This section provides an extensive overview of the procedures and techniques involved in maintaining and rejuvenating a specific type of power unit. The focus is on ensuring optimal performance and longevity through systematic approaches and thorough understanding of the underlying mechanics.

Within these guidelines, you will discover valuable insights into troubleshooting common issues, as well as effective strategies for restoration. By following the recommended steps, users can enhance their knowledge and skills, enabling them to tackle various challenges with confidence.

Emphasis is placed on practical advice and detailed instructions, facilitating a seamless experience for those engaged in the upkeep of these essential components. With careful attention to detail and a commitment to quality, this resource serves as a trusted companion for enthusiasts and professionals alike.

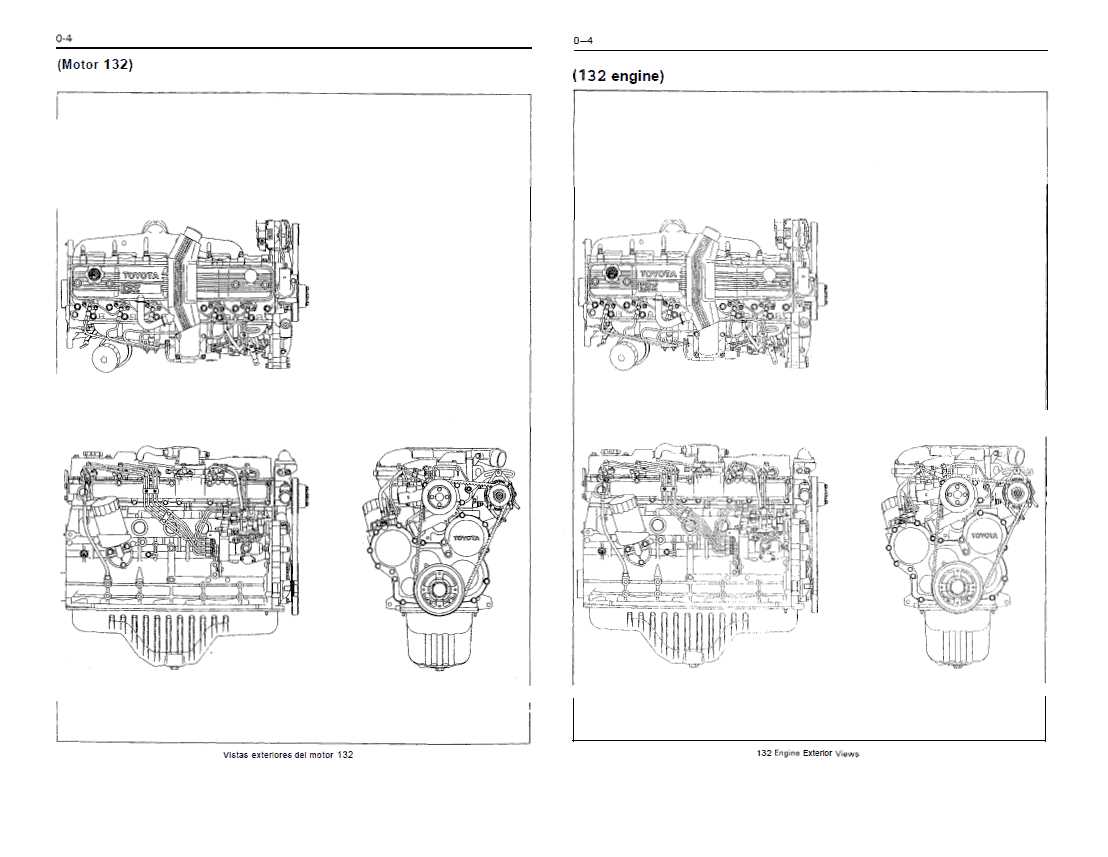

This section provides an insightful overview of a well-regarded power unit known for its reliability and performance in various applications. Understanding the key characteristics and specifications of this unit is essential for effective maintenance and troubleshooting.

Key Features

- Robust construction designed for longevity

- Efficient fuel consumption rates

- Adaptability to multiple vehicle types

Technical Specifications

- Cylinder configuration and capacity

- Power output range

- Cooling system details

By grasping the fundamental aspects of this power unit, users can enhance their knowledge and improve their ability to address any issues that may arise during operation.

Common Diesel Engine Issues

In the realm of internal combustion systems, certain challenges frequently arise that can affect performance and reliability. Understanding these prevalent complications can assist in timely identification and resolution, ensuring optimal functionality over time.

Frequent Complications

- Fuel Contamination: Impurities in the fuel can lead to inefficiencies and potential damage.

- Overheating: Excessive temperatures can result from inadequate cooling or excessive load.

- Starting Difficulties: Various factors can impede starting, including battery issues or fuel delivery problems.

- Excessive Smoke: Abnormal exhaust emissions may indicate underlying issues with combustion.

- Noise and Vibration: Unusual sounds or excessive vibration often signal mechanical concerns.

Maintenance Practices

- Regular Oil Changes: Keeping lubricants fresh helps maintain proper function and longevity.

- Air Filter Inspection: Ensuring clean air intake is crucial for performance.

- Fuel System Maintenance: Routine checks of the fuel system can prevent contamination and promote efficiency.

- Cooling System Servicing: Regular assessments of cooling components prevent overheating.

- Monitoring Exhaust Emissions: Observing emission patterns can help identify combustion issues early.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Various instruments not only streamline the process but also enhance precision, ensuring that every aspect is addressed properly. Familiarity with essential items is vital for achieving successful outcomes.

Basic Equipment

Every toolkit should include fundamental devices such as wrenches, sockets, and screwdrivers. These items form the backbone of any repair effort, allowing users to tighten, loosen, and adjust components as needed. Investing in high-quality tools ensures durability and reliability over time.

Specialized Instruments

In addition to standard tools, certain specialized instruments can significantly improve efficiency. For instance, diagnostic equipment aids in identifying issues accurately, while torque wrenches help apply the correct amount of force to fasteners. These enhancements not only save time but also contribute to the longevity of the system.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the longevity and optimal performance of your vehicle’s components. By following systematic procedures, you can enhance reliability and efficiency, minimizing potential issues over time.

Essential Tools and Supplies

- Wrenches and socket set

- Screwdrivers of various sizes

- Oil filter wrench

- Fuel line disconnect tool

- Cleaning materials

- Replacement parts as needed

Maintenance Steps

- Begin by checking fluid levels, including oil, coolant, and fuel.

- Replace the oil filter and drain old oil, refilling with new lubricant.

- Inspect and clean air intake filters, replacing them if necessary.

- Examine fuel filters and replace them to ensure clean fuel supply.

- Check all hoses and belts for signs of wear or damage, replacing any that show significant wear.

- Perform a thorough inspection of the exhaust system for leaks or blockages.

- Finally, conduct a visual inspection of all electrical connections and fuses.

Diagnosing Performance Problems

Identifying issues related to functionality can be a challenging task. It often requires a systematic approach to uncover the root causes that may affect the overall efficiency of the machinery. By focusing on various indicators, one can assess the operational state and pinpoint potential malfunctions.

Initial Assessment: Start by observing the performance trends over time. Note any irregularities such as decreased power output, unusual noises, or increased emissions. These signs can provide crucial insights into underlying issues.

Visual Inspection: Conduct a thorough examination of components. Look for signs of wear, leaks, or blockages that might hinder proper operation. Ensuring that all parts are in good condition is vital for optimal performance.

System Checks: Utilize diagnostic tools to evaluate various systems. Monitoring parameters like pressure, temperature, and fuel flow can help identify discrepancies that indicate problems. Proper readings will assist in determining whether adjustments or replacements are necessary.

Consult Documentation: Reference technical resources for troubleshooting guidelines. These materials often provide valuable information about common issues and recommended solutions, aiding in the diagnostic process.

By following a structured approach to diagnosing performance challenges, one can effectively address problems and restore functionality, ensuring smooth operation moving forward.

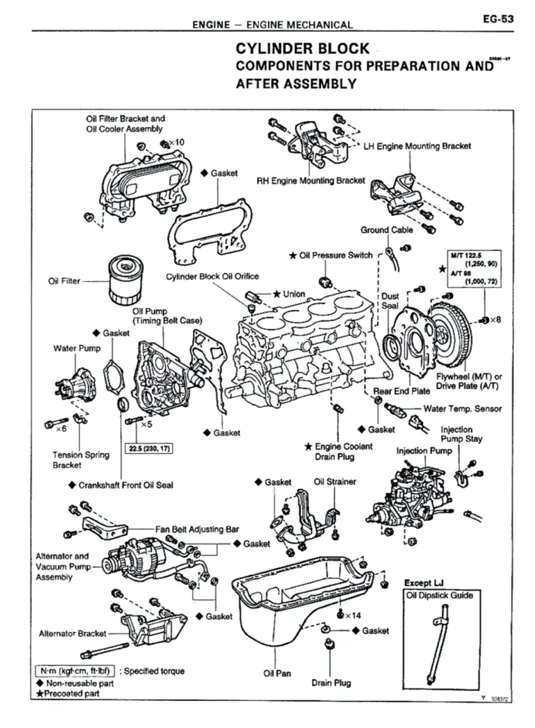

Replacing Engine Components

When it comes to the maintenance of a vehicle, one of the crucial aspects involves the substitution of various parts that contribute to its performance. Proper knowledge of the components and their functions can significantly enhance the efficiency and longevity of the machine.

Here are some essential steps to consider during the replacement process:

- Assessment: Begin by evaluating the current state of the parts. Identify which components require replacement based on signs of wear or damage.

- Gather Tools: Ensure you have the necessary tools for the task. Commonly needed items include wrenches, screwdrivers, and specific instruments for particular parts.

- Disassembly: Carefully remove the old components, taking note of how they are installed. This will aid in the correct installation of the new parts.

- Replacement: Install the new parts, ensuring they fit properly and securely. Pay attention to any specific requirements related to the component.

- Testing: After installation, perform a thorough check to confirm that everything functions as intended. Look for any leaks or unusual noises that might indicate issues.

By following these guidelines, one can effectively enhance the functionality of the vehicle while ensuring a smoother and more reliable driving experience.

Fuel System Troubleshooting

This section provides insights into diagnosing common issues within the fuel delivery system. Proper understanding of the components and their functions can aid in identifying problems that may affect performance and efficiency.

Common Symptoms and Causes

When fuel delivery problems occur, various symptoms may arise, including poor acceleration, stalling, or difficulty starting. Below are typical indicators and their potential causes:

| Symptom | Possible Cause |

|---|---|

| Poor acceleration | Clogged fuel filter or malfunctioning injectors |

| Stalling | Air in the fuel line or insufficient fuel pressure |

| Difficulty starting | Contaminated fuel or weak fuel pump |

Diagnostic Steps

To effectively troubleshoot the fuel system, follow these essential steps:

- Inspect the fuel lines for leaks or blockages.

- Check the condition of the fuel filter and replace it if necessary.

- Test the fuel pressure to ensure it meets specifications.

Electrical System Checks

Assessing the electrical components is essential for ensuring optimal functionality. Proper evaluation of these systems can prevent potential issues and enhance performance.

- Battery Inspection:

- Check for corrosion on terminals.

- Ensure proper voltage levels are maintained.

- Cable Connections:

- Examine all wiring for wear or damage.

- Verify tight connections to prevent power loss.

- Fuse Condition:

- Inspect fuses for any signs of damage.

- Replace blown fuses with appropriate ratings.

- Lighting Functionality:

- Test headlights, taillights, and indicators for proper operation.

- Ensure all bulbs are in working condition.

Conducting these evaluations periodically will contribute to the longevity and reliability of the system.

Cooling System Maintenance

The efficiency of a vehicle’s performance significantly relies on the upkeep of its cooling mechanism. Regular attention to this system ensures optimal operation and longevity of the machinery involved. A well-maintained cooling setup prevents overheating and promotes effective temperature regulation.

To begin with, it is crucial to periodically check the coolant level. Insufficient fluid can lead to severe overheating issues. Ensure that the coolant reservoir is filled to the recommended level, and inspect for any leaks that may compromise the system’s integrity.

Additionally, the coolant should be replaced at regular intervals to maintain its effectiveness. Over time, the fluid can become contaminated, reducing its ability to absorb heat. It is advisable to follow the guidelines for coolant change, which typically suggest intervals based on mileage or time.

Inspecting hoses and connections is equally important. Look for signs of wear, such as cracks or bulges, which could lead to leaks. Replacing any damaged components promptly can prevent further complications and ensure the system functions correctly.

Lastly, the radiator should be cleaned to remove any debris that may obstruct airflow. A clean radiator enhances heat dissipation, contributing to the overall efficiency of the cooling system. Regular maintenance not only protects the vehicle but also enhances its performance over time.

Engine Specifications and Standards

This section provides a comprehensive overview of the fundamental characteristics and requirements that govern the operation of specific propulsion systems. Understanding these parameters is crucial for ensuring optimal performance and longevity of the unit.

Key specifications typically encompass various metrics such as displacement, power output, and torque levels. Each of these elements plays a significant role in determining how effectively the unit operates under diverse conditions. Compliance with established standards ensures that the system meets necessary regulatory and performance criteria, promoting reliability and efficiency.

Additionally, tolerances and dimensions are critical for maintaining proper functionality. Accurate measurements facilitate seamless integration with associated components, minimizing the risk of operational failures. Regular assessments against these benchmarks are recommended to uphold performance standards and address any potential deviations promptly.

Preventive Measures for Longevity

Ensuring the extended lifespan of mechanical systems requires diligent care and attention. By adopting proactive strategies, users can significantly enhance performance and reduce the likelihood of issues over time.

Regular Maintenance Practices

- Conduct routine inspections to identify potential wear and tear.

- Change lubricants and fluids as recommended to maintain optimal function.

- Clean air filters regularly to ensure proper airflow and efficiency.

Operating Guidelines

- Avoid overloading beyond specified capacities to prevent strain.

- Warm up the system adequately before engaging in heavy tasks.

- Utilize appropriate fuel types to ensure compatibility and efficiency.