Ensuring the longevity and efficiency of your vehicle’s components is essential for optimal performance. Understanding the intricacies of its shifting mechanisms can save time and money, while enhancing driving experience. This section aims to provide essential insights into the processes involved in maintaining and servicing these crucial elements.

Familiarizing yourself with the fundamental concepts of how these systems operate will empower you to tackle common challenges effectively. By delving into the specifics of adjustments, lubricants, and troubleshooting techniques, you can develop a comprehensive approach to care and enhancement.

Equipping yourself with knowledge regarding signs of wear and potential issues will allow for timely interventions. With the right guidance, you can navigate the complexities of these systems, ensuring reliability and functionality for years to come.

This section aims to provide a comprehensive understanding of the complex system that ensures smooth power delivery in vehicles. By exploring its components and functions, readers can gain insights into its operation and importance.

- Basic Functionality: The mechanism plays a crucial role in optimizing engine performance and efficiency.

- Key Components:

- Gear Sets

- Hydraulic System

- Control Units

- Common Issues: Identifying typical problems can aid in early detection and maintenance.

- Importance of Maintenance: Regular upkeep is vital to extend the lifespan and performance of the entire assembly.

Common Transmission Issues

Vehicles often encounter a variety of challenges related to their gear systems, which can lead to performance issues and decreased efficiency. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth driving experience.

Fluid Leaks

One of the most frequent complications involves fluid leaks. When the fluid level drops, it can result in inadequate lubrication and overheating, potentially leading to significant damage. Regular checks can help identify leaks early and prevent further issues.

Shifting Difficulties

Drivers may also experience difficulties when changing gears, which can manifest as hesitation or slipping. These symptoms often indicate underlying issues with the system’s components or fluid quality. Timely diagnostics can help address these problems before they escalate.

Tools Needed for Repairs

When undertaking maintenance work on vehicle systems, having the right instruments is essential for achieving efficient and effective results. A well-equipped workspace can significantly enhance the quality of the task at hand, ensuring all components are handled correctly and safely.

Essential Instruments

The following tools are fundamental for any mechanical work:

- Wrenches: A set of adjustable and fixed wrenches is crucial for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips-head screwdrivers are necessary for accessing and securing covers and components.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Additional Equipment

In addition to the basic tools, consider the following:

- Fluid Extractor: Useful for draining fluids without making a mess, keeping the workspace clean.

- Multimeter: Essential for diagnosing electrical issues and ensuring proper connectivity in the system.

- Jack and Stands: Necessary for safely lifting the vehicle to access lower components.

Investing in high-quality tools can make a significant difference in the outcome of your work, facilitating a smoother process and enhancing your overall experience.

Step-by-Step Repair Process

This section outlines the detailed procedure for addressing issues related to the vehicle’s power transfer system. Following a structured approach ensures that each aspect is thoroughly examined and resolved, leading to optimal functionality.

Initial Assessment: Begin by evaluating the symptoms presented by the system. Check for any unusual noises, fluid leaks, or shifting difficulties. Document your observations for reference.

Fluid Inspection: Examine the fluid levels and condition. Contaminated or low fluid can indicate underlying issues. Replace or top off as necessary, ensuring the right specifications are met.

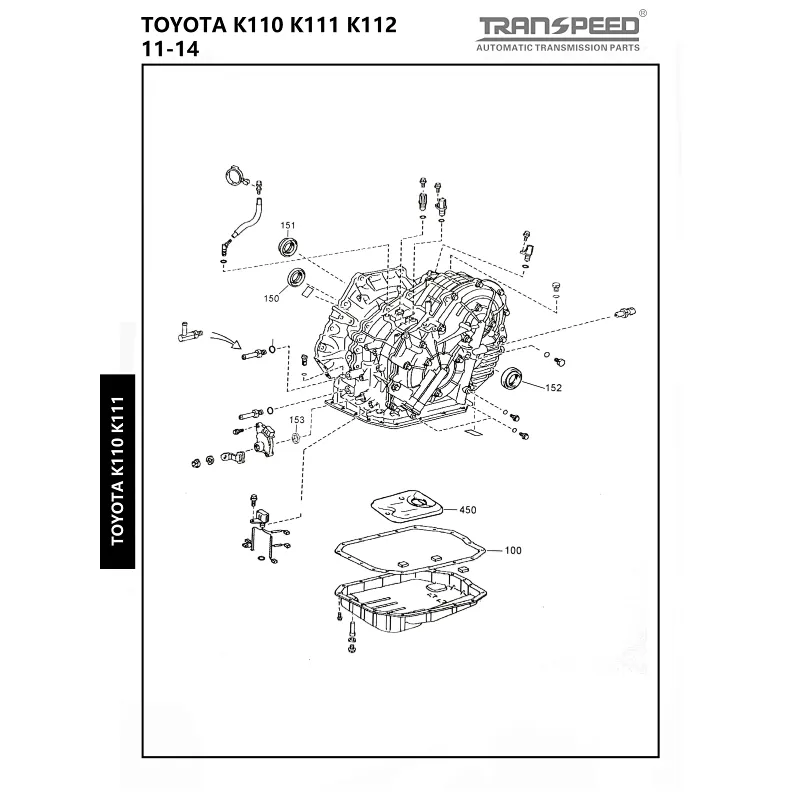

Component Examination: Carefully inspect the various elements involved in the power transfer process. Look for signs of wear, damage, or misalignment. Use appropriate tools to access and assess each component.

System Disassembly: If the problem persists, proceed to disassemble the system. Take detailed notes and photographs during this process to aid in reassembly. Organize parts to avoid confusion.

Repairs and Replacements: Identify any components that require fixing or replacement. Utilize high-quality parts that meet or exceed original specifications to ensure longevity and reliability.

Reassembly: Carefully reassemble all parts in reverse order of disassembly. Ensure that each component is securely fastened and aligned correctly to prevent future issues.

Final Testing: Once reassembled, conduct thorough testing to confirm that the system operates smoothly. Monitor for any irregularities and address them promptly to guarantee performance.

Fluid Types and Maintenance

Maintaining the correct liquids in your vehicle’s system is crucial for optimal performance and longevity. Different types of fluids serve specific functions and should be regularly checked and replaced as needed to ensure smooth operation.

Types of Fluids

- Automatic Fluid: Designed to lubricate components and facilitate gear shifting.

- Manual Fluid: Often thicker, providing essential protection for gears and bearings.

- Cooling Liquid: Helps regulate temperature and prevent overheating during operation.

Maintenance Tips

- Check levels regularly: Ensure fluid levels are within the recommended range.

- Inspect for leaks: Look for any signs of leakage under the vehicle.

- Change fluids as recommended: Follow the manufacturer’s guidelines for replacement intervals.

- Use quality products: Select fluids that meet the required specifications for your system.

Symptoms of Transmission Failure

Understanding the indicators of a malfunctioning gear system is crucial for timely intervention. Recognizing these signs early can prevent further damage and costly repairs.

One of the primary symptoms is unusual noises, such as grinding or whining sounds, which often signal internal issues. Additionally, if you experience slipping, where the vehicle unexpectedly changes gears or hesitates, this may indicate a significant problem. Other warning signs include delayed engagement when shifting from park to drive or reverse, and fluid leaks under the vehicle, which could suggest serious internal damage.

Finally, warning lights on the dashboard may also illuminate, providing a clear signal that something is amiss. Paying attention to these indicators can help maintain optimal performance and extend the lifespan of your vehicle.

Safety Precautions During Repairs

Ensuring safety while working on automotive components is crucial to prevent accidents and injuries. Adhering to specific guidelines not only protects the individual performing the work but also safeguards the vehicle’s integrity.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate clothing to shield yourself from harmful substances and sharp objects. |

| Work in a Ventilated Area | Ensure that the workspace is well-ventilated to avoid inhaling toxic fumes from fluids or materials. |

| Disconnect Power Source | Before starting any work, disconnect the battery to prevent electrical shocks and accidental starts. |

| Use Proper Tools | Utilize the correct tools for the job to avoid damaging components and ensure efficient operation. |

| Follow Manufacturer Guidelines | Adhere to provided guidelines and recommendations to maintain safety and effectiveness during the process. |

Parts Replacement Guidelines

Replacing components in a vehicle’s drive system requires careful consideration and adherence to established protocols. This section provides essential advice for effectively swapping out parts to ensure optimal functionality and longevity.

Assessment Before Replacement

Before initiating the replacement process, a thorough evaluation of the existing components is crucial. Identify any signs of wear, damage, or malfunction that may necessitate a swap. Proper diagnostics will help in selecting the right parts for replacement.

Replacement Procedure Steps

Follow these general steps for a successful replacement:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and components for the job. |

| 2 | Ensure the vehicle is securely positioned and supported. |

| 3 | Remove the faulty component following safety guidelines. |

| 4 | Install the new part, ensuring a secure fit. |

| 5 | Test the system to verify proper operation post-replacement. |

Troubleshooting Tips for Technicians

Effective diagnostics are essential for resolving issues within complex vehicle systems. Technicians must be equipped with strategies that enhance their problem-solving skills, enabling them to identify and address malfunctions efficiently.

Start by conducting a thorough examination of the components involved, paying close attention to any unusual noises or performance irregularities. Utilize diagnostic tools to gather data, as this information can provide valuable insights into potential underlying causes. Additionally, a systematic approach to troubleshooting can prevent oversight of critical factors.

Consider the history of the vehicle and any previous repairs made, as this context can illuminate patterns that may influence current performance. Collaborate with fellow professionals to share experiences and techniques, fostering a supportive environment for continuous learning. Remember, patience and methodical thinking are key to successfully resolving challenges in this field.

Cost Considerations for Repairs

When facing issues with your vehicle’s drivetrain system, understanding the financial implications is crucial. Various factors contribute to the overall expenses involved in resolving these concerns, ranging from labor charges to component costs.

Factors Influencing Costs

- Labor Rates: Different service centers may have varying hourly rates based on location and expertise.

- Parts Quality: Choosing between OEM and aftermarket components can significantly affect the budget.

- Complexity of the Issue: More intricate problems may require additional time and resources to address.

- Additional Services: Alignments or other maintenance services might be necessary alongside the main fix.

Estimating Your Budget

To get a clearer picture of what to expect, consider obtaining multiple quotes from different workshops. This approach not only helps in finding competitive pricing but also provides insights into the quality of service offered. Always ensure that you are aware of any warranties on parts and services to safeguard your investment.

FAQs on Transmission Maintenance

This section addresses common inquiries regarding the upkeep of automotive gear systems. Understanding these aspects can significantly enhance vehicle performance and longevity.

What are the signs of a failing gear system?

Common indicators include unusual noises, slipping gears, and delayed engagement. If you experience any of these symptoms, it’s advisable to seek professional assessment promptly.

How often should I check the fluid levels?

Regular inspections of fluid levels are recommended every few months or as specified in the vehicle’s service guidelines. Maintaining optimal fluid levels is crucial for the smooth operation of the system.