Owning a reliable automobile is essential for daily life, and understanding its upkeep can significantly enhance performance and longevity. This guide aims to provide thorough insights into the intricacies of maintaining a specific model from a well-known manufacturer. Knowledge of the key components and systems involved will empower owners to navigate challenges effectively.

From troubleshooting common issues to performing routine check-ups, having access to structured information can make a substantial difference. Familiarity with maintenance procedures not only ensures safety on the road but also contributes to the overall driving experience. This resource is designed to equip you with the necessary tools and techniques for effective vehicle care.

In the following sections, we will delve into various aspects of maintenance, including detailed instructions for servicing, diagnostic tips, and preventive measures. Emphasizing a proactive approach can help avoid costly repairs and extend the lifespan of your vehicle, allowing you to enjoy every journey with peace of mind.

Overview of the 2007 Model

This section provides a comprehensive look at a popular sedan known for its reliability and comfort. It offers a blend of performance and efficiency, making it a top choice among consumers seeking a practical yet stylish vehicle.

Key Features

The vehicle stands out with a range of features designed for both safety and convenience. It boasts a spacious interior, user-friendly technology, and a strong reputation for longevity, appealing to a broad audience.

Specifications

| Feature | Specification |

|---|---|

| Engine Type | V6 / 4-cylinder |

| Horsepower | 158 – 268 hp |

| Fuel Economy | Up to 34 mpg highway |

| Seating Capacity | 5 passengers |

| Trunk Space | 15.4 cubic feet |

Common Issues and Solutions

This section addresses frequent challenges encountered in vehicles of a certain model year and provides practical solutions. Understanding these common problems can help owners maintain their vehicles effectively and prevent further complications.

Electrical Problems

One of the most prevalent issues relates to the electrical system, which can manifest as battery drain or malfunctioning lights. These problems often stem from worn-out components or faulty wiring.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Battery Drain | Faulty alternator, short circuits | Test alternator output, inspect wiring |

| Malfunctioning Lights | Burnt-out bulbs, wiring issues | Replace bulbs, check connections |

Engine Performance

Engine-related issues can lead to decreased performance and efficiency. Common symptoms include rough idling and reduced power during acceleration, often linked to air intake or fuel delivery problems.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Rough Idling | Dirty air filter, faulty sensors | Clean or replace air filter, check sensor functionality |

| Reduced Power | Clogged fuel injectors, exhaust blockages | Clean injectors, inspect exhaust system |

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring longevity and efficiency of any vehicle. Following a structured maintenance timetable helps prevent issues and enhances overall performance. This section outlines key tasks that should be performed at specified intervals to keep your automobile running smoothly.

Monthly Checks

- Inspect fluid levels: engine oil, coolant, brake fluid, and transmission fluid.

- Examine tire pressure and tread depth for safety and fuel efficiency.

- Check lights: headlights, brake lights, and turn signals for functionality.

Every 5,000 Miles

- Change engine oil and oil filter.

- Inspect and replace air filter if necessary.

- Rotate tires to promote even wear.

Every 15,000 Miles

- Replace cabin air filter to maintain air quality inside the vehicle.

- Check and clean fuel system components to ensure optimal combustion.

- Inspect brake pads and discs for wear and tear.

Every 30,000 Miles

- Flush and replace coolant to prevent overheating.

- Inspect and replace spark plugs to ensure efficient ignition.

- Examine the exhaust system for leaks or damage.

Annual Service

- Comprehensive inspection of the vehicle’s overall condition.

- Update software and check diagnostic systems.

- Inspect suspension and steering components for wear.

Adhering to this maintenance schedule not only enhances reliability but also helps in avoiding costly repairs down the line. Always consult with a qualified technician to tailor the schedule according to specific driving habits and conditions.

Essential Tools for DIY Repairs

When tackling automotive maintenance on your own, having the right instruments is crucial for efficiency and effectiveness. A well-equipped workspace can make even the most challenging tasks manageable. Here, we outline the fundamental tools that every enthusiast should consider having on hand.

Basic Hand Tools

- Wrenches: A set of adjustable and socket wrenches is vital for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help you tackle different types of screws.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating various components.

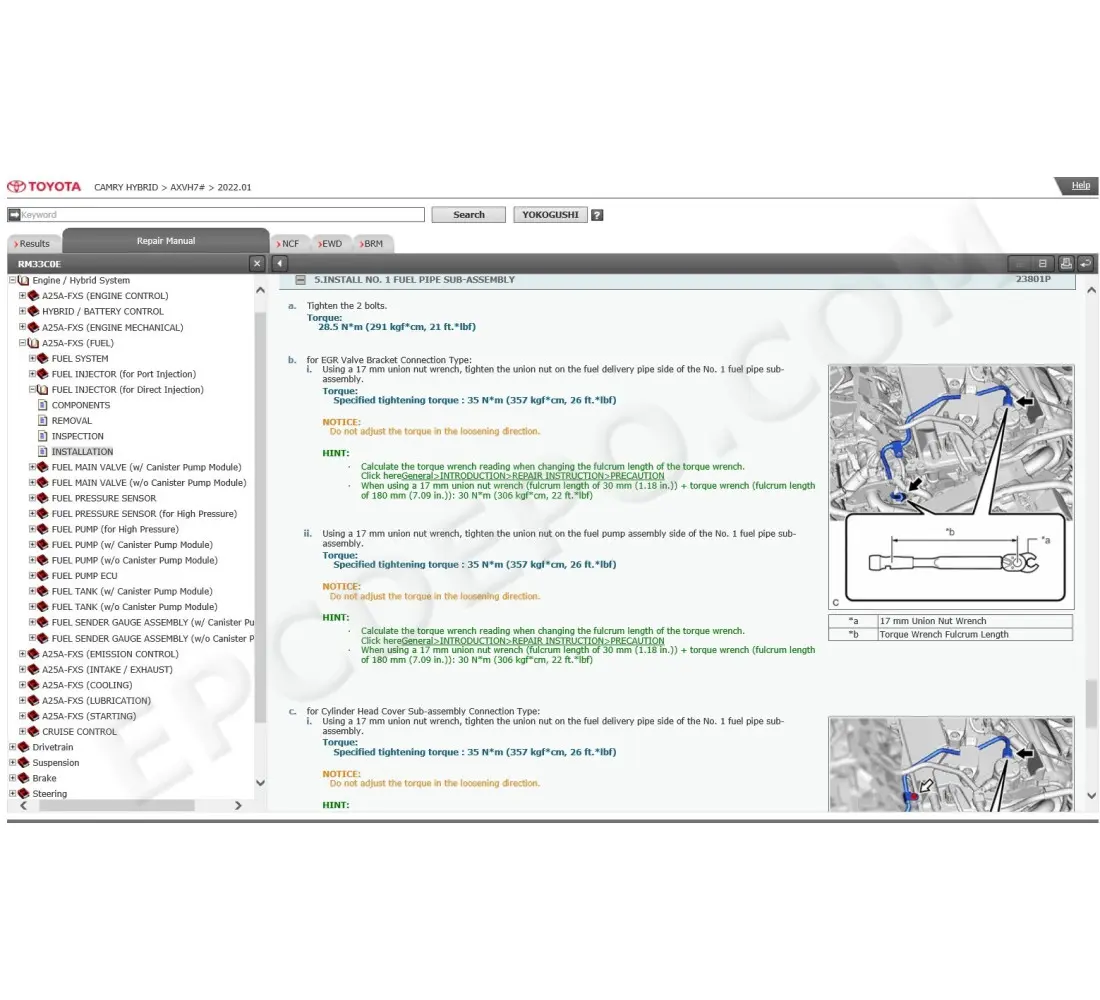

Specialized Equipment

- Jack and Jack Stands: Essential for lifting the vehicle safely when performing work underneath.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

Having these essential instruments at your disposal not only simplifies your tasks but also enhances your confidence in handling various automotive projects. Investing in quality tools will pay off in the long run, making your DIY experiences more enjoyable and successful.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to assist you in addressing various issues systematically. Following clear instructions will help ensure that the task is completed efficiently and effectively. Each step is designed to promote safety and accuracy, reducing the likelihood of errors.

Preparation: Begin by gathering all necessary tools and materials. Ensure that your workspace is clean and organized to facilitate the process. Having everything on hand will minimize interruptions and help maintain focus.

Diagnosis: Carefully assess the situation to identify the problem. Use appropriate diagnostic tools to gather data and confirm your findings. A thorough understanding of the issue is essential before proceeding to any corrective measures.

Disassembly: Once the issue is identified, follow a methodical approach to disassemble the relevant components. Document each step with notes or photographs to assist with reassembly. Handle all parts gently to avoid damage.

Repair or Replacement: Depending on the findings, perform the necessary repairs or replace defective parts. Ensure that all new components meet the required specifications and are compatible with the system.

Reassembly: Reassemble the components in the reverse order of disassembly. Double-check each connection and fastening to ensure that everything is secure. Refer to your notes or photographs to guide you through this phase.

Testing: After reassembly, conduct thorough tests to confirm that the problem has been resolved. Monitor the system closely during this phase to catch any potential issues early on.

Final Checks: Once testing is complete, perform a final inspection of all work. Ensure that tools and materials are cleared from the workspace and that everything is in order. Document your work for future reference.

Electrical System Troubleshooting Guide

The electrical system of a vehicle is crucial for its overall functionality, affecting everything from starting the engine to powering accessories. Diagnosing issues within this system can often be daunting, but a methodical approach can simplify the process. This guide aims to provide insights into common electrical problems and effective strategies for identifying and resolving them.

Identifying Symptoms: Begin by observing the signs of electrical malfunction. Common indicators include flickering lights, difficulty starting, or unresponsive electronic components. Documenting these symptoms will aid in pinpointing the underlying issue.

Checking the Battery: The battery is often the first component to investigate. Ensure that the terminals are clean and tightly connected. A weak or dead battery can lead to a range of problems, so testing its voltage and condition is essential.

Examining Fuses: Fuses act as protectors of the electrical system. Inspecting them for signs of damage or failure can reveal issues. If a fuse has blown, replace it with one of the correct amperage and check for any recurring problems.

Testing Wiring and Connectors: Frayed wires or loose connections can cause intermittent faults. Carefully inspect the wiring harness for any visible damage and ensure all connectors are secure. Using a multimeter can help verify continuity and detect short circuits.

Utilizing Diagnostic Tools: If basic checks do not reveal the problem, employing diagnostic tools such as OBD-II scanners can provide deeper insights. These devices can retrieve error codes that indicate specific faults within the electrical system.

In conclusion, troubleshooting electrical issues requires patience and a systematic approach. By following the steps outlined, one can effectively diagnose and resolve common electrical problems, ensuring the vehicle operates smoothly.

Engine Specifications and Diagnostics

This section provides crucial insights into the powertrain details and diagnostic procedures essential for maintaining optimal performance. Understanding engine specifications and how to effectively troubleshoot issues can significantly enhance the longevity and reliability of the vehicle.

Engine Specifications

- Engine Type: Inline 4-cylinder or V6

- Displacement: 2.4L (4-cylinder) or 3.5L (V6)

- Fuel System: Multi-point fuel injection

- Compression Ratio: Varies by engine type

- Horsepower: Approximately 158 hp (4-cylinder) or 268 hp (V6)

- Torque: Roughly 161 lb-ft (4-cylinder) or 248 lb-ft (V6)

- Transmission: 5-speed automatic or 6-speed automatic

Diagnostics Procedures

Effective diagnostics are vital for identifying and resolving engine-related issues. The following steps outline a general approach:

- Visual Inspection:

- Check for leaks, corrosion, or damage in engine components.

- Inspect belts and hoses for wear.

- Utilize Diagnostic Tools:

- Connect an OBD-II scanner to retrieve trouble codes.

- Analyze live data for engine performance metrics.

- Test Key Components:

- Examine the ignition system, including spark plugs and coils.

- Evaluate fuel pressure and delivery.

- Conduct Performance Tests:

- Measure engine compression to assess health.

- Perform a leak-down test if necessary.

By adhering to these specifications and diagnostic practices, vehicle owners can ensure efficient engine operation and preemptively address potential issues.

Transmission Maintenance and Repair Tips

Proper upkeep of the transmission system is crucial for ensuring the longevity and performance of your vehicle. Regular maintenance helps prevent costly repairs and enhances the overall driving experience. This section provides essential guidelines for maintaining and addressing issues within the transmission, allowing for smoother operation and improved efficiency.

Regular Fluid Checks

One of the most vital aspects of transmission care is monitoring fluid levels. Regularly check the transmission fluid to ensure it is at the recommended level and in good condition. Clean, clear fluid should be bright red; if it appears dark or has a burnt smell, it may need to be replaced. Always refer to the specifications for the appropriate fluid type for your vehicle.

Routine Inspection and Maintenance

Conducting routine inspections can help identify potential problems early. Look for signs of leaks under the vehicle, listen for unusual noises during gear shifts, and pay attention to any warning lights on the dashboard. Timely intervention can often save you from more extensive repairs down the line. It is advisable to have a professional technician perform a thorough inspection at regular intervals.

Braking System Inspection Process

The braking system is a critical component of any vehicle, ensuring safety and control during operation. Regular examination of this system helps identify potential issues before they escalate into serious problems. This section outlines a systematic approach to assessing the functionality and integrity of the braking components.

To effectively inspect the braking system, follow these key steps:

- Visual Inspection:

- Check for fluid leaks around brake lines and calipers.

- Examine the condition of brake pads and rotors for wear and damage.

- Inspect hoses for cracks or deterioration.

- Brake Fluid Level:

- Ensure the fluid reservoir is at the recommended level.

- Inspect fluid for contamination or discoloration.

- Testing Brake Operation:

- Perform a pedal feel test to check for firmness and responsiveness.

- Listen for unusual noises when applying brakes, indicating possible issues.

- Brake Performance Evaluation:

- Conduct a test drive to assess braking efficiency and response.

- Monitor for vibrations or pulling to one side while braking.

Following these steps ensures a thorough examination of the braking system, contributing to enhanced vehicle safety and performance. Regular inspections should be part of routine maintenance to prolong the lifespan of braking components.

Suspension System Maintenance Guide

The suspension system plays a crucial role in ensuring a smooth and safe driving experience. Regular upkeep is essential to maintain optimal performance, enhance comfort, and prolong the lifespan of various components. This guide outlines key maintenance practices to keep the suspension in peak condition.

Routine Inspections

Performing routine inspections can help identify potential issues before they escalate. Key areas to focus on include:

- Shock absorbers and struts

- Control arms and bushings

- Ball joints

- Spring integrity

- Alignment and tire wear

Check for signs of wear, leaks, or damage during these inspections. If any abnormalities are noted, timely repairs are advised.

Maintenance Tips

Follow these maintenance tips to ensure the suspension system remains functional:

- Regularly check and adjust tire pressure.

- Rotate tires every 5,000 to 7,500 miles to promote even wear.

- Replace worn or damaged components promptly.

- Ensure proper wheel alignment at regular intervals.

- Keep the undercarriage clean to prevent rust and corrosion.

By adhering to these practices, vehicle owners can significantly enhance the longevity and performance of their suspension system, resulting in a more comfortable ride and improved handling.

Understanding Fluid Types and Changes

Proper maintenance of a vehicle involves a keen awareness of various fluid types that play crucial roles in its operation. These fluids are essential for ensuring optimal performance, enhancing longevity, and preventing mechanical failures. Regularly checking and changing these fluids according to the manufacturer’s guidelines is vital for maintaining a reliable and efficient driving experience.

Key Fluid Types

There are several essential fluids within any vehicle, each serving a specific purpose. Engine oil lubricates the internal components, reducing friction and wear. Coolant regulates engine temperature, preventing overheating. Transmission fluid facilitates smooth gear shifts, while brake fluid is critical for effective braking performance. Additionally, power steering fluid ensures easy maneuverability, and windshield washer fluid maintains visibility. Understanding the role of each fluid helps drivers recognize when changes are necessary.

Importance of Regular Changes

Changing fluids at recommended intervals is crucial for maintaining vehicle health. Over time, fluids can become contaminated or break down, leading to decreased efficiency and potential damage. Regular inspections allow for early detection of issues, ensuring timely replacements. Adhering to the maintenance schedule not only enhances performance but also extends the life of the vehicle, providing a safer and more enjoyable driving experience.

Safety Features and Recommendations

Ensuring the safety of occupants in any vehicle is paramount, and modern automobiles are equipped with a range of protective features designed to enhance passenger security. Understanding these elements and adhering to safety guidelines can significantly reduce the risk of accidents and injuries on the road.

Key Safety Elements

Contemporary vehicles come with numerous advanced safety technologies. Among these are anti-lock braking systems (ABS), electronic stability control (ESC), and multiple airbags strategically placed throughout the cabin. These systems work together to provide better handling and protection in various driving conditions, thereby minimizing the likelihood of collisions.

Best Practices for Safety

In addition to the built-in features, adopting safe driving habits is crucial. Always wear seatbelts, obey speed limits, and avoid distractions such as mobile devices while driving. Regular maintenance checks, including tire inspections and brake assessments, also play a vital role in ensuring that safety features function correctly. By following these recommendations, drivers can enhance their protection and that of their passengers.