When household equipment encounters difficulties, understanding how to address common issues becomes essential for maintaining functionality and efficiency. This section provides insights into diagnosing typical problems that may arise with multifunctional units designed for laundry tasks.

Equipping oneself with knowledge about the components and mechanisms of these appliances is vital for effective solutions. The following information offers guidance on identifying symptoms, implementing fixes, and ensuring optimal performance, ultimately helping users save time and resources.

tags. Each heading is meaningful and avoids repetition: Understanding Common Issues”>

tags. Each heading is meaningful and avoids repetition: Understanding Common Issues”>

This section will delve into prevalent challenges encountered by users of laundry appliances. By identifying these frequent problems, users can gain insights into effective troubleshooting methods, thereby enhancing the longevity and performance of their equipment.

Identifying Symptoms of Malfunction

Understanding the specific symptoms that indicate a malfunction is crucial for addressing issues promptly. Common signs include unusual noises, failure to start, or inconsistent cleaning results.

Assessing Performance Decline

Over time, appliances may exhibit a decline in performance. Recognizing the indicators of reduced efficiency can help in implementing timely maintenance measures.

Common Error Codes Explained

Many modern units display error codes when problems arise. Familiarity with these codes can facilitate quick diagnosis and resolution of issues.

Understanding Drainage Problems

Drainage issues are a frequent cause of malfunction in laundry devices. It’s important to identify potential clogs or pump failures that may impede proper water removal.

Addressing Heating Failures

Heating problems can significantly affect the drying process. Users should be aware of the signs that indicate a failure in the heating element or thermostat.

Investigating Electrical Issues

Electrical malfunctions can lead to various operational problems. Understanding how to troubleshoot these issues is essential for restoring functionality.

Maintaining Proper Ventilation

Poor ventilation can lead to overheating and performance issues. Users should ensure that vents are clear and unobstructed to maintain optimal airflow.

Examining Water Supply Concerns

Inadequate water supply can hinder cleaning efficiency. Identifying issues with hoses or valves is crucial for resolving these types of problems.

Understanding Component Wear and Tear

Regular use can lead to wear and tear on various components. Awareness of which parts are prone to failure can aid in preventive maintenance.

Importance of Regular Maintenance

Routine maintenance is vital for prolonging the lifespan of laundry machines. Establishing a maintenance schedule can help prevent common issues from arising.

Utilizing User Guides Effectively

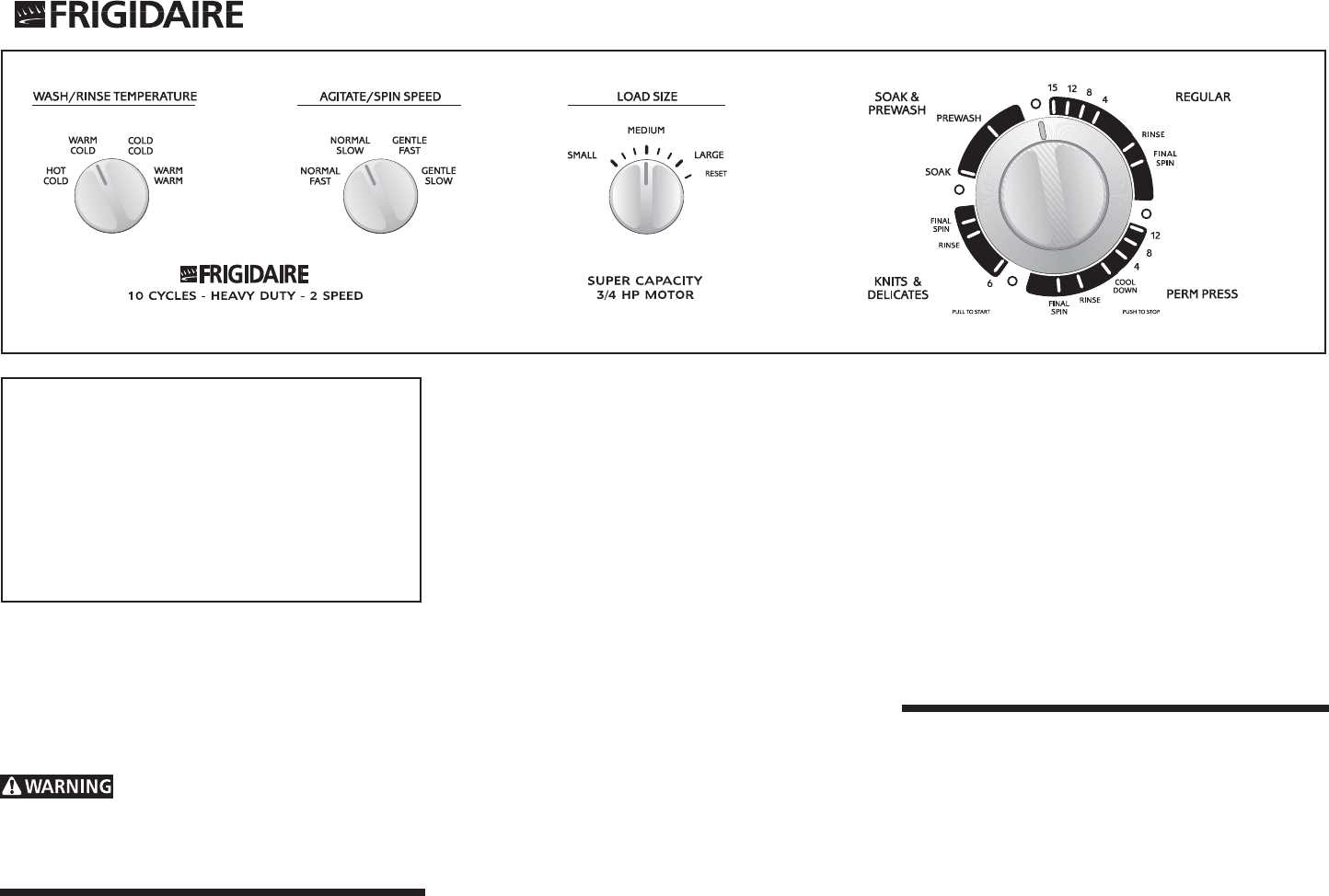

User guides contain valuable information for troubleshooting and maintenance. Knowing how to navigate these resources can empower users to resolve issues independently.

Consulting Professionals When Necessary

In some cases, professional assistance may be required. Recognizing when to seek help can save time and prevent further damage to the equipment.

| Issue | Possible Cause | Recommended Action | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Failure to Start | Electrical fault | Ch

Tools Needed for RepairHaving the right equipment is essential for effective troubleshooting and fixing of malfunctioning appliances. A well-stocked toolkit can make the difference between a smooth repair process and unnecessary complications. Below is a list of essential instruments that can assist in the restoration of functionality.

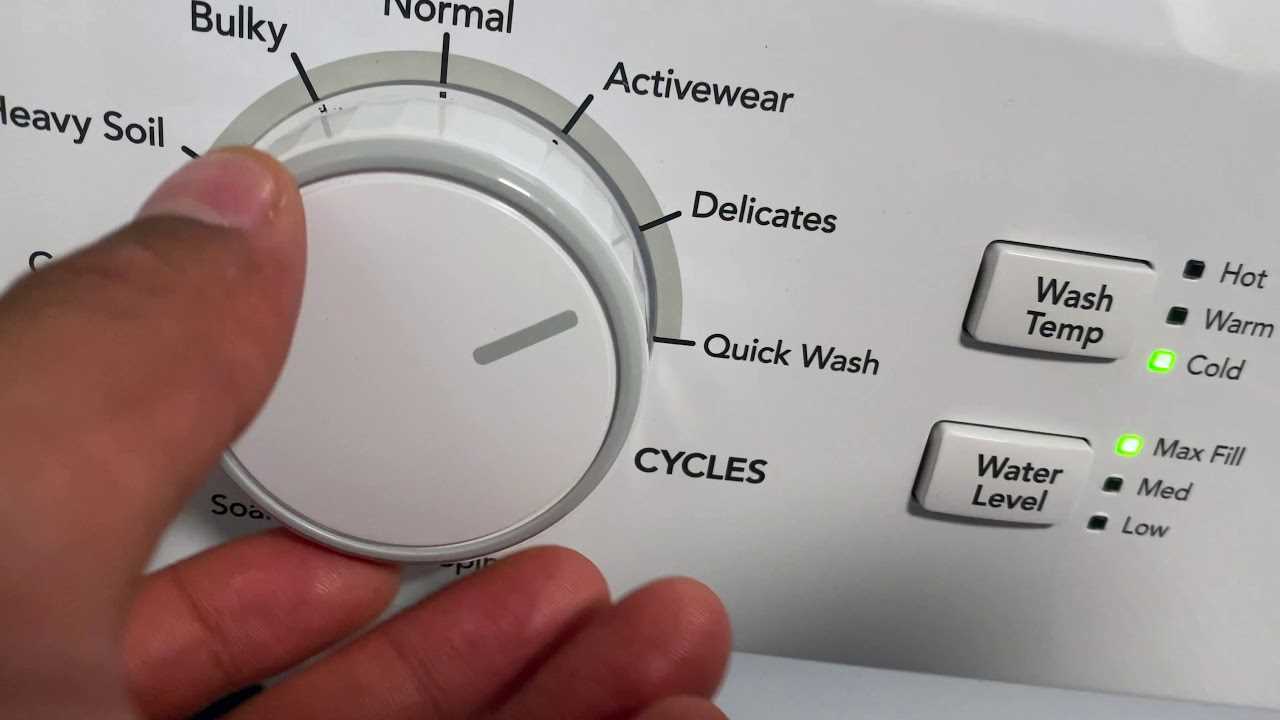

Step-by-Step Troubleshooting GuideThis section provides a systematic approach to identifying and resolving common issues encountered with household laundry appliances. Following these outlined steps can assist users in diagnosing problems effectively and finding appropriate solutions without the need for professional assistance. Identifying the ProblemThe first step involves determining the exact nature of the malfunction. Listen for unusual noises, observe any error codes displayed, and note if the appliance fails to start or complete cycles. Documenting these details will help in pinpointing the issue. Common SolutionsOnce the problem is identified, begin troubleshooting by checking the power supply, ensuring that the unit is properly plugged in and that circuit breakers are functioning. Next, inspect the water supply hoses and filters for clogs or kinks that may disrupt operations. Additionally, verify that all settings are correctly adjusted according to the desired cycle. By following this guide, users can systematically address problems and restore their laundry equipment to optimal performance. Replacing the Door SealOver time, the seal around the entrance of your appliance may wear out or become damaged, leading to issues like leaks or inefficient operation. Addressing this problem is crucial for maintaining optimal performance and preventing further complications. Identifying the ProblemBefore starting the replacement process, it’s essential to confirm that the seal is indeed the source of the issue. Look for signs such as water pooling around the base or a noticeable gap in the door closure. If you detect any of these symptoms, replacing the seal will likely resolve the problem. Steps for ReplacementBegin by disconnecting the unit from the power source for safety. Next, carefully remove the old seal from its groove, taking care not to damage the surrounding surfaces. Clean the area thoroughly to ensure a secure fit for the new seal. Once prepared, insert the new seal, ensuring it fits snugly and evenly in the groove. Finally, reconnect the unit to the power source and check for any leaks during operation. Cleaning the Lint Filter

Maintaining optimal performance of your laundry appliance involves regular upkeep of its components, including the lint filter. This essential task prevents buildup that can hinder functionality and pose safety hazards. Keeping the filter clean not only ensures efficient drying but also enhances the longevity of the machine. Why Clean the Lint Filter?Cleaning the lint filter is crucial for several reasons:

How to Clean the Lint Filter

Follow these simple steps to effectively clean the lint filter:

Water Supply ProblemsIssues with the water supply can significantly affect the performance of your appliance. When water flow is disrupted or inadequate, it can lead to various operational challenges. Understanding the common causes and solutions for these problems is essential for maintaining optimal functionality. Here are some common water supply issues to consider:

To address these issues, consider the following steps:

Draining Issues and SolutionsMany users encounter challenges related to water evacuation in their laundry appliances, which can lead to unsatisfactory cleaning results and potential damage. Understanding common drainage problems and their resolutions is essential for maintaining optimal performance and extending the lifespan of your unit. Common Causes of Drainage ProblemsSeveral factors can contribute to inadequate water removal. Clogs in the drainage system, malfunctioning pumps, or improper installation are frequent culprits. Additionally, foreign objects lodged in hoses or filters can obstruct flow, hindering effective evacuation. Effective Solutions

To address drainage issues, start by inspecting and clearing any visible blockages in the hoses or filters. Ensure that the appliance is level and properly installed, as uneven positioning can affect drainage efficiency. If problems persist, consider checking the pump for functionality and replacing it if necessary. Regular maintenance and cleaning can help prevent future complications. Electrical Component CheckThis section focuses on the importance of assessing electrical elements within the appliance. Proper functioning of these components is crucial for optimal performance and longevity of the unit. By conducting a thorough examination, potential issues can be identified and resolved promptly, ensuring reliable operation. Key Electrical Components

Inspection Steps

Maintenance Tips for Longevity

To ensure the long-lasting performance of your laundry appliance, regular upkeep and attention to detail are essential. Implementing a few straightforward practices can significantly enhance its efficiency and lifespan. By taking proactive measures, you can avoid common pitfalls that may lead to more significant issues over time. Regular CleaningRoutine cleaning is crucial for maintaining optimal functionality. Residue from detergents and lint can accumulate and cause operational difficulties. Here are some cleaning tips:

Proper Usage Practices

Adopting correct usage habits can also extend the life of your appliance. Consider the following guidelines:

When to Call a ProfessionalIdentifying the right moment to seek expert assistance can significantly impact the longevity and efficiency of your appliance. While some issues may seem minor and manageable, others may require specialized knowledge and tools to resolve effectively. Consider reaching out to a specialist in the following scenarios:

By recognizing these signs, you can ensure your appliance remains in optimal condition and avoid potential complications down the line. Parts Replacement GuideThis section offers essential information for individuals seeking to replace components in their laundry appliances. Understanding when and how to substitute parts can enhance the efficiency and longevity of the unit. It is crucial to identify the specific elements that may require replacement to ensure optimal functionality. Identifying Faulty Components Before proceeding with any substitutions, it’s vital to diagnose which parts are malfunctioning. Common indicators include unusual noises, leaks, or failure to operate as expected. Consulting a troubleshooting resource can assist in pinpointing the exact issue. Gathering Necessary Tools Having the right tools on hand simplifies the replacement process. Typically, you may need screwdrivers, pliers, and possibly a multimeter for electrical components. Ensure that all tools are readily accessible before starting the work to avoid interruptions. Steps for Replacement When ready to replace a component, follow these general steps:

Testing the Appliance Once the new part is installed, it’s essential to test the appliance to verify that the issue has been resolved. Monitor its performance closely during the first few uses to ensure everything functions correctly. Safety Precautions During RepairsWhen performing maintenance on home appliances, it is crucial to prioritize safety to prevent accidents and damage. Adhering to established guidelines minimizes risks and ensures that tasks are carried out effectively and securely.

|