Understanding the intricacies of vehicle drivetrain components can be essential for ensuring smooth and reliable operation. This guide aims to provide clear and detailed instructions on how to effectively handle the disassembly, inspection, and reassembly of gear mechanisms found in various four-wheel-drive systems. By focusing on common issues, practical solutions, and step-by-step procedures, it is designed to assist both experienced mechanics and enthusiasts in maintaining and restoring functionality.

Within the following sections, you will find essential information on identifying worn-out parts, addressing typical faults, and executing precise adjustments. Whether dealing with clutch components, gear synchronizers, or housing seals, this resource delivers thorough explanations and practical tips to make the process more approachable. Emphasis is placed on achieving accuracy and durability, ensuring that every part works in harmony to provide a seamless driving experience.

Additionally, the guide includes insights into preventive measures, highlighting how regular maintenance can extend the longevity of gear units and reduce the need for frequent repairs. Through the use of structured breakdowns and detailed visuals, readers can gain a deeper understanding of how to handle complex systems effectively, ensuring safety and performanc

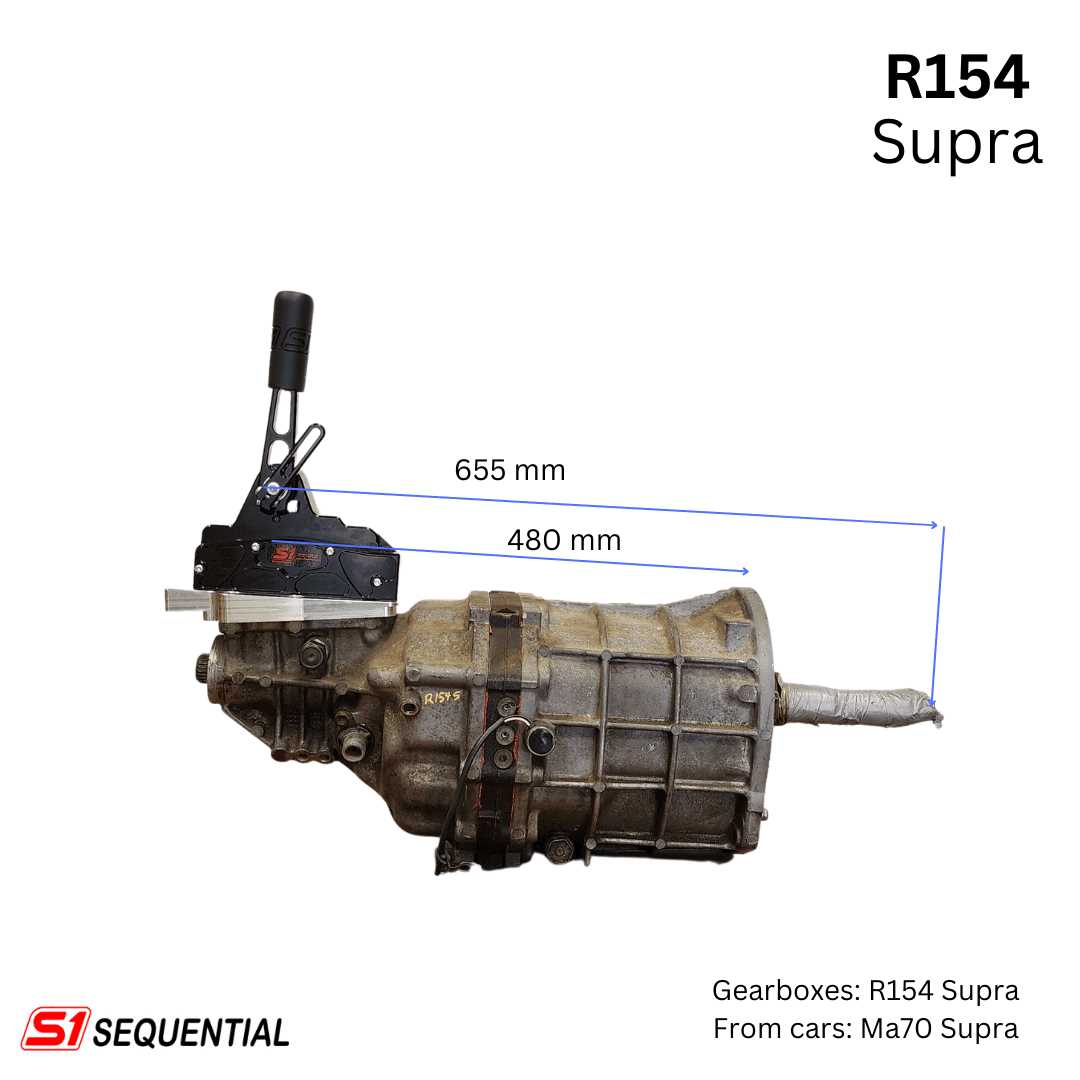

Maintenance Guide for R-Series Gearbox

Proper upkeep of a vehicle’s gearbox is crucial to ensuring smooth performance and extending the lifespan of the unit. This section outlines essential care practices, checks, and recommendations to help maintain optimal operation of your drivetrain system.

- Regularly inspect fluid levels and replace the lubricant according to the manufacturer’s intervals. Proper fluid ensures smooth shifting and reduces wear on internal components.

- Pay attention to unusual sounds or vibrations. Early detection of irregularities can prevent major breakdowns and costly repairs.

- Keep an eye on seals and gaskets. These components can deteriorate over time, leading to leaks and reduced efficiency.

- Make sure to periodically check and tighten bolts and fasteners. Loose components can cause misalignment and potential damage.

Following these maintenance practices will help keep the gearbox in top condition, preventing common issues and enhancing vehicle reliability.

Understanding Common Transmission Problems

Vehicles rely on intricate systems to function smoothly, and one of the most vital components is responsible for efficiently transferring power. However, over time, issues can emerge, causing disruptions in the driving experience. Identifying these problems early can help in addressing them effectively, ensuring long-term performance and safety.

Some of the most frequent concerns include unusual noises, such as grinding or whining, which may indicate internal component wear or insufficient lubrication. Additionally, difficulties in gear shifting, whether delayed engagement or unexpected slipping, often point to underlying mechanical faults. Fluid leaks are another common symptom, as proper fluid levels are crucial for smooth operation. Ignoring these signs can lead to more severe malfunctions, making regular checks and prompt attention essential.

To mitigate these issues, routine maintenance is key. Regular inspections can detect wear and tear, fluid degradation, and other early warning signs, allowing for timely repairs and adjustments. By understanding typical issues and their symptoms, drivers can take proactive steps to maintain the system’s integrity and ensure a reliable driving experience.

Essential Tools for Transmission Repair

Working on gear mechanisms requires specific instruments that ensure precision and efficiency. Proper equipment helps to address different tasks during maintenance, enhancing the overall process. Understanding the correct tools can save time and prevent issues that may arise during complex adjustments.

Basic Hand Tools

- Socket Set: A comprehensive set of sockets is crucial for loosening and tightening bolts and nuts of varying sizes.

- Torque Wrench: Ensures that fasteners are secured to the correct specifications, preventing over-tightening or insufficient clamping.

- Screwdrivers: Both flathead and Phillips are necessary for accessing internal parts and making adjustments.

Specialized Instruments

- Gear Pullers: Essential for removing gears or bearings without causing damage to the components.

- Measuring Calipers: Provides accurate measurements for parts, ensuring proper fitti

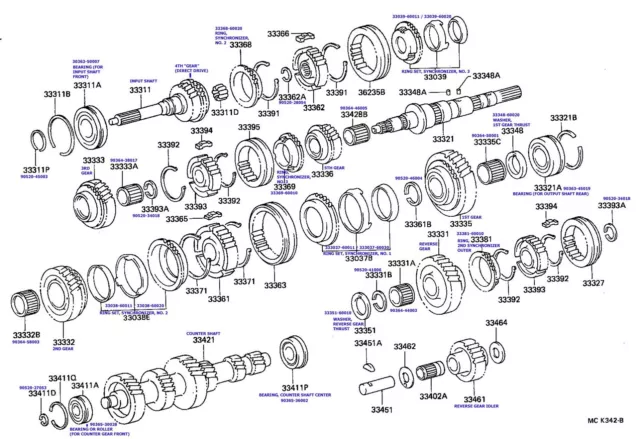

Step-by-Step Gearbox Disassembly Instructions

In this section, you will find a detailed guide on how to carefully take apart a gearbox system. Each step has been designed to help you methodically dismantle the unit, ensuring all components are handled properly and organized throughout the process.

Preparation and Required Tools

Before starting, gather all necessary tools such as wrenches, screwdrivers, and pliers. Make sure you have a clean workspace, where parts can be laid out systematically. This will help prevent misplacement and make reassembly more straightforward.

Initial Disassembly Steps

Begin by removing any external covers, bolts, and fasteners. Carefully detach any connected shafts or cables. Pay close attention to the sequence in which parts are removed, and keep smaller components, like screws and washers, in labeled containers. This practice will simplify the later stages of reassembly.

Next, proceed to loosen and extract the casing. Apply even pressure to avoid damaging the structure, and gently lift off the housing. Take care when separating the sections, as some components might still be interlinked.

Continue by examining the internal gear sets. De

Inspecting and Replacing Worn Parts

Regular assessment of mechanical components is crucial to ensure optimal performance and extend the lifespan of the system. By identifying signs of wear early, it is possible to address issues before they develop into significant problems. This process involves a thorough inspection of various parts, checking for damage, corrosion, or irregularities, and replacing those that no longer meet the required standards.

Start by carefully examining seals, gaskets, and bearings. Look for any signs of cracking, leaks, or unusual noises during operation, which may indicate that a component is no longer functioning properly. Seals and gaskets play a vital role in preventing fluid loss, while bearings ensure smooth movement and reduce friction. Damaged or worn-out parts can lead to further complications, so immediate replacement is recommended.

When replacing parts, ensure that new components are of high quality and compatible with the existing system. It is advisable to follow the manufacturer

How to Reassemble the R151F Transmission

Reassembling this particular gear assembly requires careful attention to detail and a methodical approach. By following specific steps and utilizing the correct tools, one can ensure that all components are properly aligned and function as intended. This section will guide you through the essential procedures for successfully putting together the assembly, emphasizing the importance of precision at every stage.

Preparation Before Assembly

Before diving into the assembly process, it’s crucial to gather all necessary tools and components. A clean workspace can greatly enhance efficiency and reduce the risk of losing parts. Ensure that all elements are free from dirt and debris, as this can affect performance. Below is a checklist of items to prepare:

Tools Purpose Torque wrench To tighten fasteners to the correct specifications. Sockets and ratchets For removing and installing bolts and nuts. Clean cloths To wipe down parts and keep the workspace tidy. Lubricants To ensure smooth operation and prevent wear. Assembly Steps

With all tools ready, begin the assembly by following these steps:

- Start with the main housing and ensure that all sealing surfaces are clean.

- Carefully place the internal components back into their designated locations, paying attention to orientation.

- Gradually insert the fasteners, tightening them in a crisscross pattern to ensure even pressure.

- Once all parts are secured, perform a final inspection to confirm that everything is correctly positioned.

Adjusting Gear Shifting Mechanism

Proper calibration of the gear engagement system is essential for ensuring smooth operation and enhancing vehicle performance. Fine-tuning this mechanism can significantly improve responsiveness and overall driving experience, allowing for seamless transitions between gear ratios.

Begin by examining the linkage and connections associated with the shifting assembly. Any signs of wear or misalignment can lead to inefficiencies in gear selection. Adjustments should focus on ensuring that the shifter moves freely and engages each gear without obstruction.

Next, check the tension in the cables or rods involved in the shifting process. Proper tension is crucial, as too much slack can cause delayed engagement, while excessive tightness may hinder smooth operation. Make necessary adjustments to achieve an optimal balance.

After completing the initial adjustments, test the system by cycling through the gears while the vehicle is stationary. Listen for any unusual noises and monitor the ease of engagement. If further refinements are needed, repeat the adjustment process until satisfactory performance is achieved.

Troubleshooting Synchronizer Issues

Identifying and resolving issues with the synchronizer mechanism is crucial for maintaining optimal gear shifting performance. Common symptoms may include difficulty in changing gears, grinding noises, or unexpected disengagement. By understanding these problems, one can enhance the overall functionality of the system.

Common Symptoms

Several indicators suggest that the synchronizer may not be functioning correctly. Pay attention to the following signs:

Symptom Possible Cause Difficulty shifting gears Worn synchronizer rings or misalignment Grinding noises during shifting Insufficient lubrication or damaged components Gears popping out Faulty synchronizer engagement Unusual vibrations Worn bearings or imbalance in the assembly Steps for Diagnosis

To effectively troubleshoot synchronizer issues, follow these diagnostic steps:

- Inspect the fluid levels and condition.

- Check for any visible damage or wear on components.

- Examine the linkage for proper alignment and function.

- Perform a test drive to replicate symptoms under controlled conditions.

Proper Lubrication Techniques for Smooth Operation

Ensuring effective lubrication is crucial for optimal performance and longevity of mechanical systems. Proper techniques not only facilitate smooth functioning but also help prevent wear and tear, reducing the likelihood of costly failures. Understanding the best practices for applying and maintaining lubricants can greatly enhance the reliability of your equipment.

One of the fundamental aspects of lubrication is selecting the appropriate lubricant type based on the specific requirements of the machinery. Factors such as operating temperature, load conditions, and the materials involved play a significant role in this selection process.

Lubricant Type Best Uses Synthetic Oil High-performance applications requiring stability at extreme temperatures Mineral Oil General-purpose lubrication for various machines Grease Applications where retention and resistance to leakage are essential In addition to the right lubricant, the application method is equally important. Techniques such as manual application, centralized lubrication systems, or automatic dispensers can ensure that every moving part receives adequate coverage. Regular monitoring and maintenance of lubricant levels and conditions are essential to avoid performance degradation.

Checking and Replacing Transmission Bearings

Ensuring the proper functioning of internal components is crucial for any machinery’s longevity and performance. One essential aspect of maintaining these systems involves inspecting and, if necessary, substituting the support elements that facilitate smooth operation. This section delves into the process of assessing and changing these critical parts.

Assessment Procedure

To effectively evaluate the condition of the support elements, follow these steps:

- Begin by removing the casing or housing to gain access to the interior components.

- Visually inspect the elements for any signs of wear, such as pitting, discoloration, or excessive play.

- Utilize a dial gauge to measure the clearance and ensure it falls within the manufacturer’s specified tolerances.

- Rotate the assembly by hand to listen for unusual noises, indicating potential issues.

Replacement Guidelines

If the assessment reveals that the support elements require replacement, adhere to the following guidelines:

- Carefully remove the worn components using appropriate tools to avoid damaging adjacent parts.

- Clean the housing and prepare the surface for the new elements.

- Select replacements that meet the specifications for size and material.

- Install the new components, ensuring proper alignment and secure fitting.

- Reassemble the casing and perform a final check to confirm everything is correctly positioned.

Diagnosing Unusual Noises and Vibrations

Identifying abnormal sounds and vibrations in your vehicle is crucial for maintaining optimal performance. Such issues can indicate underlying problems that may affect overall functionality. By recognizing and addressing these symptoms early on, you can prevent more extensive damage and ensure a smoother driving experience.

Common Symptoms to Observe

Unusual noises may manifest as grinding, whining, or clunking sounds, each suggesting different potential issues. Vibrations can also vary in intensity and frequency, often felt through the steering wheel or floorboards. Observing when these symptoms occur–such as during acceleration, deceleration, or while cruising–can help narrow down the possible causes.

Steps for Effective Diagnosis

Begin by listening carefully and noting the specific conditions under which the noises or vibrations occur. Conduct a visual inspection of the vehicle’s components, paying close attention to any loose or damaged parts. Utilizing diagnostic tools, if available, can further aid in pinpointing the source of the issue. If necessary, consulting a professional mechanic may provide additional insights and solutions.

Transmission Testing and Final Adjustments

This section outlines the procedures necessary to ensure optimal functionality of the gear shifting system. Testing and adjustments are crucial steps in achieving the desired performance and reliability of the vehicle’s power transfer mechanism.

Testing Procedures

To accurately assess the performance of the assembly, follow these testing guidelines:

- Conduct a preliminary inspection for any visible leaks or wear.

- Check fluid levels and quality, replacing any contaminated fluid.

- Perform a road test to evaluate shifting smoothness and responsiveness.

- Monitor for unusual noises or vibrations during operation.

Final Adjustments

After testing, make necessary adjustments to enhance the overall operation:

- Adjust cable tension to ensure proper engagement of the shifting mechanism.

- Calibrate the linkage for accurate gear selection.

- Recheck fluid levels and top off if required.

- Test drive again to confirm improvements in performance.

Preventive Maintenance for Prolonged Transmission Life

Regular upkeep is essential for enhancing the longevity of your vehicle’s shifting system. By adhering to a schedule of preventative measures, you can significantly reduce the likelihood of unexpected failures and maintain optimal performance. This section outlines key practices that contribute to the durability of your drivetrain components.

- Fluid Checks: Regularly inspect the fluid levels and quality. Ensure that fluids are clean and at the proper levels to facilitate smooth operation.

- Filter Replacements: Change filters periodically to prevent contaminants from causing damage to the internal components.

- Inspections: Conduct visual examinations of the system for signs of leaks or wear. Early detection can prevent larger issues from developing.

- Fluid Changes: Adhere to the recommended intervals for fluid changes. Fresh fluid is crucial for maintaining optimal performance and preventing overheating.

- Driving Habits: Adopt gentle driving practices. Avoid harsh acceleration and sudden stops to minimize stress on the system.

Implementing these practices will not only extend the life of your shifting system but also enhance the overall driving experience. A little attention today can lead to significant savings and reliability in the future.