Understanding the intricacies of your home cleaning device can enhance its longevity and performance. This section provides essential insights into common issues that may arise during operation and how to address them effectively.

In this comprehensive overview, we will explore various strategies to diagnose and resolve problems encountered with your appliance. From minor glitches to more significant complications, you’ll find practical solutions designed to restore optimal functionality.

Equipped with the right knowledge, you can confidently tackle maintenance tasks and ensure your appliance remains in top condition. Embrace the opportunity to become more familiar with the workings of your device and empower yourself to handle challenges that may come your way.

This section provides a systematic approach to identifying and resolving common issues encountered with laundry appliances. Following these steps can help in diagnosing problems effectively and determining the necessary actions to restore functionality.

Common Issues and Solutions

| Issue | Possible Causes | Suggested Actions |

|---|---|---|

| Machine won’t start | Power supply issues, door not closed | Check power connection, ensure door is securely closed |

| Water not filling | Hose kinked, water supply turned off | Inspect hose for kinks, verify water supply is on |

| Cycle not completing | Blocked drain, unbalanced load | Clear drain filter, redistribute laundry evenly |

Further Steps

If issues persist after following the above recommendations, consider consulting a professional technician or referring to detailed documentation for advanced diagnostics. Regular maintenance can also help prevent future complications.

Essential Tools for Repairs

Having the right equipment on hand is crucial for effective maintenance tasks. This section highlights the fundamental instruments that ensure efficiency and precision when addressing common issues.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers allows for the removal and installation of screws in different sizes and types. |

| Wrench | Adjustable or fixed wrenches assist in loosening or tightening bolts and nuts, providing the necessary torque. |

| Pliers | Essential for gripping, twisting, and cutting wires or components, offering versatility in handling various tasks. |

| Multimeter | This device measures voltage, current, and resistance, crucial for diagnosing electrical issues. |

| Utility Knife | Ideal for cutting through packaging or materials, it proves useful in various scenarios during maintenance. |

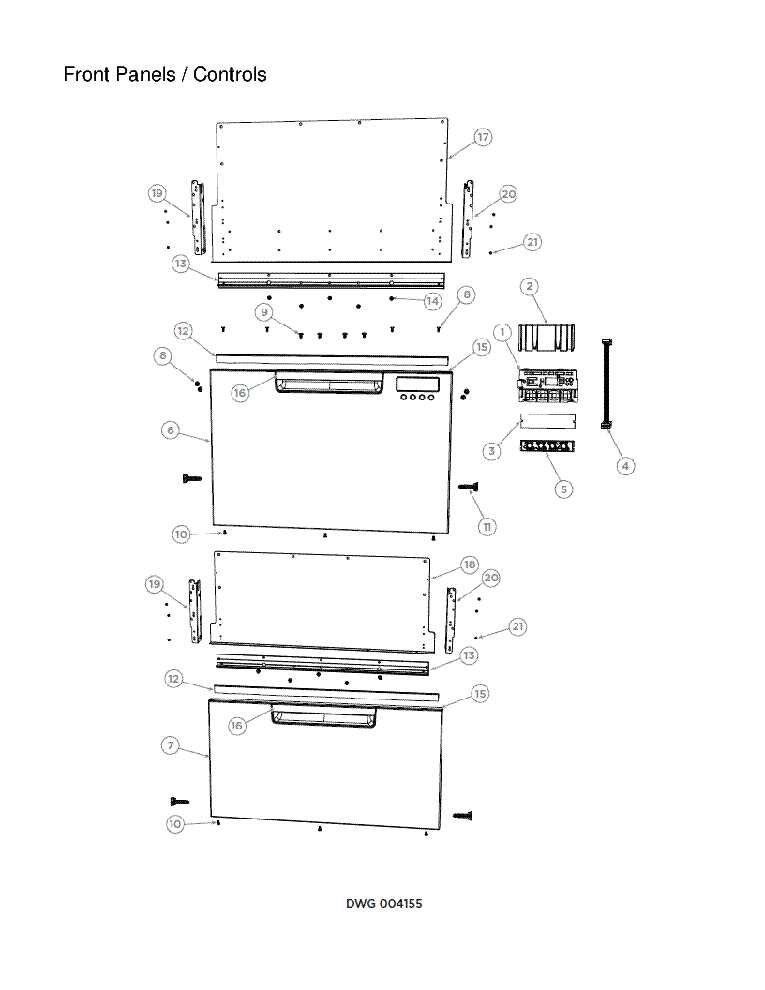

How to Access Washer Components

To effectively troubleshoot or maintain your appliance, it is essential to reach its internal parts. This process allows for a thorough inspection and ensures that all elements function optimally.

Start by disconnecting the unit from its power source to ensure safety. Next, locate the screws or clips securing the front or back panel. Carefully remove these fasteners, and gently lift the panel away to expose the inner workings. Take note of any wiring connections to avoid confusion during reassembly.

For deeper access, you may need to detach additional components such as the drum or pump. Follow the manufacturer’s guidelines for specific instructions regarding these parts, ensuring a systematic approach to avoid damage.

Replacing the Door Seal Effectively

Maintaining a proper seal on the entry point of your appliance is crucial for optimal performance. Over time, wear and tear can compromise this component, leading to leaks and inefficiencies. This section outlines the essential steps to replace this critical element smoothly and effectively.

Tools Needed

- Flathead screwdriver

- Phillips screwdriver

- New door seal

- Cleaning cloth

Steps to Follow

- Unplug the appliance to ensure safety during the process.

- Remove the old seal by gently prying it from its groove using the flathead screwdriver.

- Thoroughly clean the area to remove any debris or residue.

- Carefully position the new seal in the groove, ensuring it fits snugly.

- Check for any gaps or misalignments and adjust as necessary.

- Reconnect the appliance to power and test for proper functionality.

Motor and Belt Maintenance Tips

Ensuring optimal performance of the appliance requires regular attention to key components, particularly the drive system. Proper care of these elements can enhance efficiency and extend the lifespan of the unit.

- Check for wear and tear on the drive belt. Look for cracks or fraying that may indicate the need for replacement.

- Inspect the motor for any unusual noises. Grinding or squeaking sounds may suggest internal issues that require professional evaluation.

- Ensure the drive belt is properly tensioned. A loose belt can slip, leading to poor performance and potential damage.

- Keep the motor and surrounding area clean. Dust and debris can hinder operation and contribute to overheating.

Regularly scheduled maintenance can prevent unexpected breakdowns and maintain the efficiency of the machine. Following these tips will help in achieving smooth operation and prolonging the service life of critical components.

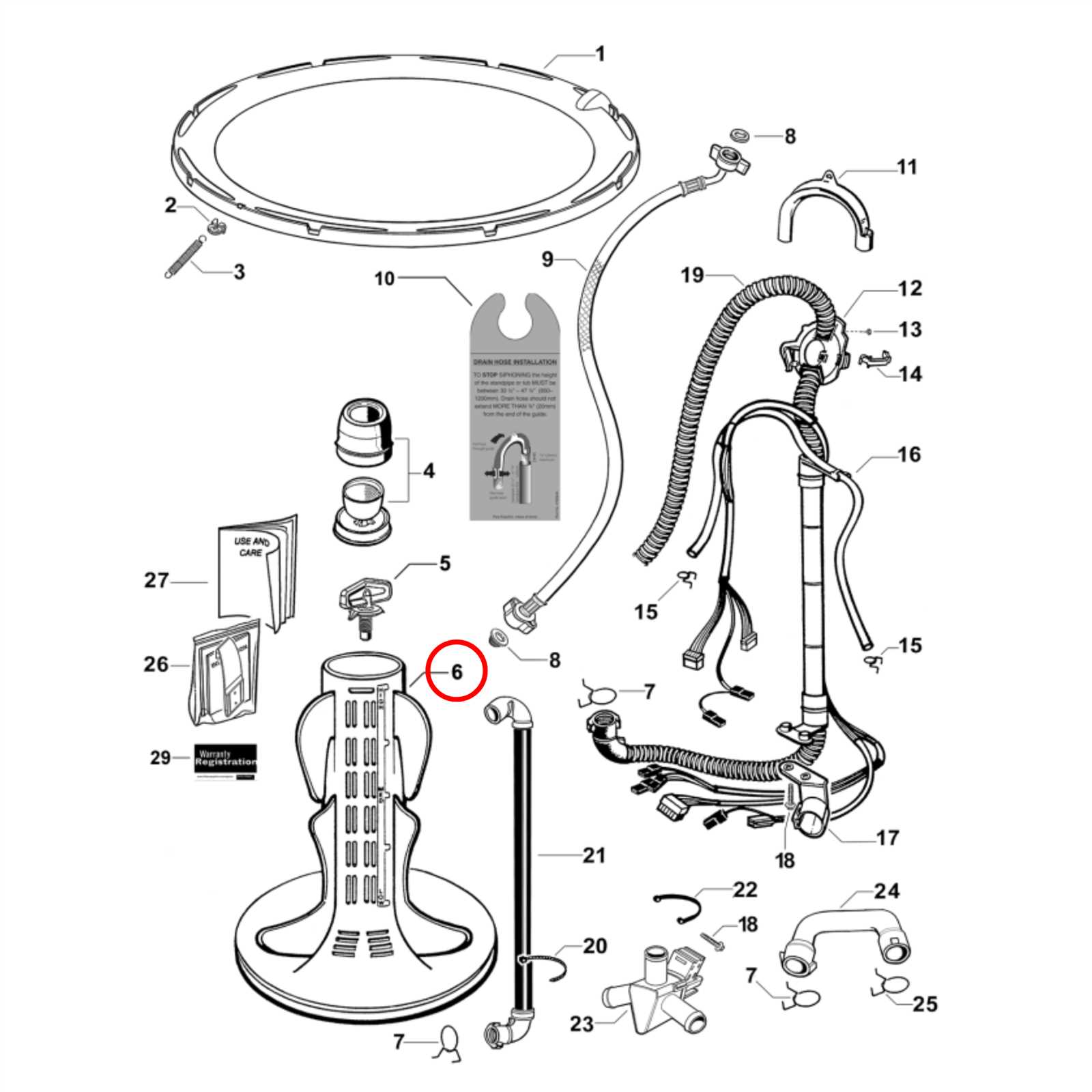

Dealing with Water Drainage Problems

Issues related to the expulsion of liquid can significantly hinder the functionality of your appliance. Recognizing and addressing these complications promptly is essential for maintaining efficiency and preventing further damage. This section outlines common challenges associated with water drainage and offers practical solutions.

Common Symptoms of Drainage Issues

Several indicators can signal that your appliance is facing difficulties in removing excess liquid. Observing these signs early can facilitate quicker resolutions.

| Symptoms | Description |

|---|---|

| Water accumulation | Puddles or standing water within the machine or beneath it. |

| Unpleasant odors | Foul smells emanating from the appliance, often due to stagnant liquid. |

| Slow drainage | Liquid takes longer than usual to empty after a cycle. |

Troubleshooting Steps

To effectively tackle drainage concerns, follow these systematic troubleshooting steps:

- Check for blockages in the drainage hose.

- Inspect the filter for debris or buildup.

- Ensure the drainage pump is functioning correctly.

Electrical System Safety Precautions

Ensuring the safety of electrical components is paramount when dealing with home appliances. Proper precautions can prevent accidents, injuries, and damage to equipment. Understanding these measures will help maintain a secure environment during maintenance or troubleshooting.

General Guidelines

When engaging with electrical systems, it is essential to adhere to specific protocols. Always disconnect power sources before commencing any work. Utilize appropriate tools designed for electrical tasks to minimize risks.

Personal Protective Equipment

Wearing suitable personal protective equipment (PPE) is critical. This includes insulated gloves, safety goggles, and non-conductive footwear to enhance safety while handling electrical components.

| Precaution | Description |

|---|---|

| Disconnect Power | Always turn off the main switch or unplug the device before starting work. |

| Use Insulated Tools | Employ tools with insulated handles to reduce the risk of electric shock. |

| Check for Voltage | Use a voltage tester to confirm that no electrical current is present before touching any components. |

| Wear PPE | Protective gear should be worn to shield against potential hazards during work. |

Understanding Error Codes and Solutions

When encountering issues with your appliance, recognizing the significance of various codes can greatly assist in diagnosing problems. These indicators serve as a communication method between the device and the user, providing insights into underlying malfunctions.

Common error messages may relate to different operational failures, from water supply issues to electrical malfunctions. Addressing these alerts promptly can prevent further complications.

Typical Error Codes

- Error Code 1: Indicates a water supply problem.

- Error Code 2: Suggests an issue with drainage.

- Error Code 3: Points to a malfunction in the door lock mechanism.

- Error Code 4: Denotes an electrical fault.

Solutions to Common Issues

- For water supply issues:

- Check if the inlet hoses are kinked or blocked.

- Ensure that the water supply is turned on.

- For drainage problems:

- Inspect the drain hose for clogs.

- Make sure the drain filter is clean.

- For door lock failures:

- Examine the door latch for any obstructions.

- Test the door lock mechanism for proper operation.

- For electrical faults:

- Verify that the appliance is properly plugged in.

- Check for tripped circuit breakers or blown fuses.

Addressing these alerts systematically can enhance the longevity and efficiency of your device. Regular maintenance and timely responses to error codes will ensure optimal performance.

Preventative Maintenance for Longevity

Regular upkeep is essential to extend the lifespan of your laundry appliance. By implementing simple strategies, you can prevent potential issues and enhance performance, ensuring efficient operation for years to come.

Start by frequently cleaning the exterior and interior components to avoid the buildup of dirt and residues. Check seals and hoses for wear, as these elements are crucial for maintaining optimal functionality. Additionally, ensure that the appliance is leveled correctly to minimize vibrations during cycles.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean lint filter | After each use | Remove lint and debris to maintain airflow. |

| Inspect hoses | Monthly | Look for leaks or cracks; replace if necessary. |

| Wipe down surfaces | Weekly | Use a damp cloth to remove dust and stains. |

| Run a maintenance cycle | Monthly | Utilize a cleaning solution to eliminate odors. |

By adhering to these practices, you can significantly enhance the reliability and efficiency of your appliance, leading to a longer service life and a more pleasant user experience.