Ensuring the optimal performance of automotive systems is crucial for longevity and efficiency. Regular maintenance and thorough understanding of these intricate mechanisms can prevent significant issues down the line. This section aims to provide essential insights into servicing and troubleshooting complex gear arrangements, enabling vehicle owners to achieve peak functionality.

Understanding the various components involved in the gear assembly is vital for effective upkeep. Each part plays a crucial role in the overall operation, and familiarity with their functions can aid in diagnosing potential challenges. Proper knowledge and techniques will empower users to address concerns promptly, enhancing the driving experience.

Maintenance procedures are designed to extend the lifespan of these systems and improve overall vehicle performance. By following structured guidelines and employing suitable methods, individuals can carry out essential upkeep tasks confidently. This guidance serves as a valuable resource for those seeking to enhance their automotive knowledge and skills.

ZF systems are known for their robust performance, yet they can encounter various challenges over time. Understanding these common problems can aid in better maintenance and timely intervention, ensuring optimal functionality.

- Fluid Leaks: Leaks can occur at seals and gaskets, leading to insufficient lubrication and potential damage.

- Overheating: Excessive heat can result from low fluid levels or inefficient cooling systems, affecting performance.

- Shifting Delays: Hesitation during gear changes may indicate issues with sensors or hydraulic pressure.

- Unusual Noises: Grinding or clunking sounds often suggest internal wear or component failure.

- Warning Lights: Dashboard alerts may indicate malfunctions that require immediate attention to prevent further damage.

Regular inspections and proactive maintenance can help mitigate these issues, prolonging the lifespan of ZF systems.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance and troubleshooting tasks. Quality instruments not only facilitate the process but also enhance efficiency and accuracy, minimizing the risk of errors. Below are key items that should be included in any toolkit for effective servicing.

Basic Hand Tools

- Wrenches: A variety of sizes is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

Specialized Equipment

- Pressure Gauge: Measures hydraulic pressure to ensure optimal performance.

- Fluid Transfer Pump: Helps in draining and refilling essential liquids.

- Diagnostic Scanner: Identifies issues through error codes, aiding in precise troubleshooting.

- Magnetic Tool Holder: Keeps tools organized and easily accessible during the process.

Step-by-Step Repair Procedures

This section outlines a comprehensive guide for addressing mechanical issues systematically. Each phase will detail essential tasks, ensuring clarity and precision in execution.

1. Preparation: Begin by gathering all necessary tools and components. A clean and organized workspace enhances efficiency.

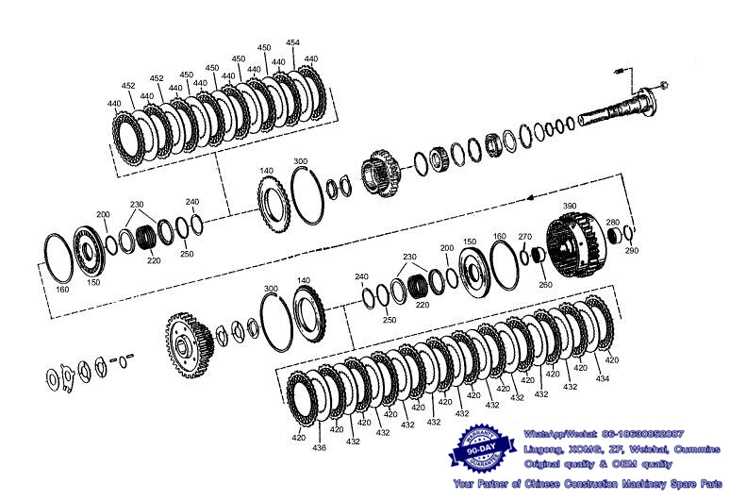

2. Disassembly: Carefully remove the exterior casing. Document the order of components to facilitate reassembly.

3. Inspection: Examine each part for wear and damage. Identifying potential failures early aids in effective solutions.

4. Replacement: Substitute any defective components with quality alternatives. Ensure compatibility to maintain optimal performance.

5. Reassembly: Follow your documented order to put the assembly back together. Verify that all fasteners are securely tightened.

6. Testing: Conduct functionality tests to confirm that the system operates smoothly. Look for any signs of leakage or unusual noises.

7. Final Checks: Perform a thorough review of the entire assembly. This ensures that everything is in its proper place and functioning as intended.

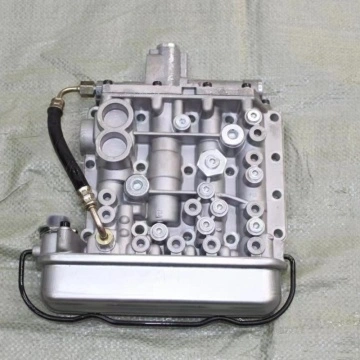

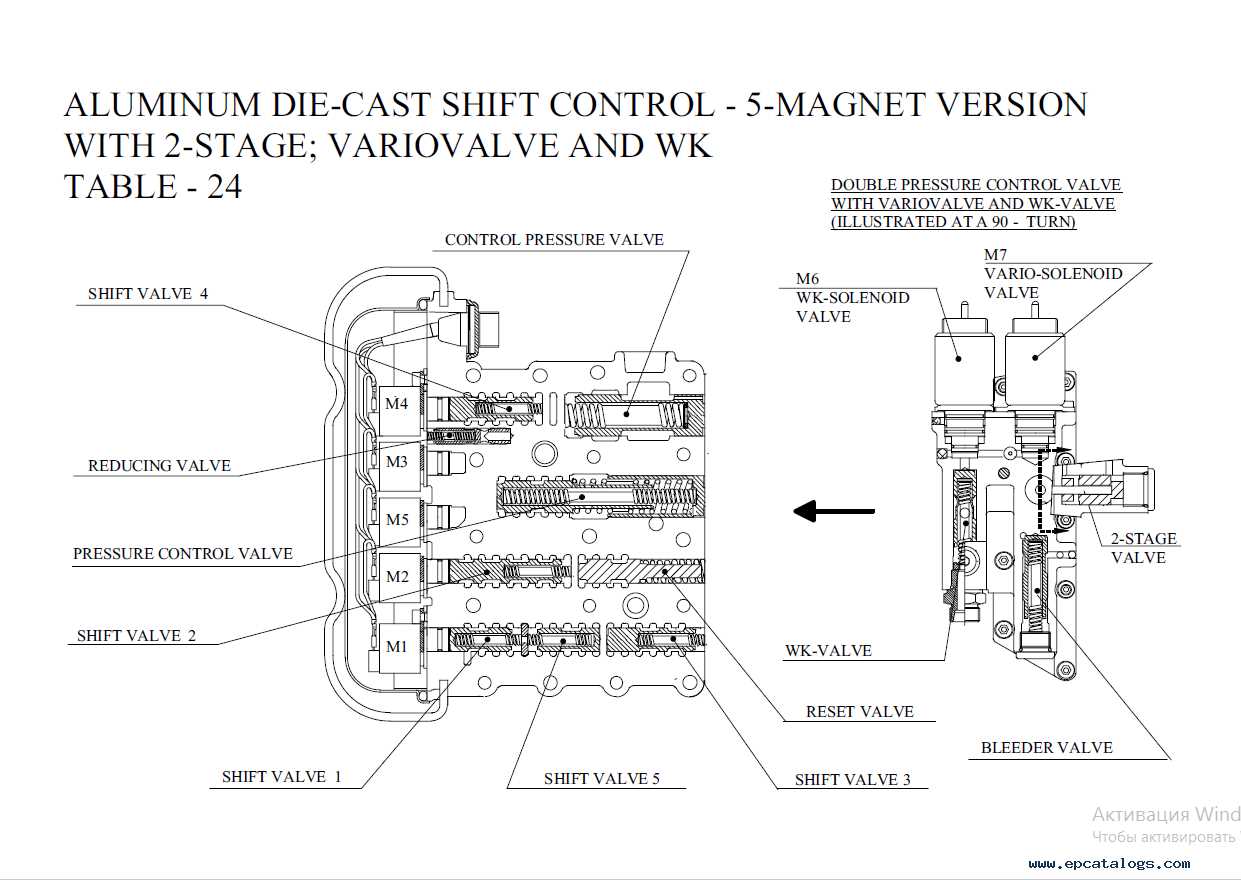

Understanding Transmission Components

This section explores the essential elements that comprise the gear-shifting mechanism found in vehicles. Each part plays a crucial role in the overall functionality, ensuring smooth operation and optimal performance.

Main Elements of the Gear-Shifting Mechanism

- Gears: These are the core elements that determine speed and torque. Different gear ratios allow for varying power outputs.

- Shafts: These components transfer rotational energy between gears, facilitating motion throughout the system.

- Bearings: Providing support and reducing friction, bearings ensure that the gears and shafts operate smoothly.

- Clutches: These mechanisms engage and disengage gears, allowing for seamless transitions during shifting.

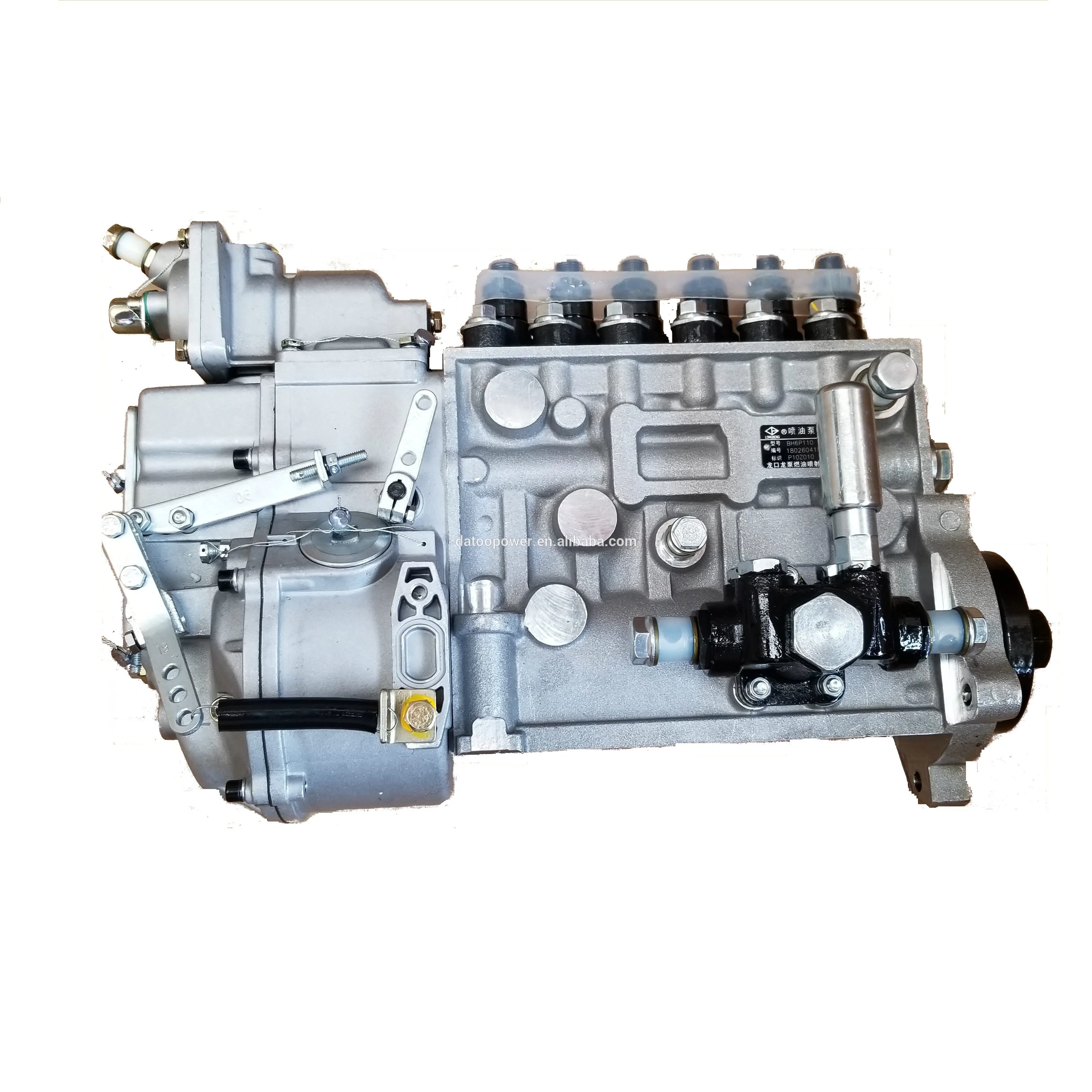

- Hydraulic System: This system uses fluid pressure to operate various components, enhancing shifting efficiency.

Importance of Regular Maintenance

- Regular inspections help identify wear and tear before they escalate into significant issues.

- Fluid changes are vital to prevent overheating and ensure that all parts function correctly.

- Cleaning and replacing filters enhance performance and extend the lifespan of the system.

Diagnosing Transmission Failures

Identifying issues within a vehicle’s power transfer system requires a systematic approach to pinpoint the root cause of malfunctions. Common symptoms can manifest through unusual noises, shifting difficulties, or fluid leaks, signaling potential problems that need attention.

Step-by-step assessment begins with a thorough inspection of the system. Visual checks for leaks or damage are essential, as they can provide immediate clues. Next, evaluate fluid quality; burnt or contaminated fluid may indicate underlying issues.

Furthermore, testing the system under various conditions can reveal inconsistencies. Conducting a road test while paying attention to behavior during gear changes can uncover significant faults. Utilizing diagnostic tools can aid in reading error codes, which are invaluable for understanding specific failures.

Ultimately, a combination of visual assessments, fluid evaluations, and diagnostic testing provides a comprehensive overview of the system’s health, paving the way for effective solutions.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your vehicle’s drivetrain system requires regular attention and care. By following a few essential guidelines, you can enhance its lifespan and minimize the likelihood of unexpected issues.

Regular fluid checks and changes are vital. Maintaining optimal levels and quality of the lubricating fluids helps prevent wear and tear on internal components. Additionally, routine inspections for leaks or signs of damage will allow you to address potential problems early.

Keep an eye on operating temperatures. Excess heat can lead to severe damage over time, so ensuring proper cooling mechanisms are functioning is crucial. If you notice any irregularities in temperature, investigate promptly.

Driving habits also play a significant role in longevity. Avoiding aggressive acceleration and abrupt stops reduces stress on the system. Smooth transitions and gentle handling can greatly extend the life of the components involved.

Lastly, consulting with a qualified technician for periodic assessments is beneficial. Professional insights can help identify underlying issues that may not be evident during routine checks, allowing for proactive measures to be taken.

Replacing Transmission Fluids Effectively

Maintaining optimal performance in automotive systems requires regular fluid changes. This practice not only ensures the longevity of components but also enhances efficiency. Understanding the best methods for fluid replacement can significantly impact overall vehicle operation.

When it comes to fluid replacement, preparation is essential. The following steps outline an effective approach:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and supplies, including a fluid pump, appropriate fluid type, and a drain pan. |

| 2 | Safely elevate the vehicle and ensure stability before beginning the process. |

| 3 | Locate the fluid reservoir and drain the old fluid completely, taking care to avoid spills. |

| 4 | Inspect the drained fluid for any contaminants, as this can indicate underlying issues. |

| 5 | Refill with new fluid using a pump for precision, ensuring to follow the manufacturer’s specifications for the correct type and quantity. |

| 6 | Run the engine for a few minutes, then check for leaks and ensure proper fluid levels. |

Regularly changing the fluid can lead to improved performance and a smoother driving experience. Following these guidelines will contribute to the overall health of the vehicle’s systems.

Upgrading ZF Transmission Performance

Enhancing the functionality of ZF systems can significantly boost vehicle efficiency and driving experience. By focusing on key components and implementing specific modifications, owners can achieve remarkable improvements in power delivery and responsiveness. This section explores various strategies for optimizing performance and ensuring long-term reliability.

Key Modifications for Enhanced Efficiency

One effective approach to elevate performance is the installation of high-quality components. Upgrading parts such as clutches, gears, and filters can lead to smoother operation and increased durability. Additionally, utilizing specialized fluids designed for advanced performance can enhance shifting precision and overall system efficiency.

Tuning and Calibration Adjustments

Adjusting the control parameters of the system is another vital step in the optimization process. Fine-tuning the electronic control unit (ECU) settings can significantly improve shift timing and responsiveness. Implementing performance tuning can also lead to better fuel efficiency and enhanced acceleration, creating a more enjoyable driving experience.

Safety Precautions During Repair

Ensuring safety is paramount when undertaking maintenance tasks on vehicles. Proper precautions help prevent accidents and injuries, safeguarding both the technician and the equipment.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep the area clean and organized to reduce trip hazards and facilitate movement.

- Disconnect the vehicle’s battery before starting any work to prevent electrical shocks.

- Use jack stands and ramps correctly to stabilize the vehicle when raised.

Tool and Equipment Safety

- Inspect tools for damage before use and replace any that are worn or defective.

- Store tools in designated areas when not in use to prevent clutter.

- Follow manufacturer instructions for all equipment to ensure proper operation.

- Keep flammable materials away from heat sources and open flames.

FAQs About 4WG200 Transmission

This section addresses common inquiries regarding a specific gearbox model, focusing on its functionality, maintenance, and issues often encountered by users. Understanding these aspects can aid in troubleshooting and enhancing the longevity of the equipment.

What are the common signs of malfunction? Users typically notice irregular noises, slipping gears, or warning lights. These symptoms can indicate the need for further inspection.

How often should maintenance be performed? Regular check-ups and fluid changes are recommended to ensure optimal performance. A routine schedule can prevent potential issues.

Can I perform repairs myself? While some basic maintenance tasks can be handled independently, complex issues should be evaluated by professionals to avoid further damage.

What type of fluid is needed? It is crucial to use the specified lubricant to ensure proper operation. Always refer to the manufacturer’s guidelines for the correct type.

How can I improve its lifespan? Maintaining proper fluid levels, regular inspections, and avoiding excessive load can significantly enhance the durability of the system.

Resources for Further Learning

Expanding your knowledge on vehicle systems and their maintenance can significantly enhance your skills. There are numerous resources available that cater to various learning preferences, from books and online courses to forums and video tutorials.

- Books: Explore literature focused on automotive technology, diagnostics, and troubleshooting techniques. Many comprehensive guides cover a wide range of topics relevant to vehicle mechanics.

- Online Courses: Platforms like Coursera and Udemy offer courses designed by industry professionals, covering essential skills and advanced techniques.

- YouTube Channels: Numerous automotive experts share practical insights and step-by-step tutorials, making complex topics accessible to learners at all levels.

- Forums and Communities: Engaging with online communities allows you to exchange ideas, ask questions, and share experiences with fellow enthusiasts and professionals.

- Workshops and Seminars: Participating in hands-on training sessions can provide invaluable practical experience and the opportunity to learn from seasoned experts.

Utilizing these resources can foster a deeper understanding and proficiency in automotive systems, paving the way for successful maintenance and improvement of vehicle performance.