This section provides a thorough overview of essential practices and techniques for maintaining and diagnosing issues in advanced automotive systems. Here, you will find detailed instructions on how to approach and manage common mechanical complications, ensuring a smooth and reliable experience with your vehicle’s core components.

Understanding Key Operations in these systems is crucial to enhance performance and prevent future malfunctions. By following the outlined methods, users can gain insights into effective handling, regular check-ups, and preventive actions. This guide is structured to cater both to those with technical experience and to newcomers, offering easy-to-follow steps and practical tips.

For optimal results, routine assessments and timely adjustments are recommended. Readers will also find expert advice on interpreting system signals and managing potential challenges in diverse conditions. With this comprehensive approach, even complex mechanisms become more accessible and manageable for users.

Fnr5 Transmission Repair Manual

This section provides guidance on addressing common issues related to the performance and functionality of your vehicle’s gear system. Focusing on essential diagnostics and techniques, this guide aims to assist both beginners and experienced mechanics in maintaining optimal operation.

- Identifying Issues: Learn the signs of possible malfunctions within the system, from unusual noises to responsiveness issues, and understand how to accurately pinpoint root causes.

- Basic Maintenance Tips: Regular upkeep can significantly prolong the life of your vehicle’s components. This includes monitoring fluid levels, inspecting key parts, and addressing minor issues before they escalate.

- Step-by-Step Restoration: Explore a detailed series of steps to restore and improve your vehicle’s gear performance, with practical tips for working on specific areas.

Following this guide will help you ensure reliability and efficiency, supporting smoother performance and preventing future complications through proactive care.

Understanding Fnr5 Transmission Components

The inner workings of this mechanical system rely on a range of key parts designed to transfer power and ensure smooth vehicle movement. Each component has a unique role in controlling power flow, enabling precise shifts and delivering efficiency across various driving conditions. Examining these parts offers insight into how they work together to enhance performance and reliability.

Main Gears and Shafts

Central to this setup are the main gears and shafts that coordinate rotational energy transfer. Gears of various sizes work in unison, adjusting speed and torque to meet different driving demands. Shafts serve as the structural axis, transferring the generated motion across the system, aligning with the gears to create the desired output.

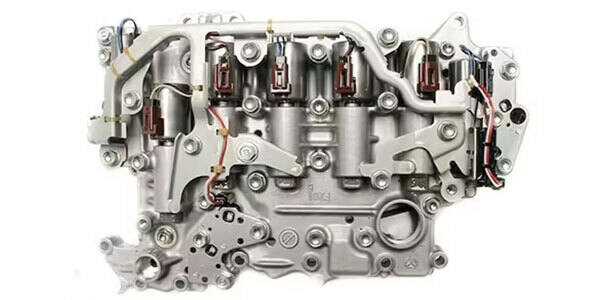

Clutch Packs and Valve Body

The clutch packs and valve body play essential roles in regulating engagement and fluid flow. Clutch packs activate to manage gear changes, while the valve body directs hydraulic fluid, ensuring smooth transitions and precise control. Together, these parts maintain balance within the system, providing a reliable driving experience.

Common Issues in Fnr5 Transmissions

Many drivers encounter a range of recurring concerns in these systems, which can affect the smoothness and responsiveness of operation. Recognizing early indicators can help prevent extensive complications and maintain optimal performance.

- Unexpected Shifts: One frequent problem involves sudden changes in speed, often noticed during acceleration. This may lead to abrupt movements that can be unsettling and signal internal component wear.

- Fluid Leaks: Leaks from the housing are common and can lead to a decrease in efficiency, as well as potential overheating. Regular inspections of fluid levels and the surrounding area can catch leaks before they cause significant damage.

- Overheating Symptoms: Elevated temperatures may result from excessive friction within the system. Indicators include a burning smell or sluggish operation, often due to poor fluid circulation or component misalignment.

- Delayed Engagement: A delay in response when switching between driving modes is another sign of underlying issues. This lag can be due to valve or solenoid blockages that prevent fluid from moving freely.

Addressing these common concerns early can extend system longevity and ensure smooth functionality. Regular maintenance and monitoring help mitigate these issues, preserving efficiency over time.

Basic Steps for Transmission Diagnosis

Identifying the root cause of functional issues in a vehicle’s drive system requires a structured approach to analysis. This process helps in pinpointing possible sources of malfunctions that affect performance, allowing for efficient resolution.

Step 1: Preliminary Visual Check – Begin by observing any visible signs of wear or damage. Check for unusual leaks or disconnected components under the hood. A quick visual inspection can reveal obvious signs of wear and identify areas requiring deeper examination.

Step 2: Review of Warning Signals – Pay attention to dashboard lights and error codes. These signals often provide clues about potential issues within the system. Refer to the diagnostic code guide for specifics on each warning light or error message.

Step 3: Fluid Assessment – Inspect the fluid levels and c

Necessary Tools for Fnr5 Repair

To achieve effective and precise results, a range of specialized instruments is essential. Each tool plays a critical role in ensuring that adjustments and installations proceed smoothly, enabling detailed work on various components.

- Socket Set: A quality set of sockets is crucial for loosening and securing fasteners of different sizes.

- Torque Wrench: Ensures that bolts and nuts are tightened to the appropriate levels, preventing over- or under-tightening.

- Hydraulic Jack: This lifting device allows for stable elevation, providing safe and easy access to the vehicle’s undercarriage.

- Oil Drain Pan: Essential for collecting fluids during disassembly, helping to keep the workspace clean and organized.

- Screwdriver Set: Both flathead and Phillips screwdrivers are necessary for handling various small components and panels.

- Pry Bars: Used to gently separate parts without causing damage, particularly useful for tightly fitted sections.

- Diagnostic Scanner: Enables detection of system code

Identifying Transmission Fluid Problems

Recognizing issues with the fluid that facilitates the functioning of your vehicle’s shifting system is crucial for maintaining optimal performance. Various signs can indicate that there are underlying problems that need immediate attention. Being aware of these symptoms can help prevent more serious damage and costly repairs.

Common Indicators of Fluid Issues

One of the primary signs of fluid-related problems is discoloration or a burnt smell. Normally, this fluid should appear bright red and have a pleasant odor. If you notice a dark brown or black hue accompanied by a burnt scent, it’s essential to investigate further. Additionally, any fluid leaks under the vehicle can signal significant concerns that should not be overlooked.

Effects of Insufficient Fluid Levels

Low levels of this vital liquid can lead to inadequate lubrication, resulting in erratic gear shifting and potential component wear. If you experience unusual noises or difficulty in changing gears, it may be a direct consequence of insufficient fluid. Regularly checking levels and ensuring timely replenishment can mitigate these risks and enhance the overall health of your vehicle.

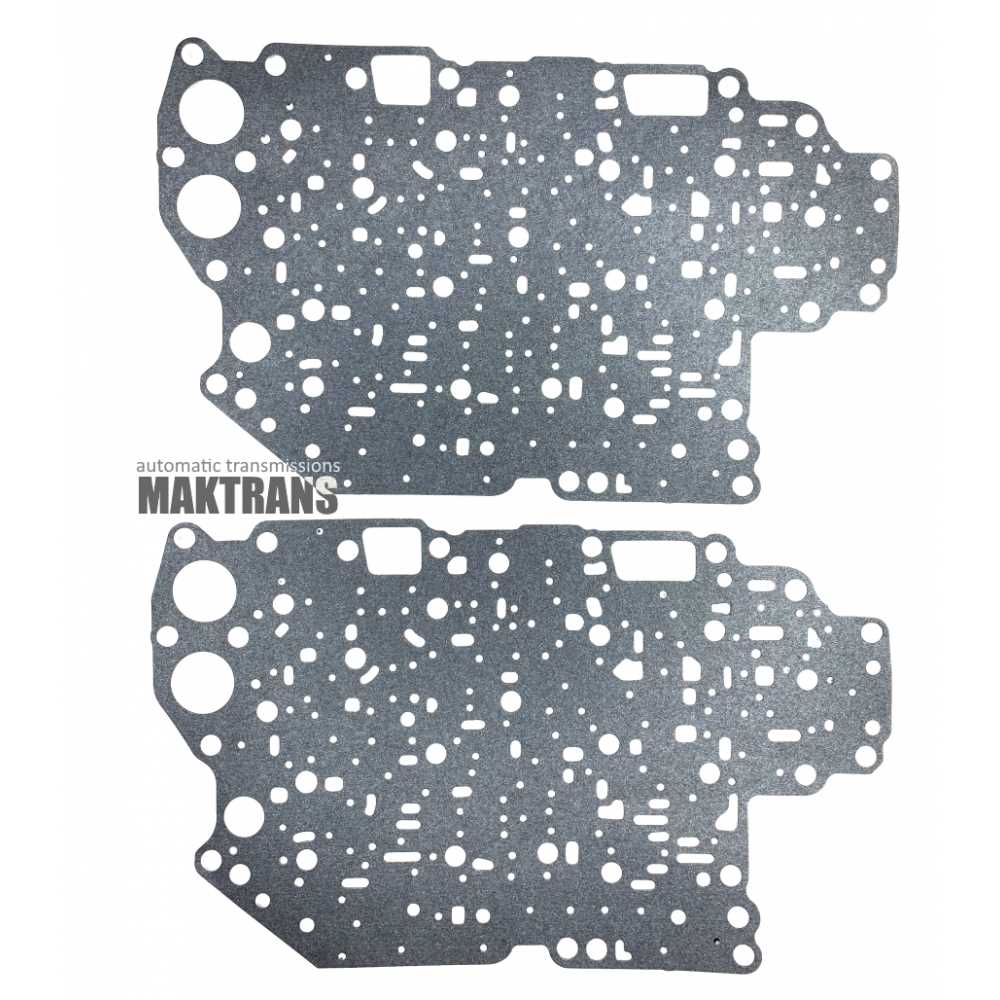

Guidelines for Transmission Disassembly

The process of separating components within a vehicle’s power transfer system requires careful planning and attention to detail. Proper techniques not only ensure the integrity of parts but also facilitate an efficient assembly later. Understanding the sequence and methods of dismantling is crucial for a successful operation.

Preparation is Key: Before starting the disassembly process, ensure that you have all necessary tools and a clean workspace. Familiarize yourself with the component layout and make notes of any specific procedures that need to be followed.

Step-by-Step Approach: Begin by disconnecting any electrical connections and fluid lines. Use a systematic approach to remove fasteners and document the order in which parts are taken apart. This will help avoid confusion during reassembly.

Safety First: Always wear appropriate personal protective equipment, such as gloves and safety glasses. Be aware of any sharp edges or potential hazards that may arise during the process. Taking precautions will protect both the technician and the components involved.

By adhering to these guidelines, you can ensure a smooth disassembly process that minimizes the risk of damage and simplifies the subsequent reassembly.

Replacing Worn-Out Fnr5 Parts

Over time, components within a vehicle’s core systems may experience natural wear, affecting overall performance. Proper upkeep and timely replacement of these elements can help restore functionality and extend the lifespan of essential parts. Addressing worn-out pieces ensures smoother operation and avoids more significant issues down the road.

Identifying Components Needing Replacement

To maintain optimal performance, regular inspections are essential. Look for signs of wear, such as unusual sounds, fluid leaks, or shifts in handling. By catching these symptoms early, you can pinpoint the specific parts requiring attention and prevent them from causing further complications.

Steps to Replace Key Elements

Preparation is key before beginning any work on vehicle parts. First, gather the necessary tools and replacement pieces to ensure a seamless process. Carefully remove the old components, paying attention to alignment and positioning, and install the new parts with precision. A proper installation can restore the system’s efficiency, allowing for a more stable and reliable driving experience.

Proper Cleaning Techniques for Transmissions

Maintaining the cleanliness of vehicle components is essential for ensuring their efficient performance and longevity. Consistent upkeep helps prevent buildup of debris that can lead to malfunction or wear. This section outlines key practices to achieve thorough cleaning and preserve optimal functionality.

Below is a detailed table on essential tools and cleaning agents:

Tool/Agent Purpose Usage Tips Brush with soft bristles Removes surface dust and loose particles Use gentle strokes to avoid scratching Compressed air Blows out dust from tight spaces Ensure proper ventilation while using Non-abrasive cleaner Dissolves oil and grease residue Apply evenly and rinse thoroughly Reassembly Tips for Smooth Operation

Proper alignment and fitting of each component are essential for reliable performance. Precision and attention to detail during reassembly help ensure smooth functioning and extend the lifespan of the equipment. This guide offers practical advice to facilitate an effective reassembly process, minimizing the chances of errors and enhancing overall stability.

Below is a table highlighting crucial reassembly aspects to consider:

Step Action Purpose 1 Inspect all parts for wear or damage before assembly Ensures components are fit for reuse and identifies replacements early 2 Apply lubrication to specified areas Reduces friction Adjusting for Optimal Performance

To achieve peak functionality and smooth operation, precise calibration is essential. Focusing on critical adjustments ensures the mechanism works seamlessly under varying conditions, enhancing longevity and responsiveness. Proper fine-tuning can prevent potential issues and support consistent performance.

Start by evaluating the control settings, as these directly impact efficiency. Incremental adjustments to these settings allow the system to respond more accurately during shifts, reducing unnecessary wear. It’s crucial to monitor for any unusual sounds or delays in movement, as these may indicate areas needing further refinement.

Regular inspection and maintenance of fluid levels also play a significant role in optimizing performance. Maintaining adequate fluid quality and volume minimizes friction and keeps the system running smoothly. Periodic replacement and checking for contaminants can prevent potential disruptions, promoting durability and reliability.

Essential Safety Precautions During Repair

Ensuring a secure environment and following proper procedures is critical to avoid accidents and protect both the equipment and the individual working on it. Observing basic guidelines can significantly reduce risks and promote an efficient process.

- Wear Appropriate Protective Gear: Always use gloves, safety glasses, and other protective wear to guard against potential hazards.

- Work in a Well-Ventilated Area: Proper ventilation helps prevent inhalation of fumes and improves air quality in the workspace.

- Disconnect Power Sources: Before beginning, make sure all power sources are turned off to prevent accidental starts or electrical hazards.

- Use Tools Correctly: Familiarize yourself with all tools and use them for their intended purposes to avoid injuries.

- Keep the Workspac

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s components is key to a smoother driving experience and reduced need for servicing. Regular upkeep not only prevents issues but also extends the lifespan of essential parts, helping maintain optimal performance over time.

- Regular Fluid Checks: Consistently monitor and replenish essential fluids. Clean, sufficient fluid levels prevent overheating and ensure smooth operation.

- Cooling System Care: Overheating can lead to costly problems. Regularly inspect the cooling system and ensure there are no leaks, maintaining proper levels of coolant.

- Filter Replacement: Replacing filters as recommended helps maintain clean fluid flow, reducing strain on internal systems and improving efficiency.

- Driving Habits: Avoid sudden starts and stops, as they put extra strain on the vehicle. Smooth and steady driving contributes significantly to part longevity.

- Regular Inspections: Scheduling periodic checks by a professional can catch early signs of wear, preventing larger issues and maintaining optimal functionality.