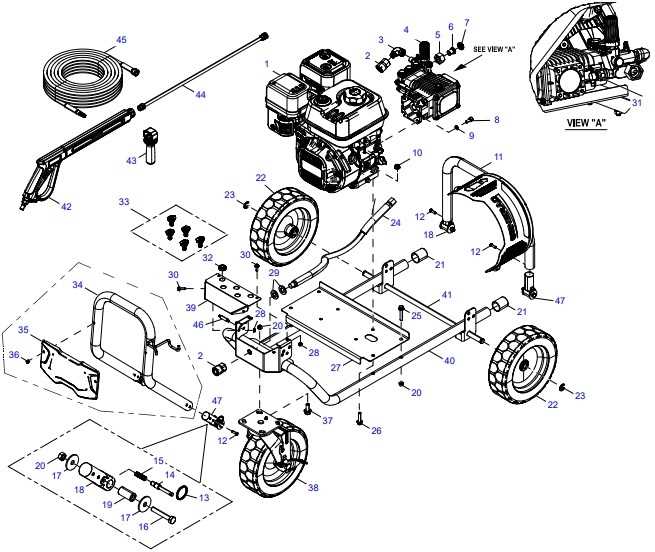

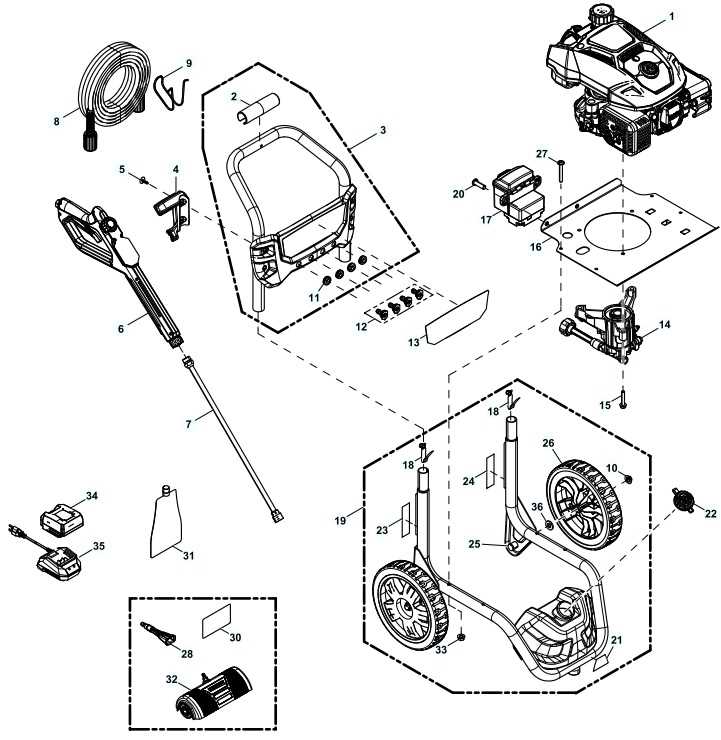

How to Replace Essential Parts

Maintaining your cleaning device involves replacing crucial components to ensure optimal performance. This section outlines the necessary steps to efficiently change out vital parts for effective operation.

Before starting, gather the required tools and materials. It’s important to work in a well-lit environment and follow safety precautions.

- Identify the Parts:

Determine which components need replacement. Common items include:

- Hoses

- Filters

- Connections

- Disconnect Power Source:

For safety, ensure the device is unplugged or the fuel supply is turned off before proceeding.

- Remove Old Components:

Carefully detach the worn-out parts. Use the appropriate tools to avoid damage.

- Install New Parts:

Align and secure the new components as per the manufacturer’s guidelines. Make sure all connections are tight.

- Test Functionality:

Once the new parts are installed, reconnect the power source and perform a test to ensure everything is working correctly.

Regularly replacing key components not only enhances efficiency but also extends the lifespan of your equipment.

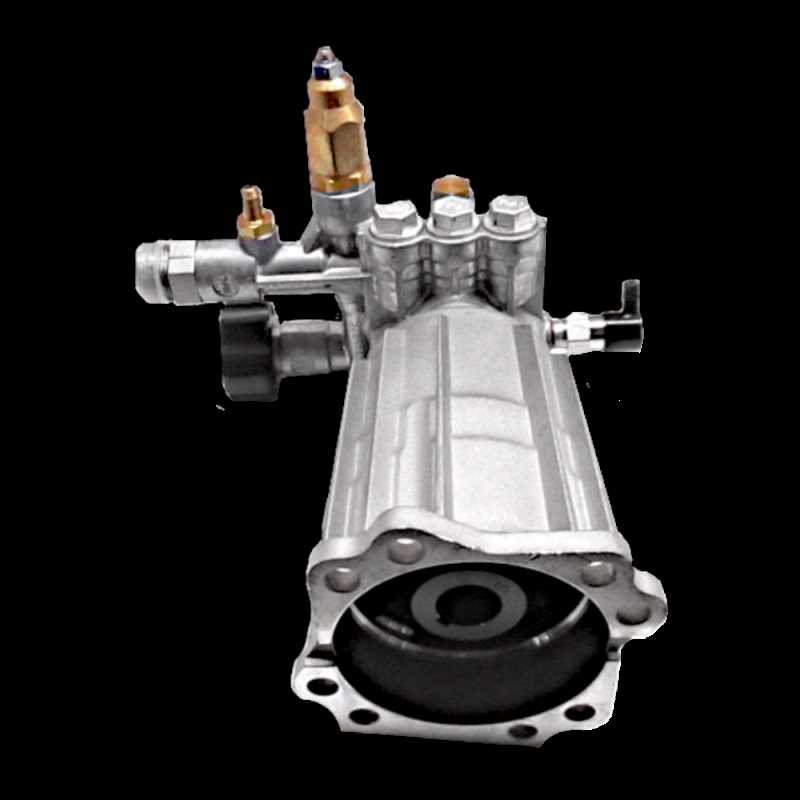

Identifying Leaks and Their Solutions

Detecting fluid escapes in equipment is crucial for maintaining optimal performance and preventing further damage. Recognizing the signs of leakage early on can save time and resources in the long run. This section will guide you through the common indicators of leaks and provide effective solutions to address them.

Common Signs of Leakage

- Visible fluid pooling beneath the unit

- Unusual wet spots on surrounding surfaces

- Decreased performance or efficiency

- Unpleasant odors emanating from the equipment

Effective Solutions

- Inspect all connections and hoses for wear or damage.

- Tighten loose fittings to ensure a secure seal.

- Replace any damaged seals or gaskets promptly.

- Conduct regular maintenance checks to prevent future issues.

Importance of Proper Storage Practices

Effective storage methods play a crucial role in maintaining the longevity and functionality of various tools and equipment. When items are stored appropriately, they are less likely to suffer from damage caused by environmental factors or improper handling. This ensures that they remain in optimal condition for future use.

Prevention of Damage

One of the primary benefits of appropriate storage is the prevention of wear and tear. By keeping devices in a dry and protected environment, users can avoid issues such as rust, corrosion, or degradation of materials. Additionally, using suitable containers or racks can further shield equipment from accidental impacts or falls.

Enhanced Lifespan

Adopting correct storage practices not only safeguards against immediate damage but also extends the overall lifespan of tools. When items are organized and stored with care, they are more likely to perform efficiently over time. This proactive approach ultimately saves users from the costs associated with replacements and repairs.

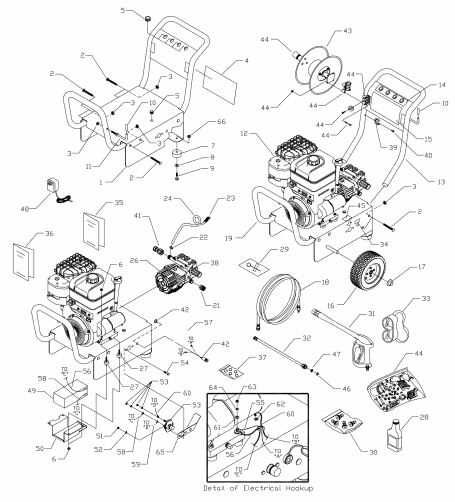

Electrical System Checks and Repairs

Ensuring the functionality of the electrical components is crucial for the optimal operation of your equipment. This section will guide you through essential diagnostics and corrective actions to maintain the electrical integrity of your device.

Common Electrical Issues

- Inconsistent power supply

- Faulty wiring connections

- Burnt fuses or circuit breakers

- Defective switches or controls

Diagnostic Steps

- Inspect the power source for any visible damage or loose connections.

- Test the voltage output using a multimeter to ensure it meets specifications.

- Check for any signs of wear or corrosion on terminals and connectors.

- Replace any blown fuses or reset tripped circuit breakers as needed.

By following these guidelines, you can effectively troubleshoot and resolve electrical problems, ensuring that your equipment remains in good working order.

Ensuring Safe Operation Procedures

To guarantee the safety of users while operating cleaning equipment, it is crucial to follow established protocols and guidelines. Proper practices help prevent accidents and ensure effective performance of the device.

Prior to using the equipment, it is advisable to review the operational guidelines carefully. This preparation involves understanding the features and capabilities of the machine, as well as recognizing potential hazards associated with its use. Below is a table outlining essential safety precautions:

| Safety Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety goggles, gloves, and appropriate footwear to protect yourself from debris and splashes. |

| Check for Damage | Inspect the equipment for any signs of wear or damage before starting. Ensure all components are functioning correctly. |

| Use in Well-Ventilated Areas | Operate the device in areas with good airflow to avoid inhaling harmful fumes or vapors. |

| Keep a Safe Distance | Maintain a safe distance from bystanders and pets to prevent accidents during operation. |

| Follow Manufacturer’s Instructions | Adhere to the guidelines provided by the manufacturer for safe and efficient usage. |

By following these safety measures, users can ensure a secure and efficient experience while utilizing cleaning equipment.

Seasonal Maintenance Checklist

Regular upkeep of your equipment is essential to ensure optimal performance throughout the year. Following a seasonal maintenance checklist helps identify potential issues early, prolonging the lifespan of your tools and ensuring they operate efficiently when needed.

Inspect the Engine: Check the oil level and replace it if necessary. Ensure that all filters are clean and functioning properly to prevent contaminants from affecting performance.

Clean the Components: Remove any debris and buildup from the exterior and internal parts. This includes checking hoses and connections for any signs of wear or damage.

Check Fuel System: Ensure that the fuel is fresh and free from impurities. If the equipment has not been used for an extended period, consider draining old fuel and refilling with new.

Test Safety Features: Verify that all safety mechanisms are operational. This includes checking switches and automatic shut-off features to ensure they function correctly.

Store Properly: After maintenance, store the equipment in a dry, sheltered area to protect it from the elements. Covering the machinery can also prevent dust accumulation.

By adhering to this checklist, you can maintain your equipment in peak condition, ready for any task that may arise.